Canon imageRUNNER Advance C2020L

Рейтинг

Снят с производства

Снят с производства

Тип устройства

МФУ

Технология печати

лазерная

Макс. формат

A3

Скорость печати

A4

20

Цветность печати

цветная

Общие характеристики |

|

|---|---|

Копир |

|

Сканер |

|

Тип устройства |

МФУ |

Размещение |

напольный |

Макс. формат |

A3 |

Технология печати |

лазерная |

Тип |

лазерный/светодиодный |

Цветность печати |

цветная |

Телефон |

|

Факс |

|

Печать фотографий |

|

Принтер |

|

Двусторонняя печать |

|

Прямая печать |

|

Пигментные чернила |

|

Печать без полей |

|

Время разогрева |

38 |

Количество цветов |

4 |

Макс, разрешение для ч/б печати |

|

| По X | 1 200 |

| По Y | 1 200 |

Скорость ч/б печати |

|

| A4 | 20 |

Копир |

|

Шаг масштабирования |

0,01 |

Макс, количество копий за цикл |

999 |

Время выхода первой копии |

5,9 |

Значение масштаба |

|

| Минимальное | 0,25 |

| Максимальное | 4 |

Макс, разрешение (ч/б) |

|

| По Y | 600 |

| По X | 600 |

Скорость ч/б копирования |

|

| A3 | 15 |

Сканер |

|

Стандарт TWAIN |

|

Макс. формат оригинала |

A3 |

Отправка изображения по e-mail |

|

Разрешение сканера |

|

| По Х | 600 |

Скорость сканирования |

|

| Ч/б | 44 |

| Цветн, | 30 |

Расходные материалы |

|

Количество картриджей |

4 |

Печать на: |

|

| CD/DVD |

|

| Фотобумаге |

|

| Рулоне |

|

| Глянцевой бумаге |

|

| Карточках |

|

| Пленках |

|

| Этикетках |

|

| Матовой бумаге |

|

| Конвертах |

|

Плотность бумаги |

|

| Максимальная | 220 |

| Минимальная | 64 |

Факс |

|

Цветной |

|

Телефон |

|

Проводная трубка |

|

Беспроводная трубка |

|

АОН |

|

Спикерфон |

|

Стандарт DECT |

|

Автоответчик |

|

Caller ID |

|

Языки управления |

|

| PostScript 2 |

|

| PostScript 3 |

|

| PostScript |

|

| PCL 5c |

|

| PCL 5e |

|

| PCL 6 |

|

| PPDS |

|

Лотки |

|

Емкость лотка ручной подачи |

100 |

Подача бумаги |

|

| Максимальная | 2 000 |

| Стандартная | 900 |

Финишер |

|

Степлер |

|

Брошюровщик |

|

Сортер |

|

Интерфейсы |

|

USB |

|

Ethernet (RJ-45) |

|

Версия USB |

2,0 |

Устройство для чтения карт памяти |

|

RS-232 |

|

Инфракрасный порт |

|

LPT |

|

Bluetooth |

|

FireWire (IEEE 1394) |

|

Wi-Fi |

|

Память/Процессор |

|

Частота процессора |

800 |

Объем памяти |

2 048 |

Дополнительная информация |

|

Диагональ дисплея |

5,7 |

Экран |

|

Работа от аккумулятора |

|

Поддержка ОС |

|

| Windows |

|

| Mac OS |

|

Потребляемая мощность |

|

| При работе | 1 500 |

Габариты |

|

Вес |

69 |

Глубина |

650 |

Ширина |

565 |

Высота |

791 |

Модули

810 FIXING ASSEMBLY

A11 BASE ASSEMBLY (ADF MODEL)

A41 PAPER FEED ASSEMBLY (ADF MODEL) 2

100 EXTERNAL COVERS, PANELS, ETC. 2

352 2ND/3RD DELIVERY GUIDE ASSY (2/3 DELIVERY MODEL) 2

T21 SPEAKER ASSEMBLY (G3 FAX MODEL)

T22 1 LINE PCB ASSEMBLY (G3 FAX MODEL)

300 CASSETTE ASSEMBLY (UPPER)

312 PAPER PICK-UP DRIVE ASSEMBLY (LOWER) (EXCEPT 1 CASSETTE MODEL)

A12 PAPER PICK-UP COVER ASSEMBLY (ADF MODEL)

109 MACHINE REAR PLATE 2

140 POWER CORD TERMINAL ASSY

460 LASER SCANNER UNIT

A01 ADF MOUNTING ASSEMBLY (ADF MODEL)

A41 PAPER FEED ASSEMBLY (ADF MODEL)

T20 G3 FAX ASSEMBLY, 1 LINE (G3 FAX MODEL)

A21 ESTRANGEMENT DRIVE ASSEMBLY (ADF MODEL)

900 CONTROLLER BOX ASSEMBLY

980 HIGH VOLTAGE ASSEMBLY

930 MAIN CONTROLLER PCB ASSY, 1

301 CASSETTE ASSEMBLY (LOWER) (EXCEPT 1 CASSETTE MODEL)

250 MAIN DRIVE ASSEMBLY

A10 ADF MAIN BODY (ADF MODEL)

100 EXTERNAL COVERS, PANELS, ETC.

108 MACHINE REAR PLATE 1

311 PAPER PICK-UP ASSEMBLY (LOWER) (EXCEPT 1 CASSETTE MODEL)

960 AC DRIVER PCB ASSEMBLY

351 2ND/3RD DRIVE FRAME ASSEMBLY (2/3 DELIVERY MODEL)

105 INTERNAL COMPONENTS 4

130 CONTROL PANEL ASSEMBLY

104 INTERNAL COMPONENTS 3

101 RIGHT DOOR ASSEMBLY

102 INTERNAL COMPONENTS 1

931 MAIN CONTROLLER PCB ASSY, 2

D11 READER ASSEMBLY (EXCEPT EUR)

310 PAPER PICK-UP ASSEMBLY (UPPER)

352 2ND/3RD DELIVERY GUIDE ASSY (2/3 DELIVERY MODEL)

103 INTERNAL COMPONENTS 2

107 INTERNAL COMPONENTS 6

530 INTER. TRANSFER BELT ASSY

A13 DOCUMENT TRAY ASSEMBLY (ADF MODEL)

101 RIGHT DOOR ASSEMBLY 2

350 2ND/3RD PAPER DELIVERY ASSY (2/3 DELIVERY MODEL)

106 INTERNAL COMPONENTS 5

Детали 352 2ND/3RD DELIVERY GUIDE ASSY (2/3 DELIVERY MODEL)

| Деталь: | FIXING ASSEMBLY |

| Парткод: | FM4-6226-000 |

| Деталь: | FIXING ASSEMBLY |

| Парткод: | FM4-6227-000 |

| Деталь: | FIXING ASSEMBLY |

| Парткод: | FM4-6228-000 |

| Деталь: | GUIDE, FIXING DELIVERY, UPPER |

| Парткод: | FM4-7712-000 |

| Деталь: | GUIDE, FIXING DELIVERY, UPPER |

| Парткод: | FM4-7713-000 |

| Деталь: | FIXING ASSEMBLY |

| Парткод: | NPN |

| Деталь: | SHAFT, PAPER FEED ROLLER |

| Парткод: | FC5-4285-030 |

| Деталь: | ROLLER, PAPER FEED, 1 |

| Парткод: | FC5-4286-000 |

| Деталь: | ROLLER, PAPER FEED, 2 |

| Парткод: | FC5-4287-000 |

| Деталь: | CLIP |

| Парткод: | FC5-4425-000 |

| Деталь: | ROLLER, PLATEN |

| Парткод: | FC6-8973-000 |

| Деталь: | HOLDER, SOLENOID |

| Парткод: | FC8-6319-000 |

| Деталь: | SPRING, LEAF |

| Парткод: | FC8-6322-000 |

| Деталь: | ROLLER, READ 2 PINCH |

| Парткод: | FC8-6404-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2652-000 |

| Деталь: | SHEET, PAPER FEED |

| Парткод: | FC8-6422-000 |

| Деталь: | SHEET, PAPER FEED |

| Парткод: | FC8-6423-000 |

| Деталь: | HOLDER, ROLLER, SMALL |

| Парткод: | FL2-9933-000 |

| Деталь: | HOLDER, ROLLER, LARGE |

| Парткод: | FL2-9934-000 |

| Деталь: | COVER, BASE, LOWER |

| Парткод: | FL3-2942-000 |

| Деталь: | LEVER, READ 1 PRESSURE |

| Парткод: | FC8-6331-000 |

| Деталь: | COLLAR, READ 1 PRESSURE |

| Парткод: | FC8-6332-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FU7-2653-000 |

| Деталь: | BUSHING |

| Парткод: | FU5-1168-000 |

| Деталь: | ROLLER, DELIVERY |

| Парткод: | FC8-6316-000 |

| Деталь: | HOLDER, DELIVERY ROLLER |

| Парткод: | FC8-6317-000 |

| Деталь: | CAM, DELIVERY ESTRANGEMENT |

| Парткод: | FC8-6318-000 |

| Деталь: | DAMPER, DELIVERY |

| Парткод: | FC8-6419-000 |

| Деталь: | PIN, DOWEL |

| Парткод: | XD3-2200-122 |

| Деталь: | BASE ASSEMBLY |

| Парткод: | NPN |

| Деталь: | FLANGE, BELT |

| Парткод: | FC5-4353-000 |

| Деталь: | CLIP |

| Парткод: | FC5-4425-000 |

| Деталь: | ROLLER, PLATEN |

| Парткод: | FC6-8973-000 |

| Деталь: | GUIDE, PLATEN, 2 |

| Парткод: | FC8-6368-000 |

| Деталь: | FLAPPER, REVERSE |

| Парткод: | FL2-9949-000 |

| Деталь: | LEVER, READ SENSOR |

| Парткод: | FC8-6371-000 |

| Деталь: | LEVER, PAPER DELIVERY SENSOR |

| Парткод: | FC8-6372-000 |

| Деталь: | HOLDER, SENSOR |

| Парткод: | FC8-6377-000 |

| Деталь: | DUCT, HARNESS |

| Парткод: | FC8-6378-010 |

| Деталь: | FLANGE, PULLEY |

| Парткод: | FC8-6379-000 |

| Деталь: | CLIP |

| Парткод: | FC8-6380-000 |

| Деталь: | ROLLER, BELT TENSION |

| Парткод: | FC8-6382-000 |

| Деталь: | JOINT, DELIVERY GEAR |

| Парткод: | FC8-6385-000 |

| Деталь: | DIAL, JAM |

| Парткод: | FC8-6386-000 |

| Деталь: | ROLLER, DELIVERY |

| Парткод: | FC8-6395-000 |

| Деталь: | ROLLER, REGISTRATION |

| Парткод: | FC8-6396-000 |

| Деталь: | ROLLER, READ |

| Парткод: | FC8-6397-000 |

| Деталь: | JOINT, READ PULLEY |

| Парткод: | FC8-6418-000 |

| Деталь: | BELT, TIMING |

| Парткод: | FC8-6421-000 |

| Деталь: | MOTOR, STEPPING, DC |

| Парткод: | FK2-6869-000 |

| Деталь: | CLUTCH, ELECTROMAGNETIC |

| Парткод: | FK2-6870-000 |

| Деталь: | FLAG, REGISTRATION SENSOR |

| Парткод: | FL2-9937-000 |

| Деталь: | BEARING, BALL, MF128ZZ |

| Парткод: | XG9-0507-000 |

| Деталь: | JOINT, PICK-UP |

| Парткод: | FC8-6383-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC8-6411-000 |

| Деталь: | GEAR, 22T |

| Парткод: | FU8-0304-000 |

| Деталь: | JOINT, REGISTRATION |

| Парткод: | FC8-6384-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC8-6412-000 |

| Деталь: | GEAR, 18T |

| Парткод: | FU8-0307-000 |

| Деталь: | ELIMINATOR, STATIC CHARGE |

| Парткод: | FC8-6399-000 |

| Деталь: | ARM, PLATEN, FRONT |

| Парткод: | FC8-6373-000 |

| Деталь: | ARM, PLATEN, REAR |

| Парткод: | FC8-6374-000 |

| Деталь: | SPACER, READ, FRONT |

| Парткод: | FC8-6375-000 |

| Деталь: | SPACER, READ, REAR |

| Парткод: | FC8-6376-000 |

| Деталь: | ROLLER, WHITE |

| Парткод: | FC8-6398-000 |

| Деталь: | GUIDE, PLATEN, 1 |

| Парткод: | FL2-9939-000 |

| Деталь: | LINK, SOLENOID |

| Парткод: | FC8-6381-000 |

| Деталь: | DAMPER, REV. GUIDE RETAINING |

| Парткод: | FC8-6403-000 |

| Деталь: | SOLENOID |

| Парткод: | FK2-6871-000 |

| Деталь: | GEAR, 25T |

| Парткод: | FU8-0306-000 |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000 |

| Деталь: | SEPARATION REVERSE GUIDE ASSY |

| Парткод: | FM4-2459-000 |

| Деталь: | HOLDER, SEPARATION PAD UNIT |

| Парткод: | FL2-9942-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2657-000 |

| Деталь: | LED PCB UNIT |

| Парткод: | FM3-6916-000 |

| Деталь: | LABEL, JAM CLEARING OPERATION |

| Парткод: | FS9-0204-000 |

| Деталь: | LABEL, GREEN |

| Парткод: | FS9-0205-000 |

| Деталь: | SCREW, W/WASHER, M3X6 |

| Парткод: | XA9-0702-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-002 |

| Деталь: | BUSHING |

| Парткод: | FU5-1172-000 |

| Деталь: | BUSHING |

| Парткод: | FU5-1626-000 |

| Деталь: | BUSHING |

| Парткод: | FU6-1088-000 |

| Деталь: | BUSHING |

| Парткод: | FU6-1089-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FU7-2658-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2659-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2660-000 |

| Деталь: | GEAR PULLEY, 27T/22T |

| Парткод: | FU8-0303-000 |

| Деталь: | GEAR, 18T |

| Парткод: | FU8-0305-000 |

| Деталь: | GEAR, 22T |

| Парткод: | FU8-0308-000 |

| Деталь: | GEAR PULLEY, 36T/54T/28T |

| Парткод: | FU8-0309-000 |

| Деталь: | PULLEY, 36T |

| Парткод: | FU8-0310-000 |

| Деталь: | GEAR, 18T |

| Парткод: | FU8-0312-000 |

| Деталь: | GEAR, 18T |

| Парткод: | FU8-0313-000 |

| Деталь: | GEAR, 14T |

| Парткод: | FU8-0314-000 |

| Деталь: | GEAR, 39T |

| Парткод: | FU8-0315-000 |

| Деталь: | GEAR, 21T |

| Парткод: | FU8-0316-000 |

| Деталь: | GEAR, 32T |

| Парткод: | FU8-0317-000 |

| Деталь: | GEAR, 48T/62T |

| Парткод: | FU8-0318-000 |

| Деталь: | SCREW,RS,M3X6.5 |

| Парткод: | XA9-1164-000 |

| Деталь: | BELT, TIMING |

| Парткод: | XF2-1607-640 |

| Деталь: | SHEET, CLEANING, LARGE |

| Парткод: | FC8-6356-000 |

| Деталь: | SHEET, CLEANING, SMALL |

| Парткод: | FC8-6357-000 |

| Деталь: | PIN, DOWEL |

| Парткод: | XD3-2200-122 |

| Деталь: | PAPER FEED ASSEMBLY |

| Парткод: | FM4-2458-000 |

| Деталь: | COVER, MAIN SWITCH |

| Парткод: | FC8-4000-000 |

| Деталь: | PLATE, 2ND DELIV. TRAY SUPPORT |

| Парткод: | FC8-5363-000 |

| Деталь: | MOUNT, SWITCH COVER |

| Парткод: | FC8-5378-000 |

| Деталь: | COVER, ENV. HEATER SWITCH |

| Парткод: | FC8-4137-000 |

| Деталь: | COVER, RIGHT REAR SUB |

| Парткод: | FC8-8444-000 |

| Деталь: | COVER, INNER SUB, 1 |

| Парткод: | FC8-8186-000 |

| Деталь: | COVER, 1ST PAPER DELIVERY |

| Парткод: | FC8-8187-000 |

| Деталь: | TRAY, 1ST PAPER DELIVERY |

| Парткод: | FC8-8189-000 |

| Деталь: | COVER, RIGHT LOWER SUB, 2 |

| Парткод: | FC8-8190-000 |

| Деталь: | COVER, RIGHT LOWER SUB, 1 |

| Парткод: | FC8-8191-000 |

| Деталь: | COVER, REAR UPPER, 1 |

| Парткод: | FC8-8192-000 |

| Деталь: | COVER, INNER REAR, 2 |

| Парткод: | FC8-8193-000 |

| Деталь: | COVER, REAR |

| Парткод: | FC8-8196-000 |

| Деталь: | COVER, LEFT FRONT |

| Парткод: | FC8-8197-000 |

| Деталь: | COVER, LEFT LOWER |

| Парткод: | FC8-8198-000 |

| Деталь: | COVER, GRIP |

| Парткод: | FC8-8201-000 |

| Деталь: | ARM, FRONT COVER, B |

| Парткод: | FC8-8203-000 |

| Деталь: | MOUNT, STOPPER ARM |

| Парткод: | FC8-8204-000 |

| Деталь: | HOOK, COVER, FRONT |

| Парткод: | FC8-8205-000 |

| Деталь: | COVER, INNER REAR, 1 |

| Парткод: | FC8-8207-000 |

| Деталь: | COVER, RIGHT FRONT SUB |

| Парткод: | FC8-8443-000 |

| Деталь: | COVER, REAR UPPER, 3 |

| Парткод: | FC8-8286-000 |

| Деталь: | COVER, INNER SUB, 2 |

| Парткод: | FC8-8290-000 |

| Деталь: | COVER, RIGHT UPPER |

| Парткод: | FC8-8291-000 |

| Деталь: | PLATE, FRONT DOOR FIXED |

| Парткод: | FC8-8512-000 |

| Деталь: | PLATE, STATIC CHARGE, LEFT |

| Парткод: | FC8-8638-000 |

| Деталь: | PLATE, STATIC CHARGE, RIGHT |

| Парткод: | FC8-8637-000 |

| Деталь: | COVER, CONNECTOR, 1 |

| Парткод: | FC8-8344-000 |

| Деталь: | COVER, FAX CONNECTOR |

| Парткод: | FC8-8346-000 |

| Деталь: | COVER, HARD DISK DRIVE |

| Парткод: | FC8-8359-000 |

| Деталь: | COVER, INNER BOTTOM |

| Парткод: | FC8-8445-000 |

| Деталь: | ROLLER, BOTTLE TRAY |

| Парткод: | FC8-4649-000 |

| Деталь: | GUIDE, REVERSE BACK END |

| Парткод: | FC9-8612-000 |

| Деталь: | COVER, 2ND PAPER DELIVERY |

| Парткод: | FC8-8543-000 |

| Деталь: | COVER, REVERSE BLANKING |

| Парткод: | FC8-8544-000 |

| Деталь: | LABEL, TONER MODEL |

| Парткод: | FC8-8582-000 |

| Деталь: | LABEL, TONER MODEL |

| Парткод: | FC8-8622-000 |

| Деталь: | LABEL, TONER MODEL |

| Парткод: | FC8-8623-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2759-000 |

| Деталь: | LABEL, MODULAR |

| Парткод: | FC8-8615-000 |

| Деталь: | COVER, RIGHT LOWER SUB, 3 |

| Парткод: | FC8-8617-000 |

| Деталь: | COVER, REAR UPPER, 2 |

| Парткод: | FC8-8631-000 |

| Деталь: | LABEL, MAIN POWER SUPPLY |

| Парткод: | FC9-7861-000 |

| Деталь: | LABEL, MAIN POWER SUPPLY |

| Парткод: | FC9-7862-000 |

| Деталь: | LABEL, MAIN POWER SUPPLY |

| Парткод: | FC9-7863-000 |

| Деталь: | LABEL, MAIN POWER SUPPLY |

| Парткод: | FC0-0225-000 |

| Деталь: | LABEL, MAIN POWER SUPPLY |

| Парткод: | FC0-0226-000 |

| Деталь: | BUSHING |

| Парткод: | FU5-1035-000 |

| Деталь: | COVER, SLOT |

| Парткод: | FC8-8645-000 |

| Деталь: | HOLDER, SERVICE BOOK |

| Парткод: | FC0-2633-000 |

| Деталь: | EMBLEM |

| Парткод: | FL3-1185-000 |

| Деталь: | FRONT UPPER COVER ASSEMBLY |

| Парткод: | FM3-8077-000 |

| Деталь: | FRONT DOOR ASSEMBLY |

| Парткод: | FM3-8078-000 |

| Деталь: | LEFT REAR COVER ASSEMBLY |

| Парткод: | FM3-8079-000 |

| Деталь: | LABEL, LASER CAUTION |

| Парткод: | FC0-2901-000 |

| Деталь: | LABEL, GROUNDING CAUTION |

| Парткод: | FU7-8494-000 |

| Деталь: | LABEL, GROUNDING CAUTION |

| Парткод: | FU7-8521-000 |

| Деталь: | RIGHT UPPER SUB COVER ASSEMBLY |

| Парткод: | FM3-8083-000 |

| Деталь: | LABEL, HARD DISK DRIVE CAUTION |

| Парткод: | FU7-8471-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FS7-2788-000 |

| Деталь: | HINGE, RIGHT DOOR, FRONT |

| Парткод: | FC8-8228-000 |

| Деталь: | HOLDER, M.P. STOPPER |

| Парткод: | FC8-8240-000 |

| Деталь: | COVER, CASSETTE RIGHT UPPER, 1 |

| Парткод: | FC8-8515-000 |

| Деталь: | COVER, CASSETTE RIGHT UPPER, 2 |

| Парткод: | FC8-8516-000 |

| Деталь: | COVER, WASTE TONER |

| Парткод: | FC8-8341-000 |

| Деталь: | SHEET, GLASS CLEANING |

| Парткод: | FC8-8634-000 |

| Деталь: | PAD, GLASS CLEANING |

| Парткод: | FC8-8635-000 |

| Деталь: | GLASS CLEANING ARM ASSEMBLY |

| Парткод: | FM3-8260-000 |

| Деталь: | HOOK, RIGHT DOOR |

| Парткод: | FC5-0631-000 |

| Деталь: | ROLLER, PAPER FEED |

| Парткод: | FC8-3782-000 |

| Деталь: | STOPPER, DOOR, RIGHT LOWER |

| Парткод: | FC8-5164-000 |

| Деталь: | HANDLE, DOOR |

| Парткод: | FC8-8172-000 |

| Деталь: | DOOR ASSEMBLY, RIGHT LOWER |

| Парткод: | FM3-8150-000 |

| Деталь: | EXTERNAL COVERS, PANELS, ETC. |

| Парткод: | NPN |

| Деталь: | FLAG, 2ND DELIVERY SENSOR |

| Парткод: | FC5-0996-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC5-0997-000 |

| Деталь: | FLAG, DUPLEX ENTRANCE SENSOR |

| Парткод: | FC5-1005-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC5-1006-000 |

| Деталь: | FLAG, 3RD DELIVERY SENSOR |

| Парткод: | FC5-1010-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC0-0636-000 |

| Деталь: | GUIDE, 3RD DELIVERY |

| Парткод: | FC8-8293-000 |

| Деталь: | HANDLE, PAPER DELIVERY DOOR |

| Парткод: | FC8-8297-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC8-8298-000 |

| Деталь: | GUIDE, DUPLEX ENTRANCE, 1 |

| Парткод: | FC8-8300-000 |

| Деталь: | GUIDE, 3RD DELIVERY, UPPER |

| Парткод: | FC8-8301-000 |

| Деталь: | GUIDE, REVERSE ENTRANCE |

| Парткод: | FC8-8304-000 |

| Деталь: | GUIDE, DUPLEX ENTRANCE, 2 |

| Парткод: | FC8-8309-000 |

| Деталь: | ROLLER, 2ND PAPER DELIVERY |

| Парткод: | FC8-8311-000 |

| Деталь: | COVER, 2ND DELIVERY GEAR |

| Парткод: | FC8-8331-000 |

| Деталь: | COVER, 3RD DELIVERY GEAR |

| Парткод: | FC8-8332-000 |

| Деталь: | SUPPORT, 2ND DELIVERY GEAR |

| Парткод: | FC8-8338-000 |

| Деталь: | SUPPORT, 3RD DELIVERY GEAR |

| Парткод: | FC8-8339-000 |

| Деталь: | GUIDE, ENTRANCE, 2 |

| Парткод: | FC8-8340-000 |

| Деталь: | GUIDE, SHAFT |

| Парткод: | FC8-8408-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC8-8410-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC8-8411-000 |

| Деталь: | COVER, 3RD DELIVERY ROLLER |

| Парткод: | FC8-8503-000 |

| Деталь: | ELIMINATOR, STATIC CHARGE |

| Парткод: | FC8-8591-000 |

| Деталь: | SHEET, PAPER DELIVERY |

| Парткод: | FC9-8580-000 |

| Деталь: | GUIDE, ENTRANCE, 1 |

| Парткод: | FL3-0641-000 |

| Деталь: | PAPER DELIVERY ROLLER ASSEMBLY |

| Парткод: | FM3-8053-000 |

| Деталь: | 3RD DELIVERY FLAPPER ASSY |

| Парткод: | FM3-8054-000 |

| Деталь: | 2ND FLAPPER SOLENOID ASSY |

| Парткод: | FM3-8056-000 |

| Деталь: | 3RD FLAPPER SOLENOID ASSY |

| Парткод: | FM3-8057-000 |

| Деталь: | ROLLER, REFORM |

| Парткод: | FC9-8621-000 |

| Деталь: | ROLLER, 3RD PAPER DELIVERY |

| Парткод: | FC8-8294-000 |

| Деталь: | 2ND UPPER GUIDE ASSEMBLY |

| Парткод: | FM3-8060-000 |

| Деталь: | PAPER DELIVERY FLAPPER ASSY |

| Парткод: | FM3-8062-000 |

| Деталь: | TOGGLE COVER ASSEMBLY |

| Парткод: | FM3-8063-000 |

| Деталь: | COLLAR, REGISTRATION MULTI |

| Парткод: | FS5-6945-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FS7-2859-000 |

| Деталь: | BUSHING |

| Парткод: | FU5-1453-000 |

| Деталь: | BUSHING, POLYACETAR |

| Парткод: | FU5-1469-000 |

| Деталь: | GEAR, 24T |

| Парткод: | FU6-0076-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FU7-2772-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2783-000 |

| Деталь: | GEAR, 18T |

| Парткод: | FU8-0396-000 |

| Деталь: | GEAR, 20T |

| Парткод: | FU8-0397-000 |

| Деталь: | GEAR, 22T |

| Парткод: | FU8-0403-000 |

| Деталь: | ROLLER, DUPLEXING PAPER FEED |

| Парткод: | RC2-7271-000 |

| Деталь: | BUSHING |

| Парткод: | RS5-1567-000 |

| Деталь: | GEAR, 28T |

| Парткод: | RU6-0852-000 |

| Деталь: | GEAR, 17T |

| Парткод: | RU6-0855-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-002 |

| Деталь: | IC,PHOTO-INTERRUPTER,LG248NL1A |

| Парткод: | WG8-5783-000 |

| Деталь: | SCREW, D, M3X8 |

| Парткод: | XA9-1671-000 |

| Цена: | 170 ₽ |

| Деталь: | RING, E |

| Парткод: | XD9-0136-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FC9-8582-000 |

| Деталь: | SHEET, ENTRANCE GUIDE, 1 |

| Парткод: | FC8-8310-000 |

| Деталь: | GUIDE, 2ND DELIVERY ENTRANCE |

| Парткод: | FC0-0598-000 |

| Деталь: | STOPPER, GUIDE, UPPER |

| Парткод: | FC9-8645-000 |

| Деталь: | STOPPER, GUIDE, LOWER |

| Парткод: | FC9-8646-000 |

| Деталь: | SHEET, COMPENSATION |

| Парткод: | FC9-8579-000 |

| Деталь: | ELIMINATOR, STATIC CHARGE |

| Парткод: | FC8-8590-000 |

| Деталь: | PIN, DOWEL |

| Парткод: | XD3-2200-122 |

| Деталь: | 2ND/3RD DELIVERY GUIDE ASSY |

| Парткод: | FM3-8052-000 |

| Деталь: | DAMPER, RUBBER |

| Парткод: | FC6-5059-000 |

| Деталь: | HOLDER, SPEAKER |

| Парткод: | FC7-2362-000 |

| Деталь: | SPEAKER |

| Парткод: | FK2-0428-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-002 |

| Деталь: | SCREW, D, M3X8 |

| Парткод: | XA9-1671-000 |

| Цена: | 170 ₽ |

| Деталь: | SPEAKER ASSEMBLY |

| Парткод: | FM3-8186-000 |

| Деталь: | IC, GATE ARRAY |

| Парткод: | FK2-5396-000 |

| Деталь: | 1 LINE PCB ASSEMBLY |

| Парткод: | FM4-0838-000 |

| Деталь: | WINDOW, CST FR. COVER IND. |

| Парткод: | FC8-4967-000 |

| Деталь: | BUTTON, PUSHING |

| Парткод: | FC8-4985-000 |

| Деталь: | CASSETTE ASSEMBLY |

| Парткод: | RM1-6150-000 |

| Деталь: | COVER, CASSETTE FRONT |

| Парткод: | FC8-8181-000 |

| Деталь: | RING, BUTTON |

| Парткод: | FC8-8182-000 |

| Деталь: | LABEL, PAPER SIZE, BACK END |

| Парткод: | FC8-8596-000 |

| Деталь: | LABEL, PAPER SIZE, SIDE |

| Парткод: | FC8-8597-000 |

| Деталь: | LABEL, PAPER PICK-UP OPERATION |

| Парткод: | FC8-8616-000 |

| Деталь: | COVER, SIZEPLATE |

| Парткод: | FC9-4042-000 |

| Деталь: | BUTTON LINK ASSEMBLY |

| Парткод: | FM3-8046-000 |

| Деталь: | CASSETTE ASSEMBLY |

| Парткод: | NPN |

| Деталь: | PULLEY, 34T |

| Парткод: | FC6-5022-000 |

| Деталь: | MOTOR, STEPPING |

| Парткод: | FK2-7586-000 |

| Деталь: | GEAR, 80T/16T |

| Парткод: | FU3-0285-000 |

| Деталь: | RING, E |

| Парткод: | XD9-0136-000 |

| Деталь: | BELT, TIMING |

| Парткод: | XF2-1604-940 |

| Деталь: | PAPER PICK-UP DRIVE ASSEMBLY |

| Парткод: | FM3-8151-000 |

| Деталь: | ROLLER, REGISTRATION, 1 |

| Парткод: | FC5-4323-000 |

| Деталь: | ROLLER, REGISTRATION, 2 |

| Парткод: | FC5-4324-000 |

| Деталь: | CLIP |

| Парткод: | FC5-4425-000 |

| Деталь: | CASE, LED |

| Парткод: | FC8-6345-000 |

| Деталь: | KNOB, PAPER PICK-UP COVER |

| Парткод: | FC9-6190-000 |

| Деталь: | LEVER, EMPTY SENSOR |

| Парткод: | FC8-6347-000 |

| Деталь: | LEVER, TIMING SENSOR |

| Парткод: | FC8-6348-000 |

| Деталь: | GEAR, 24T |

| Парткод: | FU8-0302-000 |

| Деталь: | SHUTTER |

| Парткод: | FL2-9948-000 |

| Деталь: | COVER, PAPER PICK-UP |

| Парткод: | FL3-2940-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FU7-2656-000 |

| Деталь: | GUIDE, PAPER PICK-UP, LOWER |

| Парткод: | FL3-2941-000 |

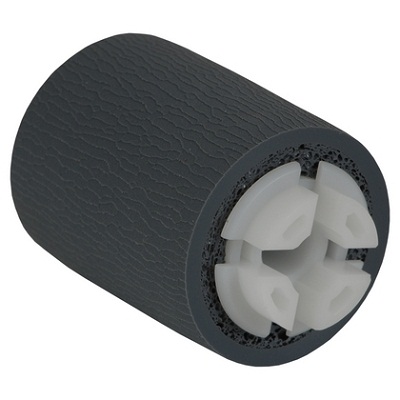

| Деталь: | PAPER PICK-UP ROLLER UNIT |

| Парткод: | FM3-6892-010 |

| Цена: | 7 500 ₽ |

| Деталь: | ROLLER, PAPER SEPARATION |

| Парткод: | FC6-2784-000 |

| Деталь: | LEVER, STOP |

| Парткод: | FC6-8971-010 |

| Деталь: | ARM, PICK, FRONT |

| Парткод: | FC8-6351-000 |

| Деталь: | ARM, PICK, REAR |

| Парткод: | FC8-6352-000 |

| Деталь: | JOINT |

| Парткод: | FC8-6353-000 |

| Деталь: | ROLLER, PICK-UP |

| Парткод: | FC8-6355-000 |

| Цена: | 700 ₽ |

| Деталь: | SPRING, TORSION |

| Парткод: | FC8-6410-010 |

| Деталь: | GEAR, 20T |

| Парткод: | FU8-0299-000 |

| Деталь: | GEAR, 22T |

| Парткод: | FU8-0300-000 |

| Деталь: | GEAR, 33T |

| Парткод: | FU8-0301-000 |

| Деталь: | BUSHING |

| Парткод: | FU5-1172-000 |

| Деталь: | BUSHING |

| Парткод: | FU5-1626-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2654-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2655-000 |

| Деталь: | SHEET, CLEANING, LARGE |

| Парткод: | FC8-6356-000 |

| Деталь: | SHEET, CLEANING, SMALL |

| Парткод: | FC8-6357-000 |

| Деталь: | PIN, DOWEL |

| Парткод: | XD3-2200-102 |

| Деталь: | PAPER PICK-UP COVER ASSEMBLY |

| Парткод: | FM4-4309-000 |

| Деталь: | COVER, HIGH VOLTAGE |

| Парткод: | FC0-0599-000 |

| Деталь: | MOUNT, POSITIONING |

| Парткод: | FC8-7940-000 |

| Деталь: | HOLDER, DEVELOPING COUPLING |

| Парткод: | FC8-8085-000 |

| Деталь: | HOLDER, LINK |

| Парткод: | FC8-8369-000 |

| Деталь: | GUARD, EDGE |

| Парткод: | FC8-8474-000 |

| Деталь: | RACK, M.P. STOPPER |

| Парткод: | FC8-8493-000 |

| Деталь: | COVER, RACK |

| Парткод: | FC8-8494-000 |

| Деталь: | MOUNT, HIGH VOLTAGE CASE |

| Парткод: | FC8-8594-000 |

| Деталь: | LIFTER DRIVE ASSEMBLY |

| Парткод: | FM3-8034-000 |

| Деталь: | STOPPER ASSEMBLY |

| Парткод: | FM3-8047-000 |

| Деталь: | WASTE TONER FEED ASSEMBLY |

| Парткод: | FM3-8157-000 |

| Деталь: | HIGH VOLTAGE HOLDER ASSY |

| Парткод: | FM3-8160-000 |

| Деталь: | H.V. HOLDER ASSY, AUXILIARY |

| Парткод: | FM3-8161-000 |

| Деталь: | H.V. CONTACT GUIDE ASSY, Y |

| Парткод: | FM3-8162-000 |

| Деталь: | H.V. CONTACT GUIDE ASSY, MCK |

| Парткод: | FM3-8163-000 |

| Деталь: | 1ST TRANSFER H.V. PCB ASSEMBLY |

| Парткод: | FM3-8599-000 |

| Деталь: | 2ND TRANSFER H.V. PCB ASSEMBLY |

| Парткод: | FM3-8610-000 |

| Деталь: | LIFTER MOTOR UNIT |

| Парткод: | FM4-1915-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2779-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2809-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2793-000 |

| Деталь: | SHUTTER, EXHAUST |

| Парткод: | RC2-7010-000 |

| Деталь: | SEAL, TONER SUPPORTER GUIDE, 1 |

| Парткод: | FC0-3654-000 |

| Деталь: | SIZE DETECT SWITCH UNIT |

| Парткод: | RM1-5058-000 |

| Деталь: | SCREW, D, M3X6 |

| Парткод: | XA9-1980-000 |

| Деталь: | REVERSE DRIVE ASSEMBLY |

| Парткод: | RM1-6005-000 |

| Деталь: | FIXING MOTOR ASSEMBLY |

| Парткод: | RM1-6074-000 |

| Деталь: | CABLE, DRAWER |

| Парткод: | RM1-6857-000 |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000 |

| Деталь: | GEAR, 18T/29T |

| Парткод: | RU6-0775-000 |

| Деталь: | PLATE, MOUNTING, RIGHT |

| Парткод: | FC8-8437-000 |

| Деталь: | PLATE, MOUNTING, LEFT |

| Парткод: | FC0-2639-000 |

| Деталь: | FIXING GEAR ASSY |

| Парткод: | RM1-7914-060 |

| Деталь: | CABLE, 2ND TRANSFER H.V. |

| Парткод: | FM4-1902-000 |

| Деталь: | CABLE, FIXING HEATER |

| Парткод: | FM3-8624-000 |

| Деталь: | CABLE, FIXING HEATER |

| Парткод: | FM3-8639-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-002 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-004 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7207-004 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7207-017 |

| Деталь: | SCREW, D, M3X8 |

| Парткод: | XA9-1671-000 |

| Цена: | 170 ₽ |

| Деталь: | MACHINE REAR PLATE 2 |

| Парткод: | NPN |

| Деталь: | CORD, POWER SUPPLY |

| Парткод: | FK2-0146-000 |

| Деталь: | CORD, POWER SUPPLY |

| Парткод: | FK2-0148-000 |

| Деталь: | CORD, POWER SUPPLY |

| Парткод: | FK2-2987-000 |

| Деталь: | POWER CORD TERMINAL ASSY |

| Парткод: | FM3-8172-000 |

| Деталь: | POWER CORD TERMINAL ASSY |

| Парткод: | FM3-8191-000 |

| Деталь: | POWER CORD TERMINAL ASSY |

| Парткод: | FM3-8192-000 |

| Деталь: | LASER SCANNER UNIT |

| Парткод: | FM3-8074-000 |

| Деталь: | LABEL, HINGE CAUTION |

| Парткод: | FU7-8226-000 |

| Деталь: | LABEL, HINGE CAUTION |

| Парткод: | FU7-8455-000 |

| Деталь: | COVER, HINGE BLANKING |

| Парткод: | FC9-6192-000 |

| Деталь: | SHEET, BLANKING |

| Парткод: | FC9-6193-000 |

| Деталь: | SCREW, STEPPED, M5X6 |

| Парткод: | FU5-9139-000 |

| Деталь: | SCREW, STEPPED, M4X10 |

| Парткод: | FU5-9140-000 |

| Деталь: | ADF MOUNTING ASSEMBLY |

| Парткод: | NPN |

| Деталь: | FLANGE, BELT |

| Парткод: | FC5-4353-000 |

| Деталь: | CLIP |

| Парткод: | FC5-4425-000 |

| Деталь: | ROLLER, PLATEN |

| Парткод: | FC6-8973-000 |

| Деталь: | GUIDE, PLATEN, 2 |

| Парткод: | FC8-6368-000 |

| Деталь: | FLAPPER, REVERSE |

| Парткод: | FL2-9949-000 |

| Деталь: | LEVER, READ SENSOR |

| Парткод: | FC8-6371-000 |

| Деталь: | LEVER, PAPER DELIVERY SENSOR |

| Парткод: | FC8-6372-000 |

| Деталь: | HOLDER, SENSOR |

| Парткод: | FC8-6377-000 |

| Деталь: | DUCT, HARNESS |

| Парткод: | FC8-6378-010 |

| Деталь: | FLANGE, PULLEY |

| Парткод: | FC8-6379-000 |

| Деталь: | CLIP |

| Парткод: | FC8-6380-000 |

| Деталь: | ROLLER, BELT TENSION |

| Парткод: | FC8-6382-000 |

| Деталь: | JOINT, DELIVERY GEAR |

| Парткод: | FC8-6385-000 |

| Деталь: | DIAL, JAM |

| Парткод: | FC8-6386-000 |

| Деталь: | ROLLER, DELIVERY |

| Парткод: | FC8-6395-000 |

| Деталь: | ROLLER, REGISTRATION |

| Парткод: | FC8-6396-000 |

| Деталь: | ROLLER, READ |

| Парткод: | FC8-6397-000 |

| Деталь: | JOINT, READ PULLEY |

| Парткод: | FC8-6418-000 |

| Деталь: | BELT, TIMING |

| Парткод: | FC8-6421-000 |

| Деталь: | MOTOR, STEPPING, DC |

| Парткод: | FK2-6869-000 |

| Деталь: | CLUTCH, ELECTROMAGNETIC |

| Парткод: | FK2-6870-000 |

| Деталь: | FLAG, REGISTRATION SENSOR |

| Парткод: | FL2-9937-000 |

| Деталь: | BEARING, BALL, MF128ZZ |

| Парткод: | XG9-0507-000 |

| Деталь: | JOINT, PICK-UP |

| Парткод: | FC8-6383-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC8-6411-000 |

| Деталь: | GEAR, 22T |

| Парткод: | FU8-0304-000 |

| Деталь: | JOINT, REGISTRATION |

| Парткод: | FC8-6384-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC8-6412-000 |

| Деталь: | GEAR, 18T |

| Парткод: | FU8-0307-000 |

| Деталь: | ELIMINATOR, STATIC CHARGE |

| Парткод: | FC8-6399-000 |

| Деталь: | ARM, PLATEN, FRONT |

| Парткод: | FC8-6373-000 |

| Деталь: | ARM, PLATEN, REAR |

| Парткод: | FC8-6374-000 |

| Деталь: | SPACER, READ, FRONT |

| Парткод: | FC8-6375-000 |

| Деталь: | SPACER, READ, REAR |

| Парткод: | FC8-6376-000 |

| Деталь: | ROLLER, WHITE |

| Парткод: | FC8-6398-000 |

| Деталь: | GUIDE, PLATEN, 1 |

| Парткод: | FL2-9939-000 |

| Деталь: | LINK, SOLENOID |

| Парткод: | FC8-6381-000 |

| Деталь: | DAMPER, REV. GUIDE RETAINING |

| Парткод: | FC8-6403-000 |

| Деталь: | SOLENOID |

| Парткод: | FK2-6871-000 |

| Деталь: | GEAR, 25T |

| Парткод: | FU8-0306-000 |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000 |

| Деталь: | SEPARATION REVERSE GUIDE ASSY |

| Парткод: | FM4-2459-000 |

| Деталь: | HOLDER, SEPARATION PAD UNIT |

| Парткод: | FL2-9942-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2657-000 |

| Деталь: | LED PCB UNIT |

| Парткод: | FM3-6916-000 |

| Деталь: | LABEL, JAM CLEARING OPERATION |

| Парткод: | FS9-0204-000 |

| Деталь: | LABEL, GREEN |

| Парткод: | FS9-0205-000 |

| Деталь: | SCREW, W/WASHER, M3X6 |

| Парткод: | XA9-0702-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-002 |

| Деталь: | BUSHING |

| Парткод: | FU5-1172-000 |

| Деталь: | BUSHING |

| Парткод: | FU5-1626-000 |

| Деталь: | BUSHING |

| Парткод: | FU6-1088-000 |

| Деталь: | BUSHING |

| Парткод: | FU6-1089-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FU7-2658-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2659-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2660-000 |

| Деталь: | GEAR PULLEY, 27T/22T |

| Парткод: | FU8-0303-000 |

| Деталь: | GEAR, 18T |

| Парткод: | FU8-0305-000 |

| Деталь: | GEAR, 22T |

| Парткод: | FU8-0308-000 |

| Деталь: | GEAR PULLEY, 36T/54T/28T |

| Парткод: | FU8-0309-000 |

| Деталь: | PULLEY, 36T |

| Парткод: | FU8-0310-000 |

| Деталь: | GEAR, 18T |

| Парткод: | FU8-0312-000 |

| Деталь: | GEAR, 18T |

| Парткод: | FU8-0313-000 |

| Деталь: | GEAR, 14T |

| Парткод: | FU8-0314-000 |

| Деталь: | GEAR, 39T |

| Парткод: | FU8-0315-000 |

| Деталь: | GEAR, 21T |

| Парткод: | FU8-0316-000 |

| Деталь: | GEAR, 32T |

| Парткод: | FU8-0317-000 |

| Деталь: | GEAR, 48T/62T |

| Парткод: | FU8-0318-000 |

| Деталь: | SCREW,RS,M3X6.5 |

| Парткод: | XA9-1164-000 |

| Деталь: | BELT, TIMING |

| Парткод: | XF2-1607-640 |

| Деталь: | SHEET, CLEANING, LARGE |

| Парткод: | FC8-6356-000 |

| Деталь: | SHEET, CLEANING, SMALL |

| Парткод: | FC8-6357-000 |

| Деталь: | PIN, DOWEL |

| Парткод: | XD3-2200-122 |

| Деталь: | PAPER FEED ASSEMBLY |

| Парткод: | FM4-2458-000 |

| Деталь: | PLATE, GROUNDING |

| Парткод: | FC8-8553-000 |

| Деталь: | PSEUDO CI2 PCB ASSEMBLY |

| Парткод: | FM3-5580-000 |

| Деталь: | MODULAR PCB ASSEMBLY |

| Парткод: | FM4-0788-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-003 |

| Деталь: | CORE, FERRITE |

| Парткод: | WE8-6096-000 |

| Деталь: | G3 FAX ASSEMBLY, 1 LINE |

| Парткод: | FM3-8176-000 |

| Деталь: | CLIP |

| Парткод: | FC5-4425-000 |

| Деталь: | DUCT, ESTRANGEMENT HARNESS |

| Парткод: | FC8-6406-000 |

| Деталь: | CAM, ESTRANGEMENT |

| Парткод: | FC8-6407-000 |

| Деталь: | MOTOR, STEPPING, DC |

| Парткод: | FK2-0207-000 |

| Деталь: | GEAR PULLEY, 40T/20T |

| Парткод: | FU8-0311-000 |

| Деталь: | GEAR, 31T |

| Парткод: | FU8-0319-000 |

| Деталь: | GEAR, 30T |

| Парткод: | FU8-0320-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-004 |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000 |

| Деталь: | SCREW,RS,M4 |

| Парткод: | XA9-0732-000 |

| Деталь: | BELT, TIMING |

| Парткод: | XF2-1607-640 |

| Деталь: | ESTRANGEMENT DRIVE ASSEMBLY |

| Парткод: | NPN |

| Деталь: | HOLDER, PCB |

| Парткод: | FC8-8455-000 |

| Деталь: | LABEL, MEMORY CAUTION |

| Парткод: | FU6-8861-000 |

| Деталь: | HOLDER, HDD |

| Парткод: | FC8-8643-000 |

| Деталь: | GUIDE, CABLE |

| Парткод: | FC9-8619-000 |

| Деталь: | DIMM, SMD-E51288HG-6E, SDRAM |

| Парткод: | FK2-8341-000 |

| Деталь: | HARD DISK DRIVE |

| Парткод: | FK2-9250-000 |

| Деталь: | CABLE, FLAT |

| Парткод: | FK2-9200-000 |

| Деталь: | CABLE, SATA POWER SUPPLY |

| Парткод: | FK2-9239-000 |

| Деталь: | CABLE, IP-READER FLAT |

| Парткод: | FK2-9240-000 |

| Деталь: | CABLE, STANDARD SATA POWER |

| Парткод: | FK2-9248-000 |

| Деталь: | TPM PCB ASSEMBLY |

| Парткод: | FM4-0783-000 |

| Деталь: | DIMM ASSY |

| Парткод: | FM4-3146-000 |

| Деталь: | SCREW, MACH. PAN HEAD, M3X4 |

| Парткод: | XA9-1979-000 |

| Деталь: | DAMPER, CUSHION |

| Парткод: | XH9-0132-000 |

| Деталь: | CONTROLLER BOX ASSEMBLY |

| Парткод: | NPN |

| Деталь: | HOLDER, PCB, LEFT |

| Парткод: | FC8-8270-000 |

| Деталь: | PLATE, HIGH VOLTAGE CONTACT |

| Парткод: | FC8-8367-000 |

| Деталь: | HOLDER, PCB, RIGHT |

| Парткод: | FC8-8416-000 |

| Деталь: | PLATE, H.V. CONTACT, YELLOW |

| Парткод: | FC8-8417-000 |

| Деталь: | PLATE, H.V. CONTACT, BLACK |

| Парткод: | FC8-8418-000 |

| Деталь: | 1ST CORONA PCB ASSEMBLY |

| Парткод: | FM3-8611-000 |

| Деталь: | DEV. HIGH VOLTAGE PCB ASSEMBLY |

| Парткод: | FM3-8612-000 |

| Деталь: | AUXILIARY H.V. PCB ASSEMBLY |

| Парткод: | FM3-8613-000 |

| Деталь: | HIGH VOLTAGE PCB ASSEMBLY |

| Парткод: | FM3-8175-000 |

| Деталь: | FAN |

| Парткод: | FK2-9244-000 |

| Деталь: | IC, LE80578EG800C |

| Парткод: | FK2-6692-000 |

| Деталь: | MAIN CONTROLLER PCB ASSY, 1 |

| Парткод: | FM4-3139-000 |

| Деталь: | MAIN CONTROLLER PCB ASSY, 1 |

| Парткод: | FM4-3140-000 |

| Деталь: | MAIN CONTROLLER PCB ASSY, 1 |

| Парткод: | FM4-3141-000 |

| Деталь: | DIAL, DETECT, SMALL |

| Парткод: | FC8-2469-000 |

| Деталь: | DIAL, DETECT, LARGE |

| Парткод: | FC8-2470-000 |

| Деталь: | SHAFT, SUPPORT |

| Парткод: | FC8-2474-000 |

| Деталь: | PLATE, JOINT |

| Парткод: | FC8-2475-000 |

| Деталь: | PLATE, FREE STOP |

| Парткод: | FC8-2670-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC8-2671-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC8-2672-000 |

| Деталь: | LABEL, SIZE INDEX, SIDE, LARGE |

| Парткод: | FC8-4962-000 |

| Деталь: | LABEL, SIZE INDEX, END, LARGE |

| Парткод: | FC8-4963-000 |

| Деталь: | LABEL, PAPER PICK-UP OPERATION |

| Парткод: | FC8-4966-000 |

| Деталь: | WINDOW, CST FR. COVER IND. |

| Парткод: | FC8-4967-000 |

| Деталь: | ROLLER, CASSETTE SWING |

| Парткод: | FC8-4970-000 |

| Деталь: | BUTTON, PUSHING |

| Парткод: | FC8-4985-000 |

| Деталь: | PIN, SIZE DETECT POSITIONING |

| Парткод: | FC8-4989-000 |

| Деталь: | GEAR, 14T |

| Парткод: | FC8-4990-000 |

| Деталь: | WIRE,CENTER PLATE GROUNDING,L |

| Парткод: | FC8-4992-000 |

| Деталь: | PLATE, COVER ATTACHMENT, LEFT |

| Парткод: | FC8-4993-000 |

| Деталь: | COVER, TOP |

| Парткод: | FC8-4996-000 |

| Деталь: | SCREW, B, M4X8 |

| Парткод: | XA9-1523-000 |

| Деталь: | COVER, CASSETTE FRONT |

| Парткод: | FC8-8181-000 |

| Деталь: | RING, BUTTON |

| Парткод: | FC8-8182-000 |

| Деталь: | GEAR, 9T |

| Парткод: | FC9-0129-000 |

| Деталь: | LINK, BACK END DETECT |

| Парткод: | FC9-0130-000 |

| Деталь: | PAPER SIDE END EXTENSION ASSY |

| Парткод: | FM3-8912-000 |

| Деталь: | HOLDER, SIZE INDEX |

| Парткод: | FC9-0136-000 |

| Деталь: | COVER, SIZEPLATE |

| Парткод: | FC9-4042-000 |

| Деталь: | LABEL, PAPER SIZE, CAUTION |

| Парткод: | FC9-7245-000 |

| Деталь: | PLATE, CENTER |

| Парткод: | FL2-9472-000 |

| Деталь: | BUTTON LINK ASSEMBLY |

| Парткод: | FM3-8913-000 |

| Деталь: | PLATE, LIFTER |

| Парткод: | FL3-2859-000 |

| Деталь: | SIDE END PLATE ASSEMBLY, FRONT |

| Парткод: | FM3-8905-000 |

| Деталь: | SIDE END PLATE ASSEMBLY, REAR |

| Парткод: | FM3-8906-010 |

| Деталь: | BACK END LIMIT PLATE ASSEMBLY |

| Парткод: | FM3-8907-000 |

| Деталь: | CASSETTE ASSEMBLY |

| Парткод: | FM3-8153-000 |

| Деталь: | MAIN DRIVE MOTOR UNIT |

| Парткод: | FM3-8145-000 |

| Деталь: | MOTOR, STEPPING, DC |

| Парткод: | RK2-3298-000 |

| Деталь: | SCREW, D, M3X6 |

| Парткод: | XA9-1833-000 |

| Деталь: | MAIN DRIVE ASSEMBLY |

| Парткод: | FM4-7716-000 |

| Деталь: | LABEL, DIAL OPERATION |

| Парткод: | FS9-0203-000 |

| Деталь: | LABEL, HINGE CAUTION |

| Парткод: | FU7-8142-000 |

| Деталь: | LABEL, HINGE CAUTION |

| Парткод: | FU7-8225-000 |

| Деталь: | LABEL, HINGE CAUTION |

| Парткод: | FU7-8226-000 |

| Деталь: | LABEL, HINGE CAUTION, C |

| Парткод: | FU7-8453-000 |

| Деталь: | LABEL, HINGE CAUTION, C |

| Парткод: | FU7-8454-000 |

| Деталь: | LABEL, HINGE CAUTION |

| Парткод: | FU7-8455-000 |

| Деталь: | COVER, STAMP |

| Парткод: | FC8-6311-000 |

| Деталь: | LEVER, READ 1 ESTRANGEMENT |

| Парткод: | FC8-6330-000 |

| Деталь: | HOLDER, TRAY SUPPORT |

| Парткод: | FC8-6387-000 |

| Деталь: | HOLDER, FEEDER SHAFT |

| Парткод: | FC8-6388-000 |

| Деталь: | SHEET, READ 2 LEAD |

| Парткод: | FC8-6405-000 |

| Деталь: | HINGE, LEFT |

| Парткод: | FC8-6420-000 |

| Деталь: | SCREW,RS,M4 |

| Парткод: | XA9-0732-000 |

| Деталь: | FAN |

| Парткод: | FK2-6872-000 |

| Деталь: | COVER, COPYBOARD |

| Парткод: | FL2-9945-000 |

| Деталь: | COVER, FRONT |

| Парткод: | FL3-2934-000 |

| Деталь: | COVER, REAR |

| Парткод: | FL3-2935-000 |

| Деталь: | BUSHING |

| Парткод: | FU5-1173-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2651-000 |

| Деталь: | CABLE, INTERFACE |

| Парткод: | FM4-3338-000 |

| Деталь: | LABEL, DOCUMENT SIZE |

| Парткод: | FU7-8447-000 |

| Деталь: | LABEL, DOCUMENT SIZE |

| Парткод: | FU7-8449-000 |

| Деталь: | LABEL, DOCUMENT SIZE |

| Парткод: | FU7-8450-000 |

| Деталь: | LABEL, PROHIBITION DOCUMENT |

| Парткод: | FU7-8444-000 |

| Деталь: | LABEL, PROHIBITION DOCUMENT |

| Парткод: | FU7-8446-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-002 |

| Деталь: | ADF PCB ASSEMBLY |

| Парткод: | FM4-3023-000 |

| Деталь: | STAMPER |

| Парткод: | FB5-9410-000 |

| Деталь: | SOLENOID |

| Парткод: | FK2-0216-000 |

| Деталь: | LABEL, HINGE CAUTION |

| Парткод: | FU7-8223-000 |

| Деталь: | LABEL, HINGE CAUTION |

| Парткод: | FU7-8452-000 |

| Деталь: | ADF MAIN BODY |

| Парткод: | NPN |

| Деталь: | COVER, MAIN SWITCH |

| Парткод: | FC8-4000-000 |

| Деталь: | PLATE, 2ND DELIV. TRAY SUPPORT |

| Парткод: | FC8-5363-000 |

| Деталь: | MOUNT, SWITCH COVER |

| Парткод: | FC8-5378-000 |

| Деталь: | COVER, ENV. HEATER SWITCH |

| Парткод: | FC8-4137-000 |

| Деталь: | COVER, RIGHT REAR SUB |

| Парткод: | FC8-8444-000 |

| Деталь: | COVER, INNER SUB, 1 |

| Парткод: | FC8-8186-000 |

| Деталь: | COVER, 1ST PAPER DELIVERY |

| Парткод: | FC8-8187-000 |

| Деталь: | TRAY, 1ST PAPER DELIVERY |

| Парткод: | FC8-8189-000 |

| Деталь: | COVER, RIGHT LOWER SUB, 2 |

| Парткод: | FC8-8190-000 |

| Деталь: | COVER, RIGHT LOWER SUB, 1 |

| Парткод: | FC8-8191-000 |

| Деталь: | COVER, REAR UPPER, 1 |

| Парткод: | FC8-8192-000 |

| Деталь: | COVER, INNER REAR, 2 |

| Парткод: | FC8-8193-000 |

| Деталь: | COVER, REAR |

| Парткод: | FC8-8196-000 |

| Деталь: | COVER, LEFT FRONT |

| Парткод: | FC8-8197-000 |

| Деталь: | COVER, LEFT LOWER |

| Парткод: | FC8-8198-000 |

| Деталь: | COVER, GRIP |

| Парткод: | FC8-8201-000 |

| Деталь: | ARM, FRONT COVER, B |

| Парткод: | FC8-8203-000 |

| Деталь: | MOUNT, STOPPER ARM |

| Парткод: | FC8-8204-000 |

| Деталь: | HOOK, COVER, FRONT |

| Парткод: | FC8-8205-000 |

| Деталь: | COVER, INNER REAR, 1 |

| Парткод: | FC8-8207-000 |

| Деталь: | COVER, RIGHT FRONT SUB |

| Парткод: | FC8-8443-000 |

| Деталь: | COVER, REAR UPPER, 3 |

| Парткод: | FC8-8286-000 |

| Деталь: | COVER, INNER SUB, 2 |

| Парткод: | FC8-8290-000 |

| Деталь: | COVER, RIGHT UPPER |

| Парткод: | FC8-8291-000 |

| Деталь: | PLATE, FRONT DOOR FIXED |

| Парткод: | FC8-8512-000 |

| Деталь: | PLATE, STATIC CHARGE, LEFT |

| Парткод: | FC8-8638-000 |

| Деталь: | PLATE, STATIC CHARGE, RIGHT |

| Парткод: | FC8-8637-000 |

| Деталь: | COVER, CONNECTOR, 1 |

| Парткод: | FC8-8344-000 |

| Деталь: | COVER, FAX CONNECTOR |

| Парткод: | FC8-8346-000 |

| Деталь: | COVER, HARD DISK DRIVE |

| Парткод: | FC8-8359-000 |

| Деталь: | COVER, INNER BOTTOM |

| Парткод: | FC8-8445-000 |

| Деталь: | ROLLER, BOTTLE TRAY |

| Парткод: | FC8-4649-000 |

| Деталь: | GUIDE, REVERSE BACK END |

| Парткод: | FC9-8612-000 |

| Деталь: | COVER, 2ND PAPER DELIVERY |

| Парткод: | FC8-8543-000 |

| Деталь: | COVER, REVERSE BLANKING |

| Парткод: | FC8-8544-000 |

| Деталь: | LABEL, TONER MODEL |

| Парткод: | FC8-8582-000 |

| Деталь: | LABEL, TONER MODEL |

| Парткод: | FC8-8622-000 |

| Деталь: | LABEL, TONER MODEL |

| Парткод: | FC8-8623-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2759-000 |

| Деталь: | LABEL, MODULAR |

| Парткод: | FC8-8615-000 |

| Деталь: | COVER, RIGHT LOWER SUB, 3 |

| Парткод: | FC8-8617-000 |

| Деталь: | COVER, REAR UPPER, 2 |

| Парткод: | FC8-8631-000 |

| Деталь: | LABEL, MAIN POWER SUPPLY |

| Парткод: | FC9-7861-000 |

| Деталь: | LABEL, MAIN POWER SUPPLY |

| Парткод: | FC9-7862-000 |

| Деталь: | LABEL, MAIN POWER SUPPLY |

| Парткод: | FC9-7863-000 |

| Деталь: | LABEL, MAIN POWER SUPPLY |

| Парткод: | FC0-0225-000 |

| Деталь: | LABEL, MAIN POWER SUPPLY |

| Парткод: | FC0-0226-000 |

| Деталь: | BUSHING |

| Парткод: | FU5-1035-000 |

| Деталь: | COVER, SLOT |

| Парткод: | FC8-8645-000 |

| Деталь: | HOLDER, SERVICE BOOK |

| Парткод: | FC0-2633-000 |

| Деталь: | EMBLEM |

| Парткод: | FL3-1185-000 |

| Деталь: | FRONT UPPER COVER ASSEMBLY |

| Парткод: | FM3-8077-000 |

| Деталь: | FRONT DOOR ASSEMBLY |

| Парткод: | FM3-8078-000 |

| Деталь: | LEFT REAR COVER ASSEMBLY |

| Парткод: | FM3-8079-000 |

| Деталь: | LABEL, LASER CAUTION |

| Парткод: | FC0-2901-000 |

| Деталь: | LABEL, GROUNDING CAUTION |

| Парткод: | FU7-8494-000 |

| Деталь: | LABEL, GROUNDING CAUTION |

| Парткод: | FU7-8521-000 |

| Деталь: | RIGHT UPPER SUB COVER ASSEMBLY |

| Парткод: | FM3-8083-000 |

| Деталь: | LABEL, HARD DISK DRIVE CAUTION |

| Парткод: | FU7-8471-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FS7-2788-000 |

| Деталь: | HINGE, RIGHT DOOR, FRONT |

| Парткод: | FC8-8228-000 |

| Деталь: | HOLDER, M.P. STOPPER |

| Парткод: | FC8-8240-000 |

| Деталь: | COVER, CASSETTE RIGHT UPPER, 1 |

| Парткод: | FC8-8515-000 |

| Деталь: | COVER, CASSETTE RIGHT UPPER, 2 |

| Парткод: | FC8-8516-000 |

| Деталь: | COVER, WASTE TONER |

| Парткод: | FC8-8341-000 |

| Деталь: | SHEET, GLASS CLEANING |

| Парткод: | FC8-8634-000 |

| Деталь: | PAD, GLASS CLEANING |

| Парткод: | FC8-8635-000 |

| Деталь: | GLASS CLEANING ARM ASSEMBLY |

| Парткод: | FM3-8260-000 |

| Деталь: | HOOK, RIGHT DOOR |

| Парткод: | FC5-0631-000 |

| Деталь: | ROLLER, PAPER FEED |

| Парткод: | FC8-3782-000 |

| Деталь: | STOPPER, DOOR, RIGHT LOWER |

| Парткод: | FC8-5164-000 |

| Деталь: | HANDLE, DOOR |

| Парткод: | FC8-8172-000 |

| Деталь: | DOOR ASSEMBLY, RIGHT LOWER |

| Парткод: | FM3-8150-000 |

| Деталь: | EXTERNAL COVERS, PANELS, ETC. |

| Парткод: | NPN |

| Деталь: | PLATE, READER JOINT |

| Парткод: | FC8-8486-000 |

| Деталь: | STRAP, WASTE TONER |

| Парткод: | FC8-8496-000 |

| Деталь: | HOLDER, SWITCH, UPPER |

| Парткод: | FC8-8497-000 |

| Деталь: | LEVER, SENSOR |

| Парткод: | FC8-8498-000 |

| Деталь: | HOLDER, SWITCH, LOWER WASTE |

| Парткод: | FC8-8499-000 |

| Деталь: | TONER CASE ASSEMBLY WASTE |

| Парткод: | FM3-8137-000 |

| Деталь: | TONER INNER CASE ASSY AC |

| Парткод: | FM3-8138-000 |

| Деталь: | CABLE ASSEMBLY ENVIRONMENT |

| Парткод: | FM3-8178-000 |

| Деталь: | HEATER PCB ASSY |

| Парткод: | FM3-8187-000 |

| Деталь: | ENVIRONMENT HEATER PCB ASSY |

| Парткод: | FM3-8190-000 |

| Деталь: | DC CONTROLLER PCB ASSEMBLY |

| Парткод: | FM3-8600-000 |

| Деталь: | CABLE, HEATER |

| Парткод: | FM3-8623-000 |

| Деталь: | CABLE, WASTE TONER SENSING |

| Парткод: | FM4-1894-000 |

| Деталь: | SWITCH CABLE UNIT, ENVIRONMENT |

| Парткод: | FM3-8626-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-002 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-003 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-004 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-006 |

| Деталь: | CONNECTOR, SNAP TIGHT, BL |

| Парткод: | VS1-8412-009 |

| Деталь: | CONNECTOR, SNAP TIGHT, BL |

| Парткод: | VS1-8412-015 |

| Деталь: | CONNECTOR, SNAP TIGHT, 31P, BL |

| Парткод: | VS1-8412-031 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7207-003 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7207-004 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7207-008 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7207-014 |

| Деталь: | SCREW, D, M3X8 |

| Парткод: | XA9-1671-000 |

| Цена: | 170 ₽ |

| Деталь: | CAP, WASTE TONER CASE |

| Парткод: | FC8-8363-000 |

| Деталь: | CORE, FERRITE |

| Парткод: | WE8-6391-000 |

| Деталь: | MACHINE REAR PLATE 1 |

| Парткод: | NPN |

| Деталь: | HOLDER, PAPER PICK-UP ROLLER |

| Парткод: | FB6-3380-020 |

| Деталь: | GUIDE, VERTICAL PATH |

| Парткод: | FB6-3387-000 |

| Деталь: | GUIDE, VERTICAL PATH |

| Парткод: | FL2-8282-000 |

| Деталь: | ROD, SEPARATION ROLLER RELEASE |

| Парткод: | FB6-3388-000 |

| Деталь: | CLAW, PICK-UP |

| Парткод: | FB6-3389-000 |

| Деталь: | GEAR, RATCHET |

| Парткод: | FB6-3391-000 |

| Деталь: | SPRING, LEAF |

| Парткод: | FB6-3392-020 |

| Деталь: | ARM, PAPER FEED SHAFT |

| Парткод: | FB6-3395-000 |

| Деталь: | LOCK, PICK-UP |

| Парткод: | FB6-3396-010 |

| Деталь: | FLAG, PAPER SENSOR |

| Парткод: | FB6-3397-000 |

| Деталь: | FLAG, PAPER DETECT SENSOR |

| Парткод: | FB6-3398-000 |

| Деталь: | GEAR, RATCHET |

| Парткод: | FB6-3402-000 |

| Деталь: | COUPLING, FEED SHAFT STOP |

| Парткод: | FB6-3403-000 |

| Деталь: | COUPLING, SEPARATION SHAFT |

| Парткод: | FB6-3404-000 |

| Деталь: | ROLLER, PAPER PICK-UP |

| Парткод: | FB6-3405-000 |

| Цена: | 550 ₽ |

| Деталь: | ROLLER, PAPER PICK-UP |

| Парткод: | FC7-9381-000 |

| Деталь: | COLLAR, PAPER PICK-UP SHAFT |

| Парткод: | FB6-3413-000 |

| Деталь: | ROLLER, VERTICAL PATH |

| Парткод: | FB6-4852-000 |

| Деталь: | ROLLER, VERTICAL PATH |

| Парткод: | FM3-4150-000 |

| Деталь: | CAM, LOCK |

| Парткод: | FB6-7078-000 |

| Деталь: | ROLLER, SEPARATION |

| Парткод: | FC6-6661-000 |

| Цена: | 600 ₽ |

| Деталь: | ROLLER, FEED/SEPARATION |

| Парткод: | FC6-7083-000 |

| Деталь: | ROLLER, FEED/SEPARATION |

| Парткод: | FC7-9502-000 |

| Деталь: | RING, RETAINING |

| Парткод: | FC6-9867-000 |

| Деталь: | PAD, PAPER PICK-UP HOLDER |

| Парткод: | FC8-1205-000 |

| Деталь: | STOPPER, ROLLER |

| Парткод: | FC7-5845-000 |

| Деталь: | CLAW, PAPER PICK-UP |

| Парткод: | FC8-1178-000 |

| Деталь: | DAMPER |

| Парткод: | FC8-1202-000 |

| Деталь: | LIMITER, TORQUE |

| Парткод: | FC8-8621-000 |

| Деталь: | JOINT, RETARD |

| Парткод: | FC9-4290-000 |

| Деталь: | ARM, LIFTING |

| Парткод: | FC9-7253-000 |

| Деталь: | GEAR, 46T |

| Парткод: | FF6-2397-000 |

| Деталь: | PHOTO-INTERRUPTER, TLP1252(C6) |

| Парткод: | FK2-0149-000 |

| Деталь: | SOLENOID |

| Парткод: | FK2-0408-000 |

| Деталь: | FLAG, REGISTRATION SENSOR |

| Парткод: | FL2-6580-000 |

| Деталь: | PICK-UP ARM UNIT |

| Парткод: | FM3-4146-000 |

| Деталь: | PICK-UP DRIVE SIDE PLATE ASSY |

| Парткод: | FM4-1201-000 |

| Деталь: | HOLDER, SEPARATION ROLLER |

| Парткод: | FM4-2525-000 |

| Деталь: | BUSHING |

| Парткод: | FS1-1205-000 |

| Деталь: | BUSHING |

| Парткод: | FS5-1943-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FS7-2800-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FS7-2801-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FS7-2803-000 |

| Деталь: | GEAR, 15T |

| Парткод: | FU3-0280-000 |

| Деталь: | GEAR, 21T |

| Парткод: | FU3-0282-000 |

| Деталь: | GEAR, 21T |

| Парткод: | FU3-0283-000 |

| Деталь: | GEAR, 16T |

| Парткод: | FU3-0284-000 |

| Деталь: | GEAR, 21T |

| Парткод: | FU3-0288-000 |

| Деталь: | GEAR, 14T |

| Парткод: | FU3-0289-000 |

| Деталь: | GEAR, 41T |

| Парткод: | FU3-0347-000 |

| Деталь: | GEAR, 41T |

| Парткод: | FU3-0349-000 |

| Деталь: | GEAR, 41T/41T |

| Парткод: | FU3-0350-000 |

| Деталь: | GEAR, 16T/16T |

| Парткод: | FU3-0352-000 |

| Деталь: | BUSHING |

| Парткод: | FU5-1763-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU6-2684-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU6-2784-000 |

| Деталь: | GEAR, 42T |

| Парткод: | FU7-0445-000 |

| Деталь: | GEAR, 51T |

| Парткод: | FU7-0848-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-5378-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-002 |

| Деталь: | SCREW,RS,M3X10 |

| Парткод: | XA9-0656-000 |

| Деталь: | RING, E |

| Парткод: | XD9-0136-000 |

| Деталь: | LABEL, CAUTION |

| Парткод: | FU7-8477-000 |

| Деталь: | PIN, DOWEL |

| Парткод: | XD3-2200-122 |

| Деталь: | PAPER PICK-UP ASSEMBLY |

| Парткод: | FM3-8255-000 |

| Деталь: | PAPER PICK-UP ASSEMBLY |

| Парткод: | FM4-6225-000 |

| Деталь: | FUSE |

| Парткод: | VD7-2941-002 |

| Деталь: | FUSE |

| Парткод: | VD7-2951-502 |

| Деталь: | AC DRIVER PCB ASSEMBLY |

| Парткод: | FM3-8602-000 |

| Деталь: | AC DRIVER PCB ASSEMBLY |

| Парткод: | FM3-8606-000 |

| Деталь: | AC DRIVER PCB ASSEMBLY |

| Парткод: | FM3-8614-000 |

| Деталь: | FLAG, REVERSE SENSOR |

| Парткод: | FC5-0987-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC5-0988-000 |

| Деталь: | ROLLER, REVERSE |

| Парткод: | FC8-4749-000 |

| Деталь: | BUSHING |

| Парткод: | FC8-4751-000 |

| Деталь: | IC,PHOTO-INTERRUPTER,LG248NL1A |

| Парткод: | WG8-5783-000 |

| Деталь: | HOLDER, TOGGLE |

| Парткод: | FC8-8320-000 |

| Деталь: | COVER, 2ND/3RD DELIVERY, LOWER |

| Парткод: | FC8-8323-000 |

| Деталь: | ROLLER, REVERSE |

| Парткод: | FC8-8326-000 |

| Деталь: | GUIDE, SWING GEAR |

| Парткод: | FC8-8333-000 |

| Деталь: | CLAMP, SWING GEAR |

| Парткод: | FC8-8334-000 |

| Деталь: | SPRING, GROUNDING |

| Парткод: | FC8-8447-000 |

| Деталь: | MOTOR, STEPPING, DC |

| Парткод: | RK2-0997-000 |

| Деталь: | GUIDE, MOVABLE |

| Парткод: | FC8-8625-000 |

| Деталь: | 2ND/3RD DELIVERY PCB ASSEMBLY |

| Парткод: | FM3-8601-000 |

| Деталь: | BUSHING |

| Парткод: | FU5-1453-000 |

| Деталь: | BUSHING, POLYACETAR |

| Парткод: | FU5-1469-000 |

| Деталь: | GEAR, 22T |

| Парткод: | FU6-0085-000 |

| Деталь: | GEAR, 31T/20T |

| Парткод: | FU6-0140-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2446-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2770-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FU7-2784-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2818-000 |

| Деталь: | GEAR, 32T/19T |

| Парткод: | FU8-0398-000 |

| Деталь: | GEAR, 74T/25T |

| Парткод: | FU8-0408-000 |

| Деталь: | LEVER, TOGGLE |

| Парткод: | RC2-6734-000 |

| Деталь: | SCREW, D, M3X8 |

| Парткод: | XA9-1671-000 |

| Цена: | 170 ₽ |

| Деталь: | RING, E |

| Парткод: | XD9-0136-000 |

| Деталь: | SPRING, GROUNDING |

| Парткод: | FC0-3650-000 |

| Деталь: | PIN, DOWEL |

| Парткод: | XD3-2200-122 |

| Деталь: | 2ND/3RD DRIVE FRAME ASSEMBLY |

| Парткод: | FM3-8051-000 |

| Деталь: | LEVER, TOGGLE, COLOR |

| Парткод: | FC8-7978-000 |

| Деталь: | LEVER, TOGGLE, BLACK |

| Парткод: | FC8-7979-000 |

| Деталь: | LEVER, HOLD, BLACK |

| Парткод: | FC8-7991-000 |

| Деталь: | LEVER, HOLD, COLOR |

| Парткод: | FC8-7992-000 |

| Деталь: | LEVER, SHUTTER, 1 |

| Парткод: | FC8-8026-000 |

| Деталь: | LEVER, SHUTTER, 2 |

| Парткод: | FC8-8027-000 |

| Деталь: | LEVER, SHUTTER, 3 |

| Парткод: | FC8-8028-000 |

| Деталь: | LINK, SHUTTER, 1 |

| Парткод: | FC8-8032-000 |

| Деталь: | LINK, SHUTTER, 2 |

| Парткод: | FC8-8033-000 |

| Деталь: | GUIDE, CROSSMEMBER, LOWER |

| Парткод: | FC8-8220-000 |

| Деталь: | HOLDER, CONNECTOR |

| Парткод: | FC8-8530-000 |

| Деталь: | GUIDE, FRONT |

| Парткод: | FC8-8606-000 |

| Деталь: | SPRING, RETAINING |

| Парткод: | FC9-8606-000 |

| Деталь: | CABLE, FLEXIBLE FLAT |

| Парткод: | FK2-9199-000 |

| Деталь: | CAP, SHUTTER LEVER |

| Парткод: | FC8-8029-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2750-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2763-000 |

| Деталь: | GUIDE, 2 |

| Парткод: | RC2-6629-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-002 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-003 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-005 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-006 |

| Деталь: | CONNECTOR, SNAP TIGHT, BL |

| Парткод: | VS1-8412-015 |

| Деталь: | CONNECTOR, SNAP TIGHT, BL |

| Парткод: | VS1-8412-027 |

| Деталь: | CONNECTOR, SNAP TIGHT, BL |

| Парткод: | VS1-8412-029 |

| Деталь: | INTERNAL COMPONENTS 4 |

| Парткод: | NPN |

| Деталь: | KEY TOP, BRIGHTNESS ADJUSTMENT |

| Парткод: | FC8-7824-000 |

| Деталь: | KEY TOP, SETTINGS/REGISTRATION |

| Парткод: | FC8-8649-000 |

| Деталь: | KEY TOP, POWER |

| Парткод: | FC8-8650-000 |

| Деталь: | KEY TOP, RESET |

| Парткод: | FC9-9237-000 |

| Деталь: | KEY TOP, STOP |

| Парткод: | FC9-9235-000 |

| Деталь: | KEY TOP, CANCEL |

| Парткод: | FC9-9238-000 |

| Деталь: | KEY TOP, COUNTER CHECK |

| Парткод: | FC8-8655-000 |

| Деталь: | KEY TOP, MAIN MENU |

| Парткод: | FC9-9239-000 |

| Деталь: | KEY TOP, PORTAL |

| Парткод: | FC9-9240-000 |

| Деталь: | COVER, KEY TOP, LEFT |

| Парткод: | FC9-4390-000 |

| Деталь: | COVER, KEY TOP, RIGHT |

| Парткод: | FC9-4391-000 |

| Деталь: | COVER, LIQUID CRYSTAL DISPLAY |

| Парткод: | FC9-5278-000 |

| Деталь: | SHEET, ANTISTATIC |

| Парткод: | FC9-5279-000 |

| Деталь: | COVER, CONTROL PANEL |

| Парткод: | FC9-5283-000 |

| Деталь: | COVER, LAMP |

| Парткод: | FC9-5284-000 |

| Деталь: | KEY TOP, NUMBERS |

| Парткод: | FC9-5290-000 |

| Деталь: | COVER, UPPER |

| Парткод: | FC9-5303-000 |

| Деталь: | COVER, LOWER, 1 |

| Парткод: | FC9-5304-000 |

| Деталь: | COVER, PEN |

| Парткод: | FC9-6232-000 |

| Деталь: | COVER, LOWER, 2 |

| Парткод: | FC9-6233-000 |

| Деталь: | KEY TOP, VOLUME |

| Парткод: | FC9-6236-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC9-8187-000 |

| Деталь: | TOUCH PANEL ASSEMBLY |

| Парткод: | FK2-8949-000 |

| Деталь: | CABLE, USB |

| Парткод: | FK2-8957-000 |

| Деталь: | PEN, TOUCH PANEL |

| Парткод: | FL3-0626-000 |

| Деталь: | KEY TOP, START |

| Парткод: | FL3-0833-000 |

| Деталь: | CONTROL PANEL VOLUME ASSEMBLY |

| Парткод: | FM4-1198-000 |

| Деталь: | CONTROL PANEL HUB ASSEMBLY |

| Парткод: | FM4-2430-000 |

| Деталь: | CPU PCB ASSEMBLY |

| Парткод: | FM4-2183-000 |

| Деталь: | PANEL, LCD |

| Парткод: | FM4-2185-000 |

| Деталь: | SUB KEY PCB ASSEMBLY |

| Парткод: | FM4-2431-000 |

| Деталь: | NUMBERS KEY PCB ASSEMBLY |

| Парткод: | FM4-2432-000 |

| Деталь: | RING CORE |

| Парткод: | WE8-5731-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-5282-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-6237-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-6238-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-6239-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-6240-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-6241-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-6246-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-6247-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-6249-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-6242-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-6243-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-6244-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-6245-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-9433-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-9434-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-9436-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-9437-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-9438-000 |

| Деталь: | SHEET, CONTROL PANEL |

| Парткод: | FC9-9439-000 |

| Деталь: | PLATE, FIXED, LEFT |

| Парткод: | FC9-5306-000 |

| Деталь: | PLATE, FIXED, RIGHT |

| Парткод: | FC9-6235-000 |

| Деталь: | CONTROL PANEL ASSEMBLY |

| Парткод: | FM4-2184-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | RC2-7187-000 |

| Деталь: | ITB GUIDE RAIL ASSY, FRONT, 1 |

| Парткод: | FM3-8013-000 |

| Деталь: | ITB GUIDE RAIL ASSY, REAR, 1 |

| Парткод: | FM3-8014-000 |

| Деталь: | I.T.BELT GUIDE RAIL ASSY, F |

| Парткод: | FM3-8018-000 |

| Деталь: | HANDLE,MAIN BODY |

| Парткод: | FM3-8021-000 |

| Деталь: | RIGHT DOOR TOGGLE ASSY, FRONT |

| Парткод: | FM3-8031-000 |

| Деталь: | RIGHT DOOR TOGGLE ASSY, REAR |

| Парткод: | FM3-8032-000 |

| Деталь: | I.T.BELT GUIDE RAIL ASSY,REAR |

| Парткод: | FM3-8033-000 |

| Деталь: | LEVER, SWITCHING |

| Парткод: | RC2-7186-000 |

| Деталь: | LOW VOLTAGE POWER SUPPLY ASSY |

| Парткод: | FM3-8179-000 |

| Деталь: | CORE, FERRITE |

| Парткод: | WE8-6449-000 |

| Деталь: | LOCK, DOOR LINK, RIGHT |

| Парткод: | RC2-7234-000 |

| Деталь: | PLATE, RT. DOOR LINK FIXED, FR |

| Парткод: | RL1-2281-000 |

| Деталь: | PLATE, RT. DOOR LINK FIXED, RR |

| Парткод: | RL1-2282-000 |

| Деталь: | SHAFT, RIGHT DOOR LINK |

| Парткод: | RU5-4979-000 |

| Деталь: | SCREW, D, M3X8 |

| Парткод: | XA9-1671-000 |

| Цена: | 170 ₽ |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-003 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7207-019 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7207-003 |

| Деталь: | INTERNAL COMPONENTS 3 |

| Парткод: | NPN |

| Деталь: | SHAFT |

| Парткод: | FC0-0618-000 |

| Деталь: | LINK, HANDLE |

| Парткод: | FC0-0619-000 |

| Деталь: | LEVER, LINK |

| Парткод: | FC0-0620-000 |

| Деталь: | LATCH, FRONT |

| Парткод: | FC0-0622-000 |

| Деталь: | LATCH, REAR |

| Парткод: | FC0-0623-000 |

| Деталь: | HOLDER, LATCH, FRONT |

| Парткод: | FC0-0624-000 |

| Деталь: | HOLDER, LATCH, REAR |

| Парткод: | FC0-0625-000 |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000 |

| Деталь: | HOOK |

| Парткод: | FC0-0627-000 |

| Деталь: | LEVER, LOCK |

| Парткод: | FC0-0628-000 |

| Деталь: | SHEET, BASE GUIDE |

| Парткод: | FC0-0629-000 |

| Деталь: | PIN, PRESSURE |

| Парткод: | FC0-0630-000 |

| Деталь: | STOPPER, PAPER DELIVERY GUIDE |

| Парткод: | FC8-8226-000 |

| Деталь: | STOPPER |

| Парткод: | FC8-8241-000 |

| Деталь: | SPRING, GROUNDING |

| Парткод: | FC8-8348-000 |

| Деталь: | LABEL, LASER CAUTION |

| Парткод: | FC8-8355-000 |

| Деталь: | FLAG, OPEN/CLOSE SENSOR |

| Парткод: | FC8-8356-000 |

| Деталь: | PIN, POSITIONING |

| Парткод: | FC8-8413-000 |

| Деталь: | ROLLER, REEL |

| Парткод: | FC8-8492-000 |

| Деталь: | SHEET, NOISE-PROOF |

| Парткод: | FC8-8524-000 |

| Деталь: | SHAFT, HANDLE FIXED |

| Парткод: | FC8-8538-000 |

| Деталь: | HANDLE |

| Парткод: | FC8-8539-000 |

| Деталь: | COVER, PAPER PICK-UP ROLLER |

| Парткод: | FC9-8674-000 |

| Деталь: | MULTI PAPER PICK-UP TRAY ASSY |

| Парткод: | FM3-8038-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2768-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2782-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2792-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2797-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2798-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2799-000 |

| Деталь: | SPRING, POWER DISPATCHING |

| Парткод: | FU7-2800-000 |

| Деталь: | SPRING, GROUNDING |

| Парткод: | FU7-2801-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2803-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2804-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2805-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2814-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2819-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2820-000 |

| Деталь: | CLAMP, LEVER, REAR |

| Парткод: | RC2-6592-000 |

| Деталь: | STOPPER, PAPER PICK-UP SHAFT |

| Парткод: | RC2-6800-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | RC2-6836-000 |

| Деталь: | FLAG, SENSOR |

| Парткод: | RC2-7064-000 |

| Деталь: | COVER, GEAR |

| Парткод: | RC2-7072-000 |

| Деталь: | HOOK, SPRING, LEFT |

| Парткод: | RC2-7076-000 |

| Деталь: | PIN, SPRING HOOK |

| Парткод: | RC2-7077-000 |

| Деталь: | HOOK, SPRING, RIGHT |

| Парткод: | RC2-7078-000 |

| Деталь: | LINK, M.P. HINGE |

| Парткод: | RC2-7086-000 |

| Деталь: | PLATE, GROUNDING |

| Парткод: | RC2-7217-000 |

| Деталь: | CLIP |

| Парткод: | RC2-7248-000 |

| Деталь: | COVER, GROUNDING |

| Парткод: | RC2-7253-000 |

| Деталь: | ROLLER, DUPLEXING PAPER FEED |

| Парткод: | RC2-7271-000 |

| Деталь: | ROLLER, REG. |

| Парткод: | RC2-7280-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | RC2-8412-000 |

| Деталь: | HOOK, FRONT |

| Парткод: | RC2-8413-000 |

| Деталь: | HOOK, REAR |

| Парткод: | RC2-8414-000 |

| Деталь: | GUIDE, CONDUCTIVE |

| Парткод: | RC2-8415-000 |

| Деталь: | HOOK |

| Парткод: | RC2-8450-000 |

| Деталь: | COVER, CABLE |

| Парткод: | RC2-9644-000 |

| Деталь: | SECONDARY TRANSFER GUIDE ASSY |

| Парткод: | RM1-6041-000 |

| Деталь: | M.P. PAPER PICK-UP GEAR ASSY |

| Парткод: | RM1-6049-000 |

| Деталь: | M.P. PAPER PICK-UP SHAFT ASSY |

| Парткод: | RM1-6050-000 |

| Деталь: | MP LIFTER PLATE ASSY |

| Парткод: | RM1-6124-000 |

| Деталь: | DUPLEXING GEAR COVER ASSEMBLY |

| Парткод: | RM1-6151-000 |

| Деталь: | ROLLER, PAPER PICK-UP |

| Парткод: | RM1-6177-000 |

| Деталь: | ROLLER, PAPER PICK-UP |

| Парткод: | RL1-2244-000 |

| Цена: | 2 900 ₽ |

| Деталь: | MULTI-PURPOSE SEP. PAD KIT |

| Парткод: | RM1-6178-000 |

| Деталь: | MULTI-PURPOSE SEP. PAD KIT |

| Парткод: | RM1-6163-000 |

| Деталь: | 2ND TRANSFER ROLLER ASSY |

| Парткод: | RM1-7928-000 |

| Деталь: | SOLENOID |

| Парткод: | RM1-6790-000 |

| Деталь: | BUSHING |

| Парткод: | FU6-1110-000 |

| Деталь: | BUSHING |

| Парткод: | RU5-1313-000 |

| Деталь: | BUSHING |

| Парткод: | RU5-1336-000 |

| Деталь: | BUSHING |

| Парткод: | RU5-1340-000 |

| Деталь: | BUSHING |

| Парткод: | RU5-1341-000 |

| Деталь: | GEAR, 16T |

| Парткод: | RU6-0819-000 |

| Деталь: | GEAR, 21T |

| Парткод: | RU6-0829-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | RU6-2691-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RU6-2693-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | RU6-2695-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RU6-2732-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | RU6-2735-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-002 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7207-003 |

| Деталь: | CONNECTOR, SNAP TIGHT |

| Парткод: | VS1-7207-007 |

| Деталь: | LABEL, FEED SIZE |

| Парткод: | FC8-8598-000 |

| Деталь: | LABEL, FEED SIZE |

| Парткод: | FC8-8599-000 |

| Деталь: | LABEL, FEED SIZE |

| Парткод: | FC8-8600-000 |

| Деталь: | LABEL, FEED SIZE |

| Парткод: | FC8-8601-000 |

| Деталь: | LABEL, PAPER SET INSTRUCTION |

| Парткод: | FC9-8584-000 |

| Деталь: | LABEL, PAPER SET INSTRUCTION |

| Парткод: | FC9-8585-000 |

| Деталь: | GUIDE, RIGHT DOOR, UPPER |

| Парткод: | FC8-8235-000 |

| Деталь: | GUIDE, PAPER DELIVERY, 1 |

| Парткод: | FC8-8251-000 |

| Деталь: | GUIDE, PAPER DELIVERY, 2 |

| Парткод: | FC8-8252-000 |

| Деталь: | HINGE, RIGHT DOOR, REAR |

| Парткод: | FCS-8353-000 |

| Деталь: | RIGHT DOOR INNER GUIDE ASSY |

| Парткод: | FM3-8039-000 |

| Деталь: | RIGHT DOOR ASSEMBLY |

| Парткод: | FM3-8036-000 |

| Деталь: | FILTER, AIR |

| Парткод: | FC6-4023-000 |

| Деталь: | PLATE, READER FIXED |

| Парткод: | FC8-8105-000 |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2811-000 |

| Деталь: | LABEL, SERVICE |

| Парткод: | FL3-0697-000 |

| Деталь: | HOLDER, SWITCH |

| Парткод: | FC8-8273-000 |

| Деталь: | HOLDER, ENVIRONMENT SENSOR |

| Парткод: | FC8-8274-000 |

| Деталь: | ARM, COVER |

| Парткод: | FC8-8342-000 |

| Деталь: | LINK, DOOR, FRONT |

| Парткод: | FC8-8364-000 |

| Деталь: | HOLDER, LINK |

| Парткод: | FC8-8365-000 |

| Деталь: | HOLDER, INTERLOCK SWITCH |

| Парткод: | FC8-8464-000 |

| Деталь: | ARM, COVER |

| Парткод: | FC8-8626-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC8-8627-000 |

| Деталь: | LEVER, TOGGLE |

| Парткод: | RC2-6734-000 |

| Деталь: | LEVER, INTERLOCK |

| Парткод: | RC2-6684-000 |

| Деталь: | SHAFT |

| Парткод: | FC8-8636-000 |

| Деталь: | FERRITE CORE |

| Парткод: | WE8-5601-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-004 |

| Деталь: | FAN |

| Парткод: | FK2-0360-000 |

| Цена: | 1 600 ₽ |

| Деталь: | ENVIRONMENT SENSOR PCB ASSY |

| Парткод: | RK2-2884-000 |

| Деталь: | FAN |

| Парткод: | FK2-2064-000 |

| Деталь: | SWITCH, MAIN POWER SUPPLY |

| Парткод: | FK2-7264-000 |

| Деталь: | CABLE, USER INTERFACE |

| Парткод: | FK2-9243-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2778-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FU7-2810-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2817-000 |

| Деталь: | CABLE, SWITCH |

| Парткод: | FM3-8622-000 |

| Деталь: | SWITCH CABLE UNIT, INTERLOCK |

| Парткод: | FM4-1895-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-003 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2773-000 |

| Деталь: | INTERNAL COMPONENTS 1 |

| Парткод: | NPN |

| Деталь: | IC, MB87L8650, GATE ARRAY |

| Парткод: | FK2-3218-000 |

| Деталь: | IC, MB87Q1911, ASIC |

| Парткод: | FK2-7574-000 |

| Деталь: | IC, R8A03018ABG U100, ASIC |

| Парткод: | FK2-7835-000 |

| Деталь: | IC, T6TH5EFG-0002(0), STANDARD |

| Парткод: | FK2-7852-000 |

| Деталь: | IC, MB87S1801 |

| Парткод: | FK2-8321-000 |

| Деталь: | IC, CLOCK GENERATOR, HYBRID |

| Парткод: | FK2-9242-000 |

| Деталь: | MAIN CONTROLLER PCB ASSY, 2 |

| Парткод: | FM4-3138-000 |

| Деталь: | ARM, OPEN/CLOSE SENSOR |

| Парткод: | FC9-7292-000 |

| Деталь: | CABLE, CCD |

| Парткод: | FM4-3392-000 |

| Деталь: | SCREW, RS, M3X8.5 |

| Парткод: | XA9-1567-000 |

| Деталь: | COVER, READER SUB, FRONT |

| Парткод: | FC9-7301-000 |

| Деталь: | COVER, PCB |

| Парткод: | FC9-7298-000 |

| Деталь: | COVER, READER SUB, REAR |

| Парткод: | FC9-7550-000 |

| Деталь: | LABEL, SERVICE |

| Парткод: | FL3-3691-000 |

| Деталь: | CARRIAGE ASSEMBLY |

| Парткод: | FM4-3379-000 |

| Деталь: | CASE, OPEN/CLOSE SENSOR |

| Парткод: | FC8-6188-010 |

| Деталь: | CASE, PAPER SIZE SENSOR |

| Парткод: | FC9-7284-000 |

| Деталь: | CCD MIRROR CLEANING UNIT |

| Парткод: | FL3-3207-000 |