Canon imageRUNNER Advance 500

Рейтинг

Модули

103 INTERNAL COMPONENTS 3

460 LASER SCANNER UNIT

T20 FAX ASSEMBLY, 1 LINE (FAX model)

T90 1 LINE PCB ASSEMBLY (FAX model)

315 PRE-REGISTRATION GUIDE ASSY

102 INTERNAL COMPONENTS 2

B12 PAPER PICK-UP COVER ASSEMBLY (ADF)

105 MACHINE REAR PLATE 2

104 MACHINE REAR PLATE 1

300 CASSETTE ASSEMBLY

312 MULTI PAPER PICK-UP ASSEMBLY

770 WASTE TONER BOX ASSEMBLY

980 HIGH VOLTAGE PCB ASSEMBLY

250 MAIN DRIVE ASSEMBLY

B10 INTERNAL COMPONENTS (ADF)

101 INTERNAL COMPONENTS 1

B13 DOCUMENT TRAY ASSEMBLY (ADF)

400 READER ASSEMBLY

620 HOPPER ASSEMBLY

280 FIXNG DRIVE ASSY

350 PAPER DELIVERY REVERSE ASSY

B40 PAPER FEED ASSEMBLY (ADF)

130 CONTROL PANEL ASSEMBLY

640 DEVELOPING UNIT

100 EXTERNAL COVERS, PANELS, ETC.

810 FIXING ASSEMBLY

935 ENGINE CONTROLLER PCB ASSY

110 RIGHT DOOR ASSEMBLY

320 TRANSFER PAPER FEED ASSEMBLY

310 PAPER PICK-UP ASSEMBLY

930 MAIN CONTROLLER PCB ASSEMBLY

B30 DRIVE ASSEMBLY (ADF)

Детали 400 READER ASSEMBLY

| Деталь: | HANDLE, PRESSURE |

| Парткод: | FC0-5123-000 |

| Деталь: | CABLE, DEVELOPING FAN |

| Парткод: | FM4-7834-000 |

| Деталь: | RAIL, CARTRIDGE, RIGHT |

| Парткод: | FC0-1005-000 |

| Деталь: | STOPPER |

| Парткод: | FC0-1131-000 |

| Деталь: | BUSHING |

| Парткод: | FC0-1133-000 |

| Деталь: | CAM, DEVELOPING PRESSURE |

| Парткод: | FC0-4005-000 |

| Деталь: | GUIDE, HOPPER LOWER |

| Парткод: | FC0-4012-000 |

| Деталь: | PLATE, GROUNDING |

| Парткод: | FC0-5104-000 |

| Деталь: | BUSHING |

| Парткод: | FC0-5113-000 |

| Деталь: | CLIP |

| Парткод: | FC8-6380-000 |

| Деталь: | FAN |

| Парткод: | FK2-2530-000 |

| Деталь: | CLUTCH |

| Парткод: | FK2-9154-000 |

| Деталь: | REGISTRATION UNIT |

| Парткод: | FM4-6509-000 |

| Деталь: | DRAWER CABLE UNIT |

| Парткод: | FM1-A632-000 |

| Деталь: | REGISTRATION ROLLER UNIT |

| Парткод: | FM4-6527-000 |

| Деталь: | POWER SUPPLY ASSEMBLY |

| Парткод: | FM1-A513-000 |

| Деталь: | POWER SUPPLY ASSEMBLY |

| Парткод: | FM1-A671-000 |

| Деталь: | HV GUIDE UNIT |

| Парткод: | FM4-6590-000 |

| Деталь: | HV GUIDE UNIT, UPPER |

| Парткод: | FM4-7989-000 |

| Деталь: | RAIL UNIT, CARTRIDGE, LEFT |

| Парткод: | FM4-8004-000 |

| Деталь: | POWER SWITCH UNIT |

| Парткод: | FM1-A515-000 |

| Деталь: | BUSHING |

| Парткод: | FU5-1030-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU8-2648-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU8-2661-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-003 |

| Деталь: | CONNECTOR, SNAP TIGHT, 6P, W |

| Парткод: | VS1-7173-006 |

| Деталь: | SCREW, RS, M3X8.5 |

| Парткод: | XA9-1567-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-004 |

| Деталь: | CABLE, HVT |

| Парткод: | FM1-A939-000 |

| Деталь: | INTERNAL COMPONENTS 3 |

| Парткод: | NPN |

| Деталь: | LASER SCANNER UNIT |

| Парткод: | FM0-1846-010 |

| Деталь: | OFF-HOOK DETECT PCB ASSEMBLY |

| Парткод: | FM3-2163-000 |

| Деталь: | MODULAR PCB ASSEMBLY |

| Парткод: | FM4-0834-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-8412-007 |

| Деталь: | CABLE, FAX 1 |

| Парткод: | FM1-A949-000 |

| Деталь: | CABLE, SPEAKER |

| Парткод: | FM1-A950-000 |

| Деталь: | CABLE, FAX 2 |

| Парткод: | FM1-A951-000 |

| Деталь: | CABLE, OFF HOOK 2 |

| Парткод: | FM1-A953-000 |

| Деталь: | CABLE, OFF HOOK 3 |

| Парткод: | FM1-A954-000 |

| Деталь: | CABLE, MODULAR 1 |

| Парткод: | FM1-A955-000 |

| Деталь: | SPEAKER ASSEMBLY |

| Парткод: | FM4-9135-000 |

| Деталь: | FAX ASSEMBLY, 1 LINE |

| Парткод: | NPN |

| Деталь: | IC, GATE ARRAY |

| Парткод: | FK2-5396-000 |

| Деталь: | 1 LINE PCB ASSEMBLY |

| Парткод: | FM4-0838-000 |

| Деталь: | PHOTO-SENSOR, KUA0055C |

| Парткод: | FK2-6470-000 |

| Деталь: | PRE-REGISTRATION GUIDE ASSY |

| Парткод: | FM4-6517-000 |

| Деталь: | RAIL, FIXING GUIDE |

| Парткод: | FC0-1010-000 |

| Деталь: | LOCK, RIGHT DOOR |

| Парткод: | FC0-1144-000 |

| Деталь: | RAIL UNIT, FIXING, FRONT |

| Парткод: | FM4-6502-000 |

| Деталь: | VERTICAL PATH GUIDE UNIT |

| Парткод: | FM4-6524-000 |

| Деталь: | LASER SHUTTER UNIT |

| Парткод: | FM4-8018-000 |

| Деталь: | DRAWER CABLE UNIT, FIXING |

| Парткод: | FM4-8064-000 |

| Деталь: | SCREW, RS, M3X8.5 |

| Парткод: | XA9-1567-000 |

| Деталь: | CABLE, LASER |

| Парткод: | FM1-A933-000 |

| Деталь: | CABLE, POLYGON |

| Парткод: | FM1-A941-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BL |

| Парткод: | VS1-8412-019 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-003 |

| Деталь: | CABLE, REVERSE UNIT |

| Парткод: | FM1-A940-000 |

| Деталь: | INTERNAL COMPONENTS 2 |

| Парткод: | NPN |

| Деталь: | LINK, OPEN/CLOSE |

| Парткод: | FC0-2970-000 |

| Деталь: | CLIP |

| Парткод: | FC5-4425-000 |

| Деталь: | GUIDE, PAPER PICK-UP, LOWER |

| Парткод: | FL3-5532-000 |

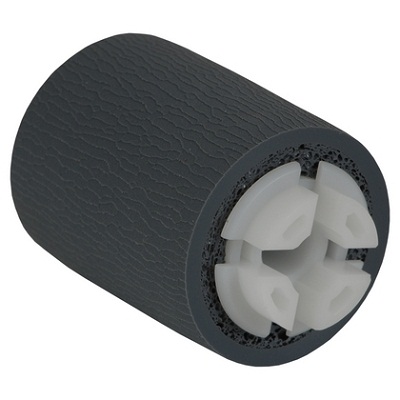

| Деталь: | PAPER PICK-UP ROLLER UNIT |

| Парткод: | FM4-7732-000 |

| Деталь: | BUSHING |

| Парткод: | FU5-1626-000 |

| Деталь: | BUSHING |

| Парткод: | FC0-2985-000 |

| Деталь: | GEAR, 23 |

| Парткод: | FU9-0354-000 |

| Деталь: | PAPER PICK-UP COVER ASSEMBLY |

| Парткод: | 4G8-0008-000 |

| Деталь: | HDD UNIT |

| Парткод: | FM1-A510-000 |

| Деталь: | LLABEL, CAUTION |

| Парткод: | FU8-8257-000 |

| Деталь: | DRAWER CABLE UNIT, CASSETTE |

| Парткод: | FM1-A633-000 |

| Деталь: | SIZE DETECT UNIT |

| Парткод: | FM4-6571-000 |

| Деталь: | SCREW, RS, M3X8.5 |

| Парткод: | XA9-1567-000 |

| Деталь: | SCREW, TP,M3X6 |

| Парткод: | XA9-1469-000 |

| Деталь: | CABLE, ENGINE CONTROLLER |

| Парткод: | FM1-A932-000 |

| Деталь: | CABLE, SOFT ID |

| Парткод: | FM1-A934-000 |

| Деталь: | CABLE, SATA POWER |

| Парткод: | FK4-0275-000 |

| Деталь: | CABLE, SATA SIGNAL |

| Парткод: | FK4-0276-000 |

| Деталь: | CABLE, POWER SUPPLY UINT |

| Парткод: | FM1-A931-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-004 |

| Деталь: | CONNECTOR, 9P |

| Парткод: | VS1-7177-009 |

| Деталь: | CABLE, READER |

| Парткод: | FM1-A945-000 |

| Деталь: | MACHINE REAR PLATE 2 |

| Парткод: | NPN |

| Деталь: | ROLLER, TENSION |

| Парткод: | FC0-3309-000 |

| Деталь: | FAN |

| Парткод: | FK2-2530-000 |

| Деталь: | PAPER PICK-UP MOTOR UNIT |

| Парткод: | FM4-6516-000 |

| Деталь: | LINK DRIVE UNIT |

| Парткод: | FM4-6566-000 |

| Деталь: | FAN UNIT |

| Парткод: | FM1-A133-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU8-2667-000 |

| Деталь: | BELT, TIMING, CR |

| Парткод: | XF2-1610-440 |

| Деталь: | CONNECTOR, SNAP TIGHT, 6P, W |

| Парткод: | VS1-7173-006 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-002 |

| Деталь: | CONNECTOR, 2P |

| Парткод: | VS1-7507-002 |

| Деталь: | CONNECTOR, SNAP TIGHT, BL |

| Парткод: | VS1-8412-017 |

| Деталь: | CONNECTOR, SNAP TIGHT, BL |

| Парткод: | VS1-8412-023 |

| Деталь: | SCREW, RS, M3X8.5 |

| Парткод: | XA9-1567-000 |

| Деталь: | SCREW, W/WASHER, M3X6 |

| Парткод: | XA9-0702-000 |

| Деталь: | RING, RETAINING |

| Парткод: | FC6-9867-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU8-2957-000 |

| Деталь: | CONNECTOR, SNAP TIGHT |

| Парткод: | VS1-7173-005 |

| Деталь: | CABLE, IP-READER FLAT |

| Парткод: | FK4-0150-000 |

| Деталь: | FERRITE CORE |

| Парткод: | WE8-6948-000 |

| Деталь: | CABLE, CASSETTE |

| Парткод: | FM1-A944-000 |

| Деталь: | CABLE, FIXING-WASTE TONER |

| Парткод: | FM1-A943-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, 9P, W |

| Парткод: | VS1-7173-009 |

| Деталь: | CONNECTOR, SNAP TIGHT, 12P, W |

| Парткод: | VS1-7173-012 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-003 |

| Деталь: | CONNECTOR, SNAP TIGHT, BL |

| Парткод: | VS1-8412-015 |

| Деталь: | CABLE, MAIN MOTOR |

| Парткод: | FM1-A937-000 |

| Деталь: | CABLE, READER RELAY |

| Парткод: | FM1-A947-000 |

| Деталь: | CABLE, DUPLEXING FEED RELAY |

| Парткод: | FM1-A946-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-004 |

| Деталь: | MACHINE REAR PLATE 1 |

| Парткод: | NPN |

| Деталь: | PLATE, FREE STOP |

| Парткод: | FC0-0913-000 |

| Деталь: | LINK, BACK END DETECT |

| Парткод: | FC0-0945-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC0-1159-000 |

| Деталь: | PLATE,PAPER SIDE END EXTENSION |

| Парткод: | FC0-3350-000 |

| Деталь: | GEAR, 9T |

| Парткод: | FC0-3351-000 |

| Деталь: | LABEL, PAPER SET |

| Парткод: | FC0-3427-000 |

| Деталь: | LABEL, SIZE INDEX, END, LARGE |

| Парткод: | FC0-3429-000 |

| Деталь: | LABEL, SIZE INDEX, END |

| Парткод: | FC0-3430-000 |

| Деталь: | LABEL, SIZE INDEX, SIDE |

| Парткод: | FC0-3431-000 |

| Деталь: | PLATE, JOINT |

| Парткод: | FC8-2475-000 |

| Деталь: | LINK, BUTTON, UPPER, 2 |

| Парткод: | FC8-4986-000 |

| Деталь: | LINK, BUTTON, LOWER |

| Парткод: | FC8-4987-000 |

| Деталь: | GEAR, 14T |

| Парткод: | FC8-4990-000 |

| Деталь: | SHEET, SEPARATION |

| Парткод: | FC9-7171-000 |

| Деталь: | ARM, LOCK, A |

| Парткод: | FC9-7259-000 |

| Деталь: | ARM, LOCK, B |

| Парткод: | FC9-7260-000 |

| Деталь: | ROLLER, LINK |

| Парткод: | FC9-7261-000 |

| Деталь: | PLATE, CENTER |

| Парткод: | FL3-4878-000 |

| Деталь: | CASSETTE FRONT COVER UNIT |

| Парткод: | FM1-A568-000 |

| Деталь: | BACK END LIMIT PLATE UNIT |

| Парткод: | FM4-6534-000 |

| Деталь: | SIDE END PLATE ASSEMBLY, REAR |

| Парткод: | FM4-6559-000 |

| Деталь: | SIDE END PLATE ASSEMBLY, FRONT |

| Парткод: | FM4-6560-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2518-000 |

| Деталь: | SCREW W/WASHER, M3X6 |

| Парткод: | XA9-1016-000 |

| Деталь: | SCREW, B, M4X8 |

| Парткод: | XA9-1523-000 |

| Деталь: | TOOTHED LOCK WASHER(SUS) |

| Парткод: | XD1-4100-402 |

| Деталь: | CASSETTE ASSEMBLY |

| Парткод: | FM1-A567-000 |

| Деталь: | COVER, UPPER |

| Парткод: | FL0-0447-000 |

| Деталь: | COVER, ROLLER |

| Парткод: | FL0-0446-000 |

| Деталь: | HINGE, M.P. PICK UP, LEFT |

| Парткод: | FE3-2584-000 |

| Деталь: | HINGE, M.P. PICK UP, RIGHT |

| Парткод: | FE3-2585-000 |

| Деталь: | SOLENOID |

| Парткод: | FK2-1410-000 |

| Деталь: | LIFTER PLATE UNIT |

| Парткод: | FM1-A583-000 |

| Деталь: | MULTI TRAY UNIT |

| Парткод: | FM1-A584-000 |

| Деталь: | ROLLER, MP PICK-UP |

| Парткод: | FL2-3897-000 |

| Цена: | 750 ₽ |

| Деталь: | PAD, SEPARATION |

| Парткод: | FL3-4890-000 |

| Цена: | 1 500 ₽ |

| Деталь: | SPRING, TENSION |

| Парткод: | FU6-2423-000 |

| Деталь: | LABEL, MULTI TRAY SIZE |

| Парткод: | FE3-2608-000 |

| Деталь: | LABEL, MULTI TRAY SIZE |

| Парткод: | FE3-2607-000 |

| Деталь: | LABEL, PAPER SET SIDE |

| Парткод: | FE3-2609-000 |

| Деталь: | LABEL, PAPER SET SIDE |

| Парткод: | FE3-2610-000 |

| Деталь: | MULTI PAPER PICK-UP ASSEMBLY |

| Парткод: | FM1-A582-000 |

| Деталь: | WASTE TONER BOX ASSEMBLY |

| Парткод: | FM4-8035-000 |

| Деталь: | HIGH VOLTAGE PCB ASSEMBLY |

| Парткод: | FM4-7814-000 |

| Деталь: | HIGH VOLTAGE PCB ASSEMBLY |

| Парткод: | NPN |

| Деталь: | BELT, TIMING |

| Парткод: | XF2-1607-240 |

| Деталь: | MAIN DRIVE ASSEMBLY |

| Парткод: | FM4-6497-000 |

| Деталь: | COVER, REAR |

| Парткод: | 4A8-0004-000 |

| Деталь: | HINGE |

| Парткод: | FC0-2978-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU8-2856-000 |

| Деталь: | LABEL, PROHIBITION DOCUMENT |

| Парткод: | 4A8-0017-000 |

| Деталь: | LABEL, PROHIBITION DOCUMENT |

| Парткод: | 4A8-0018-000 |

| Деталь: | LABEL, DOCUMENT SIZE |

| Парткод: | 4A8-0021-000 |

| Деталь: | LABEL, DOCUMENT SIZE |

| Парткод: | 4A8-0022-000 |

| Деталь: | SUPPORT, HINGE |

| Парткод: | FC0-5254-000 |

| Деталь: | COVER, LEFT |

| Парткод: | 4F8-0001-000 |

| Деталь: | PAD, SEPARATION |

| Парткод: | FL3-7878-000 |

| Деталь: | PANEL, COPYBOARD |

| Парткод: | FL3-5544-000 |

| Деталь: | FRONT COVER UNIT |

| Парткод: | 4G8-0010-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-002 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7207-003 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7207-004 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7207-006 |

| Деталь: | CABLE, ADF MAIN |

| Парткод: | 4G8-5001-000 |

| Деталь: | CONNECTOR, 2P |

| Парткод: | VS1-7507-002 |

| Деталь: | BASE UNIT |

| Парткод: | 4G8-0007-000 |

| Деталь: | LABEL, GLASS CLEANING |

| Парткод: | 4A8-0024-000 |

| Деталь: | LABEL, GLASS CLEANING |

| Парткод: | 4A8-0025-000 |

| Деталь: | INTERNAL COMPONENTS |

| Парткод: | NPN |

| Деталь: | LEVER, BOTTLE EXCHANGE |

| Парткод: | FC0-0922-000 |

| Деталь: | SPRING, LEAF |

| Парткод: | FC0-1003-000 |

| Деталь: | IC PHOTOINTERRUPTER, HYBRID |

| Парткод: | WG8-5836-000 |

| Деталь: | IC, PHOTO INTERRUPTER |

| Парткод: | WG8-5928-000 |

| Деталь: | LABEL, DEV. PRESSURE LOCK |

| Парткод: | FC0-3396-000 |

| Деталь: | PANEL, DEVELOPING EXCHANGE |

| Парткод: | FL0-0201-000 |

| Деталь: | LEVER, HANDLE LOCK |

| Парткод: | FC9-0503-000 |

| Деталь: | HOOK, FRONT DOOR |

| Парткод: | FC9-1698-000 |

| Деталь: | GEAR, 7T |

| Парткод: | FC9-7708-000 |

| Деталь: | CABLE, INTERFACE |

| Парткод: | FK4-0281-000 |

| Деталь: | INTERLOCK UNIT |

| Парткод: | FM4-6501-000 |

| Деталь: | WASTE TONER DRIVE UNIT |

| Парткод: | FM4-6507-000 |

| Деталь: | STAY UNIT, DEVELOPING |

| Парткод: | FM4-8027-000 |

| Деталь: | LABEL, LOCK UNLOCK |

| Парткод: | FU6-8873-010 |

| Деталь: | LABEL, LASER CAUTION |

| Парткод: | FU6-8880-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FU7-2912-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU7-2996-000 |

| Деталь: | HV GUIDE UNIT, LOWER |

| Парткод: | FM4-7990-000 |

| Деталь: | HV GUIDE UNIT, RIGHT |

| Парткод: | FM4-7991-000 |

| Деталь: | SCREW, RS, M3X8.5 |

| Парткод: | XA9-1567-000 |

| Деталь: | CABLE, CONNECTING, SENSOR |

| Парткод: | FM4-7782-000 |

| Деталь: | CABLE, USB |

| Парткод: | FK4-0283-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, 3P, W |

| Парткод: | VS1-7173-003 |

| Деталь: | CABLE, MOTOR RELAY |

| Парткод: | FM4-7818-000 |

| Деталь: | INTERNAL COMPONENTS 1 |

| Парткод: | NPN |

| Деталь: | DOCUMENT TRAY ASSEMBLY |

| Парткод: | 4G8-0009-000 |

| Деталь: | COVER, READER REAR, 1 |

| Парткод: | FE3-2519-000 |

| Деталь: | MOUNT, JUMP |

| Парткод: | FE3-2568-000 |

| Деталь: | COVER, HINGE, LEFT |

| Парткод: | FE3-2569-000 |

| Деталь: | COVER, HINGE, RIGHT |

| Парткод: | FE3-2570-000 |

| Деталь: | CLIP |

| Парткод: | FC5-4424-000 |

| Деталь: | SLIDER |

| Парткод: | FC6-4511-000 |

| Деталь: | PULLEY, 49T/17T |

| Парткод: | FC6-7598-000 |

| Деталь: | PULLEY, DRIVEN |

| Парткод: | FC6-7604-000 |

| Деталь: | CABLE, CIS-READER FLAT |

| Парткод: | FK3-1447-000 |

| Деталь: | MOTOR, STEPPING |

| Парткод: | FK3-1448-000 |

| Деталь: | READER GLASS UNIT |

| Парткод: | FL2-3941-000 |

| Деталь: | GLASS, COPYBOARD |

| Парткод: | FL3-4881-000 |

| Деталь: | GLASS, COPYBOARD |

| Парткод: | FL3-4882-000 |

| Деталь: | CARRIAGE ASSY |

| Парткод: | FM4-6514-000 |

| Деталь: | CONTACT IMAGE SENSOR UNIT |

| Парткод: | FM4-6536-000 |

| Деталь: | SUPPORT, GLASS, RIGHT |

| Парткод: | FE3-2571-000 |

| Деталь: | READER CONTROLLER PCB ASSY |

| Парткод: | FM1-B804-000 |

| Деталь: | SUPPORT, GLASS, LEFT |

| Парткод: | FE3-2572-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU8-2953-000 |

| Деталь: | IC PHOTOINTERRUPTER, HYBRID |

| Парткод: | WG8-5836-000 |

| Деталь: | SCREW, MACH., FLAT HEAD, M3X4 |

| Парткод: | XA9-0679-000 |

| Деталь: | SCREW, RS, M3X8.5 |

| Парткод: | XA9-1567-000 |

| Деталь: | BELT, TIMING |

| Парткод: | XF2-4607-230 |

| Деталь: | BELT, TIMING |

| Парткод: | XF2-4665-530 |

| Деталь: | READER ASSEMBLY |

| Парткод: | NPN |

| Деталь: | LEVER, SET |

| Парткод: | FC0-4061-000 |

| Деталь: | BOTTLE DRIVE UNIT |

| Парткод: | FM4-8029-000 |

| Деталь: | PIN |

| Парткод: | XD3-2200-222 |

| Деталь: | HOPPER ASSEMBLY |

| Парткод: | FM1-A636-000 |

| Деталь: | MOTOR, DC |

| Парткод: | FK3-1408-000 |

| Деталь: | SCREW, W/WASHER, M3X6 |

| Парткод: | XA9-0702-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-006 |

| Деталь: | FIXING DRIVE ASSY |

| Парткод: | FM1-A631-000 |

| Деталь: | FAN |

| Парткод: | FK2-8755-000 |

| Деталь: | LEVER, SENSOR |

| Парткод: | FL3-5627-000 |

| Деталь: | REVERSE DRIVE UNIT |

| Парткод: | FM4-6546-000 |

| Деталь: | GEAR, 38T |

| Парткод: | FU9-0221-000 |

| Деталь: | IC PHOTOINTERRUPTER, HYBRID |

| Парткод: | WG8-5836-000 |

| Деталь: | BUSHING |

| Парткод: | FS5-1943-000 |

| Деталь: | SPRING, ROLLER |

| Парткод: | FC0-4029-000 |

| Деталь: | ROLLER |

| Парткод: | FC0-4038-000 |

| Деталь: | PAPER DELIVERY REVERSE ASSY |

| Парткод: | FM1-A562-000 |

| Деталь: | SOLENOID |

| Парткод: | FK2-0408-000 |

| Деталь: | SOLENOID |

| Парткод: | FK2-6871-000 |

| Деталь: | STAY, READ |

| Парткод: | FL3-5556-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU7-2192-000 |

| Деталь: | IC PHOTOINTERRUPTER, HYBRID |

| Парткод: | WG8-5836-000 |

| Деталь: | PAPER FEED ASSEMBLY |

| Парткод: | FM4-7736-000 |

| Деталь: | HINGE, 1 |

| Парткод: | FC0-0969-000 |

| Деталь: | HINGE, 2 |

| Парткод: | FC0-3300-000 |

| Деталь: | PLATE, GROUNDING |

| Парткод: | FC0-8988-000 |

| Деталь: | COVER, FRONT |

| Парткод: | FE3-1728-000 |

| Деталь: | COVER, REAR |

| Парткод: | FE3-1729-000 |

| Деталь: | COVER, LCD |

| Парткод: | FE3-1731-000 |

| Деталь: | COVER, LED |

| Парткод: | FE3-1732-000 |

| Деталь: | PLATE, NAME |

| Парткод: | FL0-0297-000 |

| Деталь: | PLATE, NAME |

| Парткод: | FL0-0298-000 |

| Деталь: | PLATE, NAME |

| Парткод: | FL0-0300-000 |

| Деталь: | PLATE, NAME |

| Парткод: | FL0-0301-000 |

| Деталь: | PLATE, DIAL |

| Парткод: | FE3-1743-000 |

| Деталь: | KEY TOP, VOLUME |

| Парткод: | FE3-1744-000 |

| Деталь: | KEY TOP, STOP |

| Парткод: | FE3-1745-000 |

| Деталь: | KEY TOP, ENERGY SAVER |

| Парткод: | FE3-1746-000 |

| Деталь: | KEY TOP, TEN |

| Парткод: | FE3-1747-000 |

| Деталь: | KEY TOP, RESET |

| Парткод: | FE3-1748-000 |

| Деталь: | SHEET, INSULATION |

| Парткод: | FE3-1754-000 |

| Деталь: | DIAL, CONTRAST |

| Парткод: | FE3-1755-000 |

| Деталь: | CABLE, CPU-TEN KEY FLAT |

| Парткод: | FK4-0091-000 |

| Деталь: | KEY TOP, START |

| Парткод: | FL0-0286-000 |

| Деталь: | PEN, TOUCH PANEL |

| Парткод: | FL0-0287-000 |

| Деталь: | COVER, CONTROL PANEL, FRONT |

| Парткод: | FL0-0288-000 |

| Деталь: | COVER, CONTROL PANEL, FRONT |

| Парткод: | FL0-0289-000 |

| Деталь: | CONTROL PANEL CPU PCB ASSY |

| Парткод: | FM1-A917-000 |

| Деталь: | TEN KEY PCB ASSY |

| Парткод: | FM1-A918-000 |

| Деталь: | CONTROL PANEL ASSEMBLY |

| Парткод: | FM1-A216-000 |

| Деталь: | CONTROL PANEL ASSEMBLY |

| Парткод: | FM1-A206-000 |

| Деталь: | CONTROL PANEL ASSEMBLY |

| Парткод: | FM1-A218-000 |

| Деталь: | CONTROL PANEL ASSEMBLY |

| Парткод: | FM1-A219-000 |

| Деталь: | DEVELOPING UNIT |

| Парткод: | FM4-6494-000 |

| Деталь: | TRAY, PAPER DELIVERY, 1 |

| Парткод: | FE3-2551-000 |

| Деталь: | COVER, LEFT |

| Парткод: | FL0-0440-000 |

| Деталь: | REAR COVER ASSEMBLY |

| Парткод: | FM1-A569-000 |

| Деталь: | TRAY, PAPER DELIVERY, 2 |

| Парткод: | FE3-2552-000 |

| Деталь: | COVER, REEDER, LOWER |

| Парткод: | FE3-2553-000 |

| Деталь: | COVER, READER, LEFT |

| Парткод: | FE3-2554-000 |

| Деталь: | COVER, READER, FRONT |

| Парткод: | FE3-2555-000 |

| Деталь: | COVER, READER, RIGHT |

| Парткод: | FL0-0441-000 |

| Деталь: | COVER, RIGHT FRONT |

| Парткод: | FL0-0451-000 |

| Деталь: | TRAY, REVERSE |

| Парткод: | FE3-2558-000 |

| Деталь: | COVER, READER REAR |

| Парткод: | FE3-2520-000 |

| Деталь: | COVER, READER, RIGHT REAR |

| Парткод: | FE3-2517-000 |

| Деталь: | LABEL, GLASS CLEANING |

| Парткод: | FE3-2615-000 |

| Деталь: | LABEL, COPY INHIBITED |

| Парткод: | FE3-2622-000 |

| Деталь: | LABEL, COPY INHIBITED |

| Парткод: | FE3-2623-000 |

| Деталь: | LABEL, COPY INHIBITED |

| Парткод: | FE3-2624-000 |

| Деталь: | LABEL, COPY INHIBITED |

| Парткод: | FE3-2625-000 |

| Деталь: | LABEL, COPY INHIBITED |

| Парткод: | FE3-2626-000 |

| Деталь: | LABEL, COPY INHIBITED |

| Парткод: | FE3-2627-000 |

| Деталь: | LABEL, COPY INHIBITED |

| Парткод: | FE3-2628-000 |

| Деталь: | LABEL, COPY INHIBITED |

| Парткод: | FE3-2629-000 |

| Деталь: | RIB, STACK |

| Парткод: | FE3-2559-000 |

| Деталь: | PANEL, INNER |

| Парткод: | FE3-2556-000 |

| Деталь: | EMBLEM |

| Парткод: | FL3-1185-000 |

| Деталь: | COVER, RIGHT REAR |

| Парткод: | FE3-2495-000 |

| Деталь: | COVER UNIT, RIGHT FRONT |

| Парткод: | FM1-A580-000 |

| Деталь: | FRONT DOOR ASSEMBLY |

| Парткод: | FM1-A678-000 |

| Деталь: | PIN, HINGE |

| Парткод: | FA8-2446-000 |

| Деталь: | LABEL, WASTE TONER EXCHANGE |

| Парткод: | FC0-3392-000 |

| Деталь: | LABEL, DRUM EXCHANGE |

| Парткод: | FE3-2638-000 |

| Деталь: | RIB, HANDLE |

| Парткод: | FE3-2530-000 |

| Деталь: | LABEL, TONER SUPPLY |

| Парткод: | FC0-3403-000 |

| Деталь: | LABEL, TONER |

| Парткод: | FE3-2613-000 |

| Деталь: | LABEL, TONER |

| Парткод: | FE3-2614-000 |

| Деталь: | COVER UNIT, OPERATION, REAR |

| Парткод: | FM1-A212-000 |

| Деталь: | RING, RETAINING |

| Парткод: | FC5-4697-000 |

| Деталь: | COVER, FFC |

| Парткод: | FE3-2534-000 |

| Деталь: | LABEL,TRANSFER ROLLER CAUTION |

| Парткод: | FC0-3409-000 |

| Деталь: | COVER, FAN |

| Парткод: | FE3-2531-000 |

| Деталь: | SCREW, RS, M3X8.5 |

| Парткод: | XA9-1567-000 |

| Деталь: | AIR FILTER UNIT |

| Парткод: | FM1-A560-000 |

| Деталь: | EXTERNAL COVERS, PANELS, ETC. |

| Парткод: | NPN |

| Деталь: | GUIDE, FIXING, LOWER |

| Парткод: | FC0-0829-000 |

| Деталь: | FLAG, DELIVERY SENSOR |

| Парткод: | FC0-0830-000 |

| Деталь: | CAM |

| Парткод: | FC0-1013-000 |

| Деталь: | GUIDE, FIXING CABLE |

| Парткод: | FC0-1021-000 |

| Деталь: | FLAG, RELEASE SENSOR |

| Парткод: | FC0-1022-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC0-4054-000 |

| Деталь: | FIXING DELIVERY LOWER UNIT |

| Парткод: | FM4-6583-000 |

| Деталь: | FIXING DUPLEXING FEED UNIT |

| Парткод: | FM4-6584-000 |

| Деталь: | GEAR, 36T |

| Парткод: | FU9-0206-000 |

| Деталь: | GEAR, 29T |

| Парткод: | FU9-0207-000 |

| Деталь: | GEAR, 27T |

| Парткод: | FU9-0401-000 |

| Деталь: | GEAR, 23T |

| Парткод: | FU9-0209-000 |

| Деталь: | IC PHOTOINTERRUPTER, HYBRID |

| Парткод: | WG8-5836-000 |

| Деталь: | SCREW, W/WASHER, M3X6 |

| Парткод: | XA9-0702-000 |

| Деталь: | LABEL, HIGH TMP.CAUTION |

| Парткод: | FC0-3411-000 |

| Деталь: | LABEL, FIXING JAM DISPOSE |

| Парткод: | FC0-3413-000 |

| Деталь: | LABEL, GREEN |

| Парткод: | FC0-3414-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FC0-1045-000 |

| Деталь: | SPRING,SENSOR LEVER |

| Парткод: | FC5-1367-000 |

| Деталь: | FIXING ASSEMBLY |

| Парткод: | FM1-A680-000 |

| Деталь: | FIXING ASSEMBLY |

| Парткод: | FM1-A681-000 |

| Деталь: | IC,TC200GO2EFG-1031,GATE ARRAY |

| Парткод: | FK2-1773-000 |

| Деталь: | IC, FSA0AC211AA |

| Парткод: | FK2-6450-000 |

| Деталь: | ENGINE CONTROLLER PCB ASSY |

| Парткод: | FM1-A957-000 |

| Деталь: | RING |

| Парткод: | FC0-1083-000 |

| Деталь: | BAND, RIGHTDOOR, REAR |

| Парткод: | FC0-1090-000 |

| Деталь: | ARM, GEAR |

| Парткод: | FC0-1120-000 |

| Деталь: | HOOK UNIT, RIGHT DOOR |

| Парткод: | FM1-A634-000 |

| Деталь: | STOPPER, LEVER |

| Парткод: | FC0-1143-000 |

| Деталь: | PLATE, RIGHT DOOR |

| Парткод: | FE3-2581-000 |

| Деталь: | ROLLER |

| Парткод: | FC0-3305-000 |

| Деталь: | BAND, RIGHT DOOR, FRONT |

| Парткод: | FC0-3381-000 |

| Деталь: | HINGE, DOOR, REAR |

| Парткод: | FL3-4875-000 |

| Деталь: | BUSHING |

| Парткод: | FC9-0717-000 |

| Деталь: | FAN |

| Парткод: | FK2-6818-000 |

| Деталь: | DOOR, RIGHT |

| Парткод: | FL0-0449-000 |

| Деталь: | DUPLEXING PAPER FEED UNIT |

| Парткод: | FM4-6572-000 |

| Деталь: | SOLENOID UNIT |

| Парткод: | FM4-6573-000 |

| Деталь: | VERTICAL PATH GUIDE UNIT |

| Парткод: | FM4-6574-000 |

| Деталь: | DUPLEXING FEED MOUNT UNIT |

| Парткод: | FM4-6575-000 |

| Деталь: | DUPLEXING ENTRANCE GUIDE ASSY |

| Парткод: | FM4-6576-000 |

| Деталь: | PULLEY, 28T |

| Парткод: | FU5-3796-000 |

| Деталь: | GEAR, 18T |

| Парткод: | FU6-0934-000 |

| Деталь: | PULLEY, 28T |

| Парткод: | FU6-3074-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | FU8-2649-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU8-2663-000 |

| Деталь: | SPRING, TORSION |

| Парткод: | FU8-2669-000 |

| Деталь: | GEAR, 31T/22T |

| Парткод: | FU9-0222-000 |

| Деталь: | GEAR, 20 |

| Парткод: | FU9-0230-000 |

| Деталь: | PULLEY, 28T/GEAR, 20T/26T |

| Парткод: | FU9-0231-000 |

| Деталь: | CONNECTOR, SNAP TIGHT, 3P, W |

| Парткод: | VS1-7173-003 |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7177-003 |

| Деталь: | IC PHOTOINTERRUPTER, HYBRID |

| Парткод: | WG8-5836-000 |

| Деталь: | BELT, TIMING |

| Парткод: | XF2-1617-740 |

| Деталь: | HINGE, DOOR, FRONT |

| Парткод: | FL3-4874-000 |

| Деталь: | RIGHT DOOR ASSEMBLY |

| Парткод: | NPN |

| Деталь: | GUIDE, ELIMINATOR |

| Парткод: | FL3-4856-000 |

| Деталь: | HOLDER, ELIMINATOR |

| Парткод: | FM1-A131-000 |

| Деталь: | TRANSFER ROLLER UNIT |

| Парткод: | FM4-6522-000 |

| Деталь: | IC PHOTOINTERRUPTER, HYBRID |

| Парткод: | WG8-5836-000 |

| Деталь: | TRANSFER PAPER FEED ASSEMBLY |

| Парткод: | FM4-6520-000 |

| Деталь: | ROLLER, PAPER PICK-UP |

| Парткод: | FB6-3405-000 |

| Цена: | 550 ₽ |

| Деталь: | PLATE, GROUNDING |

| Парткод: | FC0-1156-000 |

| Деталь: | ROLLER, SEPARATION |

| Парткод: | FC6-6661-000 |

| Цена: | 600 ₽ |

| Деталь: | ROLLER, FEED/SEPARATION |

| Парткод: | FC6-7083-000 |

| Деталь: | RING, RETAINING |

| Парткод: | FC6-9867-000 |

| Деталь: | STOPPER, ROLLER |

| Парткод: | FC7-5845-000 |

| Деталь: | LIFT MOTOR UNIT |

| Парткод: | FM4-6568-000 |

| Деталь: | VERTICAL PATH ROLLER UNIT |

| Парткод: | FM4-8040-000 |

| Деталь: | BUSHING |

| Парткод: | FS5-1943-000 |

| Деталь: | GEAR, 15T |

| Парткод: | FU0-0043-000 |

| Деталь: | BUSHING |

| Парткод: | FU5-1763-000 |

| Деталь: | IC PHOTOINTERRUPTER, HYBRID |

| Парткод: | WG8-5836-000 |

| Деталь: | SCREW, RS, M3X8.5 |

| Парткод: | XA9-1567-000 |

| Деталь: | PAPER PICK-UP ASSEMBLY |

| Парткод: | FM4-6555-000 |

| Деталь: | IC, MB87L8650, GATE ARRAY |

| Парткод: | FK2-3218-000 |

| Деталь: | MAIN CONTROLLER PCB ASSEMBLY |

| Парткод: | FM1-C271-000 |

| Деталь: | MAIN CONTROLLER PCB ASSEMBLY |

| Парткод: | FM1-C272-000 |

| Деталь: | FAN |

| Парткод: | FL0-0453-000 |

| Деталь: | FERRITE CORE |

| Парткод: | WE8-6948-000 |

| Деталь: | TPM PCB ASSEMBLY |

| Парткод: | FM4-0783-000 |

| Деталь: | SCREW, MACH. PAN HEAD, M3X4 |

| Парткод: | XA9-1979-000 |

| Деталь: | IC, R8A03018ABG U100, ASIC |

| Парткод: | FK2-7835-010 |

| Деталь: | IC, T6TH5EFG-0002(0), STANDARD |

| Парткод: | FK2-7852-000 |

| Деталь: | IC, MB87S1801 |

| Парткод: | FK2-8321-000 |

| Деталь: | IC, 88E8075B0-NNC2C000, |

| Парткод: | FK2-9794-000 |

| Деталь: | IC, CLOCK GENERATOR, HYBRID |

| Парткод: | FK3-1386-000 |

| Деталь: | MAIN CONTROLLER PCB ASSEMBLY |

| Парткод: | NPN |

| Деталь: | CLIP |

| Парткод: | FC5-4424-000 |

| Деталь: | SOLENOID |

| Парткод: | FK2-0408-000 |

| Деталь: | MOTOR, STEPPING |

| Парткод: | FK3-1633-000 |

| Деталь: | MOTOR, STEPPING |

| Парткод: | FK3-1634-000 |

| Деталь: | ARM, SWING, FEED |

| Парткод: | FL3-5542-000 |

| Деталь: | ARM, SWING, REGIST |

| Парткод: | FL3-5543-000 |

| Деталь: | SPRING, TENSION |

| Парткод: | FU8-2974-000 |

| Деталь: | PULLEY, 45T/GEAR, 24T |

| Парткод: | FU9-0345-000 |

| Деталь: | PULLEY, 45T/GEAR, 36T |

| Парткод: | FU9-0358-000 |

| Деталь: | PULLEY, 33T/GEAR, 36T/24T |

| Парткод: | FU9-0367-000 |

| Деталь: | IC PHOTOINTERRUPTER, HYBRID |

| Парткод: | WG8-5836-000 |

| Деталь: | BELT, TIMING |

| Парткод: | XF2-1606-040 |

| Деталь: | BELT, TIMING |

| Парткод: | XF2-1606-940 |

| Деталь: | GEAR, 20T |

| Парткод: | FU9-0353-000 |

| Деталь: | DRIVE ASSEMBLY |

| Парткод: | FM4-7730-000 |

Коды ошибок

E000-0001

E001-0000

E001-0001

E001-0002

E002-0000

E003-0000

E004-0000

E010-0001

E010-0002

E013-0000

E014-0001

E014-0002

E014-0003

E014-0004

E020-0000

E024-0001

E025-0000

E025-0001

E110-0001

E110-0002

E110-0003

E196-0000

E197-0000

E197-0003

E202-0001

E202-0002

E240-0000

E240-0001

E246

E247

E248-0000

E261-0000

E315-0007

E315-000d

E315-000e

E315-000f

E315-0027

E315-0035

E315-0100

E315-0500

E315-0501

E315-0510

E315-0511

E315-0520

E315-0521

E315-0530

E315-0531

E315-0540

E315-0541

E315-0550

E315-0551

E350

E351-0000

E354

E355

E500-0000

E530-0001

E530-0002

E531-8001

E531-8002

E537-0001

E537-0002

E540-0001

E575-0001

E575-0002

E575-0004

E577-0001

E577-0002

E583-0001

E583-0002

E602

E604-0512

E604-1024

E604-1536

E611-0000

E613-0512

E613-1024

E613-1536

E614

E674-0001

E674-0004

E674-0008

E674-000C

E674-0010

E674-0011

E674-0030

E674-0100

E674-0200

E677-0003

E711-0001

E713-0000

E716-0000

E719-0001

E719-0002

E719-0003

E719-0004

E719-0011

E719-0012

E719-0031

E719-0032

E730-1001

E730-100A

E730-A006

E730-A007

E730-B013

E730-C000

E730-C001

E731-3000

E731-3001

E731-3002

E731-3015

E732-0010

E740-0002

E740-0003

E743-0000

E744

E746-0021

E746-0022

E746-0023

E746-0024

E746-0031

E746-0032

E746-0033

E746-0034

E746-0035

E747-1201

E748-2010

E748-2021

E748-2023

E748-2024

E748-9000

E749-0002

E749-0003

E749-0005

E749-0006

E753-0001

E804-0000

E805-0000

E805-0001

E805-0002

E805-0003

E820-0000

E820-0001

E820-0002

E820-0003

E822-0000

E822-0001

E822-0003

E822-0005

E880-0001

E881-0001

E996-0071

E996-0CA0

Описание

| Error code: | E000-0001 |

| Description: | Fixing fault |

| Causes: | After the fixing heater has gone on, the reading of the main thermistor is not 50 deg C within about 1.5 sec. Cause The fixing film unit is faulty. The engine controller PCB is faulty. |

| Remedy: | - Replace the fixing film unit. - Replace the engine controller PCB. |

| Error code: | E001-0000 |

| Description: | Abnormally high temperature (detected by main thermistor) The main thermistor detected an abnormally high temperature 235 deg C) during temperature control |

| Causes: | The main thermistor detected a temperature of higher than 255 degree C. |

| Remedy: | - Check the connector of the fixing film unit. - Replace the fixing film unit. - Replace the DC controller PCB. |

| Error code: | E001-0001 |

| Description: | Abnormally high temperature (detected by sub thermistor) The sub thermistor detected an abnormally high temperature (300 deg C) during temperature control. |

| Causes: | The sub thermistor detected a temperature of higher than 290 degree C. |

| Remedy: | - Check the connector of the fixing film unit. - Replace the fixing film unit. - Replace the DC controller PCB. |

| Error code: | E001-0002 |

| Description: | Abnormally high temperature rise of fixing unit (circuit trouble) When fixing sub-thermistor 1 has detected a high temperature (ASIC detection) |

| Causes: | The fixing film unit is faulty (i.e., the thermistor has a short circuit). The main power supply PCB is faulty. The DC controller PCB is faulty. Caution To clear the error, execute the following in service move: COPIER>FUNCTION>CLEAR>ERR. |

| Remedy: | Check the connection of the connector in the thermistor wiring (wirepinching, disconnection). Replace the fixing unit. Replace the IH unit, halogen heater, fixer and AC driver PCB. Replace the DC controller PCB 2 (MAISY). In the service mode, clear the error by selecting COPIER > FUNCTION > CLEAR > ERR. |

| Error code: | E002-0000 |

| Description: | Low temperature during temperature control. The target temperature is not reached during temperature control. |

| Causes: | The fixing film unit is faulty (i.e., the main thermistor TH1 has poor contact, or the fixing heater is faulty). The main power supply PCB is faulty. The DC controller PCB is faulty. Caution To clear the error, execute the following in service mode: COPIER>FUNCTION>FCLEAR>ERR. |

| Remedy: | - Check the connector of the fixing film unit. - Replace the fixing film unit. - Replace the DC controller PCB. |

| Error code: | E003-0000 |

| Description: | Abnormally low temperature (detected by main thermistor) After the temperature detected by the main thermistor has reached the specified value, it does not reach the specified value during initial rotation. |

| Causes: | The main thermistor detected a temperature of lower than 120 degree C for more than 1 second when 20 seconds elapsed after start of the power distribution to the heater. |

| Remedy: | - Check the connector of the fixing film unit. - Replace the fixing film unit. - Replace the DC controller PCB. |

| Error code: | E004-0000 |

| Description: | Fixing power supply drive circuit error |

| Causes: | 43 to 57Hz could not be detected continuously for more than 5 seconds when zero cross detection started. |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Replace the DC Controller Board. (2) Replace the Fixing Assembly. |

| Error code: | E010-0001 |

| Description: | Main motor error Lock of the motor fails to be detected 2 sec or more after the motor starts to operate. |

| Causes: | The main motor drive system has an excess load. The pickup main motor (M2)/delivery main motor (M16)/pedestal main motor (M19) is faulty. The serial driver PCB is faulty. The DC controller PCB is faulty. |

| Remedy: | Check on connection of the connector, Replace the motor |

| Error code: | E010-0002 |

| Description: | Main motor error After rotation of the motor becomes stable, the motor lock fails (i.e., the motor becomes unstable) for 500msec or more. |

| Causes: | The main motor drive system has an excess load. The pickup main motor (M2)/delivery main motor (M16)/pedestal main motor (M19) is faulty. The serial driver PCB is faulty. The DC controller PCB is faulty. |

| Remedy: | Check on connection of the connector, Replace the motor |

| Error code: | E013-0000 |

| Description: | Residual toner feed motor failure |

| Causes: | Residual toner feed motor failure |

| Remedy: | • Check the contact of the connector between the Residual toner feed motor (J89L) and the DC controller PCB (J137). • Replace the Residual toner feed motor |

| Error code: | E014-0001 |

| Description: | Fixing motor failure |

| Causes: | Fixing motor rotation error The motor rotated out of the target speed during rotation after the target speed was reached. |

| Remedy: | Check the contact of the connector between the fixing motor (J516) and the DC controller PCB (J81). Check the gear between the fixing motor and the fixing assembly. Replace the fixing motor. |

| Error code: | E014-0002 |

| Description: | Fixing motor error When the lock was disengaged after the motor was locked |

| Causes: | The belt motor (M15) is faulty. The belt motor drive system has an excess load. The drum drive AC generation PCB is faulty. The transfer drive AC generation PCB is faulty. The DC controller PCB is faulty. |

| Remedy: | Replace the drumITB moter. Replace the fixing moter.Replace the DCDC converterAi38VAj. Replace the fixing belt unit. |

| Error code: | E014-0003 |

| Description: | The encoder signal is not generated by the motor. |

| Causes: | The belt motor (M15) is faulty. The belt motor drive system has an excess load. The drum drive AC generation PCB is faulty. The transfer drive AC generation PCB is faulty. The DC controller PCB is faulty. |

| Remedy: | Possible cause is overload or rotation failure of the motor due to an electrical trouble 1. Check if the Fixing Assembly is installed. 2. Remove and reinstall the Fixing Assembly 3. Check the gear 4. Replace the Fixing Assembly 5. Check the harness/connector between the DC Controller PCB (UN09/ J210) and the Fixing Motor (M17). 6. Check conduction of FU1153 in the AC Driver PCB (UN14) =>Replace the AC Driver when the fuse is blown out 7. Replace the Fixing Motor (M17) 8. Replace the DC Controller PCB (UN09) |

| Error code: | E014-0004 |

| Description: | The motor rotates in the direction opposite the desired direction. |

| Causes: | The belt motor (M15) is faulty. The belt motor drive system has an excess load. The drum drive AC generation PCB is faulty. The transfer drive AC generation PCB is faulty. The DC controller PCB is faulty. |

| Remedy: | 1. Check the connector connection between the Fixing Pressure Release Sensor (PS18) or the Fixing Motor (M1) and the DC Controller PCB (PCB1). 2. Replace the Fixing Pressure Release Sensor (PS18). 3. Replace the Fixing Motor (M1). 4. Replace the DC Controller PCB (PCB1). |

| Error code: | E020-0000 |

| Description: | Density sensor failure warning |

| Error code: | E024-0001 |

| Description: | Toner level sensor failure |

| Causes: | Failure output from the toner level sensor (Magenta). Cause Memory controller PCB assembly fault, DC controller PCB assembly fault, toner cartridge fault. |

| Remedy: | - Replace toner cartridge - Replace memory controller PCB - Replace DC controller PCB |

| Error code: | E025-0000 |

| Description: | Error in the toner motor Indicates an error of Y developing assembly toner supply |

| Remedy: | Check on connection of the toner motor and the DC controller PCB, Replace the DC controller PCB, Replace the toner motor |

| Error code: | E025-0001 |

| Description: | There is an over-current in the hopper stirring motor (M23)or the black toner supply motor (M25). There is an overcurrent in the hopper stirring motor (M23). |

| Remedy: | Turn off and then on the main power. |

| Error code: | E110-0001 |

| Description: | Optical assembly error (Scanner motor) |

| Causes: | Optical assembly error (Scanner motor rotation failure) |

| Remedy: | Check the contact of the connector between the laser scanner unit and the DC controller. Replace the laser scanner unit. |

| Error code: | E110-0002 |

| Description: | Error in first artificial BD adjustment |

| Causes: | Primary pseudo BD correction |

| Error code: | E110-0003 |

| Description: | There is a scanner motor error. The FG signal is not detected while the polygon scanner is rotating stably. |

| Remedy: | Turn off the main power, and check the DC controller PCB and the 24V system fuse; then, turn on the main power. |

| Error code: | E196-0000 |

| Description: | Invalid RFU execution requested |

| Causes: | D-con update for the host machine or the optional cassette is not completed. |

| Error code: | E197-0000 |

| Description: | Printer engine communication error Erroneous communication between the DC controller PCB and image processor PCB was detected. |

| Causes: | Internal communication error |

| Remedy: | - Check the connectors of the DC controller PCB and image processor PCB. - Replace the DC controller PCB for normal connection. - Replace the image processor PCB. |

| Error code: | E197-0003 |

| Description: | There is an error in the communication with the fixing feed PCB. Following the end of initialization of the communication between the DC controller and the fixing/feeding unit, as many as 10 communication errors occur continuously. |

| Remedy: | Turn off the main power, and check the DC controller PCB wiring and the 24V system fuse; then, turn on the main power. |

| Error code: | E202-0001 |

| Description: | Reader HP sensor fault |

| Causes: | Reader HP outward fault The CCD unit moves backward, but does not move to the home position. |

| Remedy: | - Replace reader HP sensor. - Replace reader motor sensor. - Replace reader unit. |

| Error code: | E202-0002 |

| Description: | Contact Sensor HP error, Failure in return |

| Causes: | Reader HP homeward fault - Replace reader unit. The CCD unit moves forward, but does not move to the home position. |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Check the connection of Flat Cable between Main Controller Board (J5) and Contact Sensor. (2) Replace the Flat Cable between Main Controller Board (J5) and Contact Sensor. (3) Replace the Contact Sensor. (4) Replace the Main Controller Board. |

| Error code: | E240-0000 |

| Description: | Error in communication between main controller and DC controller Serial communication error |

| Causes: | The main controller PCB is faulty. The DC controller PCB is faulty. |

| Remedy: | Check the connector connections. Check the DC controller PCB (MAISY). Replace the No.1 main controller circuit. |

| Error code: | E240-0001 |

| Description: | Error in communication of controller There is no response when 3 sec passed since the main controller had sent the pickup request to DC controller during printing. |

| Remedy: | Check connector, check connection of sub PCB in the controller box, check / replace DC controller PCB / main controller PCB |

| Error code: | E246 |

| Description: | System Error |

| Causes: | System Error |

| Remedy: | Contact the sales companies. |

| Error code: | E247 |

| Description: | System Error |

| Causes: | System Error |

| Remedy: | Contact the sales companies. |

| Error code: | E248-0000 |

| Description: | There is an error in the EEPROM. At time of start-up, a check error has occurred on the SRAM board |

| Remedy: | Turn off the main power, and check the SRAM board; then, as necessary, replace the SRAM board, and turn on the main power. |

| Error code: | E261-0000 |

| Description: | Zero-cross signal error If failed to detect zero-cross signal cycle of the power supply when initializing. When the input of the zero-signal failed continuously for three seconds while controlling the temperature adjustment. |

| Causes: | The wiring is faulty (short circuit, open circuit). The main power supply PCB is faulty. The DC controller PCB is faulty. |

| Remedy: | - Replace the power supply PCB. - Replace the DC controller PCB. |

| Error code: | E315-0007 |

| Description: | There is an error in image data. There is an error in JBIG encoding. |

| Remedy: | Turn off and then back on the power. |

| Error code: | E315-000d |

| Description: | There is an error in image data. There is an error in JBIG decoding. |

| Remedy: | Turn off and then back on the power. |

| Error code: | E315-000e |

| Description: | Image data trouble Damaged data (trouble in memory or HDD) Software decoding error |

| Remedy: | Replace the image memory (SDRAM) or HDD. |

| Error code: | E315-000f |

| Description: | Image process device error Error at MemoryCopy |

| Remedy: | 1. Turn OFF and then ON the main power 2. Check connection of Main Controller PCB 2 3. Replace Main Controller PCB 2 |

| Error code: | E315-0027 |

| Description: | There is an error in image data. Error in ROTU timeout |

| Remedy: | Replace SDRAM. Replace HDD. Replace the main controller PCB. |

| Error code: | E315-0035 |

| Description: | There is an error in image data. Error in MemFill timeout |

| Remedy: | Replace the main controller PCB. |

| Error code: | E315-0100 |

| Description: | There is an error in image data. Error in PrcOverRun |

| Remedy: | Replace the main controller PCB. |

| Error code: | E315-0500 |

| Description: | There is an error in image data. Error in device timeout [location to be detected] image process module (SCIO) [Detection timing] when there is no interruption 2 min after the operation has been started |

| Remedy: | Check connection with DDI-S cable(RCON). Replace the main controller PCB. |

| Error code: | E315-0501 |

| Description: | There is an error in image data. Device: abnormal termination error [location to be detected] image process module (SCIO) [Detection timing] When abnormal interruption is detected after the operation has been started. |

| Remedy: | Check connection with DDI-S cable(RCON). Replace the main controller PCB. |

| Error code: | E315-0510 |

| Description: | There is an error in image data. Device: timeout error [Location to be detected] image process module (SCIP) [Detection timing] when there is no interruption 2 min after the operation has been started. |

| Remedy: | Check connection with DDI-S cable(RCON). Replace the main controller PCB. |

| Error code: | E315-0511 |

| Description: | There is an error in image data. Device: abnormal termination error [Location to be detected] image process module (SCIP) [Detection timing] when abnormal interruption is detected after the operation has been detected |

| Remedy: | Check connection with DDI-S cable(RCON). Replace the main controller PCB. |

| Error code: | E315-0520 |

| Description: | There is an error in image data. Device: timeout error [Location to be detected] image process module (CMIP) [Detection timing] When there is no interruption 2 min after the operation has been started |

| Remedy: | Check connection with DDI-S cable(RCON). Replace the main controller PCB. |

| Error code: | E315-0521 |

| Description: | There is an error in image data. Device: abnormal termination error [Location to be detected] image process module (CMIP) [Detection timing] when abnormal interruption is detected after the operation has been detected |

| Remedy: | Check connection with DDI-S cable(RCON). Replace the main controller PCB |

| Error code: | E315-0530 |

| Description: | There is an error in image data. Device: timeout error [Location to be detected] image process module (JPEN) [Detection timing] when there is no interruption 2 min after the operation has been started. |

| Remedy: | Turn OFF and then ON the power. Replace the main controller PCB if this occurs frequently. |

| Error code: | E315-0531 |

| Description: | There is an error in image data. Device: abnormal termination error [Location to be detected] image process module (JPEN) [Detection timing] when abnormal interruption is detected after the operation has been started. |

| Remedy: | Turn OFF and then ON the power. Replace the main controller PCB if this occurs frequently. |

| Error code: | E315-0540 |

| Description: | There is an error in image data. Device: timeout error [Location to be detected] image process module (JPDE) [Detection timing] when there is no interruption 2 min after the operation has been started. |

| Remedy: | Turn OFF and then ON the power. Replace the main controller PCB if this occurs frequently. |

| Error code: | E315-0541 |

| Description: | There is an error in image data. Device: abnormal termination error [Location to be detected] image process module (JPDE) [Detection timing] when abnormal interruption is detected after the operation has been started |

| Remedy: | Turn OFF and then ON the power. Replace the main controller PCB if this occurs frequently. |

| Error code: | E315-0550 |

| Description: | There is an error in image data. Device: timeout error [Location to be detected] image process module (PRIP) [Detection timing] when there is no interruption 2 min after the operation has been started. |

| Remedy: | Check connection with DDI-P cable(DCON). Replace the main controller PCB. |

| Error code: | E315-0551 |

| Description: | There is an error in image data. Device: abnormal termination error [Location to be detected] image process module (PRIP) [Detection timing] when abnormal interruption is detected after the operation has been started. |

| Remedy: | Check connection with DDI-P cable(DCON). Replace the main controller PCB. |

| Error code: | E350 |

| Description: | 4th drawer transport jam (paper not reaching 2nd drawer transport sensor): Paper which has passed the 3rd drawer / Tandem LCF transport sensor does not reach the 2nd drawer transport sensor during the feeding at the 4th drawer. |

| Causes: | 3rd drawer transport clutch 2nd drawer transport sensor Feed motor PFC board Rollers |

| Remedy: | Open the feed cover. Is there paper in front of the 2nd drawer transport sensor? ↓ → YES → If the paper is damaged, remove the paper and check the followings 1. Check if the paper is skewed, and correct it if it is skewed. 2. Check the paper amount. 3. Check if the paper is not the one with printing on its back side. 4. Check if the width of the side guides of the drawer is too narrow. NO Is the 2nd drawer transport sensor working? (Perform the input check in the test mode: 03-[FAX]OFF/[2]/[C] ↓ → NO → 1. Check if the connector of the 2nd drawer transport sensor is disconnected. 2. Check if the connector CN329 on the LGC board is disconnected. 3. Check if the connector pins are disconnected and the harnesses are open circuited. 4. Check if the conductor pattern on the LGC board is short circuited or open circuited. 5. Replace the 2nd drawer transport sensor. 6. Replace the LGC board. YES Are the transport clutches working? (Perform the output check in the test mode: 03-210/225/231) ↓ → NO → 1. Check if the connectors of the (lower/middle) transport clutches are disconnected. 2. Check if the connector CN329,350 on the LGC board is disconnected. 3. Check if the connector pins are disconnected and the harnesses are open circuited. 4. Check if the conductor pattern on the LGC board is short circuited or open circuited. 5. Replace the (lower/middle) transport clutches. 6. Replace the LGC board. YES 1. Check the condition of the feed roller, separation roller and pickup roller of each paper source, and clean or replace them. 2. Check the transport roller. Clean or replace it. |

| Error code: | E351-0000 |

| Description: | Main controller PCB fault |

| Causes: | Internal error of the main controller PCB Cause Main controller PCB fault. |

| Remedy: | - Check the connection of main controller PCB. - Replace main controller PCB. |

| Error code: | E354 |

| Description: | Vsg problem. Same as E353 |

| Causes: | System Error |

| Remedy: | Contact the sales companies. |

| Error code: | E355 |

| Description: | Toner density sensor problem |

| Causes: | System Error |

| Remedy: | Contact the sales companies. |

| Error code: | E500-0000 |

| Description: | The communication between the copier and the finisher is disrupted and is not corrected for 5 sec or less |

| Causes: | The copier harness is faulty. (disconnected connector, open circuit) The finisher controller PCB or the copier’s DC controller PCB is faulty. |

| Error code: | E530-0001 |

| Description: | There is a fault in alignment. Finisher-N1/Saddle Finisher-N2 There is an excess load on the alignment motor (M3), aligning plate home position sensor (PI6), or aligning plate. The aligning plate does not leave the aligning plate home position sensor when the alignment motor has been driven for 2 sec. |

| Causes: | The alignment motor (M3) is faulty. The alignment plate home position sensor (PI6) is faulty. |

| Remedy: | Replace the front adjuster plate HP sensor (PI36) , Replace the front adjuster plate motor (M33) |

| Error code: | E530-0002 |

| Description: | There is a fault in alignment. Finisher-N1/Saddle Finisher-N2 There is an excess load on the rear alignment motor (M3), rear aligning plate home position sensor (PI6), or rear aligning plate. The aligning plate does not return to its home position when the aligning plate motor has been driven for 2 sec. |

| Causes: | The alignment motor (M3) is faulty. The alignment plate home position sensor (PI6) is faulty. |

| Remedy: | Replace the front adjuster plate HP sensor (PI36) , Replace the front adjuster plate motor (M33) |

| Error code: | E531-8001 |

| Description: | Stapler error When the stapler fails to leave the stapler home position even though the stapler motor was driven for 0.5 sec. |

| Remedy: | Replace the stapler motor (M111) and stapler home position detection sensor (PI50). |

| Error code: | E531-8002 |

| Description: | Stapler error When the stapler fails to return to the stapler home position even though the stapler motor was driven for 0.5 sec. |

| Remedy: | Replace the stapler motor (M111) and stapler home position detection sensor (PI50). |

| Error code: | E537-0001 |

| Description: | Rear alignment error Finisher-Q1/Q3, Saddle Finisher-Q2/Q4 The HP sensor fails to be OFF after the swing motor rotates for a specific period of time. |

| Causes: | The alignment motor (front; M4) is faulty. The aligning plate home position sensor (front; PI4) is faulty. The finisher controller PCB is faulty. |

| Remedy: | Replace the rear adjuster plate HP sensor (PI37) , Replace the rear adjuster plate motor (M34) |

| Error code: | E537-0002 |

| Description: | Rear alignment error Finisher-Q1/Q3, Saddle Finisher-Q2/Q4 The HP sensor fails to be ON after the swing motor rotates for a specific period of time. |

| Causes: | The alignment motor (front; M4) is faulty. The aligning plate home position sensor (front; PI4) is faulty. The finisher controller PCB is faulty. |

| Remedy: | Replace the rear adjuster plate HP sensor (PI37) , Replace the rear adjuster plate motor (M34) |

| Error code: | E540-0001 |

| Description: | - Standard tray shift motor or finisher controller PCB failure - Standard tray HP sensor failure - Standard tray clock sensor failure - Standard tray shift motor load failure The standard tray was moved but the paper surface was not detected. |

| Causes: | The tray lift motor (M5) is faulty. The tray lift motor clock sensor 1/2 (PI19/PI20) is faulty. The tray home position sensor (PI8) is faulty. |

| Remedy: | - Check the connector of the standard tray HP sensor. - Check the connector of the standard tray clock sensor. - Check the connector of the standard tray shift motor. - Replace the standard tray HP sensor. - Replace the standard tray clock sensor. - Replace the standard tray shift motor. - Replace the finisher controller PCB. |

| Error code: | E575-0001 |

| Description: | - Stack delivery motor or finisher controller PCB failure - Stack delivery HP sensor failure - The stack delivery motor was driven for 2000 ms in the stack delivery direction (HP sensor approach direction), but the stack delivery HP sensor did not turn on. |

| Remedy: | - Check the connector of the stack delivery HP sensor. - Check the connector of the stack delivery motor. - Check the connector of the stack delivery HP sensor. - Replace the stack delivery motor. - Replace the finisher controller PCB. |

| Error code: | E575-0002 |

| Description: | - Stack delivery motor or finisher controller PCB failure - Stack delivery HP sensor failure - The stack delivery motor was driven for 2000 ms in the HP sensor escape direction, but the stack delivery HP sensor did not turn off. |

| Remedy: | - Check the connector of the stack delivery HP sensor. - Check the connector of the stack delivery motor. - Check the connector of the stack delivery HP sensor. - Replace the stack delivery motor. - Replace the finisher controller PCB. |

| Error code: | E575-0004 |

| Description: | Gripper Motor (M7) clock error When the Gripper Motor (M7) was driven, the Gripper Encoder Sensor (S8) detected the rotation of 400 clocks or more. |

| Remedy: | 1. Check the connector connection of the Gripper Encoder Sensor (S8) or the Gripper Motor (M7). 2. Replace the Gripper Encoder Sensor (S8). 3. Replace the Gripper Motor (M7). 4. Replace the Finisher Controller PCB (PCB1). |

| Error code: | E577-0001 |

| Description: | Paddle error Finisher-P1 The HP sensor fails to be ON within 1500ms after the paper retaining paddle starts to move to its HP. |

| Causes: | The paddle home position sensor (PI2) is faulty. The stack ascent/descent home point sensor Pixx0 is faulty. The paddle motor (M2) is faulty. The finisher controller PCB is faulty. |

| Remedy: | Replace the paddle HP sensor (SR8) , Replace the paddle motor (M6) |

| Error code: | E577-0002 |

| Description: | Paddle error Finisher-P1 The HP sensor fails to be OFF within 1000ms after the paper retaining paddle starts to move from its HP. |

| Causes: | The paddle home position sensor (PI2) is faulty. The stack ascent/descent home point sensor Pixx0 is faulty. The paddle motor (M2) is faulty. The finisher controller PCB is faulty. |

| Remedy: | Replace the paddle HP sensor (SR8) , Replace the paddle motor (M6) |

| Error code: | E583-0001 |

| Description: | Tray Auxiliary Guide Motor (M6) error The Tray Auxiliary Guide failed to move from the Tray Auxiliary Guide HP Sensor (S6) although the Tray Auxiliary Guide Motor (M6) was driven for 30mm. |

| Remedy: | 1. Check the connector connection of the Tray Auxiliary Guide HP Sensor (S6) or the Tray Auxiliary Guide Motor (M6). 2. Replace the Tray Auxiliary Guide HP Sensor (S6). 3. Replace the Tray Auxiliary Guide Motor (M6). 4. Replace the Finisher Controller PCB (PCB1). |

| Error code: | E583-0002 |

| Description: | Tray Auxiliary Guide Motor (M6) error The Tray Auxiliary Guide failed to be detected by the Tray Auxiliary Guide HP Sensor (S6) although the Tray Auxiliary Guide Motor (M6) was driven for 1.8 seconds |

| Remedy: | 1. Check the connector connection of the Tray Auxiliary Guide HP Sensor (S6) or the Tray Auxiliary Guide Motor (M6). 2. Replace the Tray Auxiliary Guide HP Sensor (S6). 3. Replace the Tray Auxiliary Guide Motor (M6). 4. Replace the Finisher Controller PCB (PCB1). |

| Error code: | E602 |

| Description: | Yellow TCR Sensor adjustment failure - TCR Sensor automatic adjustment does not function properly, failing to adjust to an appropriate value. |

| Causes: | • Photoconductor Unit /C • Photoconductor Unit /M • Photoconductor Unit /Y • Toner Supply Motor Y/M (M6) • Toner Supply Motor C/K (M7) • Mechanical Control Board (PWB-M) • Controller Board (PWB-P) |

| Remedy: | 1 Clean the TCR Sensor window on the underside of the Photoconductor Unit if dirty - - 2 M6, M7 operation check PWB-M CNDM2-10 to 13 (M6) PWB-M CNDM3-10 to 13 (M7) C-22 C-23 3 Reinstall Photoconductor Unit - - 4 Change Photoconductor Unit - - 5 Change PWB-M - - 6 Change PWB-P |

| Error code: | E604-0512 |

| Description: | The image memory (SDRAM) is faulty/insufficient Memory is faulty/insufficient (512MB is required) |

| Remedy: | Add on the SDRAM |

| Error code: | E604-1024 |

| Description: | The image memory (SDRAM) is faulty/insufficient Memory is faulty/insufficient (1024MB is required) |

| Remedy: | Add on the SDRAM |

| Error code: | E604-1536 |

| Description: | The image memory (SDRAM) is faulty/insufficient Memory is faulty/insufficient (1536MB is required) |

| Remedy: | Add on the SDRAM |

| Error code: | E611-0000 |

| Description: | Rebooting repeat error due to SRAM failure, etc. Rebooting error when the SRAM data has been destroyed, the job information saved in the SRAM can no longer be read or when rebooting is otherwise repeated when the power is shut off and restored |

| Remedy: | - Clear the SRAM. - Clear the power shutdown guaranteed jobs. |

| Error code: | E613-0512 |

| Description: | Faulty/insufficient image memory (Main Controller PCB2) No necessary memory at Main Controller PCB 2 |

| Remedy: | Make the Memory capacity at Main Controller PCB 2 as indicated by 0512. |

| Error code: | E613-1024 |

| Description: | Faulty/insufficient image memory (Main Controller PCB2) No necessary memory at Main Controller PCB 2 |

| Remedy: | Make the Memory capacity at Main Controller PCB 2 as indicated by 1024. |

| Error code: | E613-1536 |

| Description: | Faulty/insufficient image memory (Main Controller PCB2) No necessary memory at Main Controller PCB 2 |

| Remedy: | Make the Memory capacity at Main Controller PCB 2 as indicated by 1536. |

| Error code: | E614 |

| Description: | Flash PCB detection error |

| Error code: | E674-0001 |

| Description: | There is an error in the fax board. The fax board is detected, but communication is not possible. |

| Remedy: | Turn off the main power, and check the fax board and the main controller PCB; then, turn on the main power. If the machine fails to reset, replaced the fax board or the main controller PCB |

| Error code: | E674-0004 |

| Description: | FAX is abnormal. Modem IC access is abnormal |

| Remedy: | 1. Cable connection check 2. FAX board replacement 3. Main controller board replacement |

| Error code: | E674-0008 |

| Description: | FAX is abnormal. Port IC access is abnormal |

| Remedy: | 1. Cable connection check 2. FAX board replacement 3. Main controller board replacement |

| Error code: | E674-000C |

| Description: | FAX is abnormal. Modem IC/ port IC access is abnormal |

| Remedy: | 1. Cable connection check 2. FAX board replacement 3. Main controller board replacement |

| Error code: | E674-0010 |

| Description: | FAX is abnormal. |

| Remedy: | Main controller board replacement |

| Error code: | E674-0011 |

| Description: | FAX is abnormal. |

| Remedy: | Main controller board replacement |

| Error code: | E674-0030 |

| Description: | FAX is abnormal. Check sum error |

| Remedy: | System software download for 2 line FAX |

| Error code: | E674-0100 |

| Description: | Failure in communication of FAX board Logging was failed after completion of fax communication. |

| Remedy: | Turn OFF and then ON the power. The logs collected so far are deleted. |

| Error code: | E674-0200 |

| Description: | Failure in communication of FAX board An error occurred when accessing the HDD. |

| Remedy: | 1. Turn OFF and then ON the power. 2. Format and upgrade the entire HDD. 3. Replace the HDD. 4. Replace the Main Controller PCB. (Main Controller PCB 2 for 1-line Fax Board, and Main Controller PCB 1 for 2-/3-/4-line Fax Board) |

| Error code: | E677-0003 |

| Description: | There is an external controller error. An error has been detected by a check on the configuration when the external controller is being started up. |

| Remedy: | Turn off the main power, and check the cable; then, turn on the main power. If the machine fails to start up, re-install the system software of the external contro |

| Error code: | E711-0001 |

| Description: | IPC communication error When error occurrence was set 4 or more times in the error register of the IPC chip within 1.5 sec. |

| Causes: | The connector has poor connection. The ADF controller PCB is faulty. The finisher controller PCB is faulty. The DA unit PCB is faulty. The card reader PCB is faulty. |

| Remedy: | Check the cable connections. Replace the ADF controller PCB. Replace the reader controller PCB. |

| Error code: | E713-0000 |

| Description: | Communication error between the finisher and the printer Communication between the finisher and the copier stops. |

| Causes: | The connector has poor connection. The option power supply PCB is faulty. The finisher controller PCB is faulty. The DC controller PCB is faulty. |

| Remedy: | Check on connection of the cable, Replace the finisher controller PCB, Replace the DC controller PCB |

| Error code: | E716-0000 |

| Description: | Erroneous communication with optional cassette Disconnection of the optional cassette was detected after power-on, detection of normal connection to the optional cassette, and start of communication. |

| Causes: | The connector has poor connection. The main power supply PCB is faulty. The pedestal controller PCB is faulty. The DC controller PCB is faulty. |

| Remedy: | - Check the connectors of the optional cassette PCB and DC controller PCB. - Replace the optional cassette PCB for normal connection. - Replace the DC controller PCB. |

| Error code: | E719-0001 |

| Description: | Error in communication with coin vendor/card reader When the coin vendor which was connected before the power was turned OFF could not be recognized when the power was turned back ON |

| Causes: | The wiring is faulty (short circuit, open circuit). The Card Reader-C1 is faulty. The coin vendor is faulty. The main controller PCB is faulty. Caution To clear the error, execute the following in service mode: COPIER>FUNCTION>CLEAR>ERR. |

| Remedy: | Check the cable connections. |

| Error code: | E719-0002 |

| Description: | Erroneous communication with coin vendor (serial communication) - Disconnection from the coin vendor has been detected since communication started after confirmation of normal connection to the coin vendor (after power-on). - A serial communication error has occurred. (The serial communication error cannot be recovered.) |

| Causes: | Erroneous communication with coin vendor (serial communication) - Disconnection from the coin vendor has been detected since communication started after confirmation of normal connection to the coin vendor (after power-on). - A serial communication error has occurred. (The serial communication error cannot be recovered.) |

| Remedy: | - Check the connection between the image processor PCB and serial PCB. - Check the connectors of the serial PCB and coin vendor for normal connection. - Replace the serial PCB. - Check the coin vendor. - Replace the image processor PCB. |

| Error code: | E719-0003 |

| Description: | There is a coin vendor error. While the unit price is being checked at startup, an error occurs in the communication with the coin vendor. |

| Remedy: | Check the cable; thereafter, reset the condition in service mode: COPIER>FUNCTION>CLEAR>ERR. |

| Error code: | E719-0004 |

| Description: | Coin vendor error The coin vendor was connected to a model that does not support the coin vendor |

| Remedy: | 1. Disconnect the coin vendor |

| Error code: | E719-0011 |

| Description: | Error in communication with coin vendor/card reader When the card reader which was connected before the power was turned OFF could not be recognized when the power was turned back ON |

| Remedy: | In the service mode, clear the error by selecting COPIER > FUNCTION > CLEAR > ERR |

| Error code: | E719-0012 |

| Description: | Error in communication with coin vendor/card reader When a wire in the IPC cable connected with the card reader is broken or disconnected or when an error has occurred where IPC communication cannot be recovered |

| Remedy: | In the service mode, clear the error by selecting COPIER > FUNCTION > CLEAR > ERR |

| Error code: | E719-0031 |

| Description: | There is a coin vendor error. Error in communication at card reader (serial) startup Communication with the card reader cannot be started at startup. |

| Remedy: | 1. Check the connection of the cable for the card reader (connector disconnected, cable cut); thereafter, reset the condition in service mode: COPIER > FUNCTION > CLEAR > ERR. 2. Execute the following items in service mode after removing the card reader, and then install the card reader again. - COPIER > FUNCTION > CLEAR > CARD - COPIER > FUNCTION > CLEAR > ERR |

| Error code: | E719-0032 |

| Description: | There is a coin vendor error. Error in communication after card reader (serial) startup Communication with the card reader is available at startup, and then becomes unavailable. |

| Remedy: | Check the connection of the cable for the card reader (connector disconnected, cable cut); thereafter, reset the condition in service mode: COPIER > FUNCTION > CLEAR > ERR. |

| Error code: | E730-1001 |

| Description: | There is a PDL software error. An initialization error has occurred. |

| Remedy: | - Execute PDL resetting. - Turn on the power once again. |

| Error code: | E730-100A |

| Description: | Printer service call |

| Error code: | E730-A006 |

| Description: | There is a PDL software error. The PDL board does not respond. A subbootable is faulty or absent. |

| Remedy: | - Execute PDL resetting. - Turn on the power once again. - Check the connection of the UFR board. - Re-install the firmware. - Replace the main controller PCB. |

| Error code: | E730-A007 |

| Description: | There is a PDL software error. There is a mismatch between the control software of the machine and the PDL control software in regard to version. |

| Remedy: | - Execute PDL resetting. - Turn on the power once again. - Execute system formatting (all), and reinstall the system. |

| Error code: | E730-B013 |

| Description: | There is a PDL software error. Corruption in the font data |

| Remedy: | - Turn on the power once again. - Re-install the Software. - Execute system formatting (all), and reinstall the system. |

| Error code: | E730-C000 |

| Description: | An error such as memory not acquired at initialization occurred. |

| Remedy: | Turn on the power again. |

| Error code: | E730-C001 |

| Description: | An error occurred when accessing the HDD. |

| Remedy: | Turn on the power again. |

| Error code: | E731-3000 |

| Description: | Image processing module failure. |

| Remedy: | Main controller board 2 replacement |

| Error code: | E731-3001 |

| Description: | Image processing module failure. |

| Remedy: | Main controller board 2 replacement |

| Error code: | E731-3002 |

| Description: | Image processing module failure. |

| Remedy: | Main controller board 2 replacement |

| Error code: | E731-3015 |

| Description: | Image processing module failure |

| Remedy: | Main controller board 2 replacement |

| Error code: | E732-0010 |

| Description: | There is an error in the communication with the scanner Fault in detection of DDI-S Vsync signal |

| Remedy: | 1. Check the connector used to connect the scanner. 2. Check the power supply of the scanner (to see if initialization takes place at startup). 3. Replace the reader controller, scanner board, or main board as necessary. |

| Error code: | E740-0002 |

| Description: | Error detection on either Network Board or Mac address |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Check the connection of the network cable. (2) Replace the Main Controller Board. |

| Error code: | E740-0003 |

| Description: | Abnormality of the Ethernet board Incorrect network ID is detected at startup. |

| Causes: | The LAN card is faulty. The main controller PCB is faulty. |

| Remedy: | Replace the Ethernet board, Replace the main controller PCB (sub LAN-bar) |

| Error code: | E743-0000 |

| Description: | Error in main controller communication An error in reading of/writing to the Flash ROM in the Main Controller occurred. |

| Causes: | Software sequence error |

| Remedy: | 1. Turn OFF and then ON the main power. 2. Replace the Main Controller PCB. |

| Error code: | E744 |

| Description: | Stop jam at the original exit/reverse sensor |

| Causes: | Original exit/reverse sensor RADF board Perform the 05-3210 Roller Intermediate transport roller |

| Remedy: | 1. Clean the exit/reverse intermediate roller if it is stained. 2. Is the original exit/reverse sensor working? (Perform input check: 03: [FAX]/ON/[5]/[B]) * If it is working properly, proceed to 6. If not, check 3 to 5 below. 3. Check if the connector CN75 on the RADF board is disconnected from the original exit/reverse sensor or the harnesses are open-circuited. Correct if this is the case. 4. Replace the original exit/reverse sensor. 5. Replace the RADF board, and then perform the automatic adjustment for the original reading start sensor (05-356). 6. Replace the exit/reverse intermediate roller, if it is worn out. |

| Error code: | E746-0021 |

| Description: | Image analysis board self-check failure detection. |

| Remedy: | 1. Connection check of the image analysis board 2. Image analysis board replacement |

| Error code: | E746-0022 |

| Description: | Image analysis board version is invalid. |

| Remedy: | 1. Upgrading of the image analysis board software 2. Image analysis board replacement |

| Error code: | E746-0023 |

| Description: | No response from image analysis board. |

| Remedy: | 1. Connection check of the image analysis board 2. Image analysis board replacement |

| Error code: | E746-0024 |

| Description: | Image analysis board operation abnormality |

| Remedy: | 1. Connection check of the image analysis board 2. Image analysis board replacement |

| Error code: | E746-0031 |

| Description: | Hardware error (TPM) |

| Remedy: | 1. TPM board non-installation 2. Installation of TPM board from other units 3. TPM chip broken |

| Error code: | E746-0032 |

| Description: | The error that system restoration is impossible occurred (TPM) |