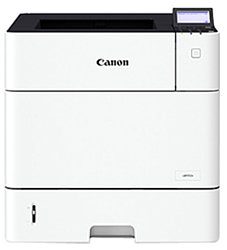

Canon i-SENSYS LBP352x

Рейтинг

Актуальный

Актуальный

Тип устройства

Принтер

Технология печати

лазерная

Макс. формат

A4

Число страниц в месяц

280000

Скорость печати

A4

62

Цветность печати

черно-белая

Общие характеристики |

|

|---|---|

Размещение |

настольный |

Макс. формат |

A4 |

Число страниц в месяц |

280 000 |

Телефон |

|

Печать фотографий |

|

Копир |

|

Сканер |

|

Факс |

|

Тип устройства |

Принтер |

Область применения |

большой офис |

Тип |

лазерный/светодиодный |

Цветность печати |

|

Технология печати |

лазерная |

Принтер |

|

Макс, ширина отпечатка |

216 |

Время разогрева |

29 |

Двусторонняя печать |

|

Макс, длина отпечатка |

356 |

Печать без полей |

|

Пигментные чернила |

|

Система непрерывной подачи чернил |

|

Макс, разрешение для ч/б печати |

|

| По Y | 1 200 |

| По X | 1 200 |

Скорость ч/б печати |

|

| A4 | 62 |

Время выхода первого отпечатка |

|

| Ч/б | 7 |

Сканер |

|

Слайд-адаптер |

|

Стандарт WIA |

|

Отправка изображения по e-mail |

|

Стандарт TWAIN |

|

Расходные материалы |

|

Ресурс ч/б картриджа/тонера |

11 000 |

Количество картриджей |

1 |

Печать на: |

|

| Карточках |

|

| Фотобумаге |

|

| CD/DVD |

|

| Рулоне |

|

| Пленках |

|

| Этикетках |

|

| Конвертах |

|

| Глянцевой бумаге |

|

| Матовой бумаге |

|

Плотность бумаги |

|

| Максимальная | 199 |

| Минимальная | 60 |

Факс |

|

Цветной |

|

Телефон |

|

Беспроводная трубка |

|

Проводная трубка |

|

АОН |

|

Caller ID |

|

Автоответчик |

|

Стандарт DECT |

|

Спикерфон |

|

Шрифты и языки управления |

|

Языки управления |

|

| PCL 6 |

|

| PostScript 3 |

|

| PostScript |

|

| PCL 5e |

|

Количество установленных шрифтов |

|

| PostScript | 136 |

| PCL | 93 |

Подача бумаги |

|

| Максимальная | 3 600 |

| Стандартная | 600 |

Интерфейсы |

|

AirPrint |

|

RS-232 |

|

Устройство для чтения карт памяти |

|

FireWire (IEEE 1394) |

|

Wi-Fi |

|

Bluetooth |

|

LPT |

|

Инфракрасный порт |

|

USB |

|

Ethernet (RJ-45) |

|

Версия USB |

2,0 |

Память/Процессор |

|

Объем памяти |

1 024 |

Частота процессора |

528 |

Дополнительная информация |

|

Экран |

|

Работа от аккумулятора |

|

Поддержка ОС |

|

| Linux |

|

| Mac OS |

|

| Windows |

|

Потребляемая мощность |

|

| При работе | 1 650 |

| В режиме ожидания | 19 |

Уровень шума |

|

| При работе | 71 |

Габариты |

|

Ширина |

415 |

Вес |

26,2 |

Глубина |

529 |

Высота |

436 |

Модули

DUPLEX

102 INTERNAL COMPONENTS 1

103B INTERNAL COMPONENTS 3 (LBP351dn,LBP352dn)

900D CONTROLLER PCB ASSEMBLY (LBP352dn,LBP352x)

104B INTERNAL COMPONENTS 4

900C CONTROLLER PCB ASSEMBLY (LBP351dn,LBP351x)

110A POWER SUPPLY ASSY (100V,120V)

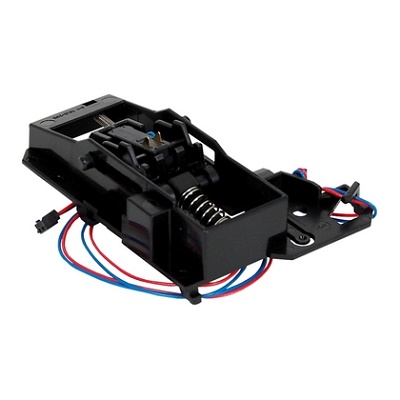

S10 DUPLEXING UNIT

EXTERNAL COVERS, PANELS, ETC.

100B EXTERNAL COVERS, PANELS, ETC. (LBP351dn,LBP352dn)

INTERMEDIATE TRANS. BELT ASSY

DRIVE

101 INTERNAL COMPONENTS 1

PAPER FEED

330 MULTI-PURPOSE PICK-UP ASSY

102 INTERNAL COMPONENTS 2

Детали 900C CONTROLLER PCB ASSEMBLY (LBP351dn,LBP351x)

| Деталь: | Пружина прижима в узле подачи бумаги |

| Парткод: | RC1-0213-000CN |

| Цена: | 150 ₽ |

| Деталь: | Подшипник |

| Парткод: | RC1-0214-000CN |

| Цена: | 170 ₽ |

| Деталь: | Шестерня передвижных ограничителей формата бумаги в кассете |

| Парткод: | RC1-0331-000CN |

| Цена: | 320 ₽ |

| Деталь: | Подшипник |

| Парткод: | RC3-1403-000CN |

| Цена: | 1 000 ₽ |

| Деталь: | Вентилятор |

| Парткод: | RK2-1988-000CN |

| Цена: | 850 ₽ |

| Деталь: | Вентилятор |

| Парткод: | RK2-1989-000CN |

| Цена: | 1 000 ₽ |

| Деталь: | Вентилятор |

| Парткод: | RK2-1992-000CN |

| Цена: | 850 ₽ |

| Деталь: | Вентилятор картриджа |

| Парткод: | RK2-3244-000CN |

| Цена: | 5 100 ₽ |

| Деталь: | Узел определения формата бумаги, в сборе |

| Парткод: | RM1-4525-000CN |

| Цена: | 750 ₽ |

| Деталь: | Датчик чтения информации с картриджа, в сборе |

| Парткод: | RM1-4539-000CN |

| Цена: | 500 ₽ |

| Деталь: | Кабель |

| Парткод: | RM1-5085-000CN |

| Цена: | 550 ₽ |

| Деталь: | Кабель мотора привода узла термозакрепления |

| Парткод: | RM1-5088-000CN |

| Цена: | 260 ₽ |

| Деталь: | Узел заземления, в сборе |

| Парткод: | RM1-5461-000CN |

| Цена: | 320 ₽ |

| Деталь: | Кабель мотора привода узла подачи бумаги |

| Парткод: | RM1-8311-000CN |

| Цена: | 650 ₽ |

| Деталь: | Кабель блока лазера |

| Парткод: | RM1-8340-000CN |

| Цена: | 1 400 ₽ |

| Деталь: | Узел регистрации, в сборе |

| Парткод: | RM1-8413-000CN |

| Цена: | 2 900 ₽ |

| Деталь: | Датчик температуры |

| Парткод: | RM1-8438-000CN |

| Цена: | 330 ₽ |

| Деталь: | Привода узла выхода бумаги, в сборе |

| Парткод: | RM2-6318-000CN |

| Цена: | 700 ₽ |

| Деталь: | Привод подъёма, в сборе |

| Парткод: | RM2-6335-000CN |

| Деталь: | Узел привода фотовала, в сборе |

| Парткод: | RM2-6920-000CN |

| Цена: | 2 000 ₽ |

| Деталь: | Шестерня |

| Парткод: | RU5-0040-000CN |

| Деталь: | Шестерня |

| Парткод: | RU5-0088-000CN |

| Цена: | 1 100 ₽ |

| Деталь: | Шестерня |

| Парткод: | RU7-0295-000CN |

| Цена: | 3 500 ₽ |

| Деталь: | Соединитель |

| Парткод: | VS1-7207-003CN |

| Деталь: | Соединитель |

| Парткод: | VS1-7514-006CN |

| Цена: | 330 ₽ |

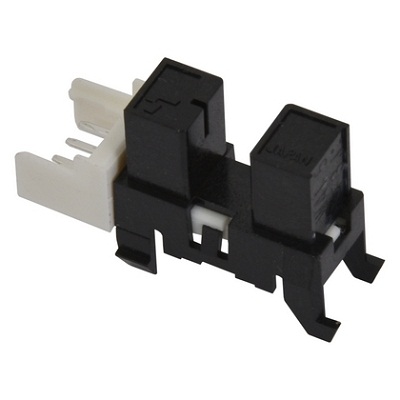

| Деталь: | Механический переключатель |

| Парткод: | WC2-5637-000CN |

| Цена: | 340 ₽ |

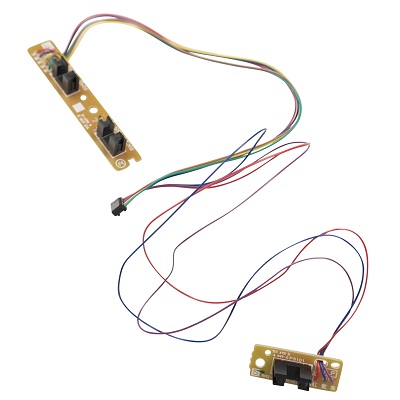

| Деталь: | Датчик наличия бумаги |

| Парткод: | WG8-5849-000CN |

| Цена: | 380 ₽ |

| Деталь: | Стопорное кольцо |

| Парткод: | XD9-0232-000CN |

| Цена: | 150 ₽ |

| Деталь: | Стопорное кольцо |

| Парткод: | XD9-0233-000CN |

| Цена: | 230 ₽ |

| Деталь: | Панель управления, в сборе |

| Парткод: | FM1-K563-000 |

| Цена: | 17 200 ₽ |

| Деталь: | Мотор привода фотовала |

| Парткод: | RM1-8358-000CN |

| Цена: | 5 500 ₽ |

| Деталь: | Блок лазера |

| Парткод: | RM1-8406-000CN |

| Цена: | 10 500 ₽ |

| Деталь: | Плата питания |

| Парткод: | RM2-6349-000CN |

| Цена: | 12 200 ₽ |

| Деталь: | Плата контроллера напряжения |

| Парткод: | RM2-7643-000CN |

| Цена: | 10 000 ₽ |

| Деталь: | FIXING ASSY (220-240V) |

| Парткод: | RM2-6308-000 |

| Деталь: | PAPER DELIVERY ASSY |

| Парткод: | FM1-J621-000 |

| Цена: | 11 200 ₽ |

| Деталь: | TEMPERATURE SENSOR ASSY |

| Парткод: | RM1-8438-000 |

| Деталь: | FAN |

| Парткод: | RK2-1988-000 |

| Деталь: | FAN |

| Парткод: | RK2-1989-000 |

| Деталь: | FAN |

| Парткод: | RK2-3244-000 |

| Деталь: | FAN |

| Парткод: | RK2-1992-000 |

| Деталь: | CABLE, FLEXIBLE FLAT |

| Парткод: | FK4-3450-000 |

| Цена: | 9 100 ₽ |

| Деталь: | SWITCH, PUSH |

| Парткод: | WC2-5637-000 |

| Деталь: | DC CONTROLLER PCB ASSY |

| Парткод: | RM2-7643-000 |

| Деталь: | FIXING MOTOR ASSY |

| Парткод: | RM1-8928-000 |

| Деталь: | IC, PHOTO INTERRUPTER |

| Парткод: | WG8-5849-000 |

| Деталь: | GEAR, 23T/19T |

| Парткод: | RU7-0295-000 |

| Деталь: | LIFTER DRIVE ASSY |

| Парткод: | RM2-6335-000 |

| Деталь: | USB CABLE ASSY |

| Парткод: | FM1-K574-000 |

| Цена: | 3 300 ₽ |

| Деталь: | RING, E |

| Парткод: | XD9-0232-010 |

| Деталь: | BUSHING, PAPER DELIVERY |

| Парткод: | RC1-0136-000 |

| Деталь: | PAPER DELIVERY DRIVE ASSY |

| Парткод: | RM2-6318-000 |

| Деталь: | CABLE, DOOR SWITCH |

| Парткод: | FM1-U851-000 |

| Цена: | 3 300 ₽ |

| Деталь: | CABLE, ENVELOPE FEEDER |

| Парткод: | RM1-5085-000 |

| Деталь: | CABLE, FIXING MOTOR |

| Парткод: | RM1-5088-000 |

| Деталь: | COVER, USB |

| Парткод: | FE4-8096-000 |

| Цена: | 9 100 ₽ |

| Деталь: | FIXING DRIVE ASSY |

| Парткод: | RM2-6321-000 |

| Деталь: | SWITCH PCB ASSY |

| Парткод: | FM1-J623-000 |

| Цена: | 1 800 ₽ |

| Деталь: | CABLE, MAIN SWITCH |

| Парткод: | FM1-U846-000 |

| Цена: | 3 400 ₽ |

| Деталь: | CONNECTOR, SNAP TIGHT, BK |

| Парткод: | VS1-7207-003 |

| Деталь: | INTERNAL COMPONENTS 3 |

| Парткод: | NPN |

| Деталь: | IC, ASIC, MB8AA4241EPBH-GE1 |

| Парткод: | FK3-1800-000 |

| Деталь: | MAIN CONTROLLER PCB ASSEMBLY |

| Парткод: | FM1-U809-000 |

| Цена: | 64 000 ₽ |

| Деталь: | CABLE, |

| Парткод: | FM1-U843-000 |

| Деталь: | CABLE, |

| Парткод: | FM1-U852-000 |

| Деталь: | COUNTER ROM PCB ASSEMBLY |

| Парткод: | FM4-8867-000 |

| Деталь: | SCREW, |

| Парткод: | XA9-1469-000 |

| Деталь: | SLEEP |

| Парткод: | FM1-U816-000 |

| Деталь: | CABLE, |

| Парткод: | FM1-U844-000 |

| Деталь: | CABLE, |

| Парткод: | FM1-K573-000 |

| Деталь: | COVER, |

| Парткод: | FE4-8016-000 |

| Деталь: | SCREW, |

| Парткод: | FC5-7039-000 |

| Деталь: | COVER, |

| Парткод: | FE4-8018-000 |

| Деталь: | LID, PS CABLE |

| Парткод: | FE4-8019-000 |

| Деталь: | SCREW, |

| Парткод: | XA9-1420-000 |

| Цена: | 1 100 ₽ |

| Деталь: | ALL NIGHT POWER SUPPLY PCB |

| Парткод: | FK3-1998-000 |

| Деталь: | AC RELAY PCB ASSY |

| Парткод: | FM1-U817-000 |

| Деталь: | COVER, |

| Парткод: | FE4-8015-000 |

| Деталь: | CABLE, |

| Парткод: | FM1-U845-000 |

| Деталь: | CABLE, |

| Парткод: | FM1-U847-000 |

| Деталь: | INTERNAL COMPONENTS 4 |

| Парткод: | NPN |

| Деталь: | IC, ASIC, MB8AA4241EPBH-GE1 |

| Парткод: | FK3-1800-000 |

| Деталь: | MAIN CONTROLLER PCB ASSEMBLY |

| Парткод: | FM1-U808-000 |

| Цена: | 64 000 ₽ |

| Деталь: | PAPER FEED ASSY |

| Парткод: | RM1-4548-000 |

| Деталь: | ENGINE POWER SUPPLY PCB ASSY |

| Парткод: | RM2-6301-000 |

| Деталь: | CONNECTOR, DRAWER, 6P |

| Парткод: | VS1-7514-006 |

| Деталь: | CABLE, EPU INPUT |

| Парткод: | FM1-U841-000 |

| Цена: | 4 800 ₽ |

| Деталь: | POWER SUPPLY ASS Y |

| Парткод: | NPN |

| Деталь: | DEFLECTOR, PAPER REPICK-UP |

| Парткод: | RC4-5907-000 |

| Деталь: | GUIDE, PAPER REPICK UP, LOWER |

| Парткод: | RC2-2599-000 |

| Деталь: | GUIDE, PAPER RE-PICK UP, UPPER |

| Парткод: | RC2-2602-000 |

| Деталь: | COVER, LEFT |

| Парткод: | FE4-8060-000 |

| Деталь: | COVER, RIGHT |

| Парткод: | FE4-8061-000 |

| Деталь: | COVER, UPPER |

| Парткод: | FE4-8059-000 |

| Деталь: | COVER, REAR |

| Парткод: | FE4-8058-000 |

| Деталь: | MOTOR, STEPPING, DC24V |

| Парткод: | RK2-7885-000 |

| Деталь: | FAN |

| Парткод: | RK2-2016-000 |

| Деталь: | MOTOR, STEPPING, DC24V |

| Парткод: | RK2-2139-000 |

| Деталь: | IC, PHOTO INTERRUPTER |

| Парткод: | WG8-5849-000 |

| Деталь: | DUPLEXING PCB ASSY |

| Парткод: | RM2-7656-000 |

| Деталь: | DUPLEXING UNIT |

| Парткод: | FM1-K577-000 |

| Деталь: | Выдвижная часть кассеты на 500 листов, в сборе |

| Парткод: | RM1-1089-000 |

| Цена: | 1 700 ₽ |

| Деталь: | COVER, TOP REAR |

| Парткод: | FE4-7997-000 |

| Цена: | 11 600 ₽ |

| Деталь: | CABLE, PANEL GND |

| Парткод: | FM1-U850-000 |

| Цена: | 3 400 ₽ |

| Деталь: | COVER, RIGHT FRONT |

| Парткод: | FM1-J622-000 |

| Цена: | 2 900 ₽ |

| Деталь: | COVER, RIGHT REAR |

| Парткод: | FE4-8006-000 |

| Деталь: | OPERATION PANEL ASSY |

| Парткод: | FM1-J624-000 |

| Деталь: | COVER, LEGAL |

| Парткод: | FE4-8007-000 |

| Цена: | 1 200 ₽ |

| Деталь: | FACE-UP TRAY ASSY |

| Парткод: | FM1-J610-000 |

| Цена: | 11 700 ₽ |

| Деталь: | FRONT COVER ASSY |

| Парткод: | FM1-J619-000 |

| Цена: | 5 000 ₽ |

| Деталь: | RIGHT COVER ASSY |

| Парткод: | FM1-J617-000 |

| Цена: | 10 600 ₽ |

| Деталь: | LEFT COVER ASSY |

| Парткод: | FM1-J618-000 |

| Цена: | 7 100 ₽ |

| Деталь: | TOP COVER ASSY |

| Парткод: | FM1-J613-000 |

| Цена: | 39 800 ₽ |

| Деталь: | COVER, RIGHT WINDOW |

| Парткод: | FE4-7999-000 |

| Цена: | 9 600 ₽ |

| Деталь: | CABLE, PANEL |

| Парткод: | FM1-U814-000 |

| Цена: | 3 600 ₽ |

| Деталь: | EXTERNAL COVERS, PANELS, ETC. |

| Парткод: | NPN |

| Деталь: | Вал переноса заряда, в сборе |

| Парткод: | CE988-67903 |

| Деталь: | Подшипник прижимного вала |

| Парткод: | BUSHING-M601 |

| Цена: | 90 ₽ |

| Деталь: | Узел термозакрепления, в сборе |

| Парткод: | CET2592 |

| Цена: | 6 300 ₽ |

| Деталь: | Узел термозакрепления |

| Парткод: | CET2705 |

| Цена: | 7 400 ₽ |

| Деталь: | Fusing assembly |

| Парткод: | E6B67-67902 |

| Цена: | 15 000 ₽ |

| Деталь: | (CET2439) Прижимной вал |

| Парткод: | LPR-M601 |

| Цена: | 1 000 ₽ |

| Деталь: | Подшипник вала выхода бумаги из узла термозакрепления |

| Парткод: | RC1-0136-000CN |

| Цена: | 900 ₽ |

| Деталь: | Нагревательный элемент узла термозакрепления |

| Парткод: | RM1-8396-HEAT |

| Цена: | 2 000 ₽ |

| Деталь: | Мотор привода узла термозакрепления, в сборе |

| Парткод: | RM1-8928-000CN |

| Цена: | 2 300 ₽ |

| Деталь: | Привод узла термозакрепления, в сборе |

| Парткод: | RM2-6321-000CN |

| Цена: | 2 400 ₽ |

| Деталь: | Шестерня прижимного вала |

| Парткод: | RU7-0296-000 |

| Цена: | 250 ₽ |

| Деталь: | COVER, ENV |

| Парткод: | FL0-6303-000 |

| Цена: | 600 ₽ |

| Деталь: | TRANSFER ROLLER KIT |

| Парткод: | RM1-8491-000 |

| Деталь: | PAPER FEED ROLLER ASSY |

| Парткод: | RM1-8411-010 |

| Деталь: | REGISTRATION ASSY |

| Парткод: | RM1-8413-000 |

| Деталь: | DRUM MOTOR ASSY |

| Парткод: | RM1-8358-000 |

| Деталь: | SIZE DETECT ASSY |

| Парткод: | RM1-4525-000 |

| Деталь: | TORQUE LIMITER |

| Парткод: | RC2-5771-000 |

| Деталь: | PAPER FEED ROLLER ASSY |

| Парткод: | RM1-0037-020 |

| Цена: | 70 ₽ |

| Деталь: | CASSETTE ASSY |

| Парткод: | FM1-J607-000 |

| Цена: | 17 700 ₽ |

| Деталь: | DRUM DRIVE ASSY |

| Парткод: | RM2-6920-000 |

| Деталь: | CABLE, DRUM MOTOR |

| Парткод: | FM1-K774-000 |

| Цена: | 3 400 ₽ |

| Деталь: | LABEL, PAPER SET |

| Парткод: | FE4-8039-000 |

| Цена: | 2 500 ₽ |

| Деталь: | GEAR, 20T |

| Парткод: | RC1-0331-000 |

| Деталь: | CASSETTE REAR ASSY |

| Парткод: | RM1-1089-030 |

| Деталь: | GEAR, 88T |

| Парткод: | RU5-0025-000 |

| Деталь: | INTERNAL COMPONENTS 1 |

| Парткод: | NPN |

| Деталь: | Ограничительный ролик в кассете на 500 листов |

| Парткод: | RC2-5771-000CN |

| Цена: | 1 000 ₽ |

| Деталь: | Ролик захвата бумаги из лотка ручной подачи |

| Парткод: | RL1-1641-000CN |

| Деталь: | Ролик отделения бумаги в лотке ручной подачи |

| Парткод: | RL1-1654-000CN |

| Деталь: | Ролик подачи бумаги в лотке ручной подачи |

| Парткод: | RL1-1663-000CN |

| Цена: | 550 ₽ |

| Деталь: | Ось привода |

| Парткод: | RL1-3020-000CN |

| Цена: | 370 ₽ |

| Деталь: | Соленоид |

| Парткод: | RL2-1409-000CN |

| Цена: | 1 800 ₽ |

| Деталь: | Pickup Roller |

| Парткод: | RM1-0036-020CN |

| Цена: | 70 ₽ |

| Деталь: | Ролик подачи / отделения бумаги из кассеты |

| Парткод: | RM1-0037-020CN |

| Цена: | 70 ₽ |

| Деталь: | Направляющая узла подачи бумаги, в сборе |

| Парткод: | RM1-4548-000CN |

| Цена: | 1 600 ₽ |

| Деталь: | Мотор привода узла подачи бумаги, в сборе |

| Парткод: | RM1-8285-000CN |

| Цена: | 2 300 ₽ |

| Деталь: | Узел подачи бумаги, в сборе |

| Парткод: | RM1-8411-010CN |

| Цена: | 2 700 ₽ |

| Деталь: | Привод узла звхвата бумаги, в сборе |

| Парткод: | RM1-8415-000CN |

| Цена: | 1 200 ₽ |

| Деталь: | Узел осей подачи бумаги, в сборе |

| Парткод: | RM1-8424-000CN |

| Цена: | 1 200 ₽ |

| Деталь: | Узел захвата ручной подачи бумаги, в сборе |

| Парткод: | RM2-6323-000CN |

| Цена: | 9 500 ₽ |

| Деталь: | Датчики узла подачи бумаги, в сборе |

| Парткод: | RM2-7687-000CN |

| Деталь: | ROLLER |

| Парткод: | RL1-1641-000 |

| Деталь: | ROLLER |

| Парткод: | RL1-1663-000 |

| Деталь: | ROLLER |

| Парткод: | RL1-1654-020 |

| Деталь: | MULTI- |

| Парткод: | RM2-6323-000 |

| Деталь: | LASER SCANNER ASSY |

| Парткод: | RM1-8406-000 |

| Деталь: | PAPER FEED MOTOR ASSY |

| Парткод: | RM1-8285-000 |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RC1-0213-000 |

| Деталь: | SOLENOID |

| Парткод: | RL2-1409-000 |

| Деталь: | PAPER PICK-UP ROLLER ASSY |

| Парткод: | RM1-0036-020 |

| Деталь: | PAPER FEED ROLLER ASSY |

| Парткод: | RM1-0037-020 |

| Цена: | 70 ₽ |

| Деталь: | PAPER PICK-UP DRIVE ASSY |

| Парткод: | RM1-8415-000 |

| Деталь: | TAG HOLDER ASSY |

| Парткод: | RM1-4539-000 |

| Деталь: | FEEDER SENSOR CABLE ASSY |

| Парткод: | RM2-7687-000 |

| Деталь: | PAPER FEED SHAFT ASSY |

| Парткод: | RM1-8424-000 |

| Деталь: | SHAFT, RETARD DRIVE |

| Парткод: | RL1-3020-000 |

| Деталь: | CABLE, LASER |

| Парткод: | RM1-8340-000 |

| Деталь: | CABLE, FEED MOTOR |

| Парткод: | RM1-8311-000 |

| Деталь: | RING, E |

| Парткод: | XD9-0232-010 |

| Деталь: | BUSHING |

| Парткод: | RC1-0214-000 |

| Деталь: | GEAR, 23T |

| Парткод: | RU5-0040-000 |

| Деталь: | GEAR, 18T |

| Парткод: | RU5-0088-000 |

| Деталь: | RING, E |

| Парткод: | XD9-0233-010 |

| Деталь: | BUSHING |

| Парткод: | RC3-1403-000 |

| Деталь: | INTERNAL COMPONENTS 2 |

| Парткод: | NPN |

Коды ошибок

A4-nn

A5-nn

A7-nn

D0-nn

D7-nn

D8-nn

D9-nn

E000-0000

E001-0000

E001-0001

E003-0000

E003-0001

E004-0000

E004-0004

E012-0000

E012-0001

E012-0008

E012-0009

E014-0000

E014-0001

E015-0001

E015-0002

E015-0003

E015-0004

E015-0005

E066-0000

E100-0000

E100-0001

E110-0000

E196-0001

E196-0002

E196-0003

E245

E245-1011

E246

E247

E350

E354

E355

E602-0001

E602-0002

E602-0003

E602-0006

E602-0007

E602-0008

E602-0009

E602-1102

E602-1112

E602-1113

E602-1302

E602-1312

E602-1313

E602-1602

E602-1612

E602-1613

E604-0000

E604-0001

E616-0001

E616-0002

E730-100A

E730-C000

E730-C001

E730-D000

E730-D001

E733-0001

E733-0004

E733-0006

E740-0002

E740-0004

E744-0800

E744-0900

E744-1000

E744-1100

E748-2012

E760-0000

E805-0001

E805-0002

E805-0008

E805-0009

E805-0010

E808-0001

E840-0000

F9-nn

Описание

| Error code: | A4-nn |

| Description: | System error |

| Causes: | System error |

| Remedy: | - Turn OFF and then ON the main power. If the error persists, obtain the following information and contact the department in charge of quality management. - Output STATUS PRINT/P-PRINT. - Collect Sublog - Collect information on conditions to reproduce the error - Obtain user`s print data (binary data) |

| Error code: | A5-nn |

| Description: | System error |

| Causes: | System error |

| Remedy: | - Turn OFF and then ON the main power. If the error persists, obtain the following information and contact the department in charge of quality management. - Output STATUS PRINT/P-PRINT. - Collect Sublog - Collect information on conditions to reproduce the error - Obtain user`s print data (binary data) |

| Error code: | A7-nn |

| Description: | System error |

| Causes: | System error |

| Remedy: | - Turn OFF and then ON the main power. If the error persists, obtain the following information and contact the department in charge of quality management. - Output STATUS PRINT/P-PRINT. - Collect Sublog - Collect information on conditions to reproduce the error - Obtain user`s print data (binary data) |

| Error code: | D0-nn |

| Description: | System error |

| Causes: | System error |

| Remedy: | - Turn OFF and then ON the main power. If the error persists, obtain the following information and contact the department in charge of quality management. - Output STATUS PRINT/P-PRINT. - Collect Sublog - Collect information on conditions to reproduce the error - Obtain user`s print data (binary data) |

| Error code: | D7-nn |

| Description: | System error |

| Causes: | System error |

| Remedy: | - Turn OFF and then ON the main power. If the error persists, obtain the following information and contact the department in charge of quality management. - Output STATUS PRINT/P-PRINT. - Collect Sublog - Collect information on conditions to reproduce the error - Obtain user`s print data (binary data) |

| Error code: | D8-nn |

| Description: | System error |

| Causes: | System error |

| Remedy: | - Turn OFF and then ON the main power. If the error persists, obtain the following information and contact the department in charge of quality management. - Output STATUS PRINT/P-PRINT. - Collect Sublog - Collect information on conditions to reproduce the error - Obtain user`s print data (binary data) |

| Error code: | D9-nn |

| Description: | System error |

| Causes: | System error |

| Remedy: | - Turn OFF and then ON the main power. If the error persists, obtain the following information and contact the department in charge of quality management. - Output STATUS PRINT/P-PRINT. - Collect Sublog - Collect information on conditions to reproduce the error - Obtain user`s print data (binary data) |

| Error code: | E000-0000 |

| Description: | Startup error The temperature detected by the main or sub thermistor does not rise to the specified value during startup control. |

| Causes: | The detection temperature of the main thermistor did not increase after start of the power distribution to the heater. |

| Remedy: | - Check the fixing film connector. - Replace the fixing film unit. - Replace the DC controller PCB. |

| Error code: | E001-0000 |

| Description: | Abnormally high temperature (detected by main thermistor) The main thermistor detected an abnormally high temperature 235 deg C) during temperature control |

| Causes: | The main thermistor detected a temperature of higher than 255 degree C. |

| Remedy: | - Check the connector of the fixing film unit. - Replace the fixing film unit. - Replace the DC controller PCB. |

| Error code: | E001-0001 |

| Description: | Abnormally high temperature (detected by sub thermistor) The sub thermistor detected an abnormally high temperature (300 deg C) during temperature control. |

| Causes: | The sub thermistor detected a temperature of higher than 290 degree C. |

| Remedy: | - Check the connector of the fixing film unit. - Replace the fixing film unit. - Replace the DC controller PCB. |

| Error code: | E003-0000 |

| Description: | Abnormally low temperature (detected by main thermistor) After the temperature detected by the main thermistor has reached the specified value, it does not reach the specified value during initial rotation. |

| Causes: | The main thermistor detected a temperature of lower than 120 degree C for more than 1 second when 20 seconds elapsed after start of the power distribution to the heater. |

| Remedy: | - Check the connector of the fixing film unit. - Replace the fixing film unit. - Replace the DC controller PCB. |

| Error code: | E003-0001 |

| Description: | Abnormally low temperature (detected by sub thermistor) After the temperature detected by the sub thermistor has reached the specified value, it does not reach the specified value during initial rotation. |

| Causes: | The sub thermistor detected a temperature of lower than 80 degree C for more than 2 seconds when 20 seconds elapsed after start of the power distribution to the heater. |

| Remedy: | - Check the connector of the fixing film unit. - Replace the fixing film unit. - Replace the DC controller PCB. |

| Error code: | E004-0000 |

| Description: | Fixing power supply drive circuit error |

| Causes: | 43 to 57Hz could not be detected continuously for more than 5 seconds when zero cross detection started. |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Replace the DC Controller Board. (2) Replace the Fixing Assembly. |

| Error code: | E004-0004 |

| Description: | Mismatch of Fixing Assembly type |

| Causes: | A fixing assembly of another product was installed. |

| Remedy: | 1. Replace the fixing assembly with that of this product. |

| Error code: | E012-0000 |

| Description: | Error in ITB motor activation. |

| Causes: | The cycle of ITB motor speed detection signal does not move in the specified cycle after ITB motor drive is started. Cause Failure in ITB motor, failure in DC controller PCB |

| Remedy: | - Check the connectors of ITB motor and DC controller PCB - Replace the ITB motor - Replace the DC controller PCB |

| Error code: | E012-0001 |

| Description: | Error in ITB motor activation. |

| Causes: | If the ITB motor speed detection signal comes off the specified cycle after it turned once to the specified cycle. Cause Failure in ITB motor, failure in DC controller PCB. |

| Remedy: | - Check the connectors of ITB motor and DC controller PCB - Replace the ITB motor - Replace the DC controller PCB |

| Error code: | E012-0008 |

| Description: | ITB motor or drum motor failure |

| Causes: | Black drum motor error (Failure in drum motor initial operation) The target speed was not reached within a specified time after startup of the motor. |

| Remedy: | Check the contact of the connector between the drum motor (J515) and the DC controller PCB (J81). Replace the drum motor. Replace the main drive assembly. |

| Error code: | E012-0009 |

| Description: | ITB motor or drum motor failure |

| Causes: | Black drum motor error (Failure in drum motor rotation) The motor rotated out of the target speed during rotation after the target speed was reached. |

| Remedy: | Check the contact of the connector between the drum motor (J515) and the DC controller PCB (J81). Replace the drum motor. Replace the main drive assembly. |

| Error code: | E014-0000 |

| Description: | Fixing motor failure |

| Causes: | Fixing motor startup error The target speed was not reached within a specified time after startup of the motor. |

| Remedy: | Check the contact of the connector between the fixing motor (J516) and the DC controller PCB (J81). Check the gear between the fixing motor and the fixing assembly. Replace the fixing motor. |

| Error code: | E014-0001 |

| Description: | Fixing motor failure |

| Causes: | Fixing motor rotation error The motor rotated out of the target speed during rotation after the target speed was reached. |

| Remedy: | Check the contact of the connector between the fixing motor (J516) and the DC controller PCB (J81). Check the gear between the fixing motor and the fixing assembly. Replace the fixing motor. |

| Error code: | E015-0001 |

| Description: | Cassette 1 lift up motor error |

| Causes: | Cassette 1 lift up motor error |

| Remedy: | Reconnect the connector J151 on the DC controller PCB and the relay connector J742. Check the cassette media stack surface sensor in the sensor monitor mode. If a failure is found, replace the lifter drive unit. Replace the lifter drive unit. |

| Error code: | E015-0002 |

| Description: | Cassette 2 lift up motor error |

| Causes: | Cassette 2 lift up motor error |

| Remedy: | Reconnect the connector J2003 on the paper feeder driver PCB and the relay connector J702. Check the paper feeder media stack surface sensor in the sensor monitor mode. If a failure is found, replace the pickup unit. Reconnect the connector J2006 on the paper feeder driver PCB. Replace the lifter drive unit. |

| Error code: | E015-0003 |

| Description: | Cassette 3 lift-up error |

| Causes: | After lift-up of the Lifting Plate of the second casstte of the Paper Feeder started, ON status of the Paper Surface Sensor of the second casstte of the Paper Feeder was not detected within the specified period of time. |

| Remedy: | 1. Turn ON the power with the cassette of the Paper Feeder removed, insert the cassette, and then check the operation sound of the Lifter Motor. When there is operation sound of the Lifter Motor, check if the Lifting Plate has been lifted up. <When the Lifting Plate has been lifted up> 1. Check the harness/connector between the Paper Feeder Controller PCB and the Paper Surface Sensor of the Paper Feeder. 2. Replace the Paper Feeder Controller PCB. 3. Replace the DC Controller PCB. <When the Lifting Plate has not been lifted up> 1. Check the condition of the gear of the Paper Feeder (missing teeth, swing). 2. Check the harness/connector between the Paper Feeder Controller PCB and the PF Lifter mater. 3. Replace the Drive Unit (included the Lifter Motor). <When there is no operation sound of the motor> 1. Check the harness/connector between the Paper Feeder Controller PCB and the PF Lifter Motor of the Paper Feeder Unit. 2. Replace the Cassette Feeder Controller PCB. 3. Replace the DC Controller PCB. |

| Error code: | E015-0004 |

| Description: | Cassette 4 lift-up error |

| Causes: | After lift-up of the Lifting Plate of the third casstte of the Paper Feeder started, ON status of the Paper Surface Sensor of the third casstte of the Paper Feeder was not detected within the specified period of time. |

| Remedy: | 1. Turn ON the power with the cassette of the Paper Feeder removed, insert the cassette, and then check the operation sound of the Lifter Motor. When there is operation sound of the Lifter Motor, check if the Lifting Plate has been lifted up. <When the Lifting Plate has been lifted up> 1. Check the harness/connector between the Paper Feeder Controller PCB and the Paper Surface Sensor of the Paper Feeder. 2. Replace the Paper Feeder Controller PCB. 3. Replace the DC Controller PCB. <When the Lifting Plate has not been lifted up> 1. Check the condition of the gear of the Paper Feeder (missing teeth, swing). 2. Check the harness/connector between the Paper Feeder Controller PCB and the PF Lifter mater. 3. Replace the Drive Unit (included the Lifter Motor). <When there is no operation sound of the motor> 1. Check the harness/connector between the Paper Feeder Controller PCB and the PF Lifter Motor of the Paper Feeder Unit. 2. Replace the Cassette Feeder Controller PCB. 3. Replace the DC Controller PCB. |

| Error code: | E015-0005 |

| Description: | Cassette 5 lift-up error |

| Causes: | Cassette 5 Lifter Motor error |

| Remedy: | 1. Check the Cassette 5 Lifter Motor (dropout, gear tooth jump, etc.). 2. Check the connector between the Cassette 5 Lifter Motor and the Cassette 5 Driver PCB. 3. Replace the Cassette 5 Lifter Motor. 4. Replace the Cassette 5 Driver PCB. |

| Error code: | E066-0000 |

| Description: | Environment sensor failure |

| Causes: | Environment sensor failure |

| Remedy: | Replace the environment sensor. |

| Error code: | E100-0000 |

| Description: | BD detection PCB failure The BD detection PCB is faulty. |

| Causes: | Yellow optical assembly failure |

| Remedy: | - Check the connector of the BD detection PCB. - Replace the laser scanner unit. - Replace the DC controller PCB. |

| Error code: | E100-0001 |

| Description: | Error detection on any of scanner motor, laser unit, and BD detection at scanner area. |

| Causes: | Magenta optical assembly failure |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Replace the Laser Scanner Unit. (2) Replace the DC Controller Board. |

| Error code: | E110-0000 |

| Description: | Optical assembly error (Scanner motor) |

| Causes: | Optical assembly error (Scanner motor initial operation failure) |

| Remedy: | Check the contact of the connector between the laser scanner unit and the DC controller. Replace the laser scanner unit. |

| Error code: | E196-0001 |

| Description: | Image processor PCB failure Error on writing and readout ROM of image processor PCB (mainn ROM). |

| Causes: | D-con update for the optional cassette is not completed. |

| Remedy: | - Putting the switch on/off of the power supply. - Replace the image processor PCB. |

| Error code: | E196-0002 |

| Description: | Image processor PCB failure Error on writing and readout ROM of image processor PCB (option ROM). |

| Causes: | Can not access to DC controller NVRAM Cause Failure in DC controller PCB |

| Remedy: | - Putting the switch on/off of the power supply. - Replace the image processor PCB. |

| Error code: | E196-0003 |

| Description: | Detection of noncompatible DC Controller |

| Causes: | DC Controller firmware of another model was detected. |

| Remedy: | 1. Replace the DC Controller with that of this model. 2. Update firmware. |

| Error code: | E245 |

| Description: | System Error |

| Causes: | System Error |

| Remedy: | Contact the sales companies. |

| Error code: | E245-1011 |

| Description: | System error |

| Causes: | System error |

| Remedy: | Contact the sales company. |

| Error code: | E246 |

| Description: | System Error |

| Causes: | System Error |

| Remedy: | Contact the sales companies. |

| Error code: | E247 |

| Description: | System Error |

| Causes: | System Error |

| Remedy: | Contact the sales companies. |

| Error code: | E350 |

| Description: | 4th drawer transport jam (paper not reaching 2nd drawer transport sensor): Paper which has passed the 3rd drawer / Tandem LCF transport sensor does not reach the 2nd drawer transport sensor during the feeding at the 4th drawer. |

| Causes: | 3rd drawer transport clutch 2nd drawer transport sensor Feed motor PFC board Rollers |

| Remedy: | Open the feed cover. Is there paper in front of the 2nd drawer transport sensor? ↓ → YES → If the paper is damaged, remove the paper and check the followings 1. Check if the paper is skewed, and correct it if it is skewed. 2. Check the paper amount. 3. Check if the paper is not the one with printing on its back side. 4. Check if the width of the side guides of the drawer is too narrow. NO Is the 2nd drawer transport sensor working? (Perform the input check in the test mode: 03-[FAX]OFF/[2]/[C] ↓ → NO → 1. Check if the connector of the 2nd drawer transport sensor is disconnected. 2. Check if the connector CN329 on the LGC board is disconnected. 3. Check if the connector pins are disconnected and the harnesses are open circuited. 4. Check if the conductor pattern on the LGC board is short circuited or open circuited. 5. Replace the 2nd drawer transport sensor. 6. Replace the LGC board. YES Are the transport clutches working? (Perform the output check in the test mode: 03-210/225/231) ↓ → NO → 1. Check if the connectors of the (lower/middle) transport clutches are disconnected. 2. Check if the connector CN329,350 on the LGC board is disconnected. 3. Check if the connector pins are disconnected and the harnesses are open circuited. 4. Check if the conductor pattern on the LGC board is short circuited or open circuited. 5. Replace the (lower/middle) transport clutches. 6. Replace the LGC board. YES 1. Check the condition of the feed roller, separation roller and pickup roller of each paper source, and clean or replace them. 2. Check the transport roller. Clean or replace it. |

| Error code: | E354 |

| Description: | Vsg problem. Same as E353 |

| Causes: | System Error |

| Remedy: | Contact the sales companies. |

| Error code: | E355 |

| Description: | Toner density sensor problem |

| Causes: | System Error |

| Remedy: | Contact the sales companies. |

| Error code: | E602-0001 |

| Description: | HDD error |

| Causes: | Lack of the HDD capacity The capacity of the HDD installed is smaller than that of the HDD used in the software. |

| Error code: | E602-0002 |

| Description: | HDD error |

| Causes: | Bootable load failure A Bootable CD was not contained. A Bootable CD was damaged. |

| Remedy: | Burn the Bootable CD again. |

| Error code: | E602-0003 |

| Description: | HDD error |

| Causes: | HDD access error An error occurred caused by the device or hardware when accessing to the HDD during execution of bootrom. (Damage to the sector / Busy device status, etc.) |

| Remedy: | Turn on the power again. |

| Error code: | E602-0006 |

| Description: | HDD error |

| Causes: | SubBootable load failure A SubBootable CD was not contained. A SubBootable CD was damaged. |

| Remedy: | Burn the SubBootable CD again. |

| Error code: | E602-0007 |

| Description: | HDD error |

| Causes: | The contents (ICC-Profile, etc.) could not be detected. (The contents were not contained. The contents were damaged, etc.) |

| Remedy: | Burn the Bootable CD again. |

| Error code: | E602-0008 |

| Description: | E602-1102 to 1613 Only LBP7680Cx is supported. |

| Causes: | Alternative block of flash memory is almost depleted. |

| Remedy: | Perform the following procedure to replace the the Main Controller PCB and export/import user information. 1. Export user information from the flash memory of the old Main Controller PCB (before replacement). 2. Replace the Main Controller PCB. Import user information to the flash memory of the new Main Controller PCB (after replacement). |

| Error code: | E602-0009 |

| Description: | MEAP cannot be started. |

| Causes: | MEAP cannot be started due to an error caused by invalid power down. |

| Remedy: | 1. Select Function.gr > MEAP > MEAP FUNCTION = ON, and turn OFF and then ON the main power. * Since the installed MEAP application and its management information are all cleared after reboot, MEAP needs to be reinstalled. |

| Error code: | E602-1102 |

| Description: | E602-1102 to 1613 Only LBP7680Cx is supported. |

| Causes: | Error detection of file system (LBP7680Cx only) |

| Remedy: | Execute the following procedures. 1. Turn OFF and then ON the power. 2. Download the /APL_CDS firmware again by Updater. If E616-0001 occurs at restart after turning OFF and then ON the power, execute the following procedures. 1. Initialize MEAP area, and install MEAP application again. (Refer to the remedy for E616-0001.) 2. Download the /APL_CDS firmware again by Updater. |

| Error code: | E602-1112 |

| Description: | E602-1102 to 1613 Only LBP7680Cx is supported. |

| Causes: | Device access error (LBP7680Cx only) |

| Remedy: | Execute the following procedures. If E616- 0001 occurs after turning OFF and then ON the power (procedure 1), install MEAP application again by following the remedy for E616-0001 first. Then, execute the procedure 2. 1. Turn OFF and then ON the power. 2. Download the /APL_CDS firmware again by Updater. |

| Error code: | E602-1113 |

| Description: | E602-1102 to 1613 Only LBP7680Cx is supported. |

| Causes: | Device access error (LBP7680Cx only) |

| Remedy: | Execute the following procedures. If E616- 0001 occurs after turning OFF and then ON the power (procedure 1), install MEAP application again by following the remedy for E616-0001 first. Then, execute the procedure 2. 1. Turn OFF and then ON the power. 2. Download the /APL_CDS firmware again by Updater. |

| Error code: | E602-1302 |

| Description: | E602-1102 to 1613 Only LBP7680Cx is supported. |

| Causes: | File system initialization error (LBP7680Cx only) |

| Remedy: | Execute the following procedures. 1. Turn OFF and then ON the power. 2. Download the /APL_CDS firmware again by Updater. |

| Error code: | E602-1312 |

| Description: | E602-1102 to 1613 Only LBP7680Cx is supported. |

| Causes: | Device access error (LBP7680Cx only) |

| Remedy: | Execute the following procedures. 1. Turn OFF and then ON the power. 2. Download the /APL_CDS firmware again by Updater. |

| Error code: | E602-1313 |

| Description: | E602-1102 to 1613 Only LBP7680Cx is supported. |

| Causes: | Device access error (LBP7680Cx only) |

| Remedy: | Execute the following procedures. 1. Turn OFF and then ON the power. 2. Download the /APL_CDS firmware again by Updater. |

| Error code: | E602-1602 |

| Description: | E602-1102 to 1613 Only LBP7680Cx is supported. |

| Causes: | File system initialization error (LBP7680Cx only) |

| Remedy: | Execute the following procedures. 1. Turn OFF and then ON the power. 2. Download the /APL_CDS firmware again by Updater. |

| Error code: | E602-1612 |

| Description: | E602-1102 to 1613 Only LBP7680Cx is supported. |

| Causes: | Device access error (LBP7680Cx only) |

| Remedy: | Execute the following procedures. 1. Turn OFF and then ON the power. 2. Download the /APL_CDS firmware again by Updater. |

| Error code: | E602-1613 |

| Description: | E602-1102 to 1613 Only LBP7680Cx is supported. |

| Causes: | Device access error (LBP7680Cx only) |

| Remedy: | Execute the following procedures. 1. Turn OFF and then ON the power. 2. Download the /APL_CDS firmware again by Updater. |

| Error code: | E604-0000 |

| Description: | Memory error |

| Causes: | Lack of memory capacity |

| Remedy: | Check the memory capacity inserted to each slot. |

| Error code: | E604-0001 |

| Description: | Insufficient memory capacity |

| Causes: | Failed to allocate the memory required to start PDL. |

| Remedy: | - Remove and then install the additional memory. - Replace the additional memory with a correct one. - Turn OFF and then ON the power. - Replace the Controller PCB. |

| Error code: | E616-0001 |

| Description: | (LBP7680Cx only) |

| Causes: | MEAP application was deleted by auto recovery at restart after E602-11XX. |

| Remedy: | Initialize MEAP area in the flash memory with the following procedures, and install MEAP application again. 1. Initialize the MEAP area. Service Mode > FUNCTION GR. > MEAP > MEAP FUNCTION > ON 2. Install MEAP application again. |

| Error code: | E616-0002 |

| Description: | System error |

| Causes: | System error |

| Remedy: | 1. Execute Setup > Initialize Menu to initialize NVRAM. |

| Error code: | E730-100A |

| Description: | Printer service call |

| Error code: | E730-C000 |

| Description: | An error such as memory not acquired at initialization occurred. |

| Remedy: | Turn on the power again. |

| Error code: | E730-C001 |

| Description: | An error occurred when accessing the HDD. |

| Remedy: | Turn on the power again. |

| Error code: | E730-D000 |

| Description: | Printer service call |

| Causes: | An error, such as failure in memory retrieval at initialization, occurred. |

| Remedy: | - Turn OFF and then ON the power. - Replace the Main Controller PCB. |

| Error code: | E730-D001 |

| Description: | Printer service call |

| Causes: | Printer communication error (communication error at initial communication and negotiation packet error) |

| Remedy: | Only LBP7680Cx is supported. |

| Error code: | E733-0001 |

| Description: | Printer communication error (Invalid communication after communication is established, Parity error) |

| Remedy: | Turn on the power again. Replace the DC controller PCB. |

| Error code: | E733-0004 |

| Description: | Printer communication error (Undefined command error) |

| Remedy: | Turn on the power again. Replace the DC controller PCB. |

| Error code: | E733-0006 |

| Description: | Printer communication error (Unknown communication error) |

| Remedy: | Turn on the power again. Replace the DC controller PCB. |

| Error code: | E740-0002 |

| Description: | Error detection on either Network Board or Mac address |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Check the connection of the network cable. (2) Replace the Main Controller Board. |

| Error code: | E740-0004 |

| Description: | LAN controller chip access error |

| Remedy: | 1.Check the area around the LAN chip. 2.Replace the board. |

| Error code: | E744-0800 |

| Description: | Model code mismatch |

| Remedy: | Replace Soft-ID PCB. |

| Error code: | E744-0900 |

| Description: | Model code mismatch |

| Remedy: | Change to proper bootable |

| Error code: | E744-1000 |

| Description: | Mismatch of the series or model of the firmware sent at the time of downloading |

| Remedy: | Check the supported series or model of the firmware, and burn the correct series or model of firmware. |

| Error code: | E744-1100 |

| Description: | Model code mismatch |

| Causes: | Detection of falsification of the Controller Board |

| Remedy: | - Turn OFF and then ON the power. - Replace the Main Controller PCB. |

| Error code: | E748-2012 |

| Description: | Failed to rewrite due to no more alternative block of Flash ROM (NAND) available. |

| Error code: | E760-0000 |

| Description: | CPU exception occurred. |

| Remedy: | Turn on the power again. |

| Error code: | E805-0001 |

| Description: | Error in duplex cooling fan |

| Causes: | Fan 1 failure |

| Error code: | E805-0002 |

| Description: | Fan Motor 2 error |

| Causes: | The Sub Fan fails to rotate at the specified rotation speed. |

| Remedy: | 1. Check the connection of the Sub Fan. 2. Replace the Sub Fan. |

| Error code: | E805-0008 |

| Description: | Fan 4 failure |

| Causes: | Fan 4 failure |

| Remedy: | 1. Check the connection of the Fan 4. 2. Replace the Fan 4. 3. Replace the DC Controller PCB. |

| Error code: | E805-0009 |

| Description: | Fan 2 failure |

| Causes: | Fan 2 failure |

| Remedy: | 1. Check the connection of the Fan 2. 2. Replace the Fan 2. 3. Replace the DC Controller PCB. |

| Error code: | E805-0010 |

| Description: | Duplex Fan failure |

| Causes: | Duplex Fan failure |

| Remedy: | 1. Check the connection of the Duplex Fan. 2. Replace the Duplex Fan. 3. Replace the DC Controller PCB. |

| Error code: | E808-0001 |

| Description: | Fixing Assembly_Edge Left Cooling Fan error |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Replace the Edge Left Cooling Fan. (2) Replace the DC Controller Board. |

| Error code: | E840-0000 |

| Description: | Pressure release mechanism failure |

| Causes: | The target pressure position was not reached even when 3.5 seconds (approximately 1.5 rotation of the cam) elapsed after start of the fixing motor reverse rotation. |

| Remedy: | Check the gears and detection flags related to fixing pressure release mechanism. Replace the fixing pressure release sensor (PS9). Replace the fixing motor. Replace the fixing assembly. |

| Error code: | F9-nn |

| Description: | System error |

| Causes: | Communication error between the Main Controller and the Control Panel |

| Remedy: | - Check for any poor contact/open circuit of the connector between the Main Controller and the Control Panel. If there is no problem with the connector but the error persists, obtain the following information and contact the department in charge of quality management. - Output STATUS PRINT/P-PRINT. - Collect Sublog - Collect information on conditions to reproduce the error |