HP LaserJet Enterprise 700 M725f

Рейтинг

Актуальный

Актуальный

Тип устройства

МФУ

Технология печати

лазерная

Макс. формат

A3

Число страниц в месяц

200000

Скорость печати

A4

41

Цветность печати

черно-белая

Общие характеристики |

|

|---|---|

Цветность печати |

|

Технология печати |

лазерная |

Тип |

лазерный/светодиодный |

Телефон |

|

Печать фотографий |

|

Размещение |

напольный |

Область применения |

большой офис |

Макс. формат |

A3 |

Число страниц в месяц |

200 000 |

Тип устройства |

МФУ |

Факс |

|

Сканер |

|

Копир |

|

Принтер |

|

Пигментные чернила |

|

Печать без полей |

|

Прямая печать |

|

Двусторонняя печать |

|

Макс, разрешение для ч/б печати |

|

| По X | 1 200 |

| По Y | 1 200 |

Скорость ч/б печати |

|

| A4 | 41 |

Время выхода первого отпечатка |

|

| Ч/б | 10 |

Копир |

|

Макс, количество копий за цикл |

9 999 |

Значение масштаба |

|

| Максимальное | 4 |

| Минимальное | 0,25 |

Макс, разрешение (ч/б) |

|

| По Y | 600 |

| По X | 600 |

| По X | 300 |

| По Y | 300 |

Сканер |

|

Емкость устройства автоподачи оригиналов |

100 |

Глубина цвета |

24 бит |

Тип сканера |

планшетный/протяжный |

Отправка изображения по e-mail |

|

Устройство автоподачи оригиналов |

двустороннее |

Слайд-адаптер |

|

Макс. формат оригинала |

A4 |

Макс, размер сканирования |

|

| По Y | 420 |

| По X | 297 |

Разрешение сканера |

|

| По Х | 600 |

Скорость сканирования |

|

| Ч/б | 50 |

| Цветн, | 30 |

Расходные материалы |

|

Количество картриджей |

1 |

Ресурс ч/б картриджа/тонера |

10 000 |

Печать на: |

|

| Глянцевой бумаге |

|

| Этикетках |

|

| Карточках |

|

| Пленках |

|

| Конвертах |

|

| Матовой бумаге |

|

| Фотобумаге |

|

| CD/DVD |

|

| Рулоне |

|

Плотность бумаги |

|

| Минимальная | 60 |

| Максимальная | 199 |

Факс |

|

Память |

100 |

PC Fax |

|

Макс, скорость передачи данных |

33,6 Кбит/с |

Цветной |

|

Телефон |

|

Стандарт DECT |

|

Проводная трубка |

|

Автоответчик |

|

Caller ID |

|

АОН |

|

Беспроводная трубка |

|

Спикерфон |

|

Языки управления |

|

| PCL 5e |

|

| PostScript |

|

| PostScript 3 |

|

| PCL 6 |

|

|

|

|

| PCL 5c |

|

| PostScript 2 |

|

| PPDS |

|

Лотки |

|

Емкость лотка ручной подачи |

100 |

Подача бумаги |

|

| Максимальная | 4 100 |

| Стандартная | 1 600 |

Вывод бумаги |

|

| Стандартный | 250 |

Финишер |

|

Сортер |

|

Брошюровщик |

|

Степлер |

|

Интерфейсы |

|

AirPrint |

|

Веб-интерфейс |

|

USB |

|

Ethernet (RJ-45) |

|

Поддержка iOS |

|

Версия USB |

2,0 |

FireWire (IEEE 1394) |

|

Bluetooth |

|

LPT |

|

Инфракрасный порт |

|

RS-232 |

|

Устройство для чтения карт памяти |

|

Wi-Fi |

|

Память/Процессор |

|

Объем памяти |

1 024 |

Частота процессора |

800 |

Емкость жесткого диска |

320 |

Макс, объем памяти |

1 536 |

Дополнительная информация |

|

Диагональ дисплея |

8,07 |

Работа от аккумулятора |

|

Экран |

|

Поддержка ОС |

|

| Mac OS |

|

| Windows |

|

| Linux |

|

| DOS |

|

Потребляемая мощность |

|

| В режиме ожидания | 39 |

| При работе | 890 |

Габариты |

|

Высота |

1 160 |

Вес |

87,1 |

Глубина |

681 |

Ширина |

745 |

Модули

Internal components (4 of 4)

Document feeder, control panel, and scanner whole units

500-sheet paper feeder (Tray 4) covers

Scanner controller board (SCB)

Document feeder assemblies

Stapler/stacker components

500-sheet paper feeder (Tray 4) components

HCI components (2 of 2)

HCI covers

Stapler/stacker covers

3x500 paper deck components

Internal components (2 of 4)

1x500 and 3x500 paper deck covers

Internal components (1 of 4)

Internal components (3 of 4)

External covers and panels

HCI components (1 of 2)

1x500 paper deck components

Scanner assemblies

Детали Scanner controller board (SCB)

| Деталь: | CABLE, FLEXIBLE FLAT, 21P |

| Парткод: | RK2-4490-000CN |

| Деталь: | CABLE, FLEXIBLE FLAT, 23P |

| Парткод: | RK2-4492-000CN |

| Деталь: | Cable, flexible flat, 25P |

| Парткод: | RK2-4494-000CN |

| Деталь: | Cable, flexible flat, 15P |

| Парткод: | RK2-4496-000CN |

| Деталь: | DC controller PCA |

| Парткод: | RM1-8934-000CN |

| Деталь: | FAN |

| Парткод: | RK2-2416-000CN |

| Цена: | 1 000 ₽ |

| Деталь: | Formatter cage |

| Парткод: | RM1-8682-000CN |

| Деталь: | Low-voltage power supply (110V) |

| Парткод: | RM1-8744-000CN |

| Деталь: | Low-voltage power supply (220V) |

| Парткод: | RM1-8745-000CN |

| Деталь: | High-voltage power supply (110V) |

| Парткод: | RM2-7538-000CN |

| Деталь: | High-voltage power supply (220V) |

| Парткод: | RM2-7539-000CN |

| Деталь: | Switch, fuser (left) door |

| Парткод: | RM1-3474-000CN |

| Деталь: | Switch, cartridge door |

| Парткод: | RM1-3471-000CN |

| Деталь: | Kit, ADF whole unit, A3 (includes foam reflector kit) |

| Парткод: | CF066-67910 |

| Деталь: | Kit, control panel |

| Парткод: | CD644-67916 |

| Деталь: | Kit, scanner whole unit (includes foam reflector kit) |

| Парткод: | CF066-67906 |

| Деталь: | Kit, reflector foam, A3 |

| Парткод: | 5851-4888 |

| Деталь: | Optional 500-sheet tray and feeder assembly kit |

| Парткод: | CF235-67914 |

| Деталь: | Handle, lock, rear |

| Парткод: | RC2-9303-000CN |

| Деталь: | COVER, RIGHT FRONT |

| Парткод: | RC2-9320-000CN |

| Деталь: | Link, right door, lower |

| Парткод: | RC2-9327-000CN |

| Деталь: | COVER, REAR |

| Парткод: | RC2-9330-000CN |

| Деталь: | COVER, LEFT |

| Парткод: | RC2-9331-000CN |

| Деталь: | Cover, handle lower |

| Парткод: | RC2-9332-000CN |

| Деталь: | Link, right door, upper |

| Парткод: | RC2-9335-000CN |

| Деталь: | RIGHT DOOR ASSEMBLY |

| Парткод: | RM1-6946-000CN |

| Деталь: | Right lower cover assembly |

| Парткод: | RM1-6948-000CN |

| Деталь: | FRONT UPPER COVER ASSEMBLY |

| Парткод: | RM1-6949-000CN |

| Деталь: | SCB, top Level Assembly |

| Парткод: | CF066-67911 |

| Деталь: | Kit, ADF separation pad spring |

| Парткод: | 5851-4879 |

| Цена: | 2 500 ₽ |

| Деталь: | ADF roller cover, A3 |

| Парткод: | CQ819-40032 |

| Деталь: | ADF hinge assembly |

| Парткод: | CQ819-60011 |

| Деталь: | Cover, ADF rear |

| Парткод: | CQ819-40005 |

| Деталь: | Cover, ADF front |

| Парткод: | CQ819-40003 |

| Деталь: | Cover, hatch |

| Парткод: | CQ819-40004 |

| Деталь: | ADF tray extender |

| Парткод: | Q7404-40020 |

| Деталь: | Kit, ADF whole unit, A3 (includes foam reflector kit) |

| Парткод: | CF066-67910 |

| Деталь: | PHOTOSENSOR |

| Парткод: | CC355-80014 |

| Деталь: | Width sensor PCA |

| Парткод: | CQ819-60022 |

| Деталь: | Media Stopper, Front |

| Парткод: | CC355-40046 |

| Деталь: | Media Stopper, rear |

| Парткод: | CC355-40047 |

| Деталь: | Kit, A3 ADF mylar |

| Парткод: | 5851-4997 |

| Деталь: | Flag, media presence |

| Парткод: | CC355-40015 |

| Деталь: | Stapler assembly |

| Парткод: | RM1-3092-000CN |

| Деталь: | Alignment assembly |

| Парткод: | RM1-8810-000CN |

| Деталь: | PAPER FEED ASSEMBLY |

| Парткод: | RM1-8826-000CN |

| Деталь: | Stapler/stacker controller PCA |

| Парткод: | RM1-9078-000CN |

| Деталь: | Switch, button |

| Парткод: | WC2-5512-000CN |

| Деталь: | MOTOR, STEPPING, DC |

| Парткод: | RK2-1331-000CN |

| Цена: | 2 500 ₽ |

| Деталь: | LIFTER DRIVE ASSEMBLY |

| Парткод: | RM1-3819-000CN |

| Деталь: | Cassette assembly kit, with Trays 2-6 label kit |

| Парткод: | CF235-67917 |

| Деталь: | Paper pickup assembly |

| Парткод: | RM1-9415-000CN |

| Деталь: | Paper feeder controller PCA |

| Парткод: | RM1-9074-000CN |

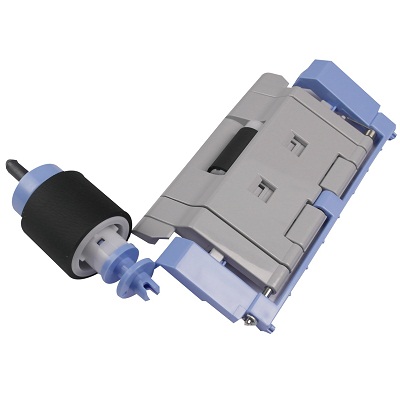

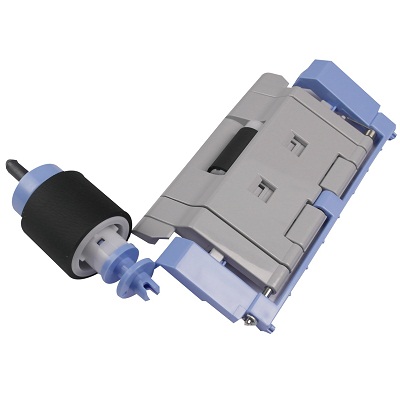

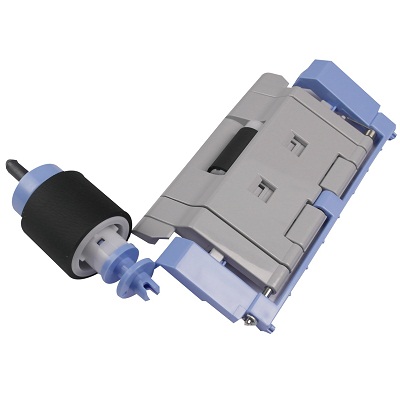

| Деталь: | Roller, pickup (part of Trays 4, 5 and 6 pickup and feed roller kit) |

| Парткод: | CC522-67909 |

| Деталь: | Paper feed roller assembly (part of Trays 4,5 and 6 pickup and feed roller kit) |

| Парткод: | CC522-67909 |

| Деталь: | Labels, cassette numbers, Trays 2-6 |

| Парткод: | 5851-5600 |

| Деталь: | Connector, 8P |

| Парткод: | VS1-7514-008CN |

| Деталь: | Connector, 8P |

| Парткод: | VS1-7500-008CN |

| Деталь: | Labels, cassette numbers, Trays 2-6 |

| Парткод: | 5851-5600 |

| Деталь: | Roller, paper pickup (part of HCI pickup and feed roller kit) |

| Парткод: | 5851-5011 |

| Деталь: | Paper feed roller assembly (part of HCI pickup and feed roller kit) |

| Парткод: | 5851-5011 |

| Деталь: | Paper pickup assembly, right |

| Парткод: | RM1-8869-000CN |

| Деталь: | Paper pickup assembly, left |

| Парткод: | RM1-8876-000CN |

| Деталь: | Crossing paper feed assembly |

| Парткод: | RM1-8888-000CN |

| Деталь: | Tray, right assembly kit, with Trays 2-6 tray label kit |

| Парткод: | CF235-60104 |

| Деталь: | Tray, left assembly kit, with Trays 2-6 tray label kit |

| Парткод: | CF235-60103 |

| Деталь: | Auto close assembly |

| Парткод: | RM1-8880-000CN |

| Деталь: | 3,500-sheet HCI feeder assembly kit |

| Парткод: | CC235-67918 |

| Деталь: | Cover, right center |

| Парткод: | RC3-3000-000CN |

| Деталь: | COVER, RIGHT LOWER |

| Парткод: | RC3-3001-000CN |

| Деталь: | COVER, RIGHT REAR |

| Парткод: | RC3-3002-000CN |

| Деталь: | COVER, REAR |

| Парткод: | RC3-3003-000CN |

| Деталь: | COVER, REAR LOWER |

| Парткод: | RC3-3004-000CN |

| Деталь: | COVER, LEFT |

| Парткод: | RC3-3005-000CN |

| Деталь: | COVER, LEFT LOWER |

| Парткод: | RC3-3006-000CN |

| Деталь: | COVER, CORNER, RIGHT |

| Парткод: | RC3-3009-000CN |

| Деталь: | RIGHT DOOR ASSEMBLY |

| Парткод: | RM1-8868-000CN |

| Деталь: | Right front lock cover assembly |

| Парткод: | RM1-9416-000CN |

| Деталь: | COVER, LEFT |

| Парткод: | RC3-2343-000CN |

| Деталь: | DOOR, LEFT |

| Парткод: | RC3-2344-000CN |

| Деталь: | COVER, REAR LEFT |

| Парткод: | RC3-2346-000CN |

| Деталь: | COVER, REAR RIGHT |

| Парткод: | RC3-2347-000CN |

| Деталь: | Cover, rear inner |

| Парткод: | RC3-2348-000CN |

| Деталь: | Cover, stack |

| Парткод: | RC3-2354-000CN |

| Деталь: | Cover, jog, top |

| Парткод: | RC3-2364-000CN |

| Деталь: | REAR COVER ASSEMBLY |

| Парткод: | RM1-8812-000CN |

| Деталь: | Stapler cover assembly |

| Парткод: | RM1-8813-000CN |

| Деталь: | Stapler door assembly |

| Парткод: | RM1-8814-000CN |

| Деталь: | Tray assembly |

| Парткод: | RM1-8815-000CN |

| Деталь: | MOTOR, STEPPING, DC |

| Парткод: | RK2-1331-000CN |

| Цена: | 2 500 ₽ |

| Деталь: | RAIL, CASSETTE, RIGHT |

| Парткод: | RL1-1390-000CN |

| Деталь: | RAIL, CASSETTE, LEFT |

| Парткод: | RL1-1391-000CN |

| Деталь: | Cable, paper pickup option |

| Парткод: | RM1-3575-000CN |

| Деталь: | CABLE, MULTI SENSOR |

| Парткод: | RM1-3647-000CN |

| Деталь: | Cable, door open switch |

| Парткод: | RM1-3651-000CN |

| Деталь: | LIFTER DRIVE ASSEMBLY |

| Парткод: | RM1-3819-000CN |

| Деталь: | Cassette assembly kit, with Trays 2-6 label kit |

| Парткод: | CF235-67917 |

| Деталь: | Paper pickup assembly |

| Парткод: | RM1-9415-000CN |

| Деталь: | Controller PCA |

| Парткод: | RM1-9076-000CN |

| Деталь: | Cable, engine interface |

| Парткод: | RM1-6991-000CN |

| Деталь: | Cable, PCA joint |

| Парткод: | RM1-6992-000CN |

| Деталь: | Switch, button |

| Парткод: | WC2-5512-000CN |

| Деталь: | Roller, pickup (part of Trays 4,5 and 6 pickup and feed roller kit) |

| Парткод: | CC522-67909 |

| Деталь: | Paper feed roller assembly (part of Trays 4,5 and 6 pickup and feed roller kit) |

| Парткод: | CC522-67909 |

| Деталь: | Caster, double lock, front |

| Парткод: | RC1-9896-000CN |

| Деталь: | Caster, rear |

| Парткод: | RC3-2994-000CN |

| Деталь: | Connector, 8P |

| Парткод: | VS1-7500-008CN |

| Деталь: | Labels, cassette numbers, Trays 2-6 |

| Парткод: | 5851-5600 |

| Деталь: | FAN |

| Парткод: | RK2-1092-000CN |

| Деталь: | FAN |

| Парткод: | RK2-3244-000CN |

| Цена: | 5 100 ₽ |

| Деталь: | SENSOR, HUMIDITY |

| Парткод: | WP2-5316-000CN |

| Деталь: | CLUTCH, ELECTROMAGNETIC |

| Парткод: | RM1-8946-000CN |

| Деталь: | Lower cassette (Tray 3) pickup assembly |

| Парткод: | RM2-0183-000CN |

| Деталь: | Roller, cassette pickup (part of Tray 2 or 3 pickup roller and separation pad kit) |

| Парткод: | CF235-67909 |

| Деталь: | LASER SCANNER ASSEMBLY |

| Парткод: | RM1-8679-000CN |

| Деталь: | Cable, multi, front |

| Парткод: | RM1-8971-000CN |

| Деталь: | Cartridge door open switch |

| Парткод: | WC2-5637-000CN |

| Цена: | 340 ₽ |

| Деталь: | 1x500 feeder and stand assembly kit |

| Парткод: | CF235-67915 |

| Деталь: | 3x500 feeder and stand assembly kit |

| Парткод: | CF235-67916 |

| Деталь: | Handle, lock, rear |

| Парткод: | RC2-9303-000CN |

| Деталь: | Link, right door, lower |

| Парткод: | RC2-9327-000CN |

| Деталь: | Link, right door, upper |

| Парткод: | RC2-9335-000CN |

| Деталь: | Cover, right corner |

| Парткод: | RC2-9343-000CN |

| Деталь: | Cover, right lower, 1 |

| Парткод: | RC2-9346-000CN |

| Деталь: | Cover, right lower, 2 |

| Парткод: | RC2-9347-000CN |

| Деталь: | COVER, REAR |

| Парткод: | RC2-9348-000CN |

| Деталь: | COVER, LEFT |

| Парткод: | RC2-9349-000CN |

| Деталь: | COVER, LEFT LOWER |

| Парткод: | RC2-9350-000CN |

| Деталь: | COVER, REAR LOWER |

| Парткод: | RC2-9357-000CN |

| Деталь: | FRONT UPPER COVER ASSEMBLY |

| Парткод: | RM1-6949-000CN |

| Деталь: | Right door assembly (1x500 paper deck) |

| Парткод: | RM1-6952-000CN |

| Деталь: | Right door assembly (3x500 paper deck) |

| Парткод: | RM1-6953-000CN |

| Деталь: | Front lower cover assembly |

| Парткод: | RM1-6958-000CN |

| Деталь: | SCREW, STEPPED |

| Парткод: | RU5-9056-000CN |

| Деталь: | Door, stock, 1 (1x500 paper deck only) |

| Парткод: | RC2-9353-000CN |

| Деталь: | Door, stock, 2 (1x500 paper deck only) |

| Парткод: | RC2-9354-000CN |

| Деталь: | Upper cassette (Tray 2) pickup assembly |

| Парткод: | RM2-0182-000CN |

| Деталь: | Roller, cassette pickup (part of Tray 2 or 3 pickup roller and separation pad kit) |

| Парткод: | CF235-67909 |

| Деталь: | REGISTRATION ASSEMBLY |

| Парткод: | RM1-8671-000CN |

| Деталь: | PHOTOINTERRUPTER |

| Парткод: | WG8-5935-000CN |

| Цена: | 900 ₽ |

| Деталь: | MAIN DRIVE ASSEMBLY |

| Парткод: | RM2-0184-000CN |

| Деталь: | PAPER FEED ASSEMBLY |

| Парткод: | RM1-8741-000CN |

| Деталь: | CLUTCH, ELECTROMAGNETIC |

| Парткод: | RM1-8946-000CN |

| Деталь: | Transfer roller assembly kit |

| Парткод: | CF235-67910 |

| Деталь: | STOPPER, LINK |

| Парткод: | RC3-2212-000CN |

| Деталь: | SPRING, TENSION |

| Парткод: | RU5-2632-000CN |

| Деталь: | GEAR, 133T |

| Парткод: | RU7-0350-000CN |

| Деталь: | LIFTER DRIVE ASSEMBLY |

| Парткод: | RM1-2969-000CN |

| Цена: | 4 300 ₽ |

| Деталь: | Upper cassette (Tray 2) assembly kit |

| Парткод: | CF235-67911 |

| Деталь: | Separation pad assembly (part of Tray 2 or 3 pickup roller and separation pad kit) |

| Парткод: | CF235-67909 |

| Деталь: | Lower cassette (Tray 3) assembly kit |

| Парткод: | CF235-67912 |

| Деталь: | Fuser drive assembly |

| Парткод: | RM1-2963-000CN |

| Деталь: | Fuser motor assembly |

| Парткод: | RM1-2538-000CN |

| Цена: | 3 500 ₽ |

| Деталь: | Fuser assembly kit (110V) |

| Парткод: | CF235-67921 |

| Деталь: | Fuser assembly kit (220V) |

| Парткод: | CF235-67922 |

| Деталь: | Paper delivery assembly Kit |

| Парткод: | CF066-67909 |

| Деталь: | PHOTOINTERRUPTER |

| Парткод: | WG8-5935-000CN |

| Цена: | 900 ₽ |

| Деталь: | Power switch PCA |

| Парткод: | RM2-7561-000CN |

| Деталь: | Duplexer, optional accessory |

| Парткод: | CF235-67913 |

| Деталь: | Back end sensor |

| Парткод: | RM1-2968-000CN |

| Деталь: | Link, face down flapper 1 |

| Парткод: | RC3-2209-000CN |

| Деталь: | Link, face down flapper 2 |

| Парткод: | RC3-2210-000CN |

| Деталь: | Cover, front, right lower |

| Парткод: | RC3-2133-000CN |

| Деталь: | Cover, front, left lower |

| Парткод: | RC3-2134-000CN |

| Деталь: | COVER, REAR |

| Парткод: | RC3-2138-000CN |

| Деталь: | Cover, right side, rear |

| Парткод: | RC3-2148-000CN |

| Деталь: | Cover, right handle |

| Парткод: | RC3-2153-000CN |

| Деталь: | Cover, left side, front, lower |

| Парткод: | RC3-2154-000CN |

| Деталь: | Cover, left side, rear, lower |

| Парткод: | RC3-2155-000CN |

| Деталь: | Cover, left handle |

| Парткод: | RC3-2156-000CN |

| Деталь: | COVER, TOP, REAR |

| Парткод: | RC3-2159-000CN |

| Деталь: | Cover, output, top |

| Парткод: | RC3-2160-000CN |

| Деталь: | Cover, rear, top |

| Парткод: | RC3-2161-000CN |

| Деталь: | Cover, left side, front, upper |

| Парткод: | RC3-2163-000CN |

| Деталь: | Cover, left side, rear, upper |

| Парткод: | RC3-2164-000CN |

| Деталь: | COVER, LEFT, UPPER |

| Парткод: | RC3-2272-000CN |

| Деталь: | Cover, facedown side |

| Парткод: | RC3-2273-000CN |

| Деталь: | Facedown cover assembly |

| Парткод: | RM1-8654-000CN |

| Деталь: | Upper front cover assembly |

| Парткод: | RM1-8656-000CN |

| Деталь: | RIGHT DOOR ASSEMBLY |

| Парткод: | RM1-8657-000CN |

| Деталь: | Cartridge door assembly |

| Парткод: | RM1-8660-000CN |

| Деталь: | Roller, paper pickup, multipurpose tray (part of Tray 1 pickup roller and separation pad kit) |

| Парткод: | CF235-67906 |

| Деталь: | Multipurpose separation pad assembly (part of Tray 1 pickup roller and separation pad kit) |

| Парткод: | CF235-67906 |

| Деталь: | Multipurpose tray (Tray 1) cover assembly |

| Парткод: | RM1-8662-000CN |

| Деталь: | LEFT DOOR ASSEMBLY |

| Парткод: | RM1-8680-000CN |

| Деталь: | Front cover assembly kit (includes product labels) |

| Парткод: | CF235-67905 |

| Деталь: | Rear pocket cover assembly |

| Парткод: | RM1-9831-000CN |

| Деталь: | MOTOR, STEPPING, DC |

| Парткод: | RK2-1331-000CN |

| Цена: | 2 500 ₽ |

| Деталь: | LIFTER DRIVE ASSEMBLY |

| Парткод: | RM1-8879-000CN |

| Деталь: | Controller PCA |

| Парткод: | RM1-9057-000CN |

| Деталь: | Paper pickup motor assembly |

| Парткод: | RM1-8872-000CN |

| Деталь: | MOTOR, STEPPING, DC |

| Парткод: | RK2-1331-000CN |

| Цена: | 2 500 ₽ |

| Деталь: | RAIL, CASSETTE, RIGHT |

| Парткод: | RL1-1390-000CN |

| Деталь: | RAIL, CASSETTE, LEFT |

| Парткод: | RL1-1391-000CN |

| Деталь: | Cable, paper pickup option |

| Парткод: | RM1-3575-000CN |

| Деталь: | Cable, multisensor |

| Парткод: | RM1-3647-000CN |

| Деталь: | Stock box assembly |

| Парткод: | RM1-6954-000CN |

| Деталь: | LIFTER DRIVE ASSEMBLY |

| Парткод: | RM1-3819-000CN |

| Деталь: | Cassette assembly kit, with Trays 2-6 label kit |

| Парткод: | CF235-67917 |

| Деталь: | Paper pickup assembly |

| Парткод: | RM1-9415-000CN |

| Деталь: | Controller PCA |

| Парткод: | RM1-9075-000CN |

| Деталь: | Cable, engine interface |

| Парткод: | RM1-6991-000CN |

| Деталь: | Connector, 8P |

| Парткод: | VS1-7500-008CN |

| Деталь: | Labels, cassette numbers, Trays 2-6 |

| Парткод: | 5851-5600 |

| Деталь: | Roller, pickup (part of Trays 4,5 and 6 pickup and feed roller kit) |

| Парткод: | CC522-67909 |

| Деталь: | Paper feed roller assembly (part of Trays 4,5 and 6 pickup and feed roller kit) |

| Парткод: | CC522-67909 |

| Деталь: | Caster, double lock, front |

| Парткод: | RC1-9896-000CN |

| Деталь: | Caster, rear |

| Парткод: | RC3-2994-000CN |

| Деталь: | Cover, ADF cable |

| Парткод: | CC522-40023 |

| Деталь: | Cover, back scanner |

| Парткод: | CC522-40017 |

| Деталь: | Cover, right scanner |

| Парткод: | CF066-40002 |

| Деталь: | Cover, front scanner |

| Парткод: | CF066-40001 |

| Деталь: | Cover, left scanner |

| Парткод: | CC522-40021 |

| Деталь: | PCA, scanner memory |

| Парткод: | 5851-4285 |

| Деталь: | Flag, document feeder open sensor |

| Парткод: | CC522-40029 |

| Деталь: | Kit, scanner whole unit (includes foam reflector kit)1 |

| Парткод: | CF066-67906 |

| Деталь: | Spring, document feeder sensor |

| Парткод: | CC522-80101 |

| Деталь: | PHOTOSENSOR |

| Парткод: | 1990-3366 |

Коды ошибок

11.00.YY

13.80.A1

13.80.D1

13.80.FF

13.84.A1

13.84.FF

13.89.31

13.A4.D4

13.A4.D5

13.A4.D6

13.A4.FF

13.A5.D5

13.A5.D6

13.A5.FF

13.A6.D6

13.A6.FF

13.A7.D5

13.A7.D6

13.A7.FF

13.AA.EE

13.AB.EE

13.AC.EE

13.AD.EE

13.B2.AD

13.B2.D1

13.B2.D2

13.B2.D3

13.B2.DD

13.B2.DX

13.B2.FF

13.B4.FF

13.B9.AX

13.B9.CX

13.B9.DD

13.B9.FF

13.BA.EE

13.D1.DX

13.D1.FF

13.D3.00

13.D3.DX

13.D3.FF

13.DE.EE

13.E1.DX

13.E1.FF

13.E6.AX

13.E6.BD

13.E6.BX

13.E6.DX

13.E6.FF

13.EA.EE

13.FF.FF

13.WX.YZ

20.00.00

21.00.00

30.01.01

30.01.06

30.01.08

30.01.41

30.01.43

30.01.44

30.01.45

30.01.46

30.03.14

30.03.20

30.03.22

30.03.23

30.03.30

30.03.45

31.01.47

31.03.30

31.03.31

31.03.32

31.08.A1

31.08.A2

31.08.A3

31.13.01

31.13.02

31.13.13

31.13.14

31.13.15

32.1C.01

32.1C.02

32.1C.03

32.1C.04

32.1C.05

32.1C.06

32.1C.07

32.1C.08

32.1C.09

32.1C.0A

32.1C.0B

32.1C.0C

32.1C.0D

32.1C.0E

32.1C.11

32.1C.12

32.1C.13

32.1C.14

32.1C.17

32.1C.18

32.1C.19

32.1C.1A

32.1C.1B

32.1C.1C

32.1C.1E

32.1C.1F

32.1C.20

32.1C.21

32.1C.22

32.1C.23

32.1C.24

32.1C.25

32.1C.26

32.1C.27

32.1C.28

32.1C.29

32.1C.2B

32.1C.2E

32.1C.2F

32.21.00

33.01.01

33.01.02

33.01.03

33.01.04

33.01.05

33.02.01

33.02.02

33.02.03

33.03.01

33.03.02

33.WX.YZ

40.00.01

40.00.02

40.00.03

40.00.04

40.00.05

40.08.0X

40.0X.05

41.03.YZ

41.05.YZ

41.WX.YZ

47.00.00

47.00.XX

47.01.XX

47.02.XX

47.03.XX

47.04.XX

47.05.00

47.06.XX

49.XX.YY

50.1X.YZ

50.2X.YZ

50.3X.YZ

50.4X.YZ

50.6X.YZ

50.7X.YZ

50.8X.YZ

50.9X.YZ

50.AX.YZ

50.BX.YZ

51.00.10

51.00.19

51.00.20

52.00.00

52.00.20

52.04.00

52.05.00

54.00.03

54.00.04

55.XX.YY

56.00.YY

57.00.01

57.00.02

57.00.03

58.00.02

58.00.04

59.00.00

59.00.20

59.00.30

59.00.40

59.05.50

59.05.60

60.00.02

60.00.03

60.00.04

60.00.05

60.00.06

60.00.11

60.10.0Y

62.00.00

66.80.02

66.80.03

66.80.19

66.80.33

69.11.YY

70.00.00

80.0X.YY

81.WX.00

81.WX.YZ

81.YY.YY

98.00.01

98.00.02

98.00.03

98.00.04

98.00.0X

99.00.01

99.00.02

99.00.03

99.00.04

99.00.05

99.00.06

99.00.07

99.00.08

99.00.09

99.00.10

99.00.11

99.00.12

99.00.13

99.00.14

99.00.2X

99.01.XX

99.02.01

99.02.09

99.09.60

99.09.61

99.09.62

99.09.63

99.09.64

99.09.65

99.09.66

99.09.67

99.09.68

99.XX.YY

Описание

| Error code: | 11.00.YY |

| Display: | 11.00.YY Internal clock error |

| Description: | The product real time clock has experienced an error. 01=dead clock 02=dead real time clock |

| Remedy: | Whenever the product is turned off and then turned on again, set the time and date at the control panel. If the error persists, you might need to replace the formatter. |

| Error code: | 13.80.A1 |

| Display: | 13.80.A1 Jam in upper left door |

| Description: | Input stay jam. This jam occurs when the inlet sensor (SR2100) stayed activated too long. |

| Remedy: | 1. Open the upper left door. 2. Remove all paper found. 3. Lower the stacker bin if it is in up position, and then close the door. 4. If the error persists, replace the stapler/stacker paper feed assembly. |

| Error code: | 13.80.D1 |

| Display: | 13.80.D1 Jam in upper left door |

| Description: | Input delay jam. Paper did not arrive at the jam inlet sensor (SR2100). |

| Remedy: | 1. Open the upper left door 2. Remove all paper found. 3. Close the upper left door. 4. If the error persists, replace the stapler/stacker paper feed assembly. |

| Error code: | 13.80.FF |

| Display: | 13.80.FF Jam in upper left door |

| Description: | Input initial jam. At power on, the paper was detected at the inlet sensor (2100). |

| Remedy: | 1. Open the upper left door. 2. Remove all paper found. 3. Lower the stacker bin if it is in the up position, and then close the upper left door. 4. If the error persists, replace the stapler/stacker. |

| Error code: | 13.84.A1 |

| Display: | 13.84.A1 Jam in upper bin |

| Description: | Exit stay jam. The paper exit sensor (SR2103) at the accumulator stayed activated for too long. |

| Remedy: | 1. Remove all paper in the upper bin. 2. Open the upper left door. 3. Remove all paper found. 4. Close the upper left door. 5. If the error persists, replace the stapler/stacker alignment assembly. |

| Error code: | 13.84.FF |

| Display: | 13.84.FF Jam in upper bin |

| Description: | Exit initialization jam. At power on, paper was detected to be present on the exit sensor (SR2103). |

| Remedy: | 1. Remove all paper from the stacker bin area. 2. Open the upper left door. 3. Remove all paper found. 4. Lower the stacker bin if it is in up position, and then close the upper left door. 5. If the error persists, replace the stapler/stacker alignment assembly. |

| Error code: | 13.89.31 |

| Display: | 13.89.31 Jam in Stapler |

| Description: | Staple jam. Stapler could not finish its cycle, but it was able to return to home position.SR2103). |

| Remedy: | 1. Open the front stapler door. 2. Remove the staple cartridge. 3. Remove all paper found. 4. Lift the metal cover on the staple cartridge. 5. Remove the sheet of staples. 6. Close the metal cover. 7. Insert the staple cartridge until it clicks. 8. Close the front stapler door. 9. If the error persists, replace the stapler assembly. |

| Error code: | 13.A4.D4 |

| Display: | 13.A4.D4 |

| Description: | Jam In Tray 4 This jam occurs when the media does not reach the Tray 4 feed sensor (PS3302) in the designated amount of time after the start of media pick-up from Tray 4. This is a no-pick jam from Tray 4. |

| Remedy: | 1. Open Tray 4, remove any jammed paper, and then close the tray. 2. Open and close the HCI right door to allow the product to attempt to clear the jam. 3. Make sure that the Tray 4 pickup, feed, and separation roller are installed correctly and show no damage or wear. 4. Clean or replace the pickup/feed rollers as needed. 5. Check the connectors at the sensor, feed motor, and the HCI controller PCA. 6. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 7. Test PS3302 using the Tray/Bin Manual sensor test to verify that the sensor are functioning correctly. 8. Touch Component Test. 9. Run the Tray 4 pickup/feed motor drive test to verify that the feed motor is functioning correctly. If it is not, replace the tray pickup assembly. 10. If the error persists, replace the tray pickup assembly. |

| Error code: | 13.A4.D5 |

| Display: | 13.A4.D5 Jam in middle right door |

| Description: | This jam occurs when the leading edge of the sheet exits the source tray, but does not reach the Tray 4 feed sensor (SR1PF) in the designated amount of time. |

| Remedy: | 1x500 paper feeder and 1x500 paper deck installed or a 1x500 paper feeder and HCI installed. 1. Open the middle right door, remove any jammed paper, and then close the middle right door. 2. Inspect the Tray 5 pick, feed and separation rollers. Clean or replace them if necessary. 3. Check the connectors at the feed sensor, solenoid, feed motor, and the controller PCA. 4. Use the Tray/bin manual sensor tests to toggle the Tray 5 feed sensor. If the sensor or lever are not properly functioning, replace the Tray 5 paper pickup assembly. 5. Use the Components tests to toggle the Tray 5 solenoid (listen for the solenoid to move). If the solenoid is not properly functioning, replace the Tray 5 paper pickup assembly. 6. Use the Components tests to activate the Tray 5 pickup motor (listen for the motor to rotate). If the motor is not properly functioning, replace the Tray 5 pickup motor. 7. Use the Tray/bin manual sensor tests to toggle the Tray 4 feed sensor. If the sensor or lever are not properly functioning, replace the HCI paper pickup assembly. |

| Error code: | 13.A4.D6 |

| Display: | 13.A4.D6 Jam in middle right door |

| Description: | This jam occurs when the leading edge of the sheet exits the source tray, but does not reach the Tray 4 feed sensor (SR1PF) in the designated amount of time. |

| Remedy: | Two 1x500 paper feeders and 1x500 paper deck installed or a 1x500 paper feeder and HCI installed. 1. Open the middle right door, remove any jammed paper, and then close the middle right door. 2. Inspect the Tray 6 pick, feed and separation rollers. Clean or replace them if necessary. 3. Check the connectors at the feed sensor, solenoid, feed motor, and the controller PCA. 4. Use the Tray/bin manual sensor tests to toggle the Tray 6 feed sensor. If the sensor or lever are not properly functioning, replace the Tray 6 paper pickup assembly. 5. Use the Components tests to toggle the Tray 6 solenoid (listen for the solenoid to move). If the solenoid is not properly functioning, replace the Tray 6 paper pickup assembly. 6. Use the Components tests to activate the Tray 6 pickup motor (listen for the motor to rotate). If the motor is not properly functioning, replace the Tray 6 pickup motor. 7. Use the Tray/bin manual sensor tests to toggle the Tray 4 feed sensor. If the sensor or lever are not properly functioning, replace the HCI paper pickup assembly. |

| Error code: | 13.A4.FF |

| Display: | 13.A4.FF |

| Description: | Residual Media Jam in Tray 4. This jam occurs when residual media is detected at the Tray 4 feed sensor (PS432). |

| Remedy: | 1. Open Tray 4, remove any jammed paper, and then close the tray. 2. Open and close the upper right door to allow the printer to attempt to clear the jam. 3. Remove the paper from the tray and check that the paper tray size guides are properly set and that the tray is not over filled with paper. 4. Make sure that the Tray 4 pickup, feed, and separation roller are installed correctly and show no damage or wear. 5. Clean or replace the pickup/feed rollers as needed. Use a damp, lint-free cloth to gently clean the rollers. 6. Check the connectors at the sensor, feed motor, and the DC controller PCA. 7. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 8. Test PS432 using the Tray/Bin Manual sensor test to verify that the sensors are functioning correctly. 9. Run the Tray 4 pickup/feed motor drive test to verify that the feed motor is functioning correctly (listen for the motor to activate). If it is not, replace the optional paper feeder assembly. 10. If either of the previous steps fail, elevate the issue to HP for possible printer replacement. NOTE: On-site technicians should check ALL connections on the Paper feed controller PCA before elevating the issue. |

| Error code: | 13.A5.D5 |

| Display: | 13.A5.D5 |

| Description: | Jam In Tray 5. This jam occurs when the media does not reach the Tray 5 feed sensor (PS3305) in the designated amount of time after the start of media pick-up from Tray 5. This is a no-pick jam from Tray 5. |

| Remedy: | 1. Open Tray 5, remove any jammed paper, and then close the tray. 2. Open and close the HCI right door to allow the product to attempt to clear the jam. 3. Make sure that the Tray 5 pickup, feed, and separation roller are installed correctly and show no damage or wear. 4. Clean or replace the pickup/feed rollers as needed. 5. Check the connectors at the sensor, feed motor, and the HCI controller PCA. 6. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 7. Test PS3305 using the Tray/Bin Manual sensor test to verify that the sensor are functioning correctly. 8. Touch Component Test. 9. Run the Tray 5 pickup/feed motor drive test to verify that the feed motor is functioning correctly. If it is not, replace the tray pickup assembly. 10. If the error persists, replace the tray pickup assembly. |

| Error code: | 13.A5.D6 |

| Display: | 13.A5.D6 Jam in lower right door |

| Description: | This jam occurs when the leading edge has passed the tray 6 feed sensor (SR91) but does not reach the tray 5 feed sensor (SR81) in the designated amount of time. |

| Remedy: | 3x500 paper deck installed. 1. Open the lower right door, remove any jammed paper, and then close the lower right door. 2. Inspect the Tray 6 pick, feed and separation rollers. Clean or replace them if necessary. 3. Check the connectors at the feed sensor, solenoid, feed motor, and the controller PCA. 4. Use the Tray/bin manual sensor tests to toggle the Tray 6 feed sensor. If the sensor or lever are not properly functioning, replace the Tray 6 paper pickup assembly. 5. Use the Components tests to toggle the Tray 6 solenoid (listen for the solenoid to move). If the solenoid is not properly functioning, replace the Tray 6 paper pickup assembly. 6. Use the Components tests to activate the Tray 6 pickup motor (listen for the motor to rotate). If the motor is not properly functioning, replace the Tray 6 pickup motor. |

| Error code: | 13.A5.FF |

| Display: | 13.A5.FF |

| Description: | Residual Media Jam in Tray 5. This jam occurs when residual media is detected at the Tray 3 feed sensor (PS432). |

| Remedy: | 1. Open Tray 5, remove any jammed paper, and then close the tray. 2. Open and close the upper right door to allow the printer to attempt to clear the jam. 3. Remove the paper from the tray and check that the paper tray size guides are properly set and that the tray is not over filled with paper. 4. Make sure that the Tray 5 pickup, feed, and separation roller are installed correctly and show no damage or wear. 5. Clean or replace the pickup/feed rollers as needed. Use a damp, lint-free cloth to gently clean the rollers. 6. Check the connectors at the sensor, feed motor, and the DC controller PCA. 7. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 8. Test PS432 using the Tray/Bin Manual sensor test to verify that the sensors are functioning correctly. 9. Run the Tray 5 pickup/feed motor drive test to verify that the feed motor is functioning correctly (listen for the motor to activate). If it is not, replace the optional paper feeder assembly. 10. If either of the previous steps fail, elevate the issue to HP for possible printer replacement. NOTE: On-site technicians should check ALL connections on the Paper feed controller PCA before elevating the issue. |

| Error code: | 13.A6.D6 |

| Display: | 13.A6.D6 Jam in tray 6 |

| Description: | No pick jam. This jam occurs when the paper does not reach the Tray 6 feed sensor in the designated amount of time. Depending on the input device configuration this could be the third tray of the 3x500 paper deck, or the left tray of the HCI (SR91-PD3x500, PS3305-HCI). |

| Remedy: | 1. Open Tray 6, remove any jammed paper, and then close Tray 6. 2. Inspect the connectors at the feed sensor and controller PCA for Tray 6. 3. Use the Tray/bin manual sensor tests to toggle the Tray 6 feed sensor. If the Tray 6 feed sensor or lever are not properly functioning, replace the Tray 6 paper pickup assembly. 4. Use the Components tests to toggle the Tray 6 solenoid (listen for the solenoid to move). If the solenoid is not properly functioning, replace the Tray 6 paper pickup assembly. 5. Use the Components tests to activate the Tray 6 pickup motor (listen for the motor to rotate). If the motor is not properly functioning, replace the Tray 6 pickup motor. |

| Error code: | 13.A6.FF |

| Display: | 13.A6.FF Jam tray 5 (inner flap) |

| Description: | Residual paper jam. This jam occurs when paper exists at any of the paper path jam sensors when the product power is turned on or after jam re-evaluation. Depending on the input device configuration this could be the third tray of the 3x500 paper deck, or the left tray of the HCI (SR91-PD3x500, PS3305-HCI). |

| Remedy: | 1. Open Tray 5 and the inner flap, remove any jammed paper, and then close Tray 5 and the inner flap. 2. Inspect the connectors at the feed sensor and controller PCA for Tray 6. 3. Use the Tray/bin manual sensor tests to toggle the Tray 6 feed sensor. If the Tray 6 feed sensor or lever are not properly functioning, replace the Tray 6 paper pickup assembly. |

| Error code: | 13.A7.D5 |

| Display: | 13.A7.D5 |

| Description: | Jam in lower Right Door (From Jam Tray 5) This jam occurs when the media does not reach the HCI Exit sensor (PS3301) in the designated amount of time after the Tray 5 feed sensor (PS3305) sensed the leading edge of the paper when printing from Tray 5. |

| Remedy: | 1. Clear the jam in the indicated area. 2. Close the door to allow the product to attempt to clear the jam. 3. Make sure that the Tray 5 pickup, feed, and separation roller are installed correctly and show no damage or wear. 4. Clean or replace the pickup/feed rollers as needed. 5. Check the connectors at the sensor, feed motor, and the HCI controller PCA. 6. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 7. Test PS3301 using the Tray/Bin Manual sensor test to verify that the sensor are functioning correctly. 8. Touch Component Test. 9. Run the Tray 5 pickup/feed motor drive test to verify that the feed motor is functioning correctly. If it is not, replace the pickup drive assembly. 10. If the error persists, replace the tray pickup assembly. |

| Error code: | 13.A7.D6 |

| Display: | 13.A7.D6 Jam tray 5 (inner flap) |

| Description: | This jam occurs when the leading edge passes the tray 6 feed sensor (PS3305), but does not reach the HCI exit sensor (PS3301) in the designated amount of time. |

| Remedy: | 1x500 paper feeder and HCI installed. 1. Open Tray 5 and the inner flap, remove any jammed paper, and then close Tray 5 and the inner flap. 2. Inspect the Tray 6 pick, feed and separation rollers. Clean or replace them if necessary. 3. Inspect the connectors at the feed sensor, solenoid, feed motor, and the controller PCA. 4. Use the Tray/bin manual sensor tests to toggle the HCI exit sensor (PS3301). If the sensor or lever are not properly functioning, replace the HCI crossing assembly. 5. Use the Components tests to toggle the Tray 6 solenoid (listen for the solenoid to move). If the solenoid is not properly functioning, replace the Tray 6 paper pickup assembly. 6. Use the Components tests to activate the Tray 6 pickup motor (listen for the motor to rotate). If the motor is not properly functioning, replace the Tray 6 pickup motor. |

| Error code: | 13.A7.FF |

| Display: | 13.A7.FF |

| Description: | Residual Media Jam in High Capacity Input (HCI) This jam occurs when residual media is detected at the HCI exit sensor (PS3301) at power on. |

| Remedy: | 1. Clear the jam in the indicated area. 2. Close the door to allow the product to attempt to clear the jam. 3. Make sure that the Tray 2 pickup, feed, and separation roller are installed correctly and show no damage or wear. 4. Clean or replace the pickup/feed rollers as needed. 5. Check the connectors at the sensor, feed motor, and the DC controller PCA. 6. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 7. Test PS1402 using the Tray/Bin Manual sensor test to verify that the sensor is functioning correctly. 8. Touch Component Test. 9. Run the Tray 2 pickup/feed motor drive test to verify that the feed motor is functioning correctly. If it is not, replace the pickup assembly. 10. Run the Tray 2 intermediate feed motor (M3) drive test to verify that the feed motor is functioning correctly. If it is not, replace the pickup assembly. 11. If the error persists, replace the paper pickup assembly. |

| Error code: | 13.AA.EE |

| Display: | 13.AA.EE |

| Description: | HCI Door Open Jam This jam occurs when the HCI right door (SW3301) is opened during printing. |

| Remedy: | 1. Close the Lower Right door to allow the product to attempt to clear the jam. 2. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 3. Test SW3301 using the Manual Sensor Switch test to verify that the switch is functioning correctly. 4. If the error persists, replace the Merge Assembly. |

| Error code: | 13.AB.EE |

| Display: | 13.AB.EE |

| Description: | HCI Door Open Jam. This jam occurs when the HCI inner flap door (PS3306) is opened during printing. |

| Remedy: | 1. Close the inner flap door to allow the product to attempt to clear the jam. 2. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 3. Test PS3306 using the Manual Sensor test to verify that the sensor is functioning correctly. 4. If the error persists, replace the left tray pickup assembly. |

| Error code: | 13.AC.EE |

| Display: | 13.AC.EE Door open jam |

| Description: | Door open jam. Lower right cover 2 open; lower right door or HCI inner flap depending on the input accessory configuration. |

| Remedy: | 1. Close the lower right door or HCI inner flap. 2. Depending on input tray configuration, check the tab of the HCI lower right door that engages the door sensor (SW3301). If it is damaged, replace the door assembly. Check the HCI inner flap door (above right HCI tray) to verify that it properly opens and closes. 3. Use the Manual sensor tests menu to toggle the lower right door (Tray 4/5) sensors. If a sensor is not properly functioning, replace the sensor. 4. The HCI (long edge feed guide open) inner flap sensor (PS3306) can not be tested using the Manual sensor tests menu. To test the sensor, open the flap (with product in the ready state) and look for a control panel message to close it. The sensor is part of HCI left paper pickup assembly. 5. Do one of the following: - 500-sheet paper deck: check the connectors (J2005) on the PD controller PCA and the connector (J705) on the PD right door open detection switch. - High capacity input feeder: check the connectors (J3006) on the HCI controller PCA and the connector (J905) on the HCI right door open detection switch. |

| Error code: | 13.AD.EE |

| Display: | 13.AD.EE Door open jam |

| Description: | Door open jam. Lower right cover 3 open (input tray configuration is 1x500 and HCI). |

| Remedy: | The HCI (long edge feed guide open) inner flap sensor (PS3306) can not be tested using the Manual sensor tests menu. To test the sensor, open the flap (with product in the ready state) and look for a control panel message instructing you to close it. The sensor is a component of the HCI left paper pickup assembly. |

| Error code: | 13.B2.AD |

| Display: | 13.B2.Az |

| Description: | This jam occurs when the media is present longer than "the expected media length plus 50mm" or more is detected at the Registration sensor (PS4) when printing from the Duplexer. |

| Remedy: | 1. Open the front door and clear the jam in the indicated area. 2. Close the door to allow the product to attempt to clear the jam. 3. Make sure that the transfer roller is seated correctly and not worn or deformed. Replace the roller if necessary. 4. Check the registration assembly for proper operation. Replace the registration assembly as needed. 5. If media is stopped under the toner cartridge, but has moved most of the way through registration, try another toner cartridge. If necessary, replace the toner cartridge. 6. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 7. Test the TOP sensor (PS4) using the Tray/Bin manual sensor test to verify that the sensor is functioning correctly. If it is not, replace the registration sensor assembly. |

| Error code: | 13.B2.D1 |

| Display: | 13.B2.Dz |

| Description: | Media delay jam at registration sensor PS4. This jam occurs when the media does not reach the Registration sensor (PS4) in the designated amount of time after the Tray 1 feed sensor (PS2502) sensed the leading edge when printing from Tray 1. |

| Remedy: | 1. Open the front and right doors and clear the jam in the indicated area. Inspect the paper path and make sure that no paper is blocking the paper path. 2. Check the registration assembly for proper orientation. Replace the registration assembly as needed. 3. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 4. Test the TOP sensor (PS4) using the Tray/Bin manual sensor test to verify that the sensor is functioning correctly. If it is not, replace the registration sensor assembly. 5. Touch Component Test. 6. Run the Tray 2 intermediate feed motor (M3) drive test to verify that the feed motor is functioning correctly. If it is not, replace the pickup assembly. 7. If the error only occurs when duplexing, check the duplexer for blockage or damage and replace as needed. |

| Error code: | 13.B2.D2 |

| Display: | 13.B2.Dz |

| Description: | Media delay jam at registration sensor PS4. This jam occurs when the media does not reach the Registration sensor (PS4) in the designated amount of time after the Tray 2C feed sensor (PS8) sensed the leading edge when printing from Tray 2. |

| Remedy: | 1. Open the front and right doors and clear the jam in the indicated area. Inspect the paper path and make sure that no paper is blocking the paper path. 2. Check the registration assembly for proper orientation. Replace the registration assembly as needed. 3. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 4. Test the TOP sensor (PS4) using the Tray/Bin manual sensor test to verify that the sensor is functioning correctly. If it is not, replace the registration sensor assembly. 5. Touch Component Test. 6. Run the Tray 2 intermediate feed motor (M3) drive test to verify that the feed motor is functioning correctly. If it is not, replace the pickup assembly. 7. If the error only occurs when duplexing, check the duplexer for blockage or damage and replace as needed. |

| Error code: | 13.B2.D3 |

| Display: | 13.B2.Dz |

| Description: | Media delay jam at registration sensor PS4. This jam occurs when the media does not reach the Registration sensor (PS4) in the designated amount of time after the Tray 2C feed sensor (PS8) sensed the leading edge when printing from Tray 3. |

| Remedy: | 1. Open the front and right doors and clear the jam in the indicated area. Inspect the paper path and make sure that no paper is blocking the paper path. 2. Check the registration assembly for proper orientation. Replace the registration assembly as needed. 3. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 4. Test the TOP sensor (PS4) using the Tray/Bin manual sensor test to verify that the sensor is functioning correctly. If it is not, replace the registration sensor assembly. 5. Touch Component Test. 6. Run the Tray 2 intermediate feed motor (M3) drive test to verify that the feed motor is functioning correctly. If it is not, replace the pickup assembly. 7. If the error only occurs when duplexing, check the duplexer for blockage or damage and replace as needed. |

| Error code: | 13.B2.DD |

| Display: | 13.B2.Dz |

| Description: | Media delay jam at registration sensor PS4. This jam occurs when the media does not reach the Registration sensor (PS4) in the designated amount of time after leaving the Duplex Wait Point when duplexing. |

| Remedy: | 1. Open the front and right doors and clear the jam in the indicated area. Inspect the paper path and make sure that no paper is blocking the paper path. 2. Check the registration assembly for proper orientation. Replace the registration assembly as needed. 3. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 4. Test the TOP sensor (PS4) using the Tray/Bin manual sensor test to verify that the sensor is functioning correctly. If it is not, replace the registration sensor assembly. 5. Touch Component Test. 6. Run the Tray 2 intermediate feed motor (M3) drive test to verify that the feed motor is functioning correctly. If it is not, replace the pickup assembly. 7. If the error only occurs when duplexing, check the duplexer for blockage or damage and replace as needed. |

| Error code: | 13.B2.DX |

| Display: | 13.B2.DX Jam in top cover area |

| Description: | Paper delay jam at top/registration sensor- This jam occurs when the leading edge of the media does not reach the TOP sensor (SR9) within the designated amount of time from Tray 4, 5, or 6. X indicates the source tray - 4 = Tray 4 - 5 = Tray 5 - 6 = Tray 6 |

| Remedy: | 1. Open the top cover, and then remove any jammed paper. IMPORTANT: Do not remove the toner cartridge. Make sure that you remove any jammed paper from the top cover area before proceeding to avoid tearing partially picked paper. Close the top cover. 2. Check for obstructions in the paper path from the source tray. 3. Check the pickup, feed, and separation rollers from the source tray. Replace the rollers if they are worn or defective. 4. Make sure that the registration assembly shutter is properly functioning. Replace the registration assembly if necessary. 5. Use the Components tests to activate the pickup motor and the pickup solenoid/clutch (listen for the motor/solenoid to rotate/move) for the source tray. If the motor or solenoid are not properly functioning, replace the motor or solenoid. 6. Use the Manual sensor tests to toggle the TOP sensor (SR9). If the sensor is not properly functioning, replace the high-voltage power supply. 7. Inspect the connector (J62) on the DC controller PCA, and connector (J901) on the high-voltage power supply. 8. Use the Components tests to activate the drum motor (listen for the motor to rotate). If the motor is not properly functioning, replace the main drive assembly. |

| Error code: | 13.B2.FF |

| Display: | 13.B2.FF Jam in top cover |

| Description: | Media residual jam in top cover at image area. Paper present at SR2 at power on or after clearing jam. |

| Remedy: | 1. Open top cover and check for media jammed in feed area. 2. Check under toner cartridge at transfer area, make sure everything is properly seated. 3. Test the top of page sensor (SR2). 4. If the sensor fails test, elevate the issue to HP for possible printer replacement. NOTE: On-site technicians should check the following connections on the DC controller PCA to ensure they are properly seated and connected before elevating the issue. (J151, J110, J144) |

| Error code: | 13.B4.FF |

| Display: | 13.B4.FF |

| Description: | Residual Media jam Loop sensor (PS9) This jam occurs when residual media is detected at the Loop sensor (PS9) at power on. |

| Remedy: | 1. Open the front door and clear the jam in the indicated area. 2. Close the door to allow the product to attempt to clear the jam. 3. If the issue persists as another specific Paper Jam, troubleshoot the specified Jam location. 4. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 5. Test the Loop sensor (PS9) using the Tray/Bin manual sensor test to verify that the sensor is functioning correctly. If it is not, replace the assembly containing Loop Sensor PS9. |

| Error code: | 13.B9.AX |

| Display: | 13.B9.AX |

| Description: | 13.B9.A2, 13.B9.A3, 13.B9.A4, 13.B9.A5, or 13.B9.AB Fuser delivery stay jam 1 (paper stayed at fuser output sensor longer than it should; fuser output.) Fuser modes • A2.Normal fuser mode • A3.Light 1/2 fuser mode • A4.Heavy 1 fuser mode • A5.Heavy 2 fuser mode • AB-Overhead transparency fuser mode |

| Remedy: | Recovery steps: 1. Open the rear door to second position. 2. Remove jammed paper if present. 3. Close the rear door. Troubleshooting and parts: 1. Clear the paper path of any jammed paper. 2. Make sure that the paper meets HP specifications. 3. Paper Sensor associated with this message: PS2. |

| Error code: | 13.B9.CX |

| Display: | 13.B9.CX |

| Description: | 13.B9.C2, 13.B9.C3, 13.B9.C4, 13.B9.C5, or 13.B9.CB Wrap jam 1 (paper first detected at fuser output sensor and then disappears from sensor before it should; fuser output . paper is wrapped around the fuser.) Fuser mode • C2.Normal fuser mode • C3.Light 1/2 fuser mode • C4.Heavy 1 fuser mode • C5.Heavy 2 fuser mode • CB-Overhead transparency fuser modes |

| Remedy: | NOTE: Pre-printed paper, overhead transparency, and labels must meet product specifications. Make sure that labels were not previously put through a printer, and that there are no adhesive areas exposed. Recovery steps: 1. Open the rear door to second position. 2. Open top cover. 3. Remove the toner cartridge. 4. Remove jammed paper if present. 5. Reinstall cartridge and then close the top cover. 6. Close the rear door. Troubleshooting and parts: 1. Make sure that the paper meets HP specifications. 2. Make sure that the tray is configured for the media size and type. Use the product control panel to check the product configuration, and check the Print Driver (from the application that causes the error). 3. Replace the fuser |

| Error code: | 13.B9.DD |

| Display: | 13.WX.YZ Jam in right door |

| Description: | Late to fuser jam, from duplexer This jam occurs when the paper does not reach the fuser output sensor in designated amount of time. |

| Remedy: | Clear the jam. |

| Error code: | 13.B9.FF |

| Display: | 13.B9.FF |

| Description: | Residual Media jam Fuser Output Sensor. Paper present at SR13 after specified time limit or on power up. |

| Remedy: | 1. Open the top and rear cover and clear the jam in the indicated area. 2. Close the covers to allow the printer to attempt to clear the jam. 3. Verify the media meets HP specification for the printer. 4. Remove the fuser and inspect the fuser sleeve, pressure roller, and delivery roller for blockage and/or damage. Replace the fuser as needed. CAUTION: The fuser might be HOT. 5. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 6. Test the Fuser Delivery sensor (SR13) using the manual sensor test to verify the sensor is functioning correctly. If it is not, replace the fuser. 7. Run the Fuser motor drive test to verify that the Fuser Drive and Gears are functioning correctly. If they are not, elevate the issue to HP for possible printer replacement. |

| Error code: | 13.BA.EE |

| Display: | 13.BA.EE |

| Description: | This jam occurs when the engine front door (SW8) is opened during printing. |

| Remedy: | 1. Close the front door. 2. Check the projection tabs of the front door that engage the door sensor (SW8). If damaged, replace the appropriate part. 3. Use the Manual sensor test to activate the door switch. Replace the switch if it is not functioning correctly. 4. Check connector J302 on the DC controller PCA and connector J3 on SW8. |

| Error code: | 13.D1.DX |

| Display: | 13.D1.DX Jam in left door |

| Description: | Late to duplex switchback jam. This jam occurs when the paper reverses direction but fails to reach the duplex switchback sensor (SR1DU) in the designated amount of time. X indicates the fuser mode - 2 = Normal - 3 = Light media 1 - 3 = Light media 2 - 4 = Heavy media 1 - 5 = Heavy media 2 - B = Transparency - D = Envelope 1 - D = Envelope 2 |

| Remedy: | 1. Open the left door, remove any jammed paper, and then close the left door. 2. Check the paper path and rollers at the fuser and duplexer for damage. Replace the fuser or duplexer if necessary. 3. Use the Manual sensor tests to toggle the duplexer switchback sensor (SR1DU). If the sensor or lever are not properly functioning, replace the duplexer. 4. Use the Components tests to activate the duplex feed motor (listen for the motor to rotate). If the motor is not properly functioning, replace the duplexer. |

| Error code: | 13.D1.FF |

| Display: | 13.D1.FF Jam in left door |

| Description: | Duplexer switchback sensor jam. This jam occurs when paper exists at any of the paper path jam sensors at power on or after jam re-evaluation. |

| Remedy: | 1. Open the left door, and clear any jammed paper. Close the left door. 2. Remove duplexer, and clear any jammed paper. Reinstall the duplexer. 3. Make sure duplexer is seated properly. 4. Run the Manual Sensor test and toggle the duplexer switchback sensor (SR1DU). 5. If the duplexer switchback sensor or lever not operating properly replace the duplexer. |

| Error code: | 13.D3.00 |

| Display: | 13.D3.00 Jam in top cover area |

| Description: | This is a firmware timing issue and not a mechanical jam problem. Late to duplex exit jam. The engine cannot pause long sheets in the duplex path. |

| Remedy: | Open the top cover, remove any jammed paper, and then close the top cover. |

| Error code: | 13.D3.DX |

| Display: | 13.D3.DX |

| Description: | 13.D3.D2, 13.D3.D3, 13.D3.D4, 13.D3.D5, or 13.D3.DB Duplex re-feed jam 1 (paper did not reach the duplex sensor in time; duplexer.) Fuser modes • D2.Normal fuser mode • D3.Light 1/2 fuser mode • D4.Heavy 1 fuser mode • D5.Heavy 2 fuser mode • DB-Overhead transparency fuser mode |

| Remedy: | Recovery steps 1. Open the rear door to second position. 2. Remove jammed paper if present. 3. Close the rear door. Troubleshooting and parts 1. Remove all paper and check for residual pieces that could cause the media not to move along the paper path. 2. Make sure that the paper meets HP specifications. 3. Paper sensor associated with this message: PS4. Replace the photointerrupter (WG8-5935-000CN or the top cover assembly (RM1-8516-000CN). |

| Error code: | 13.D3.FF |

| Display: | 13.D3.FF or 13.B2.FF |

| Description: | Residual Media in Paper path jam 1 or 2 (paper detected in the paper path.) When the product power is turned on, paper remains in the paper path, triggering the duplex sensor. • 13.D3.FF: Duplexer. • 13.B2.FF: Registration or Top sensor. |

| Remedy: | Recovery steps: 1. Remove Tray 2. 2. Remove jammed paper if present. 3. Use the green button to lower the duplex tray. 4. Remove jammed paper if present. 5. Close the duplex tray. 6. Reinstall Tray 2. Troubleshooting and parts 1. Make sure that there are no residual pieces of paper are in the paper path that could cause the paper to jam in this area. 2. Make sure that the media meets specification in both type and size for duplexing. Minimum paper size is 210 x 280 mm (8.27 x 11 inches)to 216 x 356 mm (8.5 x 14 inches). 3. Perform a paper sensor test and confirm correct operation of all sensors. In particular, check the Duplexer Paper Sensor in the following manner: a. At the start of the Paper Sensor Test, the duplexer sensor (third digit of the four in the upper left of the display) should be “0” (at the start of the test, all four digits should be “0”.) b. Remove the cassette and release the duplexer pan, when in the pan is in its full down position, the duplexer sensor digit should be “1”. c. If the sensor flag is manually moved, it the digit should show a “1” when the flag is in the full down position, a “0’ as the flag moves to the middle position and a “1” when the flag is in the full up position. d. If the sensor does not respond as described above, replace the HVPS assembly (RM1-6280-000CN). e. If the sensor is working properly, the error only happens on a duplex job, and the media is jammed in the rear door or in the fuser with only one side printed, replace the pendulum assembly (RM1-6598-000CN). f. If the error persists, replace the lower paper feed guide (P/N RM1-6263-000CN). |

| Error code: | 13.DE.EE |

| Display: | 13.DE.EE Jam in duplexer (during a print job) |

| Description: | This is a user caused jam, not a mechanical problem. This jam occurs when the duplexer is removed while paper is being delivered in the duplexer. |

| Remedy: | Remove the duplexer, remove any jammed paper, and then reinstall the duplexer. |

| Error code: | 13.E1.DX |

| Display: | 13.E1.DX Jam in left door |

| Description: | Late to bin full jam. This jam occurs when the paper fails to reach the face-down bin full sensor (SR4) within a specific time. X indicates the fuser mode - 2 = Normal - 3 = Light media 1 - 3 = Light media 2 - 4 = Heavy media 1 - 5 = Heavy media 2 - B = Transparency - D = Envelope 1 - D = Envelope 2 |

| Remedy: | 1. Open the left door, remove any jammed paper, and then close the left door. 2. Inspect the connector (J55) on the output assembly, and the connector (J45) on the DC controller PCA. 3. Use the Tray/bin manual sensor tests to toggle the output bin full sensor (SR4). If the sensor or lever are not properly functioning, replace the paper delivery assembly. |

| Error code: | 13.E1.FF |

| Display: | 13.E1.FF |

| Description: | Residual Jam - Jam in Left Door This jam occurs when residual media is detected at the face down bin full sensor (PS1452) at power on. |

| Remedy: | 1. Open the left door and clear the jam in the indicated area. 2. Close the door to allow the product to attempt to clear the jam. 3. Reseat the connections to the DC controller. 4. Make sure that the delivery flags move smoothly. 5. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 6. Test the face down bin full sensor (PS1452) using the Tray/Bin manual sensor test to verify the sensor is functioning correctly. If it is not, replace the delivery sensor assembly. 7. If the issue persists, replace the delivery unit. |

| Error code: | 13.E6.AX |

| Display: | 13.E6.AX Jam in left door |

| Description: | Stopped at output jam. This jam occurs when the paper fails to clear the output sensor (SR3) within a specific time. X indicates the fuser mode - 2 = Normal - 3 = Light media 1 - 3 = Light media 2 - 4 = Heavy media 1 - 5 = Heavy media 2 - B = Transparency - D = Envelope 1 - D = Envelope 2 |

| Remedy: | 1. Open the left door, remove any jammed paper, and then close the left door. 2. Check the paper path and rollers at the fuser and the paper delivery assembly for damage or wear. Replace the fuser or paper delivery assembly if necessary. 3. Use the Tray/bin manual sensor tests to toggle the output bin full sensor (SR4). If the sensor or lever are not properly functioning, replace the paper delivery assembly. 4. Use the Manual sensor tests to toggle the output sensor (SR3). If the sensor or lever are not properly functioning, replace the paper delivery assembly. |

| Error code: | 13.E6.BD |

| Display: | 13.E6.BD Jam in left door |

| Description: | Multi-feed from duplexer jam. This jam occurs when the engine detects a multi-feed in the output path from the duplexer. |

| Remedy: | Check the paper path and rollers at the fuser and the duplexer for damage or wear. Replace the fuser or duplexer if necessary. |

| Error code: | 13.E6.BX |

| Display: | 13.E6.BX Jam in left door |

| Description: | Multi-fold from Tray 1–6 jam. This jam occurs when the engine detects a multi-feed in the output path from the indicated source tray. X indicates the source tray - 1 = Tray 1 - 2 = Tray 2 - 3 = Tray 3 - 4 = Tray 4 - 5 = Tray 5 - 6 = Tray 6 |

| Remedy: | 1. Open the left door, remove any jammed paper, and then close the left door. 2. Check the pickup, feed, and separation rollers from the source tray. Replace the rollers if they are worn or defective |

| Error code: | 13.E6.DX |

| Display: | 13.E6.DX Jam in left door |

| Description: | Late to output jam. This jam occurs when the paper fails to reach the output sensor (SR3) within a specific time. X indicates the fuser mode - 2 = Normal - 3 = Light media 1 - 3 = Light media 2 - 4 = Heavy media 1 - 5 = Heavy media 2 - B = Transparency - D = Envelope 1 - D = Envelope 2 |

| Remedy: | 1. Open the left door, remove any jammed paper, and then close the left door. 2. Inspect the connector (J55) on the output assembly, and the connector (J45) on the DC controller PCA. 3. Use the Manual sensor tests to toggle the output sensor (SR3). If the sensor or lever are not properly functioning, replace the paper delivery assembly. |

| Error code: | 13.E6.FF |

| Display: | 13.E6.FF |

| Description: | Jam in Left Door This jam occurs when residual media is detected at the face down output sensor (PS1451) at power on. This jam code will only be in the event log if it is a residual jam at power on. |

| Remedy: | 1. Open the left door and clear the jam in the indicated area. 2. Close the door to allow the product to attempt to clear the jam. 3. Make sure that the delivery flags move smoothly. 4. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 5. Test the face down output sensor (PS1451) using the Tray/Bin manual sensor test to verify the sensor is functioning correctly. 6. If the issue persists, replace the delivery unit. |

| Error code: | 13.EA.EE |

| Display: | 13.EA.EE |

| Description: | Left Door Open Jam This jam occurs when the engine left door (SW6) is opened during printing. |

| Remedy: | 1. Close the lower right door to allow the product to attempt to clear the jam. 2. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 3. Test SW6 using the manual sensor switch test to verify the switch is functioning correctly. 4. If the issue persists, replace SW6. |

| Error code: | 13.FF.FF |

| Display: | 13.FF.FF |

| Description: | A power on residual paper jam has occurred. This error has no specific sensor designated. It could be any sensor in the media feed path. |

| Remedy: | 1. Check the printer for a jam.2. Look for media present or obstructions in paper path. View event log to determine if other Jam errors are occurring and troubleshoot those errors.3. Use the Manual sensors test or Tray/Bin manual sensors test to isolate a faulty door switch or sensor.4. Replace parts as determined by Sensor tests or obstructions. If sensor can not be replaced, elevate the issue for possible printer replacement. |

| Error code: | 13.WX.YZ |

| Display: | 13.WX.YZ Jams inside lower right door |

| Description: | A jam exists inside the lower right door. |

| Remedy: | Clear the jam. |

| Error code: | 20.00.00 |

| Display: | 20.00.00 Insufficient memory <device> |

| Description: | Insufficient memory: <Device> Event log error message 20.00.00. The product does not have enough memory to print the page. The product received more data than can fit in the available memory. You might have tried to transfer too many macros, soft fonts, or complex graphics. |

| Remedy: | Touch the OK button to print the transferred data. Some data might be lost. Reduce the page complexity or add product memory. |

| Error code: | 21.00.00 |

| Display: | 21.00.00 Page Too Complex Event log error message 21.00.00. |

| Description: | Page Too Complex Event log error message 21.00.00. The product displays this message to indicate that the page decompression process was too slow for the product. |

| Remedy: | Touch the OK button to continue. There may be some data loss on the page that was being formatted when the error occurred. |

| Error code: | 30.01.01 |

| Display: | 30.01.01 |

| Description: | The flatbed cover sensor was interrupted. The scanner flatbed cover is open. Message appears only in the event log and is not posted on the control panel. The control panel will read Flatbed Cover Open. |

| Remedy: | No action necessary. This error message should automatically clear. If the error persists, open the Scanner Tests to test the flatbed cover sensor.1. If the cover is closed, check the cover sensor at the right rear of the scanner for correct mechanical functionality, using the scanner sensor test in the Administration / Troubleshooting / Diagnostics / Scanner Tests Menu.2. Check the connectors on the scanner control board (SCB) for loose connections.3. Replace the scanner control board (SCB).4. Replace the integrated scanning assembly (ISA). |

| Error code: | 30.01.06 |

| Display: | 30.01.06 |

| Description: | Scanner Fan failure. Scanner fan error. The Copy, Fax and Send options will be grayed out or not present on the control panel and message will be posted in event log. |

| Remedy: | 1. Turn the product off, and then on again. 2. During the product initialization sequence, listen to the fan to determine if it is operating. 3. the error persists, turn the product off and then check the fan wire-harness connectors. 4. If the error persists, replace the scanner control board (SCB). 5. Replace the integrated scanning assembly (ISA). |

| Error code: | 30.01.08 |

| Display: | 30.01.08 Home position error |

| Description: | Home position error The scanner optic failed to return to the home position. |

| Remedy: | 1. Turn the product off, and then on again. 2. Observe the movement of the optics assembly. 3. If the error persists, run the scanner motor test under component test. Administration/ Troubleshooting/Scanner tests/Flatbed motor test 4. If issue still remains and firmware has been upgraded replace scanner control board (SCB). IMPORTANT: Check all cables on SCB for proper connection and seating before replacing any parts and test. 5. If the error persists, replace the integrated scanning assembly (ISA). |

| Error code: | 30.01.41 |

| Display: | 30.01.41 Scanner error |

| Description: | Scanner error. The formatter lost connections with the SCB or communication was corrupted. |

| Remedy: | 1. Turn the product off, and then on. 2. Remove and reinstall the formatter making to verify it is properly seated. 3. Upgrade the firmware. 4. Verify that all cables are connected to the product and to the interconnect board / formatter and SCB. 5. Verify that the scanner control board (SCB) has power. 6. Replace the scanner control board (SCB). 7. Replace the formatter. |

| Error code: | 30.01.43 |

| Display: | 30.01.43 Scanner memory failure |

| Description: | Scanner memory failure Scan memory error. |

| Remedy: | 1. Turn the product off, and then on again. 2. If the error persists, turn the product off, and then re-seat the formatter. 3. If the error persists, replace the formatter. |

| Error code: | 30.01.44 |

| Display: | 30.01.44 |

| Description: | Copy processor (CPB) / scanner control board (SCB) communication error |

| Remedy: | 1. Turn the product off, and then on again. 2. If the error persists, turn the product off, and then check the scanner cable. 3. Upgrade the firmware. 4. If the error persists, turn the product off, and then re-seat the formatter. 5. If the error persists, replace the scanner control board (SCB) or the formatter. |

| Error code: | 30.01.45 |

| Display: | 30.01.45 |

| Description: | Internal copy processor board (CPB) communication error. CPB code assertion error for the copy processor board firmware. |

| Remedy: | 1. Turn the product off, and then on again. 2. If the error persists, turn the product off, and then re-seat the formatter. 3. Upgrade the firmware. 4. If the error persists, replace the scanner control board (SCB). 5. If the error persists, replace the formatter. |

| Error code: | 30.01.46 |

| Display: | 30.01.46 Scanner Error |

| Description: | Scanner Error The firmware cannot find the copy processor board (CPB). |

| Remedy: | 1. Turn the product off, and then on again. 2. If the error persists, turn the product off, and then re-seat the formatter. 3. If the error persists, replace the scanner control board (SCB). |

| Error code: | 30.03.14 |

| Display: | 30.03.14 |

| Description: | A non-fatal error has occurred. A scanner EEPROM (NVM) error has occurred. |

| Remedy: | This is an informational message, and no action is required. |

| Error code: | 30.03.20 |

| Display: | 30.03.20 |

| Description: | The copy processor board firmware cannot communicate with the PCA on the optical assembly. |

| Remedy: | 1. Turn the product off, and then on again. 2. Verify that the flat flexible cables (FFCs) between scanner and the SCB are connected and properly seated. 3. Replace the integrated scanning assembly (ISA). |

| Error code: | 30.03.22 |

| Display: | 30.03.22 Scanner failure |

| Description: | Scanner failure. Front side illumination calibration failure. The scan module cannot see the illumination module, or marginal illumination. The optical assembly may not be parked under the calibration strip. |

| Remedy: | 1. Turn the product off, and then on again. 2. Upgrade the firmware. 3. Check the service event log for other scanner errors, and then resolve those errors. 4. Check the scan module flat flexible cable (FFC) connection. 5. Replace the integrated scanning assembly (ISA). |

| Error code: | 30.03.23 |

| Display: | 30.03.23 Scanner failure |

| Description: | Scanner failure. Flatbed alignment calibration error. |

| Remedy: | 1. Turn the product off, and then on again. 2. Upgrade the firmware. 3. Replace the scanner. |

| Error code: | 30.03.30 |

| Display: | 30.03.30 Scanner Failure |

| Description: | Scanner Failure. Flatbed motor shutdown. The scanner control board cannot communicate with the flatbed scanner motor. |

| Remedy: | 1. Turn the product off, and then on again. As the product turns on, verify that the scan head moves. 2. Verify that the drive belt is in the correct position. 3. Run diagnostics on the flatbed scanner to see if the scan bar moves. 4. Check the cable connection to the SCB. 5. Replace the scanner. |

| Error code: | 30.03.45 |

| Display: | 30.03.45 Scanner Error To continue turn off then on |

| Description: | Scanner Error To continue turn off then on. Scanner control board (SCB) firmware assertion failure. SCB firmware assert controls the scan head motor. |

| Remedy: | 1. Turn the product off, and then on again. 2. Upgrade the firmware. 3. Replace the Scanner control board (SCB). 4. Replace the scanner assembly. |

| Error code: | 31.01.47 |

| Display: | 31.01.47 Document feeder not detected |

| Description: | Document feeder not detected The document feeder was not detected, the document feeder might not be connected. The flatbed glass is still available for scanning. |

| Remedy: | 1. Turn the product off and then on. 2. If error persists, replace document feeder NOTE: Before replacing the document feeder, technicians should verify that the connections between the document feeder and the product are fully seated. Check One flat cable (callout 1), one ground screw (callout 2), and five connectors (callout 3). |

| Error code: | 31.03.30 |