HP LaserJet M5039 MFP

Рейтинг

Модули

Paper delivery assembly (print engine)

Separation floor assembly (ADF)

Paper feed assembly (print engine)

1X500 HCI main body

Cartridge door assembly (print engine)

Internal components (1 of 3) (print engine)

PCA assemblies (print engine)

Internal components (3 of 3) (print engine)

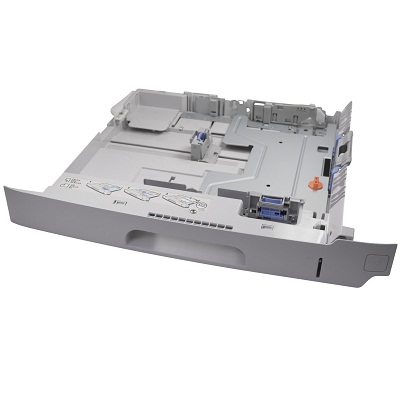

Cassette (HCI)

Scanner controller board (SCB) assembly

Main body (stapler/stacker)

Fuser pressure release assembly (print engine)

Carriage assembly (scanner optical assembly)

Front end cover (ADF)

Stapler assembly (stapler/stacker)

Registration assembly (print engine)

Scanner assembly base

External panel and covers (print engine)

Lifter drive assembly (HCI)

Hinges (ADF)

Lifter drive assembly (print engine)

Paper pickup assembly (HCI)

3X500 HCI main body

Base assembly (ADF)

Backbone assembly (ADF)

Fuser (print engine)

Paper feed assembly (stapler/stacker)

Lower cassette pickup assembly (print engine)

Upper cassette (print engine)

Separation pad assembly (ADF)

Internal components (2 of 3) (print engine)

PCA assemblies

Pickup roller assembly (ADF)

Scanner lid sensor assembly

Upper cassette pickup assembly (print engine)

Alignment/jogger assembly (stapler/stacker)

Jam Cover (ADF)

Automatic document feeder (whole unit)

Lower cassette (print engine)

Scanner transmission drive assembly

Scanner top assembly

Lower drive assembly (print engine)

Fuser drive assembly (print engine)

Stapler/stacker PCA assembly

Детали Cassette (HCI)

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000CN |

| Цена: | 350 ₽ |

| Деталь: | PAPER DELIVERY ASSEMBLY |

| Парткод: | RM1-2987-000CN |

| Деталь: | ADF separation floor assembly |

| Парткод: | Q7829-67909 |

| Деталь: | PAPER FEED ASSEMBLY |

| Парткод: | RM1-3009-000CN |

| Деталь: | Stopper, right door |

| Парткод: | RC1-9882-000CN |

| Деталь: | COVER, REAR |

| Парткод: | RC2-0151-000CN |

| Деталь: | COVER, RIGHT LOWER |

| Парткод: | RC2-0152-000CN |

| Деталь: | COVER, LEFT LOWER |

| Парткод: | RC2-0153-000CN |

| Деталь: | LINK, RIGHT DOOR |

| Парткод: | RC2-0160-000CN |

| Деталь: | COVER, RIGHT FRONT |

| Парткод: | RC2-0161-000CN |

| Деталь: | COVER, FRONT UPPER |

| Парткод: | RC2-0162-000CN |

| Деталь: | COVER, LEFT |

| Парткод: | RC2-0163-000CN |

| Деталь: | Link, right door, upper |

| Парткод: | RC2-0170-000CN |

| Деталь: | Door, stock |

| Парткод: | RC2-0181-000CN |

| Деталь: | Cover, stock box |

| Парткод: | RC2-0183-000CN |

| Деталь: | MOTOR, STEPPING, DC |

| Парткод: | RK2-1331-000CN |

| Цена: | 2 500 ₽ |

| Деталь: | RIGHT DOOR ASSEMBLY |

| Парткод: | RM1-3825-000CN |

| Деталь: | Paper feed PCA assembly |

| Парткод: | RM1-3641-000CN |

| Деталь: | ROLLER, RAIL |

| Парткод: | RC1-9231-000CN |

| Деталь: | Caster, rear |

| Парткод: | RC1-9917-000CN |

| Деталь: | Caster, front |

| Парткод: | RC2-0134-000CN |

| Деталь: | HOLDER, DRAWER |

| Парткод: | RC2-0167-000CN |

| Деталь: | Stopper, right door link upper |

| Парткод: | RC2-0169-000CN |

| Деталь: | RAIL, CASSETTE, LEFT |

| Парткод: | RL1-1391-000CN |

| Деталь: | RAIL, CASSETTE, RIGHT |

| Парткод: | RL1-1390-000CN |

| Деталь: | Cartridge door assembly |

| Парткод: | RM1-2984-000CN |

| Деталь: | Roller, multipurpose paper pickup |

| Парткод: | RL1-0915-000CN |

| Деталь: | SPRING, TENSION |

| Парткод: | RU5-2548-000CN |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RU5-2553-000CN |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000CN |

| Цена: | 350 ₽ |

| Деталь: | Multipurpose pad assembly |

| Парткод: | RM1-2462-000CN |

| Деталь: | Cartridge door base assembly |

| Парткод: | RM1-2985-000CN |

| Деталь: | Multipurpose (Tray 1) cover assembly |

| Парткод: | RM1-2986-000CN |

| Деталь: | STOPPER, CARTRIDGE DOOR |

| Парткод: | RC1-8021-000CN |

| Деталь: | Stopper, busing arm |

| Парткод: | RC1-3090-000CN |

| Деталь: | COVER, GEAR, RIGHT UPPER |

| Парткод: | RC1-7019-000CN |

| Деталь: | ROLLER, TRANSFER |

| Парткод: | RM1-2485-000CN |

| Деталь: | CAP, PAPER FEED GUIDE |

| Парткод: | RC1-7141-000CN |

| Деталь: | MAIN MOTOR ASSEMBLY |

| Парткод: | RM1-2516-000CN |

| Цена: | 3 200 ₽ |

| Деталь: | GUIDE, CARTRIDGE, RIGHT LOWER |

| Парткод: | RC1-7286-000CN |

| Деталь: | STOPPER, LINK |

| Парткод: | RC1-7288-000CN |

| Деталь: | PLATE, GEAR |

| Парткод: | RL1-0951-000CN |

| Цена: | 1 700 ₽ |

| Деталь: | GUIDE, CARTRIDGE DOOR STOPPER |

| Парткод: | RC1-8022-000CN |

| Деталь: | Lever, fuser shutter |

| Парткод: | RC1-8032-000CN |

| Деталь: | Cover, gear, rear |

| Парткод: | RC1-8164-000CN |

| Цена: | 1 000 ₽ |

| Деталь: | Mount, interlock guide |

| Парткод: | RC1-8165-000CN |

| Деталь: | CABLE, FLEXIBLE FLAT, 21P |

| Парткод: | RK2-1053-000CN |

| Деталь: | CABLE, FLEXIBLE FLAT, 23P |

| Парткод: | RK2-1055-000CN |

| Деталь: | CLUTCH, ELECTROMAGNETIC |

| Парткод: | RK2-1281-000CN |

| Цена: | 1 300 ₽ |

| Деталь: | Cable, flexible flat, 15P |

| Парткод: | RK2-1283-000CN |

| Деталь: | SPRING, GROUNDING |

| Парткод: | RC1-8052-000CN |

| Деталь: | GEAR, 14T |

| Парткод: | RU5-0564-000CN |

| Деталь: | GEAR, 15T |

| Парткод: | RU5-0553-000CN |

| Деталь: | SPRING, TENSION |

| Парткод: | RU5-2660-000CN |

| Деталь: | SPRING, TENSION |

| Парткод: | RU5-2663-000CN |

| Деталь: | RING, E |

| Парткод: | RC18358000CN |

| Деталь: | DC controller PCA assembly |

| Парткод: | RM1-3459-000CN |

| Деталь: | CONNECTOR, DRAWER |

| Парткод: | VS1-7258-007CN |

| Деталь: | GEAR, 133T |

| Парткод: | RU5-0546-000CN |

| Деталь: | GEAR, 73T |

| Парткод: | RU5-0547-000CN |

| Цена: | 310 ₽ |

| Деталь: | GEAR, 96T/52T |

| Парткод: | RU5-0548-000CN |

| Цена: | 390 ₽ |

| Деталь: | Switch, fuser door |

| Парткод: | RM1-3474-000CN |

| Деталь: | GEAR, 99T/40T |

| Парткод: | RU5-0549-000CN |

| Цена: | 340 ₽ |

| Деталь: | GEAR, 43T |

| Парткод: | RU5-0550-000CN |

| Цена: | 200 ₽ |

| Деталь: | GEAR, 26T |

| Парткод: | RU5-0551-000CN |

| Цена: | 160 ₽ |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RU5-2630-000CN |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RU5-2631-000CN |

| Деталь: | SPRING, TENSION |

| Парткод: | RU5-2632-000CN |

| Деталь: | PLATE, GROUNDING |

| Парткод: | RC1-7021-000CN |

| Деталь: | Cartridge, guide, left assembly |

| Парткод: | RC1-7121-000CN |

| Деталь: | PADDLE |

| Парткод: | RC1-7122-000CN |

| Деталь: | SPRING, TORSION |

| Парткод: | RC1-7123-000CN |

| Деталь: | SPRING, GROUNDING |

| Парткод: | RC1-7124-000CN |

| Деталь: | SPRING, TORSION |

| Парткод: | RC1-7125-000CN |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RC1-7126-000CN |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RC1-7127-000CN |

| Деталь: | SIDE PLATE, TRANSFER DRIVE |

| Парткод: | RC1-7129-000CN |

| Деталь: | HOLDER, CONTACT |

| Парткод: | RC1-7241-000CN |

| Деталь: | COVER |

| Парткод: | RC1-7265-000CN |

| Деталь: | BUSHING |

| Парткод: | RC1-7443-000CN |

| Деталь: | HOLDER, SPRING |

| Парткод: | RC1-8026-000CN |

| Деталь: | ARM, LOCK |

| Парткод: | RC1-8034-000CN |

| Деталь: | Duct, high-voltage, upper |

| Парткод: | RC1-8344-000CN |

| Деталь: | Duct, high-voltage, lower |

| Парткод: | RC1-8345-000CN |

| Деталь: | GEAR, 25T |

| Парткод: | RU5-0537-000CN |

| Деталь: | GEAR, 35T |

| Парткод: | RU5-0538-000CN |

| Деталь: | GEAR, 33T |

| Парткод: | RU5-0539-000CN |

| Цена: | 300 ₽ |

| Деталь: | SPRING, TENSION |

| Парткод: | RU5-2575-000CN |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RU5-2587-000CN |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RU5-2588-000CN |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RU5-2589-000CN |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RU5-2590-000CN |

| Деталь: | SPRING, TENSION |

| Парткод: | RU5-2591-000CN |

| Деталь: | Photo interrupter, TL1243 |

| Парткод: | WG8-5696-000CN |

| Цена: | 350 ₽ |

| Деталь: | BUSHING |

| Парткод: | RC1-7283-000CN |

| Деталь: | CAM |

| Парткод: | RC1-7284-000CN |

| Деталь: | LEVER, COUPLING |

| Парткод: | RC1-7285-000CN |

| Деталь: | GUIDE, CARTRIDGE, RIGHT UPPER |

| Парткод: | RC1-7287-000CN |

| Деталь: | GUIDE, REAR |

| Парткод: | RC1-8046-000CN |

| Деталь: | Screw, tapping, truss head, M4x10 |

| Парткод: | XB4-7401-005CN |

| Цена: | 140 ₽ |

| Деталь: | DC controller PCA assembly |

| Парткод: | RM1-3459-000CN |

| Деталь: | High-voltage PCA assembly (110V-127V) |

| Парткод: | RM1-2957-000CN |

| Деталь: | High-voltage PCA assembly (220V-240V) |

| Парткод: | RM1-2958-000CN |

| Деталь: | Low-voltage PCA assembly (110V-127V) |

| Парткод: | RM1-2994-000CN |

| Деталь: | Low-voltage PCA assembly (220V-240V) |

| Парткод: | RM1-3006-000CN |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000CN |

| Цена: | 350 ₽ |

| Деталь: | Left cassette rail assembly |

| Парткод: | RM1-2970-000CN |

| Деталь: | Right cassette rail assembly |

| Парткод: | RM1-2971-000CN |

| Деталь: | Plate, cross member auxiliary |

| Парткод: | RC1-7264-000CN |

| Деталь: | HOLDER, TOP SENSOR |

| Парткод: | RC1-7268-000CN |

| Деталь: | Guide, duplexer, front |

| Парткод: | RC1-8027-000CN |

| Деталь: | Holder, cassette, right front |

| Парткод: | RC1-8035-000CN |

| Деталь: | Holder, cassette, left front |

| Парткод: | RC1-8036-000CN |

| Деталь: | Cam, pad return, lower |

| Парткод: | RC1-8038-000CN |

| Деталь: | Guide, duplexer, rear |

| Парткод: | RC1-8048-000CN |

| Деталь: | SPRING, TORSION |

| Парткод: | RU5-2596-000CN |

| Деталь: | FLAG, LOOP SENSOR |

| Парткод: | RC1-7144-000CN |

| Деталь: | SPRING, TORSION |

| Парткод: | RC1-7145-000CN |

| Деталь: | High voltage power supply assembly (110127 V) |

| Парткод: | RM1-2957-000CN |

| Деталь: | High voltage power supply assembly (220240 V) |

| Парткод: | RM1-2958-000CN |

| Деталь: | Back end sensor assembly |

| Парткод: | RM1-2968-000CN |

| Деталь: | BUSHING |

| Парткод: | RC1-7249-000CN |

| Деталь: | FLAG, TOP SENSOR |

| Парткод: | RC1-7261-000CN |

| Деталь: | Cassette (1X500 HCI) |

| Парткод: | RM1-3815-000CN |

| Деталь: | Cassette (3X500 HCI) |

| Парткод: | RM1-3815-000CN |

| Деталь: | Cover, Scanner controller board (main board cover) |

| Парткод: | Q7829-60145 |

| Деталь: | Scanner controller board PCA (main baord) |

| Парткод: | Q7829-60165 |

| Деталь: | Door, front |

| Парткод: | RC1-9716-000CN |

| Деталь: | COVER, LEFT |

| Парткод: | RC1-9718-000CN |

| Деталь: | DOOR, LEFT |

| Парткод: | RC1-9719-000CN |

| Деталь: | Cover, stack |

| Парткод: | RC19724000 |

| Деталь: | GUIDE, FFC |

| Парткод: | RC1-9767-000CN |

| Деталь: | SPRING, TENSION |

| Парткод: | RU5-2731-000CN |

| Деталь: | Tray assembly |

| Парткод: | RM1-3093-000CN |

| Деталь: | Stapler cover assembly |

| Парткод: | RM1-3094-000CN |

| Деталь: | REAR COVER ASSEMBLY |

| Парткод: | RM1-3095-000CN |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000CN |

| Цена: | 350 ₽ |

| Деталь: | INTERLOCK ASSEMBLY |

| Парткод: | RM1-3087-000CN |

| Деталь: | Support, front door |

| Парткод: | RC1-9725-000CN |

| Деталь: | Staple stacker |

| Парткод: | Not orderable |

| Деталь: | Fuser pressure release assembly |

| Парткод: | RM1-2973-000CN |

| Деталь: | Carriage assembly (optical assembly) |

| Парткод: | Q7829-60166 |

| Цена: | 20 900 ₽ |

| Деталь: | ADF end cover (cap) front |

| Парткод: | Q782967905 |

| Деталь: | Holder, stapler |

| Парткод: | RC1-9770-000CN |

| Деталь: | Stapler assembly |

| Парткод: | RM1-3092-000CN |

| Деталь: | REGISTRATION ASSEMBLY |

| Парткод: | RM1-3001-000CN |

| Цена: | 4 500 ₽ |

| Деталь: | ROD |

| Парткод: | Q7829-60160 |

| Деталь: | Guide, glass |

| Парткод: | Q7829-60157 |

| Деталь: | Rubber, guide |

| Парткод: | Q7829-60162 |

| Деталь: | Guide, glass |

| Парткод: | Q7829-60158 |

| Деталь: | Sensor, paper |

| Парткод: | Q7829-60163 |

| Деталь: | Rail and slide sheet assembly |

| Парткод: | Q7829-60164 |

| Деталь: | Scanner |

| Парткод: | Q7829-60159 |

| Деталь: | Cover, facedown, top |

| Парткод: | RC1-82220-000CN |

| Деталь: | COVER, FRONT |

| Парткод: | RC1-8221-000CN |

| Деталь: | COVER, REAR |

| Парткод: | RC1-8222-000CN |

| Деталь: | Cover, formatter |

| Парткод: | RC1-8223-000CN |

| Деталь: | COVER, LEFT, REAR |

| Парткод: | RC1-8225-000CN |

| Деталь: | COVER, RIGHT, REAR |

| Парткод: | RC1-8226-000CN |

| Деталь: | COVER, LEFT, UPPER |

| Парткод: | RC1-8227-000CN |

| Деталь: | COVER, LEFT, LOWER |

| Парткод: | RC1-8228-000CN |

| Деталь: | Cover, facedown side |

| Парткод: | RC1-8231-000CN |

| Деталь: | COVER, TOP |

| Парткод: | RC1-8233-000CN |

| Деталь: | Cover, duplexing blanking |

| Парткод: | RC1-8235-000CN |

| Деталь: | Cover, grip, right |

| Парткод: | RC1-8236-000CN |

| Деталь: | Cover, inner top |

| Парткод: | RC1-8327-000CN |

| Деталь: | LEFT DOOR ASSEMBLY |

| Парткод: | RM1-2990-000CN |

| Цена: | 2 800 ₽ |

| Деталь: | RIGHT DOOR ASSEMBLY |

| Парткод: | RM1-2991-000CN |

| Деталь: | TRAY, SUB |

| Парткод: | RC1-8137-000CN |

| Деталь: | Lifter drive assembly (1x500) |

| Парткод: | RM1-3819-000CN |

| Деталь: | Lifter drive assembly (3X500) |

| Парткод: | RM1-3819-000CN |

| Деталь: | ADF hinge assembly (two are required for the ADF) |

| Парткод: | Q782967916 |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000CN |

| Цена: | 350 ₽ |

| Деталь: | LIFTER DRIVE ASSEMBLY |

| Парткод: | RM1-2969-000CN |

| Цена: | 4 300 ₽ |

| Деталь: | Roller, pickup |

| Парткод: | RL1-1206-000CN |

| Деталь: | PAPER FEED ROLLER ASSEMBLY |

| Парткод: | RM1-0037-000N |

| Деталь: | Paper pickup assembly (1X500 HCI) |

| Парткод: | RM1-3821-000CN |

| Деталь: | Paper pickup assembly (3X500) |

| Парткод: | RM1-3821-000CN |

| Деталь: | Stopper, right door |

| Парткод: | RC1-9882-000CN |

| Деталь: | COVER, REAR |

| Парткод: | RC2-0151-000CN |

| Деталь: | COVER, RIGHT LOWER |

| Парткод: | RC2-0152-000CN |

| Деталь: | COVER, LEFT LOWER |

| Парткод: | RC2-0153-000CN |

| Деталь: | LINK, RIGHT DOOR |

| Парткод: | RC2-0160-000CN |

| Деталь: | COVER, RIGHT FRONT |

| Парткод: | RC2-0161-000CN |

| Деталь: | COVER, FRONT UPPER |

| Парткод: | RC2-0162-000CN |

| Деталь: | COVER, LEFT |

| Парткод: | RC2-0163-000CN |

| Деталь: | Link, right door, upper |

| Парткод: | RC2-0170-000CN |

| Деталь: | MOTOR, STEPPING, DC |

| Парткод: | RK2-1331-000CN |

| Цена: | 2 500 ₽ |

| Деталь: | RIGHT DOOR ASSEMBLY |

| Парткод: | RM1-3824-000CN |

| Деталь: | Paper feed PCA assembly |

| Парткод: | RM1-3641-000CN |

| Деталь: | ROLLER, RAIL |

| Парткод: | RC1-9231-000CN |

| Деталь: | Caster, rear |

| Парткод: | RC1-9917-000CN |

| Деталь: | Caster, front |

| Парткод: | RC2-0134-000CN |

| Деталь: | HOLDER, DRAWER |

| Парткод: | RC2-0167-000CN |

| Деталь: | Stopper, right door link upper |

| Парткод: | RC2-0169-000CN |

| Деталь: | RAIL, CASSETTE, RIGHT |

| Парткод: | RL1-1390-000CN |

| Деталь: | RAIL, CASSETTE, LEFT |

| Парткод: | RL1-1391-000CN |

| Деталь: | Switch, bottom |

| Парткод: | WC2-5512-000CN |

| Деталь: | COVER, LEFT |

| Парткод: | Q782967906 |

| Деталь: | ADF diverter |

| Парткод: | Q7829-67918 |

| Деталь: | ADF photo interrupter w/connector |

| Парткод: | Q7829-67914 |

| Деталь: | ADF float assembly |

| Парткод: | Q7829-67917 |

| Цена: | 1 500 ₽ |

| Деталь: | Fuser assembly (110V-127V) |

| Парткод: | RM1-3007-000CN |

| Деталь: | Fuser assembly (220V-240V) |

| Парткод: | RM1-3008-000CN |

| Деталь: | Paper feed assembly (stapler/stacker) |

| Парткод: | RM1-3088-000CN |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000CN |

| Цена: | 350 ₽ |

| Деталь: | Paper pickup roller assembly |

| Парткод: | RM1-2998-000CN |

| Деталь: | Lower cassette pickup assembly (engine) |

| Парткод: | RM1-2977-000CN |

| Деталь: | Separation block assembly |

| Парткод: | RM1-2983-000CN |

| Деталь: | Upper cassette (engine) |

| Парткод: | RM1-2978-000CN |

| Цена: | 5 900 ₽ |

| Деталь: | Separation pad assembly (part of the ADF maintenance kit) |

| Парткод: | Q7842-67902 |

| Деталь: | Laser scanner assembly (print engine) |

| Парткод: | RM1-2555-000CN |

| Деталь: | Shutter, fuser |

| Парткод: | RC1-7163-000CN |

| Деталь: | LINK, TAG |

| Парткод: | RC1-7289-000CN |

| Деталь: | Shaft, fuser shutter |

| Парткод: | RC1-7436-000CN |

| Деталь: | LEVER, SHUTTER |

| Парткод: | RC1-7451-000CN |

| Деталь: | Link, fuser sensing, small |

| Парткод: | RC1-8058-000CN |

| Деталь: | Plate, scanner duct |

| Парткод: | RC1-8069-000CN |

| Деталь: | DUCT, SCANNER, LOWER |

| Парткод: | RC1-8328-000CN |

| Деталь: | CAM, SHUTTER |

| Парткод: | RC1-8329-000CN |

| Деталь: | Lever, pushing |

| Парткод: | RC1-8330-000CN |

| Деталь: | SPACER, SLIDE |

| Парткод: | RC1-8331-000CN |

| Деталь: | Cam, slide |

| Парткод: | RC1-8332-000CN |

| Деталь: | Ring, spacer |

| Парткод: | RC1-8333-000CN |

| Деталь: | SPRING, TORSION |

| Парткод: | RC1-8334-000CN |

| Деталь: | SPRING, TORSION |

| Парткод: | RC1-8335-000CN |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RU5-2633-000CN |

| Деталь: | SPRING, TENSION |

| Парткод: | RU5-2651-000CN |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000CN |

| Цена: | 350 ₽ |

| Деталь: | Tag holder assembly |

| Парткод: | RM1-2999-000CN |

| Деталь: | Link, fuser sensing |

| Парткод: | RC1-8059-000CN |

| Деталь: | Lever, fuser sensing switch |

| Парткод: | RC1-8060-000CN |

| Деталь: | SPRING, TORSION |

| Парткод: | RC1-8078-000CN |

| Деталь: | SPRING, COMPRESSION |

| Парткод: | RU5-2683-000CN |

| Деталь: | Power supply assembly (110127 V) |

| Парткод: | RM1-2994-000CN |

| Деталь: | Power supply assembly (220240 V) |

| Парткод: | RM1-3006-000CN |

| Деталь: | Fan, rear |

| Парткод: | RK2-1284-000CN |

| Цена: | 2 000 ₽ |

| Деталь: | Fan, front |

| Парткод: | RK2-1285-000CN |

| Цена: | 2 000 ₽ |

| Деталь: | Lock, pressure release, front |

| Парткод: | RC1-8039-000CN |

| Деталь: | LEVER, DRIVE RELEASE |

| Парткод: | RC1-8075-000CN |

| Деталь: | PAPER DELIVERY DRIVE ASSEMBLY |

| Парткод: | RM1-2962-000CN |

| Цена: | 3 000 ₽ |

| Деталь: | CONNECTOR, DRAWER |

| Парткод: | VS1-7258-0007CN |

| Деталь: | Connecting PCA assembly |

| Парткод: | RM1-2995-000CN |

| Деталь: | Switch, cartridge door |

| Парткод: | RM1-3471-000CN |

| Деталь: | Paper feed PCA assembly (1X500 HCI) |

| Парткод: | RM1-3641-000CN |

| Деталь: | Paper feed PCA assembly (3X500 HCI) |

| Парткод: | RM1-3641-000CN |

| Деталь: | ADF cover pickup roller (part of the ADF maintenance kit) |

| Парткод: | Q7842-67902 |

| Деталь: | Scanner lid sensor assembly |

| Парткод: | Q7829-60148 |

| Деталь: | PHOTO INTERRUPTER, TLP1243 |

| Парткод: | WG8-5696-000CN |

| Цена: | 350 ₽ |

| Деталь: | Paper pickup roller assembly |

| Парткод: | RM1-2988-000CN |

| Деталь: | Upper cassette paper pickup assembly (engine) |

| Парткод: | RM1-2976-000CN |

| Деталь: | SCREW, RS, M3X8 |

| Парткод: | XA9-1386-000CN |

| Деталь: | Jog guide assembly |

| Парткод: | RM1-3099-000CN |

| Деталь: | Alignment and jogger assembly |

| Парткод: | RM1-3098-000CN |

| Деталь: | Cover ADF pickup roller |

| Парткод: | Q7829-67920 |

| Цена: | 1 600 ₽ |

| Деталь: | ADF jam cover assembly |

| Парткод: | Q7829-67910 |

| Деталь: | ADF endcap back |

| Парткод: | Q7829-67904 |

| Деталь: | Cable, ADF to scanner |

| Парткод: | Q7829-67907 |

| Деталь: | PCA motor assembly |

| Парткод: | Q7829-67903 |

| Деталь: | ADF tray input assembly |

| Парткод: | Q7829-67912 |

| Цена: | 2 300 ₽ |

| Деталь: | ADF reflector foam (white backing) |

| Парткод: | Q7829-67909 |

| Деталь: | Automatic document feeder (ADF) |

| Парткод: | Q7829-67901 |

| Деталь: | ADF flag sensor LS |

| Парткод: | Q7829-67913 |

| Деталь: | ADF photo interrupter with connector |

| Парткод: | Q7829-67914 |

| Деталь: | Separation block assembly |

| Парткод: | RM1-2983-000CN |

| Деталь: | Lower cassette (engine) |

| Парткод: | RM1-2979-000CN |

| Цена: | 8 900 ₽ |

| Деталь: | Motor, transmission |

| Парткод: | Q7829-60149 |

| Деталь: | Timing belt, transmission |

| Парткод: | Q7829-60150 |

| Деталь: | Pulley, transmission |

| Парткод: | Q7829-60151 |

| Деталь: | TOP COVER |

| Парткод: | Q7829-60152 |

| Деталь: | RIGHT COVER |

| Парткод: | Q7829-60153 |

| Деталь: | Adhesive cover |

| Парткод: | Q7829-60144 |

| Деталь: | COVER, BOTTOM |

| Парткод: | Q7829-60154 |

| Деталь: | GLASS |

| Парткод: | Q7829-60143 |

| Цена: | 1 400 ₽ |

| Деталь: | Lower drive assembly |

| Парткод: | RM1-2972-000CN |

| Деталь: | Fuser motor assembly |

| Парткод: | RM1-2538-000CN |

| Цена: | 3 500 ₽ |

| Деталь: | RING, E |

| Парткод: | XD9-0233-000CN |

| Цена: | 230 ₽ |

| Деталь: | Fuser drive assembly (print engine) |

| Парткод: | RM1-2963-000CN |

| Деталь: | Staple stacker PCA assembly |

| Парткод: | RM1-3828-000CN |

Коды ошибок

10.32.00

10.XX.YY

11.XX

13.01.00

13.02.00

13.03.00

13.04.00

13.05.00

13.06.00

13.09.00

13.0A.00

13.10.00

13.12.00

13.12.07

13.12.08

13.12.09

13.12.10

13.12.11

13.12.38

13.12.42

13.13.00

13.14.00

13.1C.00

13.20.00

13.21.00

13.30.00

13.31.00

13.33.00

13.41.00

13.42.00

13.46.00

13.90.00

13.98.00

13.99.00

20.1

20.2

20.3

20.4

20.5

21

22

30.1.1

30.1.15

30.1.17

30.1.18

30.1.19

30.1.2

30.1.22

30.1.23

30.1.24

30.1.25

30.1.3

30.1.34

30.1.36

30.1.7

30.1.8

40

41.1

41.2

41.3

41.7

41.8

41.9

49.XXXXX

50.1

50.2

50.3

50.4

50.5

50.6

50.7

50.8

50.9

51.10

51.20

52.00

52.10

52.20

53.XY.ZZ

54.XX

55.00

55.01

55.02

55.03

55.04

55.06

56.01

56.02

57.01

57.03

57.04

58.03

58.04

59.10

59.20

59.30

59.40

60.XX

62

64

65.12.99

66.00.15

66.12.XX

68.X

69.X

79.XXXX

8X.YYYY

Описание

| Error code: | 10.32.00 |

| Display: | 10.32.00 - Unauthorized Supply |

| Description: | A supply has been installed that does not pass the authentication test for genuine HP supplies. |

| Remedy: | If you believe you purchased a genuine HP supply, visit us at www.hp.com/go/ anticounterfeit. Any repair required as a result of using non-HP supplies or unauthorized supplies are not covered under warranty. HP cannot ensure the accuracy or the availability of certain features. To continue printing, touch OK. |

| Error code: | 10.XX.YY |

| Display: | 10.XX.YY SUPPLY MEMORY ERROR |

| Description: | An error has occurred in one or more of the product`s supplies. Values of XX and YY are listed below: XX00 = memory is defective XX01 = memory is missing YY00 = cartridge |

| Remedy: | • Turn the product off and then on to clear the message. • Replace the print cartridge. |

| Error code: | 11.XX |

| Display: | 11.XX INTERNAL CLOCK ERROR |

| Description: | The real time clock has experienced an error. |

| Remedy: | 1. Power cycle the product to see if the message clears. 2. If possible, print a configuration page to record product information, and then perform an NVRAM initialization routine. If the initialization routine is successful, you will need to re-enter several configuration parameters (such as the page count and the serial number). 3. If the error persists, replace the formatter PCA. |

| Error code: | 13.01.00 |

| Display: | 13.01.00 Jam in Tray 1 |

| Description: | The Tray 1 pickup roller or solenoid might not be working correctly. |

| Remedy: | 1. Load paper in Tray 1, and then use the paper path test to pull paper. Verify that the roller rotates. 2. If someone has performed maintenance on the product recently, verify that the Tray 1 pickup roller, feed roller, and separation roller have been installed correctly. 3. From the DIAGNOSTICS menu, run the multipurpose tray (Tray 1) solenoid component test to verify that the solenoid moves when energized. Listen for an audible “click” when the test is initiated. If the solenoid is not being energized, verify that the solenoid connector is attached to connector J71 on the DC controller PCA. 4. If the error persists, replace the Tray 1 solenoid (SL102). |

| Error code: | 13.02.00 |

| Display: | 13.02.00 Jam inside upper right door |

| Description: | Stay jam at SR5 (top/registration sensor). SR5 continues to detect media, after the media is originally detected, longer than specified. |

| Remedy: | Clear the jam. 1. Check for paper or other obstructions to the paper path in Tray 2 and before the registration area. 2. Check SR5 (top/registration sensor) and flag for correct mechanical functionality. Repair or replace if necessary. 3. Check connector J319 on the dc controller. 4. Replace the HVPS. 5. Replace the dc controller. |

| Error code: | 13.03.00 |

| Display: | 13.03.00 JAM IN TRAY X |

| Description: | A jam has occurred in the specified location. This jam occurs when the product cannot move paper from the specified tray into the paper path. |

| Remedy: | 1. Inspect the paper path and remove any obstructions. 2. Verify that the tray is not loaded incorrectly or overfilled. 3. For Trays 3, 4, 5, or 6, verify that the trays are stacked correctly. 4. Verify that the media meets HP media specifications. 5. If maintenance has recently be performed, verify that the pickup, feed, and separation rollers have been reinstalled correctly. 6. Verify that connector J77 on the DC controller PCA is firmly seated. 7. From the DIAGNOSTICS menu, run the feed roller clutch (CL101) component test. 8. If the tray pickup motor rotates, yet the drive gears directly below the motor (on the Tray 2 pickup assembly) do not rotate, the clutch is not functioning properly. Replace the feed roller assembly. |

| Error code: | 13.04.00 |

| Display: | 13.04.00 |

| Description: | The page stayed at SR2 (duplexing-feed sensor) too long. |

| Remedy: | Clear the jam. 1. Remove the duplexer and check SR2 (duplexing-feed sensor) for correct mechanical functionality. Replace if necessary. 2. Check for paper or other obstructions to the paper path in the duplexer and between the fuser and the duplexer. 3. Check connector J1506 on the HCI controller in Tray 5. 4. Check the interface between the duplexer and the print engine. 5. Replace the duplexer. 6. Replace the dc controller. |

| Error code: | 13.05.00 |

| Display: | 13.05.00 JAM INSIDE TOP COVER |

| Description: | Paper failed to reach the delivery sensor within a specified period of time when a print job was initiated. When troubleshooting paper jams, always observe where the leading edge of the paper stops in the jam. |

| Remedy: | 1. Verify that nothing is obstructing paper movement within the paper path. 2. Verify that the fuser motor (M2) connector is firmly seated. The fuser motor wiring is hard-wired to the back of the ECU at connector J501. The motor connector is free-standing behind the ECU. To see if the fuser motor is functional, observe the output stacker rollers while turning on the device. If the rollers rotate, the motor is functional. If they do not rotate, verify the connection. |

| Error code: | 13.06.00 |

| Display: | 13.06.00 Jam inside left door |

| Description: | A jam is in the fuser area. |

| Remedy: | - Clear the jam in the area indicated. - Close the door to allow the product to attempt to clear the jam. - Replace the fuser. |

| Error code: | 13.09.00 |

| Display: | 13.09.00 Jam inside left door |

| Description: | A jam is in the face-down bin. The leading edge of the media failed to reach the face-down bin delivery sensor (PS1451) within the specified time. |

| Remedy: | - Clear the jam in the area indicated. - Close the door to allow the product to attempt to clear the jam. - Reseat the connections to the DC controller. - Make sure that the delivery flags move smoothly. - Run a service test. - Replace the delivery unit. - Replace the DC controller. |

| Error code: | 13.0A.00 |

| Display: | 13.0A.00 Jam inside left door |

| Description: | A jam is in an area accessible through the left door. The trailing edge of the media failed to leave the face-down bin delivery sensor (PS1451) within the specified time. |

| Remedy: | - Clear the jam in the area indicated. - Close the door to allow the product to attempt to clear the jam. - Replace the delivery unit. - Replace the diverter. |

| Error code: | 13.10.00 |

| Display: | 13.10.00 Jam inside left door |

| Description: | A jam is in the reversing area. The leading edge of the media did not reach the reversed paper sensor (PS2002) in the duplexer within the specified time. |

| Remedy: | - Clear the jam in the area indicated. - Close the door to allow the product to attempt to clear the jam. - Reseat the connections to the DC controller. - Replace the duplexer. |

| Error code: | 13.12.00 |

| Display: | 13.12.00 Jam inside duplexer |

| Description: | Duplexer refeed jam. The page did not reach SR2 (duplexer-refeed sensor). |

| Remedy: | Clear the jam. 1. Remove the duplexer and check sensors SR1 (duplexer-jam sensor) and SR2 (duplexer-refeed sensor) for correct mechanical functionality. Replace if necessary. 2. Check for paper or other obstructions to the paper path in the duplexer and between the fuser and the duplexer. 3. Check the interface between the duplexer and the print engine. 4. Check connector J311 on the dc controller. 5. Replace the duplexer. 6. Replace the dc controller. |

| Error code: | 13.12.07 |

| Display: | 13.12.07 Stapler jam inside front stapler door |

| Description: | Stapler jam. The stapler could not complete its cycle but was able to return to the home position. |

| Remedy: | 1. Open the front door, remove the staple cartridge, and perform the following tasks: - Lift the small tab at the green dot to release the staples. - Remove any damaged staples. - Lock the staple cartridge by pressing the small tab until it clicks into place. - Reinstall the staple cartridge. 2. If the problem persists, install a new staple cartridge. 3. If, after installing a new staple cartridge, the problem perisists, remove the staple cartridge and perform the following tasks: - Remove the front cover. - Remove the stapler. - Clear any loose or jammed staples from the stapler. - Reinstall the stapler. 4. If the problem persists, replace the stapler. |

| Error code: | 13.12.08 |

| Display: | 13.12.08 Jam in stacker bin area |

| Description: | Stapler jam. Stay jam in accumulator. SR2103 (delivery sensor) stayed activated too long. SR2103 is located in the paper path of the stapler/stacker at the exit rollers to the stacker-output bin. SR2103 is the exit sensor for the stapler/ stacker and senses media-presence as media exits the stapler/stacker into the stacker-output bin. |

| Remedy: | 1. Remove any media at the exit rollers of the stapler/stacker. 2. Open the upper left door and perform the following tasks: ?? Remove any media from the paper path. - Press down on the upper portion of the green guide and remove any media from between the green guide and the stapler/stacker exit rollers. - Check the operation of SR2103 (delivery sensor) and the sensor flag. If the sensor or the sensor flag is not working, replace the stapler/ stacker alignment assembly. 3. If, after performing the previous steps, the problem persists, replace the stapler/stacker control board. |

| Error code: | 13.12.09 |

| Display: | 13.12.09 Jam inside upper left door |

| Description: | Stapler jam. Stay jam in entry. SR2100 (inlet media sensor) stayed activated too long. SR2100 is located in the stapler/stacker feed assembly, sensing media entering the stapler/stacker. |

| Remedy: | 1. Open the lower left door and remove any paper or obstructions in the paper path. 2. Remove the stapler/stacker feed assembly and perform the following tasks. - Remove any media from SR2100. - Check the operation of the sensor flag and sensor-flag spring and make sure that the flag does not block the sensor. If the flag or the spring is damaged, replace the stapler/stacker feed assembly. - Clean SR2100 by blowing air gently into the sensing area. Check the sensor for correct mounting, cable connection, and alignment with the sensor flag. If the sensor is damaged or nor working, replace the sensor. - Check operation of the drive gears and belts at the rear of the stapler/ stacker feed assembly. Turning any of the gears should turn all of the rollers in the assembly. If the gears or belts are not working, replace the stapler/stacker feed assembly. |

| Error code: | 13.12.10 |

| Display: | 13.12.10 Jam inside upper left door |

| Description: | Stapler jam. Delay jam in entry. The page did not arrive at SR2100 (inlet media sensor) within the expected time. SR2100 is located in the stapler/stacker feed assembly, sensing media entering the stapler/stacker. |

| Remedy: | 1. Open the lower left door and remove any paper or obstructions in the paper path. 2. Turn off the device, disconnect the sensor connection at J2104 on the stapler/stacker control board, and then turn the device back on. If 13.12.11 does not appear on the control-panel display after the device warms up, replace SR2100. 3. Open the upper left door. If media is jammed in this area, replace the stapler/ stacker feed assembly. 4. Check the standard (lower) output bin to see whether media exited the device to the bin. Media exiting the device to the malfunction. - If SL2100 (flapper solenoid) is not working, replace the stapler/ stacker feed assembly. - If the flapper is broken, replace the delivery assembly. - If the SL2100 and the flapper are both working correctly, then the problem is in the stapler/stacker control board. Replace the board. 5. Open the lower left door. If media is jammed in this area, remove the stapler/ stacker feed assembly without clearing the jam. After removing the assembly, observe the location of the leading edge of the media and then perform the following tasks: - If the leading edge reached the entrance rollers of the feed assembly but stopped and jammed there, check operation of the drive gears and belts at the rear of the stapler/stacker feed assembly. Turning any of the gears should turn all of the rollers in the assembly. - If the gears or belts are not working, replace the stapler/ stacker feed assembly. - If all rollers turn correctly, replace the alignment assembly. - If the leading edge stopped at or stopped just past SR2100 (inlet media sensor), replace the stapler/ stacker feed assembly. 6. If, after performing the previous steps, the problem persists, replace the stapler/stacker control board. |

| Error code: | 13.12.11 |

| Display: | 13.12.11 Jam inside upper left door |

| Description: | Stapler jam. Initial jam at entry. At power-on, media was detected at SR2100 (inlet media sensor). SR2100 is located in the stapler/stacker feed assembly. SR2100 senses media entering the stapler/stacker. |

| Remedy: | 1. Open the upper left door and remove any media. 2. Open the lower left door and remove any media. 3. Check connection J2104 on the stapler/ stacker control board. 4. Remove the stapler/stacker feed assembly and perform the following tasks. - Remove any media from SR2100. - Check the operation of the sensor flag and sensor-flag spring and make sure that the flag does not block the sensor. If the flag or the spring is damaged, replace the stapler/stacker feed assembly. - Clean SR2100 by blowing air gently into the sensing area. Check the sensor for correct mounting, cable connection, and alignment with the sensor flag. If the sensor is damaged or nor working, replace the sensor. - Check operation of the drive gears and belts at the rear of the stapler/ stacker feed assembly. Turning any of the gears should turn all of the rollers in the assembly. If the gears or belts are not working, replace the stapler/stacker feed assembly. 5. If, after performing the previous steps, the problem persists, replace the stapler/stacker control board. |

| Error code: | 13.12.38 |

| Display: | 13.12.38 Jam inside upper left door |

| Description: | Delay jam at SR2103 (stapler/stacker delivery sensor). Media did not arrive at SR2103 within the expected time. SR2103 is located in the paper path of the stapler/stacker at the exit rollers to the stacker-output bin. SR2103 is the exit sensor for the stapler/ stacker and senses media-presence as media exits the stapler/stacker into the stacker-output bin. |

| Remedy: | 1. Open the upper left door and perform the following tasks: - Remove any paper or obstructions in the paper path. - Press down on the upper portion of the green guide and remove any media from between the green guide and the stapler/stacker exit rollers. 2. Make sure that the upper left door is mounted correctly at the bottom and that it closes securely at the top. If the door does not close correctly or if it shows signs of wear, replace the door. 3. Check the connection J2109 on the stapler/stacker control board. 4. Open the upper left door and observe the location of media in the paper path. - If the media stopped at the set of rollers located near the bottom of the left side door, replace the stapler/stacker feed assembly. - If the media stopped past the green guide, replace the stapler/stacker alighment unit. |

| Error code: | 13.12.42 |

| Display: | 13.12.42 Jam in stacker bin area |

| Description: | Stapler jam. Initial jam at exit. At power-on, media was detected at SR2103 (delivery sensor). SR2103 is located in the stapler/stacker at the exit rollers. SR2103 is the exit sensor for the stapler/stacker and senses media as the media exits the stapler/stacker into the stacker output bin. |

| Remedy: | 1. Remove any media at the exit rollers of the stapler/stacker. 2. Open the upper left door and perform the following tasks: ?? Remove any media from the paper path. - Press down on the upper portion of the green guide and remove any media from between the green guide and the stapler/stacker exit rollers. - Clean SR2100 by blowing air gently into the sensing area. Check the sensor for correct mounting, cable connection, and alignment with the sensor flag. If the sensor is damaged or nor working, replace the sensor. - Check the operation of SR2103 (delivery sensor) and the sensor flag. If the sensor or the sensor flag is not working, replace the stapler/ stacker alignment assembly. 3. If, after performing the previous steps, the problem persists, replace the stapler/stacker control board.` |

| Error code: | 13.13.00 |

| Display: | 13.13.00 Jam inside left door |

| Description: | A jam is in the duplexer area. The trailing edge of the media did not leave the duplexer paper sensor (PS2004) within a specified time. |

| Remedy: | - Clear the jam. - Close the door to allow the product to attempt to clear the jam. - Replace the duplexer. |

| Error code: | 13.14.00 |

| Display: | 13.14.00 Jam inside duplexer |

| Description: | SR2 (duplexer refeed sensor) detected residual media. |

| Remedy: | 1. Clear the jam. 2. Remove the duplexer and check sensors SR1 (duplexer-jam sensor) and SR2 (duplexer-refeed sensor) for correct mechanical functionality. Replace if necessary. 3. Check for paper or other obstructions to the paper path in the duplexer and between the fuser and the duplexer. Also check the turnaround path between the fuser and the standard face-down output bin. 4. Check the interface between the duplexer and the print engine. 5. Check connector J311 on the dc controller. 6. Replace the duplexer. 7. Replace the dc controller. |

| Error code: | 13.1C.00 |

| Display: | 13.1C.00 Paper wrapped around fuser |

| Description: | Fuser wrap jam. SR6 (fuser-exit sensor) did not detect media within the specified time after it initially detected media. |

| Remedy: | 1. Clear the jam. 2. Remove the fuser and check for media at the input and output sides of the fuser. 3. Reinstall the fuser and process a cleaning page. 4. Check SR6 (fuser-output sensor) for correct mechanical functionality. Replace the fuser if necessary. 5. Check connectors J903, J901, and J902 on the HVPS. 6. Check connector J318 and J319 on the dc controller. 7. Replace the fuser. 8. Replace the dc controller. |

| Error code: | 13.20.00 |

| Display: | 13.20.00 JAM INSIDE <LOCATION> |

| Description: | Paper has not moved past a certain paper sensor. <LOCATION> can be one of the following locations. • TRAY 2 • TOP COVER • REAR DOOR • DUPLEXER |

| Remedy: | • TRAY 2 Remove the tray, and then check the paper path for obstructions. Perform a manual sensor test and observe the prefeed sensor (PS102) status (B). Toggle the sensor flag to determine if the status changes. • TOP COVER Remove the print cartridge, and then check the paper path for obstructions. Verify that the top-of-page sensor (PS103) and the media width sensors (PS106 and PS108) are unblocked. Perform a manual sensor test and observe the status of these sensors. Toggle the sensor flags to determine if their status changes. • REAR DOOR Open or remove the rear face-up bin, and then check the paper path on each side of the fusing assembly for obstructions. Remove the fuser, if necessary. Perform a manual sensor test and observe the fuser delivery sensor (PS700) status (C). Toggle the sensor flag to determine if the status changes. • DUPLEXER Remove the duplexer, and then check the paper path for obstructions. If the message persists, replace the duplexer. |

| Error code: | 13.21.00 |

| Display: | 13.21.00 Jam inside left door |

| Description: | A door is open. |

| Remedy: | - Clear the jam. - Close the door to allow the product to attempt to clear the jam. - Run a paper path test. - Run a service test. - Check the function of the interlock switches. - Replace the left door. |

| Error code: | 13.30.00 |

| Display: | 13.30.00 Jam inside right door |

| Description: | A jam is in the pickup area of Tray 1. |

| Remedy: | Clear the jam. - Close the door to allow the product to attempt to clear the jam. - Run a service test. - Replace the paper input unit. - Replace the Tray 1 pickup rollers. - Replace Tray 1. |

| Error code: | 13.31.00 |

| Display: | 13.31.00 JAM INSIDE FRONT DOOR |

| Description: | A jam has occurred inside the front door. |

| Remedy: | 1. Verify that nothing is obstructing paper movement within the paper path. 2. Verify that the face-up tray sensor (PS1) is functioning properly. 3. Verify that connection J505 is firmly seated on the ECU. 4. Open and close the cartridge door to clear the error message |

| Error code: | 13.33.00 |

| Display: | 13.33.00 |

| Description: | Output jam. Media did not arrive at SR7 (delivery sensor) within the specified time |

| Remedy: | 1. Clear the jam. 2. Check for paper or other obstructions between SR6 (fuser exit sensor) and SR7. 3. Check the fuser and the pressurerelease assembly for correct seating and functionality. 4. Check SR6 and SR7 for correct mechanical functionality. Replace if necessary. 5. Check connector J310 on the dc controller. 6. Replace the dc controller. |

| Error code: | 13.41.00 |

| Display: | 13.41.00 Jam inside left door 13.41.00 Jam inside lower left door |

| Description: | Output jam. The leading edge of media passed SR7 (delivery sensor), but did not reach SR1 (output-bin-full sensor). |

| Remedy: | 1. Clear the jam. 2. Check for paper or other obstructions between SR7 and SR1. 3. Check SR7 and SR1 for correct mechanical functionality. Replace if necessary. 4. Check connector J310 on the dc controller. 5. Replace the dc controller. |

| Error code: | 13.42.00 |

| Display: | 13.42.00 Jam inside left door 13.42.00 Jam inside lower left door |

| Description: | Output jam. Media did not leave SR7 (delivery sensor). |

| Remedy: | 1. Clear the jam. 2. Check for paper or other obstructions on or around SR7. 3. Check the fuser and the pressurerelease assembly for correct seating and functionality. 4. Check SR7 for correct mechanical functionality. Replace if necessary. 5. Check the duplexer for paper or other obstructions in the duplex path. Also check the duplexer for damage. If the duplexer is damaged, replace the duplexer. 6. Check connector J310 on the dc controller. 7. Replace the dc controller. |

| Error code: | 13.46.00 |

| Display: | 13.46.00 Jam inside left door 13.46.00 Jam inside lower left door |

| Description: | Paper did not leave SR7 (output sensor). |

| Remedy: | 1. Clear the jam. 2. Check for paper or other obstructions in the paper path on or around SR7 (delivery sensor). 3. Verify that the fuser and the pressure release assembly are seated and operating correctly. 4. Verify that sensor SR7 is working correctly. Repair it or replace it if necessary. 5. If a duplexer is used, inspect the paper path to the duplexer for obstructions or damage. 6. Check connector J310 on the dc controller. 7. Replace the dc controller. |

| Error code: | 13.90.00 |

| Display: | 13.90.00 Unprintable Jam |

| Description: | The media was too long for the duplexer. |

| Remedy: | Clear the jam. 1. Make sure that the duplexer supports the size of media in use. 2. Remove the duplexer and check SR1 (duplexer-jam sensor) for correct mechanical functionality. Replace if necessary. 3. Check for paper or other obstructions to the paper path in the duplexer and between the fuser and the duplexer. Also check the turnaround path between the fuser and the standard face-down output bin. 4. Check the interface between the duplexer and the print engine. 5. Check connector J311 on the dc controller. 6. Replace the duplexer. 7. Replace the dc controller. |

| Error code: | 13.98.00 |

| Display: | 13.98.00 Jam inside upper right door |

| Description: | This might be a multi-pick jam in the Tray 1 and print-artridge areas, or it might be a pick error. |

| Remedy: | 1. Clear the jam. 2. Check to see that the media in Tray 1 is loaded correctly and that the size guides are set appropriately. 3. Check the Tray 1 pick roller and separation pad for excessive wear or contamination. Replace them if necessary. 4. Check for paper or other obstructions in the paper path in the Tray 1 and cartridge-door areas, and before the registration area. Replace the cartridge door assembly if problems are detected. 5. Check the SR5 (top/registration) sensor and flag for correct mechanical functionality. Repair or replace if necessary. 6. For SR 5, check connector J319 on the dc controller. 7. Replace the high-voltage power suppy (only if a problem with SR5 is suspected). 8. Replace the dc controller. |

| Error code: | 13.99.00 |

| Display: | 13.99.00 Jam inside left door 13.99.00 Jam inside lower left door |

| Description: | Non-specific jam. This message might indicate a multi-feed jam in the fuser/output area. |

| Remedy: | 1. Clear the jam. 2. Make sure that the customer is using supported media and that it is loaded correctly. 3. Check the input trays for excessive wear or contamination to the pick and separation rollers and separation pad. Replace if necessary. 4. Check the entire paper path for paper or other obstructions. 5. Check all paper-path sensors and flags for correct mechanical functionality and good electrical connections to the dc controller. 6. Check the fuser and the pressurerelease assembly for correct seating and functionality. 7. Replace the dc controller. |

| Error code: | 20.1 |

| Display: | 20.X Insufficient memory To continue touch OK |

| Description: | The device received more data than can fit in the available memory. You might have tried to transfer too many macros, soft fonts, or complex graphics. internal ROM |

| Remedy: | Touch OK to print the transferred data (some data might be lost), and then simplify the print job or install additional memory. |

| Error code: | 20.2 |

| Display: | 20.X Insufficient memory To continue touch OK |

| Description: | The device received more data than can fit in the available memory. You might have tried to transfer too many macros, soft fonts, or complex graphics. Card slot |

| Remedy: | Touch OK to print the transferred data (some data might be lost), and then simplify the print job or install additional memory. |

| Error code: | 20.3 |

| Display: | 20.X Insufficient memory To continue touch OK |

| Description: | The device received more data than can fit in the available memory. You might have tried to transfer too many macros, soft fonts, or complex graphics. non removable hard disk |

| Remedy: | Touch OK to print the transferred data (some data might be lost), and then simplify the print job or install additional memory. |

| Error code: | 20.4 |

| Display: | 20.X Insufficient memory To continue touch OK |

| Description: | The device received more data than can fit in the available memory. You might have tried to transfer too many macros, soft fonts, or complex graphics. EIO disk |

| Remedy: | Touch OK to print the transferred data (some data might be lost), and then simplify the print job or install additional memory. |

| Error code: | 20.5 |

| Display: | 20.X Insufficient memory To continue touch OK |

| Description: | The device received more data than can fit in the available memory. You might have tried to transfer too many macros, soft fonts, or complex graphics. USB device or external device |

| Remedy: | Touch OK to print the transferred data (some data might be lost), and then simplify the print job or install additional memory. |

| Error code: | 21 |

| Description: | The bar code printed on a label does not scan. |

| Causes: | The bar code is not within specifications because the print is too light or too dark. Not enough blank space around the bar code. |

| Remedy: | Perform the FEED Self Test on page 120. Adjust the darkness or print speed settings as necessary. Leave at least 1/8 in. (3.2 mm) between the bar code and other printed areas on the label and between the bar code and the edge of the label. |

| Error code: | 22 |

| Description: | Loss of printing registration on labels. Excessive vertical drift in top-of-form registration. |

| Causes: | The platen roller is dirty. Media guides are positioned improperly. The media type is set incorrectly. The media is loaded incorrectly. |

| Remedy: | Clean the platen roller according to the instructions in Clean the Printhead and Platen Roller on page 131. Ensure that the media guides are properly positioned. Set the printer for the correct media type (gap/notch, continuous, or mark). See Set Media Type on page 81. Load media correctly. See Load Media on page 58. |

| Error code: | 30.1.1 |

| Display: | 30.1.1 |

| Description: | Flatbed cover open The scanner flatbed cover is open. |

| Remedy: | 1. If the cover is open, close the cover. 2. If the cover is closed, check the cover sensor at the right rear of the scanner for correct mechancical functionality. 3. Check connector 9 on the scanner control board. 4. Replace the lid sensor assembly or replace the scanner. |

| Error code: | 30.1.15 |

| Display: | 30.1.15 Scan failure |

| Description: | A condition has prevented the scan engine from initializing. |

| Remedy: | - Verify that all covers are installed correctly and that the ADF and the ADF feeder are closed. - Turn the product off, and then on. - If the error persists, run the sensors diagnostic test to verify that the sensors are functioning correctly. - Check the LED status on the control panel. Follow the troubleshooting instructions if the LEDs are not in the ready state. |

| Error code: | 30.1.17 |

| Display: | 30.1.17 |

| Description: | The scanner carriage is locked |

| Remedy: | 1. Check the scanner lock to verify that it is in the unlocked position. 2. Turn the device off and then turn the device on. 3. Make sure that the optical unit moves freely and that it is attached to the belt. 4. Check the scanner motor connector at the SCB (connector 10). 5. Replace the SCB. If the message persists, replace the scanner. |

| Error code: | 30.1.18 |

| Display: | 30.1.18 Scan failure |

| Description: | The product has experienced an ASIC error. |

| Remedy: | - Turn the product off, and then disconnect the power cord. - Connect the power cord, and then turn the product on. - Check connections to the SCB. - Check connections to the intermediate PCA, the analog processor PCA, and the CCD driver PCA. - Replace the SCB. - Replace the flatbed optical assembly. |

| Error code: | 30.1.19 |

| Display: | 30.1.19 Scan failure |

| Description: | Lamp error |

| Remedy: | - Turn the product off, and then on. - Check to see that the scanner lamp illuminates while the product is turned on. - Check the connections to the SCB. - Replace the SCB. - Replace the flatbed optical assembly. |

| Error code: | 30.1.2 |

| Display: | 30.1.2 |

| Description: | Jam in document feeder The ADF is jammed. NOTE: Appears as 30.01.02 on the event log. |

| Remedy: | 1. Clear the jam. 2. If the ADF continues to jam, make sure that the document meets media specifications for the ADF. 3. Open the ADF cover and inspect the paper path for damage or obstructions. 4. Check the pickup rollers and separation pad for excessive wear or contamination. Replace if necessary. 5. Check the ADF paper-path sensors for correct operation. 6. Check all connectors on the ADF control board and scanner control board for loose connections. 7. If, after performing all of the previous steps, the ADF continues to jam, replace the ADF. |

| Error code: | 30.1.22 |

| Display: | 30.1.22 Scan failure |

| Description: | CP processing error. |

| Remedy: | - Turn the product off, and then disconnect the power cord. - Connect the power cord, and then turn the product on. |

| Error code: | 30.1.23 |

| Display: | 30.1.23 |

| Description: | Calibration failed A scanner calibration error has occurred. |

| Remedy: | Check the target for correctness and re-run the scanner calibration. |

| Error code: | 30.1.24 |

| Display: | 30.1.24 |

| Description: | Document feeder cover open The ADF jam-access door is open. |

| Remedy: | 1. Clear the jam and close the ADF jamaccess door. 2. Check the ADF cover sensor and the flag for correct mechanical functionality. 3. Check connector J3 on the ADF control board. 4. If the message persists, replace the ADF control board or replace the ADF. |

| Error code: | 30.1.25 |

| Display: | 30.1.25 Scan failure |

| Description: | Copy processor board error. |

| Remedy: | - Turn the product off, and then disconnect the power cord. - Connect the power cord, and then turn the product on. - Check the copy processor LED. - Check connections to the copy processor board. - Check the scan engine cable connection. - Replace the copy processor board. |

| Error code: | 30.1.3 |

| Display: | 30.1.3 |

| Description: | Document feeder pick error The ADF could not pick up the document. NOTE Appears as 30.01.03 on the event log. |

| Remedy: | 1. Clear the jam. 2. If the ADF continues to jam, make sure that the document meets media specifications for the ADF. 3. Open the ADF cover and inspect the paper path for damage or obstructions. 4. Check the pickup rollers and separation pad for excessive wear or contamination. Replace if necessary. |

| Error code: | 30.1.34 |

| Display: | 30.1.34 |

| Description: | Cable error or loss of communication with the formatter. |

| Remedy: | 1. Turn the device off and then turn the device on. 2. Make sure that the ribbon cable between the scanner control board and the formatter is not damaged and is correctly seated. 3. Make sure that the hard disk drive on the formatter is connected correctly and that the hard disk is functioning correctly. 4. If the message persists, replace the scanner control board or replace the formatter. |

| Error code: | 30.1.36 |

| Display: | 30.1.36 |

| Description: | Scanner firmware upgrade failed. |

| Remedy: | The device will automatically try to upgrade the firmware again the next time the device is turned on. Turn the MFP power off, and then on. Resend the RFU. |

| Error code: | 30.1.7 |

| Display: | 30.1.7 |

| Description: | Communication error. |

| Remedy: | 1. Turn the device off and then turn the device on. 2. Make sure that the ribbon cable between the scanner control board and the formatter is not damaged and is correctly seated. |

| Error code: | 30.1.8 |

| Display: | 30.1.8 |

| Description: | Scanner optical unit position error. |

| Remedy: | 1. Check the scanner lock to verify that it is in the unlocked position. 2. Turn the device off and then turn the device on. 3. Make sure that the optical unit moves freely and that it is attached to the belt. 4. Check the scanner motor connector at the scanner control board (connector 10). 5. If the message persists, replace the scanner. |

| Error code: | 40 |

| Display: | Scanner locked |

| Description: | 10-348 ERROR 40 FUSER MAIN LAMP FAILURE Note If this failure reoccurs three times successively, an Engine NVRAM value is set preventing further printer use until the Clear Tech Rep Fault, Clear <10-348 & 10-350> is run. |

| Causes: | 1. Deformed paper sensor actuator or faulty sensor. 2. SMPS PBA or Main PBA is defective 3. Faulty cables or connectors. |

| Remedy: | Switch printer power OFF. Remove the Fuser Assembly. Warning Fuser may be very hot. Use extreme caution to prevent burns. Measure the resistance between the Fuser Assembly connector P600-4 and P600-6. Does the resistance measure between 20K and 100K ohms? Y↓N→ Replace the Fuser Assembly. Reinstall Fuser. Remove the Rear Cover, Rear Shield and the Rear Shield Bracket. Measure the resistance between P404A-1 and P404A-2 on the Engine Control Board. Does the resistance measure between 20K and 100K ohms? Y↓N→ Repair or replace the wiring harness between the Engine Control Board and the Fuser. Replace the Engine Control Board. |

| Error code: | 41.1 |

| Display: | 41.X Error To continue touch OK |

| Description: | A temporary printing error occurred. unknown misprint error |

| Remedy: | 1. Touch OK to clear the error. If the error is not cleared, turn the device off, and then turn the device on. 2. For a 41.2 error, check the laser/ scanner wire harness connectors from the scanner to the dc controller. If the error persists, replace the laser/ scanner. For a 41.8 error, check the fuser wire harness connectors. If the error persists, replace the fuser. Replace the dc controller PCA. |

| Error code: | 41.2 |

| Display: | 41.2 Engine error |

| Description: | The product experienced an internal error. |

| Remedy: | Turn the product power off, wait at least 30 seconds, and then turn the product power on and wait for it to initialize. If you are using a surge protector, remove it. Plug the product directly into the wall socket. Turn the product power on. |

| Error code: | 41.3 |

| Display: | 41.3 UNEXPECTED SIZE IN TRAY <X> |

| Description: | You have configured the tray for a different size of paper than the print job requires. NOTE: This error can be caused by a multi feed problem. Open, and then close, the cartridge door to clear the error message. If the error persists, and the tray is correctly configured, try cleaning the Tray 1 pickup roller (or you might have to replace the roller). |

| Remedy: | 1. Reload the tray with the correct paper size. 2. Make sure the paper size that is specified in the software program, the printer driver, and the control panel are all the same. 3. Press the OK button and scroll to the TRAY <X> SIZE = <Size> option. Reconfigure the size in a tray to match the size required for the print job. 4. If the error does not clear, turn the product off and then on. 5. If the message persists, contact an HPauthorized service or support provider. |

| Error code: | 41.7 |

| Display: | 41.X Error To continue touch OK |

| Description: | A temporary printing error occurred. |

| Remedy: | 1. Touch OK to clear the error. If the error is not cleared, turn the device off, and then turn the device on. 2. For a 41.2 error, check the laser/ scanner wire harness connectors from the scanner to the dc controller. If the error persists, replace the laser/ scanner. For a 41.8 error, check the fuser wire harness connectors. If the error persists, replace the fuser. Replace the dc controller PCA. |

| Error code: | 41.8 |

| Display: | 41.X Error To continue touch OK |

| Description: | A temporary printing error occurred. fuser over temperature error |

| Remedy: | 1. Touch OK to clear the error. If the error is not cleared, turn the device off, and then turn the device on. 2. For a 41.2 error, check the laser/ scanner wire harness connectors from the scanner to the dc controller. If the error persists, replace the laser/ scanner. For a 41.8 error, check the fuser wire harness connectors. If the error persists, replace the fuser. Replace the dc controller PCA. |

| Error code: | 41.9 |

| Display: | 41.X Error To continue touch OK |

| Description: | A temporary printing error occurred. signal-noise error |

| Remedy: | 1. Touch OK to clear the error. If the error is not cleared, turn the device off, and then turn the device on. 2. For a 41.2 error, check the laser/ scanner wire harness connectors from the scanner to the dc controller. If the error persists, replace the laser/ scanner. For a 41.8 error, check the fuser wire harness connectors. If the error persists, replace the fuser. Replace the dc controller PCA. |

| Error code: | 49.XXXXX |

| Display: | 49.XXXXX ERROR |

| Description: | A critical firmware error has occurred. |

| Remedy: | 1. Turn the device off and then on. 2. Try to determine whether the error occurs intermittently, while printing, or when turning on the device. 3. If the error appears while printing, determine whether it occurs when printing from a specific computer, a specific application, or a specific file. If all other computers, applications, or files can print without the error, then the problem may be only within one print job or computer. Make sure the computer has the most current printer drivers, or use a generic printer driver. 4. Check for the latest firmware image version at the bottom of the page. If this firmware image is newer than the one installed on the device and the device can receive a firmware update, download the newer firmware upgrade. 5. Try printing a job from a different software program. If the job prints, go back to the first program and try printing a different file. If the message appears only with a certain software program or print job, contact the software vendor for assistance. 6. If the message persists, contact HP Support |

| Error code: | 50.1 |

| Display: | 50.1 FUSER ERROR |

| Description: | AC power is not being provided to the fuser assembly. AC voltage is necessary to generate heat in the fuser assembly. |

| Remedy: | 1. Verify that the fuser power cable at the back of the device is connected and the ECU is fully seated. 2. If the message persists, replace the fuser assembly. |

| Error code: | 50.2 |

| Display: | 50.<X> Fuser To continue turn off then on |

| Description: | A fuser error has occurred. fuser warm up service. |

| Remedy: | - Turn the product off, and then on. - Reseat the connection to the fuser and the DC controller. - Replace the fuser. - Replace the upper cable guide assembly. - Replace the low voltage power supply. - Replace the DC controller |

| Error code: | 50.3 |

| Display: | 50.<X> Fuser To continue turn off then on |

| Description: | A fuser error has occurred. high fuser temperature |

| Remedy: | - Turn the product off, and then on. - Reseat the connection to the fuser and the DC controller. - Replace the fuser. - Replace the upper cable guide assembly. - Replace the low voltage power supply. - Replace the DC controller |

| Error code: | 50.4 |

| Display: | 50.<X> Fuser To continue turn off then on |

| Description: | A fuser error has occurred.f aulty fuser. |

| Remedy: | - Turn the product off, and then on. - Reseat the connection to the fuser and the DC controller. - Replace the fuser. - Replace the upper cable guide assembly. - Replace the low voltage power supply. - Replace the DC controller |

| Error code: | 50.5 |

| Display: | 50.<X> Fuser To continue turn off then on |

| Description: | A fuser error has occurred. inconsistent fuser. |

| Remedy: | - Turn the product off, and then on. - Reseat the connection to the fuser and the DC controller. - Replace the fuser. - Replace the upper cable guide assembly. - Replace the low voltage power supply. - Replace the DC controller |

| Error code: | 50.6 |

| Display: | 50.6 FUSER ERROR |

| Description: | The main or sub thermistors are unable to provide temperature feedback to the ECU. The main and sub thermistors monitor the fuser assembly hot-roller temperature and provide feedback to regulate the fusing temperature. |

| Remedy: | 1. Verify that the seven-wire connector is firmly seated in connector J405 on the ECU. You might have to remove the main cooling fan to see this connection. 2. Verify that the four-wire connector at the rear of the device is firmly seated in the fuser assembly. 3. Verify that the AC voltage is being provided to the fuser assembly. 4. If the message persists, replace the fuser assembly. |

| Error code: | 50.7 |

| Display: | 50.X FUSER ERROR To continue turn off then on |

| Description: | A fuser error has occurred. fuser pressure release malfunction |

| Remedy: | 1. Turn the device off, and allow it to cool. 2. Verify that the correct model of fuser is installed. 3. Verify that the correct voltage fuser is installed. 4. Reinstall the fuser, and check the connection between the fuser and the high-voltage power supply. Replace the high-voltage power supply if the connector is damaged. 5. Replace the fuser. Replace the dc controller PCA. See DC controller PCA on page 357. 7. Replace the high-voltage power supply. |

| Error code: | 50.8 |

| Display: | 50.X FUSER ERROR To continue turn off then on |

| Description: | A fuser error has occurred. low fuser temperature |

| Remedy: | 1. Turn the device off, and allow it to cool. 2. Verify that the correct model of fuser is installed. 3. Verify that the correct voltage fuser is installed. 4. Reinstall the fuser, and check the connection between the fuser and the high-voltage power supply. Replace the high-voltage power supply if the connector is damaged. 5. Replace the fuser. Replace the dc controller PCA. See DC controller PCA on page 357. 7. Replace the high-voltage power supply. |

| Error code: | 50.9 |

| Display: | 50.X FUSER ERROR To continue turn off then on |

| Description: | A fuser error has occurred. high fuser temperature |

| Remedy: | 1. Turn the device off, and allow it to cool. 2. Verify that the correct model of fuser is installed. 3. Verify that the correct voltage fuser is installed. 4. Reinstall the fuser, and check the connection between the fuser and the high-voltage power supply. Replace the high-voltage power supply if the connector is damaged. 5. Replace the fuser. Replace the dc controller PCA. See DC controller PCA on page 357. 7. Replace the high-voltage power supply. |

| Error code: | 51.10 |

| Display: | 51.XY ERROR To continue turn off then on |

| Description: | A temporary printing error has occurred.beam detect error |

| Remedy: | 1. Turn the device off, and then turn the device on. 2. Reseat the connectors between the laser/scanner and the dc controller PCA (J801 and J321). 3. Make sure that the laser/scanner cartridge door interlock mechanism correctly functioning 4. Replace the laser/scanner assembly. 5. Replace the dc controller PCA. |

| Error code: | 51.20 |

| Display: | 51.20 |

| Description: | Black laser scanner error. An error with the laser/scanner assembly has occurred in the product. |

| Causes: | Black laser scanner error |

| Remedy: | action1. Reset the printer:a. Turn off the power by using the power switch, and then wait at least 30 seconds.b. Turn on the power and wait for the product to initialize.2. If you are using a surge protector:a. Power off the printer.b. Remove the surge protector.c. Plug the product directly into the wall socket and turn the product power on.3. If the error persists, replace the product. |

| Error code: | 52.00 |

| Display: | 52.00 ERROR |

| Description: | A scanner motor error has occurred. Scanner motor rotation is verified at the initialization of a print job. |

| Remedy: | 1. Verify that the scanner motor connector and the ribbon cable from the ECU are firmly seated on the laser/scanner assembly. 2. Verify that the scanner motor connector is firmly seated in connector J402 on the ECU. You might have to remove the main cooling fan to see this connection. 3. Verify that the ribbon cable installed in connector J403 on the ECU is fully seated You must remove the ECU in order to verify this connection. 4. If the message persists, replace the laser/scanner assembly. |

| Error code: | 52.10 |

| Display: | 52.XY ERROR To continue turn off then on |

| Description: | A temporary printing error has occurred. laser/scanner motor startup failure error |

| Remedy: | 1. Turn the device off, and then turn the device on. 2. Reseat the connectors between the laser/scanner and the dc controller PCA (J801 and J321). 3. Replace the laser/scanner assembly. 4. Replace the dc controller PCA. |

| Error code: | 52.20 |

| Display: | 52.XY ERROR To continue turn off then on |

| Description: | A temporary printing error has occurred. laser/scanner motor rotation speed error |

| Remedy: | 1. Turn the device off, and then turn the device on. 2. Reseat the connectors between the laser/scanner and the dc controller PCA (J801 and J321). 3. Replace the laser/scanner assembly. 4. Replace the dc controller PCA. |

| Error code: | 53.XY.ZZ |

| Display: | 53.XY.ZZ CHECK RAM DIMM SLOT <X> |

| Description: | There is a problem with the product memory. The DIMM that caused the error will not be used. Values of X and Y are as follows: • X = DIMM type, 0 = ROM, 1 = RAM • Y = DIMM location, 0 = Internal memory (ROM or RAM), 1 = DIMM slot 1 |

| Remedy: | Press OK to continue if you are prompted. If the message continues, you might need to replace the specified DIMM. Turn the product off, and then replace the DIMM that caused the error. |

| Error code: | 54.XX |

| Display: | 54.XX |

| Description: | The product has experienced an error with one of the internal sensors. |

| Remedy: | Turn the product power off, wait at least 30 seconds, and then turn the product power on and wait for it to initialize. If you are using a surge protector, remove it. Plug the product directly into the wall socket. Turn the product power on. |

| Error code: | 55.00 |

| Display: | 55.XX DC CONTROLLER ERROR To continue turn off then on |

| Description: | The print engine is not communicating with the formatter. communication error |

| Remedy: | Turn the device off, and then turn the device on. Reseat all connectors on the dc controller and the formatter. Reseat the formatter. Check with HP support to find out if an applicable RFU is available. If it is, perform a RFU. If the error persists, replace the dc controller. If the error persists, replace the formatter. |

| Error code: | 55.01 |

| Display: | 55.XX DC CONTROLLER ERROR To continue turn off then on |

| Description: | The print engine is not communicating with the formatter. incoming parity error |

| Remedy: | Turn the device off, and then turn the device on. Reseat all connectors on the dc controller and the formatter. Reseat the formatter. Check with HP support to find out if an applicable RFU is available. If it is, perform a RFU. If the error persists, replace the dc controller. If the error persists, replace the formatter. |

| Error code: | 55.02 |

| Display: | 55.XX DC CONTROLLER ERROR To continue turn off then on |

| Description: | The print engine is not communicating with the formatter. outgoing parity order |

| Remedy: | Turn the device off, and then turn the device on. Reseat all connectors on the dc controller and the formatter. Reseat the formatter. Check with HP support to find out if an applicable RFU is available. If it is, perform a RFU. If the error persists, replace the dc controller. If the error persists, replace the formatter. |

| Error code: | 55.03 |

| Display: | 55.XX DC CONTROLLER ERROR To continue turn off then on |

| Description: | The print engine is not communicating with the formatter. no engine response |

| Remedy: | Turn the device off, and then turn the device on. Reseat all connectors on the dc controller and the formatter. Reseat the formatter. Check with HP support to find out if an applicable RFU is available. If it is, perform a RFU. If the error persists, replace the dc controller. If the error persists, replace the formatter. |

| Error code: | 55.04 |

| Display: | 55.XX DC CONTROLLER ERROR To continue turn off then on |

| Description: | The print engine is not communicating with the formatter. communications timeout |

| Remedy: | Turn the device off, and then turn the device on. Reseat all connectors on the dc controller and the formatter. Reseat the formatter. Check with HP support to find out if an applicable RFU is available. If it is, perform a RFU. If the error persists, replace the dc controller. If the error persists, replace the formatter. |

| Error code: | 55.06 |

| Display: | 55.XX DC CONTROLLER ERROR To continue turn off then on |

| Description: | The print engine is not communicating with the formatter. dc controller NVRAM abnormal read/write or not accessible NOTE Check the Event log to distinguish between the two 55.01 errors above. |

| Remedy: | Turn the device off, and then turn the device on. Reseat all connectors on the dc controller and the formatter. Reseat the formatter. Check with HP support to find out if an applicable RFU is available. If it is, perform a RFU. If the error persists, replace the dc controller. If the error persists, replace the formatter. |

| Error code: | 56.01 |

| Display: | 56.XX ERROR To continue turn off then on |

| Description: | A temporary printing error has occurred. unknown input device, selected media input unavailable |

| Remedy: | 1. Turn the device off, and then turn the device on. 2. For 56.01 errors, check the connections to the input device (optional 1 x 500- or 3 x 500-sheet feeder.) For 56.02 errors, check the connections to the optional stapler stacker. 3. Remove all non-HP paper-handling devices. 4. Perform a RFU. |

| Error code: | 56.02 |

| Display: | 56.XX ERROR To continue turn off then on |