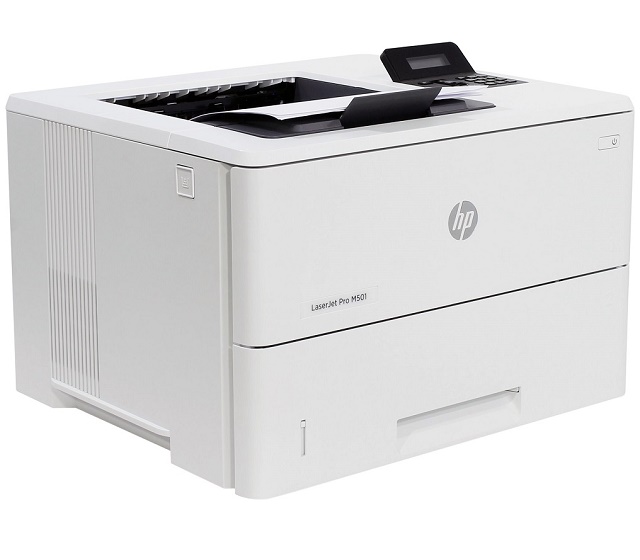

HP LaserJet Pro M501n

Рейтинг

Снят с производства

Снят с производства

Тип устройства

Принтер

Технология печати

лазерная

Макс. формат

A4

Число страниц в месяц

100000

Скорость печати

A4

43

Цветность печати

черно-белая

Общие характеристики |

|

|---|---|

Технология печати |

лазерная |

Тип |

лазерный/светодиодный |

Цветность печати |

|

Область применения |

большой офис |

Число страниц в месяц |

100 000 |

Печать фотографий |

|

Телефон |

|

Факс |

|

Сканер |

|

Копир |

|

Тип устройства |

Принтер |

Макс. формат |

A4 |

Размещение |

настольный |

Принтер |

|

Макс, длина отпечатка |

356 |

Прямая печать |

|

Макс, ширина отпечатка |

216 |

Печать без полей |

|

Пигментные чернила |

|

Двусторонняя печать |

|

Макс, разрешение для ч/б печати |

|

| По X | 600 |

| По Y | 600 |

Скорость ч/б печати |

|

| A4 | 43 |

| A4 | 43 |

Время выхода первого отпечатка |

|

| Ч/б | 5,8 |

Сканер |

|

Стандарт WIA |

|

Слайд-адаптер |

|

Отправка изображения по e-mail |

|

Стандарт TWAIN |

|

Расходные материалы |

|

Количество картриджей |

1 |

Ресурс ч/б картриджа/тонера |

9 000 |

Печать на: |

|

| CD/DVD |

|

| Фотобумаге |

|

| Рулоне |

|

| Матовой бумаге |

|

| Карточках |

|

| Этикетках |

|

| Конвертах |

|

| Пленках |

|

| Глянцевой бумаге |

|

Плотность бумаги |

|

| Минимальная | 60 |

| Максимальная | 220 |

Факс |

|

Цветной |

|

Телефон |

|

Caller ID |

|

Стандарт DECT |

|

Беспроводная трубка |

|

Проводная трубка |

|

Спикерфон |

|

Автоответчик |

|

АОН |

|

Языки управления |

|

| PCL 6 |

|

| PCL 5e |

|

| PostScript |

|

|

|

|

| PostScript 3 |

|

| PostScript 2 |

|

Лотки |

|

Емкость лотка ручной подачи |

100 |

Подача бумаги |

|

| Стандартная | 650 |

| Максимальная | 1 200 |

Вывод бумаги |

|

| Максимальный | 250 |

| Стандартный | 250 |

Интерфейсы |

|

Веб-интерфейс |

|

Поддержка iOS |

|

AirPrint |

|

USB |

|

Ethernet (RJ-45) |

|

LPT |

|

Устройство для чтения карт памяти |

|

RS-232 |

|

Инфракрасный порт |

|

Bluetooth |

|

Wi-Fi |

|

FireWire (IEEE 1394) |

|

Память/Процессор |

|

Частота процессора |

1 500 |

Макс, объем памяти |

256 |

Объем памяти |

256 |

Дополнительная информация |

|

Работа от аккумулятора |

|

Мин. системные требования |

Intel Pentium III |

Экран |

|

Поддержка ОС |

|

| Windows |

|

| Linux |

|

| Mac OS |

|

Потребляемая мощность |

|

| В режиме ожидания | 6,1 |

| При работе | 660 |

Уровень шума |

|

| При работе | 54 |

Габариты |

|

Глубина |

376 |

Высота |

289 |

Вес |

11,4 |

Ширина |

418 |

Модули

FRAME L

Internal assemblies (3 of 4)

Internal assemblies (4 of 4)

1x550-sheet paper feeder

Document feeder and image scanner assembly (M527 only)

Internal assemblies (1 of 4)

Covers (M527)

Internal assemblies (2 of 4)

PANEL

Covers (M501/M506)

REGISTRATION ASSEMBLY

Детали FRAME L

| Деталь: | Термоплёнка |

| Парткод: | RM1-6319-FILM |

| Цена: | 2 200 ₽ |

| Деталь: | (CET3111) Нагревательный элемент узла термозакрепления *220В |

| Парткод: | RM2-5692-HEAT |

| Цена: | 2 300 ₽ |

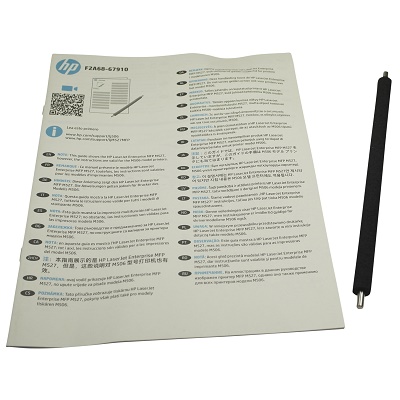

| Деталь: | Roller, transfer kit |

| Парткод: | F2A68-67910 |

| Цена: | 6 200 ₽ |

| Деталь: | Solenoid assembly (M501/M506) |

| Парткод: | RM1-5421-000CN |

| Деталь: | REGISTRATION ASSEMBLY |

| Парткод: | RM2-5671-000CN |

| Цена: | 1 900 ₽ |

| Деталь: | Gear, multi-purpose |

| Парткод: | RM2-5700-000CN |

| Цена: | 470 ₽ |

| Деталь: | Spring, compression (included in the multipurpose tray roller and separation pad kit) |

| Парткод: | RU8-2935-000CN |

| Цена: | 250 ₽ |

| Деталь: | Roller, Tray 2-3 kit (M501) |

| Парткод: | J8H60-67903 |

| Деталь: | Roller, Tray 2-x kit (M506/M527) |

| Парткод: | F2A68-67913 |

| Цена: | 13 500 ₽ |

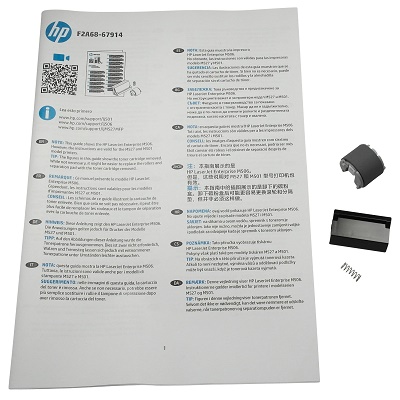

| Деталь: | Roller and pad, Tray 1 pickup and separation pad kit |

| Парткод: | F2A68-67914 |

| Деталь: | Stapler unit (M527) |

| Парткод: | B5L46-60102 |

| Деталь: | Cable, stapler 6-pin (M527) |

| Парткод: | F2A76-60113 |

| Деталь: | Near-field communications (NFC) PCA (M527) |

| Парткод: | B5L24-60001 |

| Деталь: | Bracket, WiFi PCA (M506z/M527) |

| Парткод: | F2A76-40007 |

| Деталь: | Cable, WiFi PCA (M506z/M527) |

| Парткод: | F2A76-60112 |

| Деталь: | Wireless embedded PCA (M506z/M527) |

| Парткод: | 1150-7968 |

| Деталь: | Fan (FM2) |

| Парткод: | RK2-8068-000CN |

| Деталь: | Cable, flat flexible (M506/M527) |

| Парткод: | RK2-6261-000CN |

| Деталь: | Cable, flat flexible (M501) |

| Парткод: | RK2-6526-000CN |

| Деталь: | PAPER FEED DRIVE ASSEMBLY |

| Парткод: | RM2-5715-000CN |

| Цена: | 8 200 ₽ |

| Деталь: | Fixing (fuser) power supply1 (FPS) 110V-127V |

| Парткод: | RM2-7948-000CN |

| Деталь: | Fixing (fuser) power supply1 (FPS) 220V-240V |

| Парткод: | RM2-7949-000CN |

| Цена: | 7 400 ₽ |

| Деталь: | Low-voltage power supply (LVPS) 110V-127V (M527) |

| Парткод: | RM2-7951-000CN |

| Деталь: | Low-voltage power supply (LVPS) 220V-240V (M527) |

| Парткод: | RM2-7952-000CN |

| Деталь: | Low-voltage power supply (LVPS) 110V-127V (M501/M506) |

| Парткод: | RM2-7941-000CN |

| Деталь: | Low-voltage power supply (LVPS) 220V-240V (M501/M506) |

| Парткод: | RM2-7942-000CN |

| Деталь: | Memory PCA (M506/M527) |

| Парткод: | RM2-7955-000CN |

| Деталь: | DC controller PCA (M527) |

| Парткод: | RM2-8610-000CN |

| Деталь: | DC controller PCA, simplex (M506) |

| Парткод: | RM2-8600-000CN |

| Деталь: | DC controller PCA, duplex (M506) |

| Парткод: | RM2-7940-000CN |

| Деталь: | DC controller PCA, simplex (M501) |

| Парткод: | RM2-8710-000CN |

| Деталь: | DC controller PCA, duplex (M501) |

| Парткод: | RM2-7950-000CN |

| Деталь: | Formatter PCA kit (M527) |

| Парткод: | F2A76-67910 |

| Деталь: | Case, formatter PCA (M527) |

| Парткод: | RL2-0895-000CN |

| Деталь: | Formatter PCA kit (M506n/dn) |

| Парткод: | F2A68-67915 |

| Деталь: | Formatter PCA kit (M506x) |

| Парткод: | F2A68-67916 |

| Деталь: | Formatter PCA (M501n) |

| Парткод: | J8H60-67901 |

| Цена: | 9 800 ₽ |

| Деталь: | Formatter PCA (M501n |

| Парткод: | J8H60-67902 |

| Деталь: | Formatter PCA (M501dn) |

| Парткод: | J8H61-67901 |

| Цена: | 11 300 ₽ |

| Деталь: | Formatter PCA (M501dn |

| Парткод: | J8H61-67902 |

| Деталь: | Case, formatter (M501) |

| Парткод: | RL2-0888-000CN |

| Деталь: | Case, formatter PCA (M506) |

| Парткод: | RL2-0885-000CN |

| Деталь: | Case, formatter (M527) |

| Парткод: | RL2-0895-000CN |

| Деталь: | Fax PCA (M527) |

| Парткод: | CC456-60002 |

| Деталь: | Cradle, fax PCA (M527) |

| Парткод: | 5851-5605 |

| Деталь: | Cable, fax PCA (M527) |

| Парткод: | 5851-5997 |

| Деталь: | 1x550-sheet paper feeder (whole unit) |

| Парткод: | F2A72-67901 |

| Деталь: | Document feeder (M527 Enterprise) kit |

| Парткод: | B5L47-67901 |

| Деталь: | Document feeder (M527 Flow) kit |

| Парткод: | B5L47-67902 |

| Деталь: | Image scanner assembly (M527) kit |

| Парткод: | F2A76-67909 |

| Деталь: | Control panel (M527) kit |

| Парткод: | B5L47-67018 |

| Деталь: | Keyboard US (M527) |

| Парткод: | B5L47-67019 |

| Деталь: | Keyboard UK (M527) |

| Парткод: | B5L47-67020 |

| Деталь: | Cover, HIP (M527) |

| Парткод: | B5L46-40021 |

| Деталь: | Bezel, control panel (M527) |

| Парткод: | B5L46-60117 |

| Деталь: | Cover, keyboard (M527) |

| Парткод: | B5L46-40002 |

| Деталь: | Cable, WU USB control panel (M527) |

| Парткод: | 5851-5939 |

| Деталь: | Cable, HIP USB control panel (M527) |

| Парткод: | 5851-5938 |

| Деталь: | Cable, HDMI control panel (M527) |

| Парткод: | 5851-5936 |

| Деталь: | Cable, 18-pin control panel (M527) |

| Парткод: | 5851-5935 |

| Деталь: | Cable, HDMI PAB to SCAM (M527) |

| Парткод: | B5L46-60114 |

| Деталь: | Hinge, left document feeder (M527) |

| Парткод: | COM39-60064 |

| Деталь: | Hinge, right document feeder (M527) |

| Парткод: | COM39-60065 |

| Деталь: | Cover, USB (M527) |

| Парткод: | B5L46-40028 |

| Деталь: | Cable, stapler (M527) |

| Парткод: | B5L46-60116 |

| Деталь: | Cover, rear image scanner (M527) |

| Парткод: | B5L46-40011 |

| Деталь: | Scan-control board (SCB) kit (M527) |

| Парткод: | B5L47-67903 |

| Деталь: | Keyboard overlay kit (FR, IT, RU, DE, ES: UK Kybd) |

| Парткод: | 5851-6019 |

| Деталь: | Keyboard overlay kit (FR-CN, ES-LA, ES: US Kybd) |

| Парткод: | 5851-6020 |

| Деталь: | Keyboard overlay kit (FR-SW, DE-SW, DA: UK Kybd) |

| Парткод: | 5851-6021 |

| Деталь: | Keyboard overlay kit (ZHTW, ZHCN) |

| Парткод: | 5851-6022 |

| Деталь: | Keyboard overlay kit (ES, PT) |

| Парткод: | 5851-6023 |

| Деталь: | Keyboard overlay kit (JA-KG, JA-KT) |

| Парткод: | 5851-6024 |

| Деталь: | MICROSWITCH |

| Парткод: | RK2-0535-000CN |

| Деталь: | Fan (FM1) |

| Парткод: | RK2-8068-000CN |

| Деталь: | Cable, flat-flexible |

| Парткод: | RK2-6259-000CN |

| Деталь: | Cable, flat-flexible |

| Парткод: | RK2-6260-000CN |

| Деталь: | Cable, USB (M506) |

| Парткод: | RK2-7067-000CN |

| Деталь: | Laser/Scanner assembly |

| Парткод: | RM2-5528-000CN |

| Цена: | 4 100 ₽ |

| Деталь: | Cable, TAG assembly |

| Парткод: | RM2-5702-000CN |

| Деталь: | Power supply, high-voltage (HVPS) |

| Парткод: | RM2-7945-000CN |

| Цена: | 8 100 ₽ |

| Деталь: | Cover, right (M527) |

| Парткод: | RC4-4437-000CN |

| Деталь: | Tray, paper delivery output bin (M527) |

| Парткод: | RC4-4141-000CN |

| Деталь: | Cover, top left (M527) |

| Парткод: | RC4-4147-000CN |

| Деталь: | Cover, top rear (M527) |

| Парткод: | RC4-4150-000CN |

| Деталь: | Cover, I/O (M527) |

| Парткод: | RC4-4433-000CN |

| Деталь: | Door, cartridge kit (M527) |

| Парткод: | F2A76-60112 |

| Деталь: | Door, rear (M527) |

| Парткод: | RM2-5711-000CN |

| Деталь: | Cover, left (M527) |

| Парткод: | RM2-5727-000CN |

| Деталь: | Cover, formatter (M527) |

| Парткод: | RM2-5717-000CN |

| Деталь: | Cover, top (M527) |

| Парткод: | RM2-5718-000CN |

| Деталь: | Plate, name (M527) |

| Парткод: | F2A74-40001 |

| Деталь: | Cover, stationary stapler, inner (M527c/f/z) |

| Парткод: | F2A76-40003 |

| Деталь: | Door, stapler flap (M527c/f/z) |

| Парткод: | F2A76-40004 |

| Деталь: | Cover, stapler blank (M527dn) |

| Парткод: | F2A76-40005 |

| Деталь: | Sticker, stapler cartridge replacement (M527) |

| Парткод: | B5L24-00035 |

| Деталь: | Plug/cap, fax port (M527) |

| Парткод: | 5851-1885 |

| Деталь: | Hinge, cartridge door left |

| Парткод: | RC4-3010-000CN |

| Деталь: | Link, pressure release (cartridge door) |

| Парткод: | RC4-4479-000CN |

| Деталь: | Film bias assembly |

| Парткод: | RM2-5689-000CN |

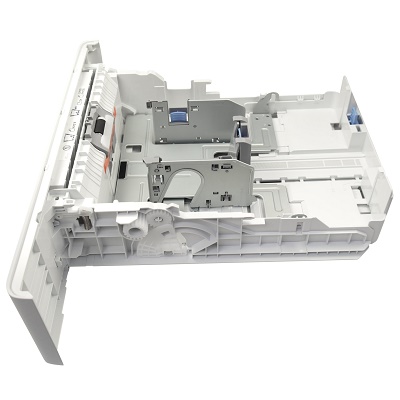

| Деталь: | Cassette (Tray 2) |

| Парткод: | RM2-5690-000CN |

| Цена: | 13 900 ₽ |

| Деталь: | Switch, lever assembly |

| Парткод: | RM2-5701-000CN |

| Деталь: | Roller, separation (Tray 2/3) |

| Парткод: | RM2-5745-000CN |

| Деталь: | Clutch, paper re-pickup assembly (M501/M506 duplex LCD and MF models) |

| Парткод: | RM2-8514-000CN |

| Деталь: | Fixing (fuser) assembly 110V-127V |

| Парткод: | RM2-5679-000CN |

| Деталь: | Fixing (fuser) assembly 220V-240V |

| Парткод: | RM2-5692-000CN |

| Цена: | 16 300 ₽ |

| Деталь: | Switch, power PCA assembly |

| Парткод: | RM2-8597-000CN |

| Деталь: | Панель управления, в сборе |

| Парткод: | J8H60-67904 |

| Деталь: | Главный мотор |

| Парткод: | RM2-9531-000CN |

| Цена: | 1 200 ₽ |

| Деталь: | Cover, right (M501/M506) |

| Парткод: | RC4-4437-000CN |

| Деталь: | Tray, paper delivery output bin (M501/M506) |

| Парткод: | RC4-4439-000CN |

| Цена: | 3 300 ₽ |

| Деталь: | Cover, HIP (M506 duplex models) |

| Парткод: | RC4-4142-000CN |

| Цена: | 550 ₽ |

| Деталь: | Cover, USB (M506) |

| Парткод: | RC4-4149-000CN |

| Деталь: | Plate, name (M506) |

| Парткод: | F2A68-40002 |

| Деталь: | Plate, name (M501) |

| Парткод: | J8H60-40001 |

| Деталь: | Cover, I/O (M506) |

| Парткод: | RC4-4433-000CN |

| Деталь: | Cable, HIP (M506 duplex models) |

| Парткод: | RK2-7104-000CN |

| Деталь: | Door, cartridge kit (M506n/dn) |

| Парткод: | F2A68-67919 |

| Деталь: | Door, cartridge kit (M506x) |

| Парткод: | F2A68-67920 |

| Деталь: | Door, cartridge (M501) |

| Парткод: | RM2-5677-000CN |

| Деталь: | Cover, top (M506 simplex models) |

| Парткод: | RM2-5687-000CN |

| Деталь: | Cover, top (M506 duplex LCD models) |

| Парткод: | RM2-5699-000CN |

| Деталь: | Cover, top (M506 duplex MF models) |

| Парткод: | RM2-5686-000CN |

| Деталь: | Cover, top (M501 duplex models) |

| Парткод: | RM2-5726-000CN |

| Деталь: | Door, rear (M501/M506 simplex models) |

| Парткод: | RM2-5712-000CN |

| Деталь: | Door, rear (M501/M506 duplex models) |

| Парткод: | RM2-5711-000CN |

| Деталь: | Cover, left (M501/M506) |

| Парткод: | RM2-5727-000CN |

| Деталь: | Cover, formatter (M501) |

| Парткод: | RC4-4200-000CN |

| Деталь: | Cover, formatter (M506) |

| Парткод: | RM2-5725-000CN |

| Деталь: | Cover, top (M501) |

| Парткод: | RM2-5735-000CN |

| Деталь: | Hinge, cartridge door left |

| Парткод: | RC4-3010-000CN |

| Деталь: | Link, pressure release (cartridge door) |

| Парткод: | RC4-4479-000CN |

| Деталь: | Дополнительный податчик документов |

| Парткод: | F2A72A |

| Цена: | 16 700 ₽ |

| Деталь: | Ролик захвата бумаги из лотка ручной подачи |

| Парткод: | RL2-0656-000CN |

| Цена: | 700 ₽ |

| Деталь: | Площадка отделения бумаги из лотка ручной подачи |

| Парткод: | RL2-0657-000CN |

| Цена: | 700 ₽ |

Коды ошибок

10.00.00

10.00.10

10.00.15

10.23.60

10.23.70

11.XX.YZ

13.00.00

13.00.EE

13.A2.D2

13.A2.FF

13.A3.FF

13.A4.FF

13.A5.FF

13.Ax.Dz

13.B2.E2

13.B2.FF

13.B9.Bz

13.B9.Cz

13.B9.Dz

13.B9.FF

13.D3.Bz

13.D3.Dz

13.E5.FF

13.EA.FF

13.EE.FF

13.FF.EE

13.FF.FF

20.00.00

21.00.00

30.01.01

30.01.08

30.01.14

30.01.15

30.01.18

30.01.19

30.01.30, 30.01.32

30.01.36

30.01.41

30.01.42

30.01.43

30.01.44

30.01.46

30.01.48

30.01.50

30.03.14

30.03.20

30.03.22

30.03.23

30.03.30

30.03.45

31.01.47

31.03.14

31.03.20

31.03.22

31.03.30

31.03.31

31.03.32

31.03.33

31.03.34

31.13.00

31.13.01

31.13.02

31.13.13

31.13.14

32.1C.05

32.1C.06

32.1C.07

32.1C.08

32.1C.09

32.1C.0A

32.1C.0D

32.1C.11

32.1C.13, 32.1C.14

32.1C.15

32.1C.2E

32.1C.2F

32.1C.48

32.1C.49

32.1C.4A

32.1C.61

32.1C.62

32.1C.68

32.1C.69

32.1C.6A

32.1C.6D

33.02.01

33.03.03

33.03.XX

40.00.01

40.00.02

40.00.03

40.00.04

40.00.05

41.01.YZ

41.02.00

41.03.02

41.03.FZ

41.03.YZ

41.04.YZ

41.05.YZ

41.XX.YZ

42.XX.YZ

44.01.XX

44.03.XX

44.34.XX

44.92.XX

47.00.XX

47.01.XX

47.02.XX

47.03.XX

47.04.XX

47.05.00

47.06.XX

48.XX.YY

49.XX.YY

50.00

50.10

50.11

50.12

50.1X.YZ

50.20

50.2X.YZ

50.30

50.3X.YZ

50.40

50.4X.YZ

50.6X.YZ

50.70

50.7X.YZ

50.80

50.90

50.9X.YZ

51.00

51.00.10

51.20

51.30

52.XX.00

54.06.21

55.0

55.00.yy

55.0601

55.0602

55.0x.yy

55.1

55.3

56.00.yy

57.00.01

57.00.02

57.01

58.00.03

58.00.04

58.01.04

58.02.04

58.04

59.00.20

59.00.30

59.00.40

59.A2.02

59.A2.0X

59.XX

60.00.0X

62.00.00

65.X0.AZ

66.00.20

66.00.40

66.00.50

66.00.77

66.00.79

66.80.YY

70.00.00

79

80.0X.YY

98.00.01, 98.01.00

98.00.02

98.00.03

98.00.04

99.00.01

99.00.02

99.00.03

99.00.04

99.00.05

99.00.06

99.00.07

99.00.08

99.00.09

99.00.10

99.00.11

99.00.12

99.00.13

99.00.14

99.00.2X

99.01.XX

99.09.60

99.09.61

99.09.62

99.09.63

99.09.64

99.09.65

99.09.66

99.09.67

99.39.64

99.39.67

99.XX.YY

Описание

| Error code: | 10.00.00 |

| Display: | 10.00.00 e-Label Memory Error |

| Description: | The printer is unable to read the cartridge data. This message indicates that the printer cannot read or write to the e-label of the toner cartridge. This error can cause the supplies status feature to be disabled. |

| Remedy: | 1. Remove, and then reinstall the indicated print cartridge. 2. If the error reappears, turn the power off, and then on. 3. Check the cartridge memory tag. If it is damaged, replace the cartridge. 4. If the error persists, replace the indicated print cartridge. |

| Error code: | 10.00.10 |

| Display: | 10.00.10 e-Label Missing Memory Error |

| Description: | The printer is unable to detect the e-label. This message indicates that the printer has determined that the e-label is missing. This error can cause the supplies status feature to be disabled. |

| Remedy: | 1. Remove and the reinstall the indicated print cartridge. 2. If the message displays again, turn the printer off then on. 3. Check the cartridge memory tag. If it is damaged, replace the cartridge. 4. If the error persists, replace the indicated print cartridge. |

| Error code: | 10.00.15 |

| Display: | 10.00.15 Install <supply> |

| Description: | The indicated supply has been removed or installed incorrectly. |

| Remedy: | Replace or install the indicated supply. See the parts chapter in the service manual for the correct supply or kit part number. |

| Error code: | 10.23.60 |

| Display: | 10.23.60 |

| Description: | The printer indicates when fuser kit is very low. The actual remaining fuse kit life might vary. You do not need to replace the fuser kit at this time unless print quality is no longer acceptable. |

| Remedy: | If print quality is no longer acceptable, replace the fuser kit. See the parts chapter in the service manual for the fuser kit part number. TIP: Advise the customer that HP recommends that they have replacement supplies available to install when the print quality is no longer acceptable. |

| Error code: | 10.23.70 |

| Display: | 10.23.70 printing past very low |

| Description: | The printer indicates when the fuser kit is very low. The actual remaining fuse kit life might vary. |

| Remedy: | If print quality is no longer acceptable, the customer must order and pay for a replacement fuser assembly (fuser kit). TIP: Advise the customer that HP recommends that they have replacement supplies available to install when the print quality is no longer acceptable. |

| Error code: | 11.XX.YZ |

| Display: | 11.00.01 or 11.00.02 Internal clock error |

| Description: | The printer real time clock has experienced an error. 01=dead clock 02=dead real time clock |

| Remedy: | 1. Whenever the printer is turned off and then turned on again, set the time and date on the control panel. 2. If the error persists, remove and reinstall the formatter making sure it is seated properly. 3. Replace the formatter. |

| Error code: | 13.00.00 |

| Display: | 13.00.00 |

| Description: | Generic jam event code. |

| Remedy: | Check the printer for a jam. See the clear jams section in the service manual. |

| Error code: | 13.00.EE |

| Display: | 13.00.EE |

| Description: | Unknown door open. |

| Remedy: | Make sure that all of the doors and covers are closed. |

| Error code: | 13.A2.D2 |

| Display: | 13.A2.D2 |

| Description: | Tray 2 media feed jam. This jam occurs when the media does not reach the pre-feed sensor (SR11) in the designated amount of time after the start of media pickup from Tray 2. This is a no-pick jam from tray 2. |

| Remedy: | 1. Verify the customer has followed steps for clearing jams on control panel.2. Open Tray 2, remove any jammed paper, and then close the tray.3. Open and close the upper TOP cover to allow the printer to attempt to clear the jam. 4. Remove the paper from the tray and check that the paper tray size guides are properly set and that the tray is not over filled with paper. 5. Make sure that the Tray 2 pickup, feed, and separation roller are installed correctly and show no damage or wear. 6. Clean or replace the pickup/feed rollers as needed. Use a damp, lint-free cloth to gently clean the rollers. 7. Verify that the media in use meets the printers specifications. 8. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 9. Run the Tray 2 pickup/feed motor drive test to verify that the feed motor is functioning correctly. If it is not, replace the pickup assembly. 10. Test SR11 using the Tray/Bin Manual sensor test to verify that the sensor is functioning correctly. 11. If either of the previous steps fail, elevate the issue to HP for possible printer replacement. NOTE: On-site technicians should check the following connections on the DC Controller before elevating the issue. (J157.SR11) (J110 and J144 . Tray 2 feed drive assy and solenoid) |

| Error code: | 13.A2.FF |

| Display: | 13.A2.FF |

| Description: | Residual Media Jam in Tray 2. This jam occurs when residual media is detected at the Tray 2 feed sensor (SR11). |

| Remedy: | 1. Open Tray 2, remove any jammed paper, and then close the tray. 2. Open and close the upper right door to allow the printer to attempt to clear the jam. 3. Remove the paper from the tray and check that the paper tray size guides are properly set and that the tray is not over filled with paper. 4. Make sure that the Tray 2 pickup, feed, and separation roller are installed correctly and show no damage or wear. 5. Clean or replace the pickup/feed rollers as needed. Use a damp, lint-free cloth to gently clean the rollers. 6. Check the connectors at the sensor, feed motor, and the DC controller PCA. 7. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 8. Test SR11 using the Tray/Bin Manual sensor test to verify that the sensors are functioning correctly. 9. Run the Tray 2 pickup/feed motor drive test to verify that the feed motor is functioning correctly (listen for the motor to activate). If it is not, replace the pickup assembly. 10. If either of the previous steps fail, elevate the issue to HP for possible printer replacement. NOTE: On-site technicians should check the following connections on the DC Controller before elevating the issue. (J157.SR11) (J110 and J144) . Tray 2 feed drive assembly and solenoid. |

| Error code: | 13.A3.FF |

| Display: | 13.A3.FF |

| Description: | Residual Media Jam in Tray 3. This jam occurs when residual media is detected at the Tray 3 feed sensor (PS432). |

| Remedy: | 1. Open Tray 3, remove any jammed paper, and then close the tray. 2. Open and close the upper right door to allow the printer to attempt to clear the jam. 3. Remove the paper from the tray and check that the paper tray size guides are properly set and that the tray is not over filled with paper. 4. Make sure that the Tray 3 pickup, feed, and separation roller are installed correctly and show no damage or wear. 5. Clean or replace the pickup/feed rollers as needed. Use a damp, lint-free cloth to gently clean the rollers. 6. Check the connectors at the sensor, feed motor, and the DC controller PCA. 7. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 8. Test PS432 using the Tray/Bin Manual sensor test to verify that the sensors are functioning correctly. 9. Run the Tray 3 pickup/feed motor drive test to verify that the feed motor is functioning correctly (listen for the motor to activate). If it is not, replace the optional paper feeder. 10. If either of the previous steps fail, elevate the issue to HP for possible printer replacement. NOTE: On-site technicians should check ALL connections on the Paper feed controller PCA before elevating the issue. |

| Error code: | 13.A4.FF |

| Display: | 13.A4.FF |

| Description: | Residual Media Jam in Tray 4. This jam occurs when residual media is detected at the Tray 4 feed sensor (PS432). |

| Remedy: | 1. Open Tray 4, remove any jammed paper, and then close the tray. 2. Open and close the upper right door to allow the printer to attempt to clear the jam. 3. Remove the paper from the tray and check that the paper tray size guides are properly set and that the tray is not over filled with paper. 4. Make sure that the Tray 4 pickup, feed, and separation roller are installed correctly and show no damage or wear. 5. Clean or replace the pickup/feed rollers as needed. Use a damp, lint-free cloth to gently clean the rollers. 6. Check the connectors at the sensor, feed motor, and the DC controller PCA. 7. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 8. Test PS432 using the Tray/Bin Manual sensor test to verify that the sensors are functioning correctly. 9. Run the Tray 4 pickup/feed motor drive test to verify that the feed motor is functioning correctly (listen for the motor to activate). If it is not, replace the optional paper feeder assembly. 10. If either of the previous steps fail, elevate the issue to HP for possible printer replacement. NOTE: On-site technicians should check ALL connections on the Paper feed controller PCA before elevating the issue. |

| Error code: | 13.A5.FF |

| Display: | 13.A5.FF |

| Description: | Residual Media Jam in Tray 5. This jam occurs when residual media is detected at the Tray 3 feed sensor (PS432). |

| Remedy: | 1. Open Tray 5, remove any jammed paper, and then close the tray. 2. Open and close the upper right door to allow the printer to attempt to clear the jam. 3. Remove the paper from the tray and check that the paper tray size guides are properly set and that the tray is not over filled with paper. 4. Make sure that the Tray 5 pickup, feed, and separation roller are installed correctly and show no damage or wear. 5. Clean or replace the pickup/feed rollers as needed. Use a damp, lint-free cloth to gently clean the rollers. 6. Check the connectors at the sensor, feed motor, and the DC controller PCA. 7. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 8. Test PS432 using the Tray/Bin Manual sensor test to verify that the sensors are functioning correctly. 9. Run the Tray 5 pickup/feed motor drive test to verify that the feed motor is functioning correctly (listen for the motor to activate). If it is not, replace the optional paper feeder assembly. 10. If either of the previous steps fail, elevate the issue to HP for possible printer replacement. NOTE: On-site technicians should check ALL connections on the Paper feed controller PCA before elevating the issue. |

| Error code: | 13.Ax.Dz |

| Display: | 13.Ax.Dz |

| Description: | Optional Tray media feed jam. This jam occurs when the media does not reach the Tray pre-feed sensor PS432 for trays 3.5 in the designated amount of time after the start of media pickup from Tray. This is a no-pick jam from the specified tray. X = Tray sensor jam occurred in. Z = Tray job was pulling from. • 13.A3.D3,D4,D5 = Tray 3: Media did not reach Tray 3 Media Feed Sensor (PS432) when pulling from Tray 3-5 • 13.A4.D4,D5, = Tray 4: Media did not reach Tray 4 Media Feed Sensor (PS432) when pulling from Tray 4-5 • 13.A5.D5, = Tray 5 Media did not reach Tray 5 Media Feed Sensor (PS432) when pulling from Tray 5 |

| Remedy: | 1. Verify the customer has followed steps for clearing jams on control panel. 2. Open and close the upper TOP cover to allow the printer to attempt to clear the jam. 3. Open Tray 2, remove any jammed paper. Remove the paper from the tray and check that the paper tray size guides are properly set and that the tray is not over filled with paper. 4. Make sure that the Tray pickup, feed, and separation roller are installed correctly and show no damage or wear. 5. Clean or replace the pickup/feed rollers as needed. Use a damp, lint-free cloth to gently clean the rollers. 6. Verify that the media in use meets the printers specifications. 7. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 8. Run the Tray pickup/feed motor drive test to verify that the feed motor is functioning correctly. If it is not, replace the pickup assembly. 9. Test PS432 using the Tray/Bin Manual sensor test to verify that the sensor is functioning correctly. 10. If either of the previous steps fail, elevate the issue to HP for possible printer replacement. NOTE: On-site technicians should check ALL connections on the Paper feed controller PCA before elevating the issue. |

| Error code: | 13.B2.E2 |

| Display: | 13.B2.E2 Jam in top cover |

| Description: | Media jam in top cover at image area due to door open. |

| Remedy: | 1. Make sure all doors and covers are closed and re-send job. 2. If all doors are closed and message still persists, Test SW2 top cover open detection switch using the diagnostic tests. 3. If the sensor fails test, elevate the issue to HP for possible printer replacement. NOTE: On-site technicians should check the following connections on the DC controller PCA to ensure they are properly seated and connected before elevating the issue. (J151, J110, J144) |

| Error code: | 13.B2.FF |

| Display: | 13.B2.FF Jam in top cover |

| Description: | Media residual jam in top cover at image area. Paper present at SR2 at power on or after clearing jam. |

| Remedy: | 1. Open top cover and check for media jammed in feed area. 2. Check under toner cartridge at transfer area, make sure everything is properly seated. 3. Test the top of page sensor (SR2). 4. If the sensor fails test, elevate the issue to HP for possible printer replacement. NOTE: On-site technicians should check the following connections on the DC controller PCA to ensure they are properly seated and connected before elevating the issue. (J151, J110, J144) |

| Error code: | 13.B9.Bz |

| Display: | 13.B9.Bz Fuser jam |

| Description: | Multi-feed jam in fuser. This jam occurs when a near complete overlap (less than 5 to 15 mm of non-overlap) multi-feed jam is detected. • 13.B9.B1 Multi-Feed jam is detected when printing from Tray 1. • 13.B9.B2 Multi-Feed jam is detected when printing from Tray 2. • 13.B9.B3 Multi-Feed jam is detected when printing from Tray 3. • 13.B9.B4 Multi-Feed jam is detected when printing from Tray 4. • 13.B9.B5 Multi-Feed jam is detected when printing from Tray 5. • 13.B9.BD Multi-Feed jam is detected when printing from the Duplexer. |

| Remedy: | 1. Open the top and rear covers and then clear any jammed paper. 2. Ensure sure that the paper meets HP printer specifications. 3. Check Fuser delivery sensor for proper functionality and movement. 4. Verify there is no debris from a previous jam stuck in the fuser or rollers leading into or out of the fuser. 5. Confirm the output bin rollers are turning.6. Perform Manuel Sensor Test and check SR13 Fuser delivery sensor. If found faulty then replace the Fuser assembly. |

| Error code: | 13.B9.Cz |

| Display: | 13.B9.Cz |

| Description: | Fuser Wrap Jam. This jam occurs when the media disappears from the fuser output sensor before a designated amount of time after the media reached the fuser output sensor (SR13). (The printer has determined that the media is being wrapped around the fuser roller.) Z = Fuser mode • 13.B9.C1 (event code) Fuser wrap jam when Auto Sense (Normal). • 13.B9.C2 (event code) Fuser wrap jam when Normal. • 13.B9.C3 (event code) Fuser wrap jam when Light 1 or Light 2 (see event log secondary jam information for specific code). • 13.B9.C4 (event code) Fuser wrap jam when Heavy 1. • 13.B9.C5 (event code) Fuser wrap jam when Heavy 2. • 13.B9.C6 (event code) Fuser wrap jam when Heavy media 3. • 13.B9.C7 (event code) Fuser wrap jam when Glossy media 1. • 13.B9.C8 (event code) Fuser wrap jam when Glossy media 2. • 13.B9.C9 (event code) Fuser wrap jam when Glossy media 3. • 13.B9.CB (event code) Fuser wrap jam when Transparency. • 13.B9.CC (event code) Fuser wrap jam when Label. • 13.B9.CD (event code) Fuser wrap jam when Envelope 1 or Envelope 2 (see event log secondary jam information for specific code). |

| Remedy: | 1. Open the top and rear covers and then clear any jammed paper.2. Ensure sure that the paper meets HP printer specifications. If the customer media is within specifications, but curls up on the output bin, you can recommend: • Open input tray and rotate new media so the top page is now the bottom page. • Explain that the media curls and it is better if it curls down than up for printing to avoid fuser wrap jams.3. Check to see if the paper jam is found wrapped around the fuser roller. If so and the media is within HP specifications for this printer replace the Fuser Assembly. |

| Error code: | 13.B9.Dz |

| Display: | 13.B9.Dz |

| Description: | Fuser delivery delay jam Media did not reach Fuser sensor SR13 specified time. • 13.B9.D1 Fuser delivery delay jam when printing from Tray 1. • 13.B9.D2 Fuser delivery delay jam when printing from Tray 2. • 13.B9.D3 Fuser delivery delay jam when printing from Tray 3. • 13.B9.D4 Fuser delivery delay jam when printing from Tray 4. • 13.B9.D5 Fuser delivery delay jam is detected when printing from Tray 5. • 13.B9.DD Fuser delivery delay jam when printing with the Duplexer. |

| Remedy: | The following are possible causes and areas that should be investigated. • The paper jam is found wrapped around the fuser roller. In this case it is a sign of a worn out fuser. • The paper jam is found underneath the toner cartridge or in the transfer area. In this case it could be the drum drive or the white collar that holds the toner cartridge in position has broken or even a damaged or defective toner cartridge. • Fuser drive or delivery issue. 1. Determine where the Jam is located. 2. Open top cover and check under the toner cartridge. 3. Open rear output bin and check for media or obstructions. Media stopped in the Toner/transfer area (Stopped BEFORE the Fuser): 1. Open top cover and check under toner cartridge for media or obstructions. 2. Ensure the Toner Cartridge and Transfer Roller are seated properly. If damaged replace toner cartridge or transfer roller. 3. Check the toner cartridge guides and the transfer roller assembly, If either are damaged elevate the issue to HP for possible printer replacement. 4. Inspect the white plastic collar that cradles the drum cartridge that is positioned around the drum drive gear. If the collar portion is broken and missing a section it will allow the cartridge to insert further than designed and not allow the drum drive to engage with the toner cartridge. elevate the issue to HP for possible printer replacement. 5. If collar is not broken, Test the drum drive motor M102 using the diagnostic test. If test fails, elevate the issue to HP for possible printer replacement. Media Stopped In or At the Fuser CAUTION: The fuser might be HOT. 1. Remove the Fuser and inspect Fuser sleeve, Pressure roller and delivery roller for blockage and/or damage. Replace Fuser as needed. 2. Verify that fuser inlet guide is not detached or broken. Replace Fuser as needed. 3. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 4. Check the media path sensors in the sensor test. (SR13) verify the sensor is functioning correctly. If it is not, replace the fuser. 5. Touch Component Test. 6. Run the Fuser motor drive test to verify that the Fuser Drive and Gears are functioning correctly. If they are not, elevate the issue to HP for possible printer replacement. If media Did not Stop "IN FUSER" or at "Toner/Transfer Area. 1. Check Media path between transfer and fuser. 2. If media has stopped in this area and will not progress beyond feed-guide assembly CLEAN the area and retest. If issue persists, elevate the issue to HP for possible printer replacement. |

| Error code: | 13.B9.FF |

| Display: | 13.B9.FF |

| Description: | Residual Media jam Fuser Output Sensor. Paper present at SR13 after specified time limit or on power up. |

| Remedy: | 1. Open the top and rear cover and clear the jam in the indicated area. 2. Close the covers to allow the printer to attempt to clear the jam. 3. Verify the media meets HP specification for the printer. 4. Remove the fuser and inspect the fuser sleeve, pressure roller, and delivery roller for blockage and/or damage. Replace the fuser as needed. CAUTION: The fuser might be HOT. 5. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests 6. Test the Fuser Delivery sensor (SR13) using the manual sensor test to verify the sensor is functioning correctly. If it is not, replace the fuser. 7. Run the Fuser motor drive test to verify that the Fuser Drive and Gears are functioning correctly. If they are not, elevate the issue to HP for possible printer replacement. |

| Error code: | 13.D3.Bz |

| Display: | 13.D3.Bz |

| Description: | Multi-feed to duplex re-feed jam. • 13.D3.B1 The fuser is printing in fuser mode Auto Sense special case distinguished from "typed" Normal. • 13.D3.B2 The fuser is printing in fuser mode Normal. • 13.D3.B3 The fuser is printing in fuser mode Light 1 or Light 2 (see the event log secondary jam information digits for specific mode). • 13.D3.B4 The fuser is printing in fuser mode Heavy 1. • 13.D3.B5 The fuser is printing in fuser mode Heavy 2. • 13.D3.B6 The fuser is printing in fuser mode Heavy media 3. • 13.D3.B7 The fuser is printing in fuser mode Glossy media 1. • 13.D3.B8 The fuser is printing in fuser mode Glossy media 2. • 13.D3.B9 The fuser is printing in fuser mode Glossy media 3. |

| Remedy: | 1. Make sure that customer is using HP Genuine cartridge and again test this printer with another working or new cartridge.2. Verify the media meets HP specification for the printer.3. Perform the continuous test in simplex mode at least 50 pages to make sure that issue is occurring while printing duplex printing only.4. Test duplexing from multiple trays to see if issue is TRAY specific or not. If jam occurs from specific tray Troubleshoot tray pick and feed issue.5. Make sure Tray is set correctly. If Tray 1 is set to ANY size ANY Type set it to the size customer is trying to print on.6. Check and Clean the status charge eliminator properly. (Next to transfer roller).7. Ensure all connections to duplex on the DC are properly seated.8. If issue persists, elevate the issue to HP for possible printer replacement. |

| Error code: | 13.D3.Dz |

| Display: | 13.D3.Dz |

| Description: | Late to duplex re-feed jam. • 13.D3.D1 The fuser is printing in fuser mode Auto Sense special case distinguished from "typed" Normal. • 13.D3.D2 The fuser is printing in fuser mode Normal. • 13.D3.D3 The fuser is printing in fuser mode Light 1 or Light 2 (see the event log secondary jam information digits for specific mode). • 13.D3.D4 The fuser is printing in fuser mode Heavy 1. • 13.D3.D5 The fuser is printing in fuser mode Heavy 2. • 13.D3.D6 The fuser is printing in fuser mode Heavy media 3. • 13.D3.D7 The fuser is printing in fuser mode Glossy media 1. • 13.D3.D8 The fuser is printing in fuser mode Glossy media 2. • 13.D3.D9 The fuser is printing in fuser mode Glossy media 3. |

| Remedy: | 1. Make sure that customer is using HP Genuine cartridge and again test this printer with another working or new cartridge.2. Verify the media meets HP specification for the printer.3. Perform the continuous test in simplex mode at least 50 pages to make sure that issue is occurring while printing duplex printing only.4. Test duplexing from multiple trays to see if issue is TRAY specific or not. If jam occurs from specific tray Troubleshoot tray pick and feed issue.5. Make sure Tray is set correctly. If Tray 1 is set to ANY size ANY Type set it to the size customer is trying to print on.6. Check and Clean the status charge eliminator properly. (Next to transfer roller).7. Ensure all connections to duplex on the DC are properly seated.8. If issue persists, elevate the issue to HP for possible printer replacement. |

| Error code: | 13.E5.FF |

| Display: | 13.E5.FF |

| Description: | A power on jam has occurred. |

| Remedy: | Check the printer for a jam. See the clear jams section in the service manual. |

| Error code: | 13.EA.FF |

| Display: | 13.EA.FF |

| Description: | A door jam has occurred. |

| Remedy: | Check the printer for a jam. See the clear jams section in the service manual. Use the component test to isolate a faulty door switch or sensor. |

| Error code: | 13.EE.FF |

| Display: | 13.EE.FF |

| Description: | A door jam has occurred. |

| Remedy: | Check the printer for a jam. See the clear jams section in the service manual. Use the Manual sensors test or Tray/Bin manual sensors test to isolate a faulty door switch or sensor. |

| Error code: | 13.FF.EE |

| Display: | 13.FF.EE |

| Description: | A power on jam has occurred. |

| Remedy: | Check the printer for a jam. See the clear jams section in the service manual. |

| Error code: | 13.FF.FF |

| Display: | 13.FF.FF |

| Description: | A power on residual paper jam has occurred. This error has no specific sensor designated. It could be any sensor in the media feed path. |

| Remedy: | 1. Check the printer for a jam.2. Look for media present or obstructions in paper path. View event log to determine if other Jam errors are occurring and troubleshoot those errors.3. Use the Manual sensors test or Tray/Bin manual sensors test to isolate a faulty door switch or sensor.4. Replace parts as determined by Sensor tests or obstructions. If sensor can not be replaced, elevate the issue for possible printer replacement. |

| Error code: | 20.00.00 |

| Display: | 20.00.00 Insufficient memory <device> |

| Description: | Insufficient memory: <Device> Event log error message 20.00.00. The product does not have enough memory to print the page. The product received more data than can fit in the available memory. You might have tried to transfer too many macros, soft fonts, or complex graphics. |

| Remedy: | Touch the OK button to print the transferred data. Some data might be lost. Reduce the page complexity or add product memory. |

| Error code: | 21.00.00 |

| Display: | 21.00.00 Page Too Complex Event log error message 21.00.00. |

| Description: | Page Too Complex Event log error message 21.00.00. The product displays this message to indicate that the page decompression process was too slow for the product. |

| Remedy: | Touch the OK button to continue. There may be some data loss on the page that was being formatted when the error occurred. |

| Error code: | 30.01.01 |

| Display: | 30.01.01 |

| Description: | The flatbed cover sensor was interrupted. The scanner flatbed cover is open. Message appears only in the event log and is not posted on the control panel. The control panel will read Flatbed Cover Open. |

| Remedy: | No action necessary. This error message should automatically clear. If the error persists, open the Scanner Tests to test the flatbed cover sensor.1. If the cover is closed, check the cover sensor at the right rear of the scanner for correct mechanical functionality, using the scanner sensor test in the Administration / Troubleshooting / Diagnostics / Scanner Tests Menu.2. Check the connectors on the scanner control board (SCB) for loose connections.3. Replace the scanner control board (SCB).4. Replace the integrated scanning assembly (ISA). |

| Error code: | 30.01.08 |

| Display: | 30.01.08 Home position error |

| Description: | Home position error The scanner optic failed to return to the home position. |

| Remedy: | 1. Turn the product off, and then on again. 2. Observe the movement of the optics assembly. 3. If the error persists, run the scanner motor test under component test. Administration/ Troubleshooting/Scanner tests/Flatbed motor test 4. If issue still remains and firmware has been upgraded replace scanner control board (SCB). IMPORTANT: Check all cables on SCB for proper connection and seating before replacing any parts and test. 5. If the error persists, replace the integrated scanning assembly (ISA). |

| Error code: | 30.01.14 |

| Display: | 30.01.14 Scan system EEPROM error |

| Description: | Scan system EEPROM error Scanner control board (SCB) EEPROM error. |

| Remedy: | 1. Turn the product off, and then on again.2. Ensure all connectors on the SCB are connected and properly seated.3. Ensure the MFP has at latest SCB firmware version.4. Replace the SCB. |

| Error code: | 30.01.15 |

| Display: | 30.01.15 Scanner error |

| Description: | Scanner error Scanner did not initialize (internal error). The scanner failed to be initialized due to an internal error. |

| Remedy: | 1. Turn the product off, and then on again.2. Verify that all covers are installed correctly and that the ADF and ADF jam cover are closed.3. Check all sensors on the scanner to ensure they are not blocked.4. Look through the vents on back of scanner check to see if GREEN SCB LEDs are lit.5. Check all connections for SCB to print engine and make sure they are properly seated.6. Replace the SCB. |

| Error code: | 30.01.18 |

| Display: | 30.01.18 Scanner Error |

| Description: | Scanner Error Scanner internal optical sensor error. |

| Remedy: | 1. Turn the product off, and then on again.2. Make sure that all the connectors on the SCB are properly seated.3. Make sure that the MFP has the latest SCB firmware version.4. Replace the SCB.5. If the error persists, replace the integrated scanning assembly (ISA) |

| Error code: | 30.01.19 |

| Display: | 30.01.19 Scanner lamp error |

| Description: | Scanner lamp error Scanner internal lamp sensor error. |

| Remedy: | 1. Turn the product off, and then on again.2. Determine if the scanner lamp turns on and off approximately 12 second after the product turns on.3. Test the lower lamp using the scanner test located in the Diagnostics menu.4. Re-seat the interconnect cables between the optical carriage and the SCB.5. Replace the integrated scanning assembly (ISA) |

| Error code: | 30.01.30, 30.01.32 |

| Display: | 30.01.30, 30.01.32 |

| Description: | HP image ASIC error. |

| Remedy: | Turn the product off, and then on again. Check all connections on the SCB. Replace the SCB. |

| Error code: | 30.01.36 |

| Display: | 30.01.36 Upgrade Error try downloading upgrade again |

| Description: | Upgrade Error Try downloading upgrade again Scanner firmware upgrade error. |

| Remedy: | 1. Re-send the scanner firmware upgrade. 2. If the error persists, replace the SCB. |

| Error code: | 30.01.41 |

| Display: | 30.01.41 Scanner error |

| Description: | Scanner error. The formatter lost connections with the SCB or communication was corrupted. |

| Remedy: | 1. Turn the product off, and then on. 2. Remove and reinstall the formatter making to verify it is properly seated. 3. Upgrade the firmware. 4. Verify that all cables are connected to the product and to the interconnect board / formatter and SCB. 5. Verify that the scanner control board (SCB) has power. 6. Replace the scanner control board (SCB). 7. Replace the formatter. |

| Error code: | 30.01.42 |

| Display: | 30.01.42 Scanner error |

| Description: | Scanner error Internal product communication error. |

| Remedy: | 1. Turn the product off, and then on again.2. If the error persists, turn the product off, and then check all scanner control board (SCB) connectors are fully seated.3. If this error occurs after a formatter, fax card or hard disk has been replaced, check that the formatter connectivity LED (smile face icon on the formatter) is illuminated. Check the fax card for proper seating on the formatter. (If fax card is not properly seated it can prevent the formatter from seating properly in the product. 4. Verify that all cables are connected to the product and to the interconnect board / formatter and SCB. 5. If the error persists, replace the scanner control board (SCB). |

| Error code: | 30.01.43 |

| Display: | 30.01.43 Scanner memory failure |

| Description: | Scanner memory failure Scan memory error. |

| Remedy: | 1. Turn the product off, and then on again. 2. If the error persists, turn the product off, and then re-seat the formatter. 3. If the error persists, replace the formatter. |

| Error code: | 30.01.44 |

| Display: | 30.01.44 |

| Description: | Copy processor (CPB) / scanner control board (SCB) communication error |

| Remedy: | 1. Turn the product off, and then on again. 2. If the error persists, turn the product off, and then check the scanner cable. 3. Upgrade the firmware. 4. If the error persists, turn the product off, and then re-seat the formatter. 5. If the error persists, replace the scanner control board (SCB) or the formatter. |

| Error code: | 30.01.46 |

| Display: | 30.01.46 Scanner Error |

| Description: | Scanner Error The firmware cannot find the copy processor board (CPB). |

| Remedy: | 1. Turn the product off, and then on again. 2. If the error persists, turn the product off, and then re-seat the formatter. 3. If the error persists, replace the scanner control board (SCB). |

| Error code: | 30.01.48 |

| Display: | 30.01.48 Scanner error |

| Description: | Scanner error Scanner error. Scanner power is not connected. |

| Remedy: | 1. Turn the product off, and then on again. 2. If the error persists, use another known good power cord, make sure printer is connected to a known good dedicated power outlet and not to UPS or surge protector. 3. If the error persists, turn the product off, and then check the scanner wire-harness connectors and the scanner power supply fan. 4. If the error persists, replace integrated scanning assembly (ISA). IMPORTANT: On-Site Technicians need to check the scanner wire-harness, All SCB connectors and the scanner power before replacing any parts. |

| Error code: | 30.01.50 |

| Display: | 30.01.50 Scanner error |

| Description: | Scanner error Internal scanner control board (SCB) error. |

| Remedy: | 1. Turn the product off, and then on again.2. Upgrade the firmware (FW).3. If the error persists, replace the SCB. |

| Error code: | 30.03.14 |

| Display: | 30.03.14 |

| Description: | A non-fatal error has occurred. A scanner EEPROM (NVM) error has occurred. |

| Remedy: | This is an informational message, and no action is required. |

| Error code: | 30.03.20 |

| Display: | 30.03.20 |

| Description: | The copy processor board firmware cannot communicate with the PCA on the optical assembly. |

| Remedy: | 1. Turn the product off, and then on again. 2. Verify that the flat flexible cables (FFCs) between scanner and the SCB are connected and properly seated. 3. Replace the integrated scanning assembly (ISA). |

| Error code: | 30.03.22 |

| Display: | 30.03.22 Scanner failure |

| Description: | Scanner failure. Front side illumination calibration failure. The scan module cannot see the illumination module, or marginal illumination. The optical assembly may not be parked under the calibration strip. |

| Remedy: | 1. Turn the product off, and then on again. 2. Upgrade the firmware. 3. Check the service event log for other scanner errors, and then resolve those errors. 4. Check the scan module flat flexible cable (FFC) connection. 5. Replace the integrated scanning assembly (ISA). |

| Error code: | 30.03.23 |

| Display: | 30.03.23 Scanner failure |

| Description: | Scanner failure. Flatbed alignment calibration error. |

| Remedy: | 1. Turn the product off, and then on again. 2. Upgrade the firmware. 3. Replace the scanner. |

| Error code: | 30.03.30 |

| Display: | 30.03.30 Scanner Failure |

| Description: | Scanner Failure. Flatbed motor shutdown. The scanner control board cannot communicate with the flatbed scanner motor. |

| Remedy: | 1. Turn the product off, and then on again. As the product turns on, verify that the scan head moves. 2. Verify that the drive belt is in the correct position. 3. Run diagnostics on the flatbed scanner to see if the scan bar moves. 4. Check the cable connection to the SCB. 5. Replace the scanner. |

| Error code: | 30.03.45 |

| Display: | 30.03.45 Scanner Error To continue turn off then on |

| Description: | Scanner Error To continue turn off then on. Scanner control board (SCB) firmware assertion failure. SCB firmware assert controls the scan head motor. |

| Remedy: | 1. Turn the product off, and then on again. 2. Upgrade the firmware. 3. Replace the Scanner control board (SCB). 4. Replace the scanner assembly. |

| Error code: | 31.01.47 |

| Display: | 31.01.47 Document feeder not detected |

| Description: | Document feeder not detected The document feeder was not detected, the document feeder might not be connected. The flatbed glass is still available for scanning. |

| Remedy: | 1. Turn the product off and then on. 2. If error persists, replace document feeder NOTE: Before replacing the document feeder, technicians should verify that the connections between the document feeder and the product are fully seated. Check One flat cable (callout 1), one ground screw (callout 2), and five connectors (callout 3). |

| Error code: | 31.03.14 |

| Display: | 31.03.14 |

| Description: | Backside scanner EEPROM (NVM) error. A non-fatal error has occurred. |

| Remedy: | This is an informational message, and no action is required. |

| Error code: | 31.03.20 |

| Display: | 31.03.20 backside scanner not detected |

| Description: | Backside scanner not detected Backside scanner not detected. |

| Remedy: | 1. Turn the product off, and then on again. 2. Verify the cables between scanner and scanner control board (SCB) are connected. (connection 6 — ADF (side 2) FFC) 3. Replace the document feeder assembly |

| Error code: | 31.03.22 |

| Display: | 31.03.22 Scanner calibration failure |

| Description: | Scanner calibration failure Backside illumination calibration failure. |

| Remedy: | 1. Turn the product off, and then on again. 2. After the product warms up, repeat the calibration process. Device Maintenance / Calibrate-Cleaning / Calibrate Scanner 3. If the error persists, clean the scanner glass and calibration strips. NOTE: Dust might appear on the underside of the glass, but this cannot be cleaned. a. Press the power button to turn the product off, and then disconnect the power cable from the electrical outlet. b. Open the scanner lid. c. Use a soft, lint-free cloth moistened with water to clean the calibration white strips and reflector plate (see call-outs). Also clean the document feeder glass, flatbed glass and plastic lid backing. NOTE: If needed, lens cleaner or nonabrasive glass cleaner can be applied to the cloth before cleaning the glass. Spray only onto the cloth and not directly onto the glass or device. Do not spray water or glass cleaner on the glass as it can seep under it and possibly damage the printer. Do not use abrasives, acetone, benzene, ethyl alcohol, or carbon tetrachloride on the glass; these can damage it and/or leave residue on the glass resulting in degraded copy/scan quality. 4. If the error persists, replace the Integrated Scanning Assembly (ISA). |

| Error code: | 31.03.30 |

| Display: | 31.03.30 Document feeder pick motor error |

| Description: | Document feeder pick motor error. The document feeder pick motor is not turning. |

| Remedy: | 1. Verify that the paper meets the product specifications. 2. Make sure that the feed tray is not overloaded. 3. Check the event log for document feeder errors, and then resolve any errors first. 4. Open and close the top cover to see if the pick motor turns without posting this error. If the motor turns, then the motor is good. 5. Verify that the motor cables are connected. 6. Re-seat the document feeder to the scanner control board (SCB). 7. Replace the document feeder assembly. |

| Error code: | 31.03.31 |

| Display: | 31.03.31 Document feeder motor stall |

| Description: | Document feeder motor stall. The document feeder feed motor is not turning. |

| Remedy: | 1. Verify that the paper meets the product specifications. 2. Make sure that the feed tray is not overloaded. 3. Check the event log for document feeder errors, and then resolve any errors first. 4. Verify that the motor cables are connected. 5. Re-seat the document feeder to the scanner control board (SCB). 6. Replace the document feeder assembly. |

| Error code: | 31.03.32 |

| Display: | 31.03.32 |

| Description: | The document feeder de-skew motor is not turning. |

| Remedy: | 1. Verify that the paper meets the product specifications. 2. Make sure that the input tray is not overloaded. 3. Check the event log for document feeder errors, and then resolve any errors first. 4. Verify that the motor cables are connected. 5. Re-seat the document feeder to scanner control board (SCB) cables. 6. Replace the document feeder assembly. |

| Error code: | 31.03.33 |

| Display: | Backside scanner calibration area dirty |

| Description: | Backside scanner calibration area dirty The white area used for backside scanner calibration is dirty. |

| Remedy: | 1. Remove the white background and clean it. 2. If the error persists, clean the scanner glass and calibration strips. NOTE: Dust might appear on the underside of the glass, but this cannot be cleaned. a. Press the power button to turn the product off, and then disconnect the power cable from the electrical outlet. b. Open the scanner lid. c. Use a soft, lint-free cloth moistened with water to clean the calibration white strips and reflector plate (see call-outs). Also clean the document feeder glass, flatbed glass and plastic lid backing. NOTE: If needed, lens cleaner or nonabrasive glass cleaner can be applied to the cloth before cleaning the glass. Spray only onto the cloth and not directly onto the glass or device. Do not spray water or glass cleaner on the glass as it can seep under it and possibly damage the printer. Do not use abrasives, acetone, benzene, ethyl alcohol, or carbon tetrachloride on the glass; these can damage it and/or leave residue on the glass resulting in degraded copy/scan quality. 3. Clean the backside scanner glass. 4. If issue remains replace the document feeder assembly. |

| Error code: | 31.03.34 |

| Display: | Background missing |

| Description: | Background missing The removable background for the backside scanner is either missing or not fully snapped into place. |

| Remedy: | 1. Remove the white background and clean it. 2. Clean the backside scanner glass. 3. If issue remains replace the document feeder assembly. |

| Error code: | 31.13.00 |

| Display: | Document feeder multi-pick error |

| Description: | Document feeder multi-pick error A multiple pick error was reported by the document feeder assembly. |

| Remedy: | 1. Open the document feeder cover, pull ALL the sheets back into the tray and then resume the job. 2. Verify that the paper meets the product specifications. 3. Make sure that the input tray is not overloaded and the tray guides are properly aligned to both edges of the media. 4. Check and clean the rollers and separation pad, and test the registration sensor. If needed, replace pickup roller assembly and separation pad. 5. Verify that the motor cables are connected. 6. Re-seat the document feeder to the scanner control board (SCB). 7. Replace the document feeder assembly. |

| Error code: | 31.13.01 |

| Display: | 31.13.01 |

| Description: | Document feeder job error, pick error. Paper pick was initiated, but the page didn`t did not make it to the pick success sensor. |

| Remedy: | 1. Open the document feeder lid, pull sheets back into input tray, and then resume the job. 2. Check the paper guides and make sure that they are set to the correct paper width. 3. Make sure that the input tray is not overloaded and the tray guides are properly aligned to both edges of the media. 4. Check the document feeder page count for roller life. 5. Verify that the paper meets the product specifications. 6. Clean the document feeder pick and feeder rollers and clean separation pad If worn or damage replace roller kit. 7. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests • Scanner Tests 8. Actuate the Pick-Success Sensor. If the sensor does not show functionality when tested, replace the document feeder. 9. If sensor is not available for replacement or does not resolve issue replace the document feeder assembly. |

| Error code: | 31.13.02 |

| Display: | 31.13.02 |

| Description: | Document feeder job error, feed jam. The paper passed the pick success sensor, and then jammed in the document feeder paper path. |

| Remedy: | 1. Clear the paper path and try feeding the page again. 2. Verify that the paper meets the product specifications. 3. Check the paper guides and make sure that they are set to the correct paper width. 4. Verify that the paper path is clear. 5. Clean the document feeder pick and feeder rollers and clean separation pad. If worn or damage replace roller kit. 6. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests • Scanner Tests 7. Actuate the Paper-Path Sensor. If the sensor does not show functionality when tested, replace the sensor. 8. If sensor is not available for replacement or does not resolve issue replace the document feeder assembly. |

| Error code: | 31.13.13 |

| Display: | 31.13.13 |

| Description: | The document feeder jam access door is open. |

| Remedy: | 1. Verify that the jam access cover is closed. 2. Verify that the flag is not broken off. 3. Open the following menus: • Administration • Troubleshooting • Diagnostic Tests • Scanner Tests 4. Actuate the document feeder Jam Cover Sensor. If the sensor does not show functionality when tested, replace the document feeder assembly. IMPORTANT: Before replacing the document feeder, technicians should verify that the connections between the document feeder and the product are fully seated. Check One flat cable (callout 1), one ground screw (callout 2), and five connectors (callout 3). |

| Error code: | 31.13.14 |

| Display: | 31.13.14 |

| Description: | Document feeder job error, over current. This is a feed jam in the document feeder, and the motor is not turning. |

| Remedy: | 1. Verify that the paper meets the product specifications. 2. Make sure that the document feeder input tray is not overloaded. 3. Check the event log for document feeder errors, and then resolve any errors first. 4. Open and close the top cover to see if the pick motor turns without posting this error. If there is no error, then the motor is good. 5. Verify that the connections between the document feeder and the product are fully seated. Check One flat cable (callout 1), one ground screw (callout 2), and five connectors (callout 3).6. Re-seat the document feeder to the scanner control board (SCB).7. Replace the document feeder assembly. |

| Error code: | 32.1C.05 |

| Display: | 32.1C.05 |

| Description: | The restore job ticket was submitted with invalid credentials. There was an error during the creation, read, or write of the restore file. |

| Remedy: | Verify the credentials that were submitted. Check the domain, user name, and password. |

| Error code: | 32.1C.06 |

| Display: | 32.1C.06 |

| Description: | The backup job ticket was submitted with invalid credentials. |

| Remedy: | Verify the credentials that were submitted. Check the domain, user name, and password. |

| Error code: | 32.1C.07 |

| Display: | 32.1C.07 |

| Description: | Backup restore permissions error. |

| Remedy: | Retry the job. |

| Error code: | 32.1C.08 |

| Display: | 32.1C.08 |

| Description: | Not enough disk space to perform backup/restore or network share issue. There was an error during the creation, read, or write of the backup file. |

| Remedy: | • Retry the job. • Remove stored jobs and retry. • Use a larger capacity storage device. • Check the network share. Remove any stored jobs, and then retry. If the error persists, try using a larger capacity storage device and check the network share settings. |

| Error code: | 32.1C.09 |

| Display: | 32.1C.09 |

| Description: | Tried to restore a backup file that was not valid for this printer. The data in the backup file specified in the restore job ticket is no longer valid due to a corruption of the data or no loner present. |

| Remedy: | Use a valid backup file. |

| Error code: | 32.1C.0A |

| Display: | 32.1C.0A |

| Description: | Backup file is invalid The data in the backup file specified in the restore job ticket is no longer valid due to a corruption of the data or no loner present. |

| Remedy: | Use a valid backup file. Reboot, and then observe the state of the printer. If the error persists, perform a partition clean from the Preboot menu. |

| Error code: | 32.1C.0D |

| Display: | 32.1C.0D |

| Description: | Backup/restore failed, auto-reboot failed, or the printer might be busy. |

| Remedy: | Reboot, and then retry the backup/restore. |

| Error code: | 32.1C.11 |

| Display: | 32.1C.11 |

| Description: | Backup/restore time-out while communicating with the engine. The backup was aborted because the printer is busy. |

| Remedy: | Wait until the printer is idle, and then try again. |

| Error code: | 32.1C.13, 32.1C.14 |

| Display: | 32.1C.13, 32.1C.14 |

| Description: | Not enough space exists to perform the backup. The backup was aborted because the disk is at a critical level or full. Scheduled backup failure |

| Remedy: | Free up disk space, and then try again. |

| Error code: | 32.1C.15 |

| Display: | 32.1C.15 |

| Description: | Restore aborted because the backup file was created by a previous version of firmware no longer supported by the feature. |

| Remedy: | - Use the current backup file. |

| Error code: | 32.1C.2E |

| Display: | 32.1C.2E |

| Description: | The restore was aborted because the printer is busy. |

| Remedy: | Wait until the printer is idle, and then try again. Turn the printer off then on, and then retry. |

| Error code: | 32.1C.2F |

| Display: | 32.1C.2F |

| Description: | Reset failure. |

| Remedy: | Turn the printer off then on, and then retry. |

| Error code: | 32.1C.48 |

| Display: | 32.1C.48 |

| Description: | The backup job ticket was submitted using an invalid network path. |

| Remedy: | Check that a share was provided as part of the network path (not blank). Check that the server and the share exists. Check that the user has permission to access the share on the provided server. |

| Error code: | 32.1C.49 |

| Display: | 32.1C.49 |

| Description: | The backup job ticket was submitted with a bad encryption. |

| Remedy: | Verify that the encryption personal identification number (PIN) meets the restrictions for the printer. |

| Error code: | 32.1C.4A |

| Display: | 32.1C.4A |

| Description: | An error occurred when creating the temporary directories used to store the backup files in transition to and from the compressed (ZIP) file. |

| Remedy: | Retry the job. If this does not resolve the issue, turn the printer off then on again and retry the job. If the error persists, perform a Partial Clean using the Preboot menu. |

| Error code: | 32.1C.61 |

| Display: | 32.1C.61 |

| Description: | The restore operation encountered an error. |

| Remedy: | Review the error log to see specific details about the failure. |

| Error code: | 32.1C.62 |

| Display: | 32.1C.62 |

| Description: | The restore operation completed, but with a warning message. |

| Remedy: | Review the error log to see specific details about the failure. |

| Error code: | 32.1C.68 |

| Display: | 32.1C.68 |

| Description: | The restore job ticket was submitted using an invalid network path. |

| Remedy: | Check that a share was provided as part of the network path (not blank). Check that the server and the share exist. Check that the user has permission to access the share on the provided server. Check that the path includes the compressed (ZIP) file name as part of the path. |

| Error code: | 32.1C.69 |

| Display: | 32.1C.69 |

| Description: | The restore job ticket was submitted with a bad encryption personal identification number (PIN). |

| Remedy: | Verify the encryption personal identification number (PIN) is the same PIN used to encrypt the backup file. |

| Error code: | 32.1C.6A |

| Display: | 32.1C.6A |

| Description: | An error occurred when creating the temporary directories used to store the restore files in transition to and from the compressed (ZIP) file. |

| Remedy: | Retry the job. |

| Error code: | 32.1C.6D |

| Display: | 32.1C.6D |

| Description: | An unusual error occurred when running the restore. |

| Remedy: | Retry the job. |

| Error code: | 33.02.01 |

| Display: | 33.02.01 Used board/disk installed |

| Description: | Used board/disk installed Used board disk installed. An encrypted board or disk with existing data previously locked to a different product has replaced the original. If you continue, data is permanently lost. |

| Remedy: | 1. Reinstall the used board or disk back into its original printer. 2. To save the data on the board or disk, turn the product off. Replace the board or disk with another board or disk. 3. To delete the data on the board or disk and continue, touch the OK button. |

| Error code: | 33.03.03 |

| Display: | 33.03.03 Incompatible formatter installed. |

| Description: | Incompatible formatter installed. This is and EFI BIOS event to prevent booting with the wrong formatter installed. |

| Remedy: | Power down the printer and install the correct formatter in the device. NOTE: If it is believed that the formatter is the correct part number and model for this printer, replace the formatter again and return the formatter in question to HP for evaluation. |

| Error code: | 33.03.XX |

| Display: | 33.03.XX |

| Description: | • 33.03.01: Save recover engine storage ID unexpected length. • 33.03.02: Data size mismatch unable to recover DCC MVRAM. |

| Remedy: | Power the printer off then back on. If issue is not resolved replace the ICB and return to HP for evaluation. |

| Error code: | 40.00.01 |

| Display: | 40.00.01 USB I/O buffer overflow To continue, touch “OK” |

| Description: | USB I/O buffer overflow To continue, touch “OK” The USB buffer has overflowed. |

| Remedy: | 1. Touch the OK button to print the transferred date (some data might be lost). 2. Check the host configuration. |

| Error code: | 40.00.02 |

| Display: | 40.00.02 Embedded I/O buffer overflow To continue, touch “OK” |

| Description: | Embedded I/O buffer overflow To continue, touch “OK” The product has experienced a JetDirect buffer overflow. |

| Remedy: | 1. Touch the OK button to print the transferred date (some data might be lost).2. Check the host configuration. |

| Error code: | 40.00.03 |

| Display: | 40.00.03 EIO <X> buffer overflow To continue, touch “OK” |

| Description: | EIO <X> buffer overflow To continue, touch “OK” Too much data was sent to the EIO card in the specified slot (x). An incorrect communications protocol might be in use. |

| Remedy: | Touch the OK button to print the transferred date (some data might be lost). |

| Error code: | 40.00.04 |

| Display: | 40.00.04 EIO <X> bad transmission To continue, touch “OK” |

| Description: | EIO <X> bad transmission To continue, touch “OK” The connection between the product and the USB device has been broken. |

| Remedy: | 1. Touch the OK button to clear the error message and continue printing.2. Remove, and then reinstall the USB device. |

| Error code: | 40.00.05 |

| Display: | 40.00.05 Embedded I/O bad transmission To continue, touch “OK” |

| Description: | Embedded I/O bad transmission To continue, touch “OK” The USB device has been removed. |

| Remedy: | 1. Touch the OK button to clear the error message (data will be lost).2. Install the USB device. |

| Error code: | 41.01.YZ |

| Display: | 41.01.YZ |

| Description: | Event log error message: 41.01.YZ. An unknown misprint error occurred on the printer. Y = Type, Z = Tray • Y = 0: Photo Media (1, 2, or 3) • Y = 1: Auto Sense (Normal) • Y = 2: Normal (typed not from Auto Sense) • Y = 3: Light media 1, 2, or 3 mode • Y = 4: Heavy media 1 • Y = 5: Heavy media 2 • Y = 6: Heavy media 3 • Y = 7: Glossy media 1 • Y = 8: Glossy media 2 • Y = 9: Glossy media 3 • Y = A: Glossy film • Y = B: OHT • Y = C: Label • Y = D: Envelope 1, 2, or 3 mode • Y = E: Rough • Y = F: Other mode • Z = 0: From unknown tray • Z = 1: From Tray 1 • Z = 2: From Tray 2 • Z = 3: From Tray 3 • Z = 4: From Tray 4 • Z = 5: From Tray 5 • Z = 6: From Tray 6 • Z = 7: From Tray 7 • Z = 8: From Tray 8 • Z = 9: From Tray 9 • Z = D: From duplex |

| Remedy: | 1. Touch OK to clear the error.2. If the error is not cleared, Turn the printer off, and then on again.3. If the error returns, check the wire harness from the laser scanner to the DC controller.4. If the error persists, replace the laser/scanner assembly.5. Replace the DC controller. |

| Error code: | 41.02.00 |

| Display: | 41.02.00 Error |

| Description: | A beam detected misprint error occurred. |

| Remedy: | 1. To clear the error message, touch OK.2. If the error persists, turn the printer off, and then on again.3. Verify that the toner cartridge is in good condition and the shutter works properly. Swap toner cartridge to test as needed.4. If the error returns, check the wire harness from the laser/scanners to the DC controller.5. If the error persists, replace the laser scanner assembly and the Laser Scanner Cable. |

| Error code: | 41.03.02 |

| Display: | 41.03.02 with slow printing |

| Description: | Some instances of slow printing and 41.03.02 have been seen caused by timing issues with the correct size media loaded. |