Kyocera TASKalfa 2551ci

Рейтинг

Модули

DRIVE SECTION 3

Paper Conveying Section 1

PANEL

DRIVE SECTION 2

Frames 3

Inner Section 1

ADF 1

Paper Conveying Section 3

COOLING SECTION

DRIVE SECTION 4

Inner Section 2

Electrical Components 3

(Узел термозакрепления)

Developer Section

Paper Conveying Section 2

Paper Conveying Section 4

Paper Feed Section 1

Image Formation Section

Paper Feed Section 3

PAPER CASSETTE

FRAMES 2

Scanner Section 1

DUPLEX

Frames 5

(Электронные компоненты)

MECH-031

Fuser Section

PAPER FEED

Paper Feed Section 4

TRANSFER SECTION

Frames 4

(Узел переноса)

SCANNER SECTION 2

Covers 1

COVERS and LABELS

Covers 2

FRAMES 1

ELECTRICAL COMPONENTS 2

PAPER FEED SECTION 2

(Комплекты)

Laser Scanner Sectionon

Electrical Components 1

Drive Section 5

Paper Feed Section 5

Operation Sectionents 3

Drive Section 1

Exit Section

Детали

| Деталь: | GUIDE WIRE MAIN DRIVE |

| Парткод: | 302K031462 |

| Деталь: | GUIDE WIRE ENGINE SUB |

| Парткод: | 302K039320 |

| Деталь: | ACCESS.SADDLE |

| Парткод: | 7YZM610013 |

| Деталь: | LID ENGINE SUB |

| Парткод: | 302K039100 |

| Деталь: | PARTS PWB ENGINE CONNECT ASSY SP |

| Парткод: | 302NP94110 |

| Деталь: | WIRE ENGINE2 - DRUM/DLP CONNECT |

| Парткод: | 302K046340 |

| Деталь: | WIRE ENGINE1-2 MOT |

| Парткод: | 302NP46200 |

| Деталь: | GUIDE WIRE SUB |

| Парткод: | 302K031620 |

| Деталь: | LID WIRE GUIDE |

| Парткод: | 303LT02020 |

| Деталь: | WIRE ENGINE-LVU |

| Парткод: | 302MV46410 |

| Деталь: | GUIDE RIGHT COVER |

| Парткод: | -302K029016 |

| Деталь: | BUSH 8 |

| Парткод: | -302H024830 |

| Деталь: | SHAFT DU |

| Парткод: | -302K329220 |

| Деталь: | PARTS GEAR DU Z27L SP |

| Парткод: | -302K394400 |

| Деталь: | PULLEY DU 26 |

| Парткод: | -302K329280 |

| Деталь: | PULLEY DU 26 B |

| Парткод: | -302K029030 |

| Деталь: | STOPPER 6 |

| Парткод: | -2BC06910 |

| Деталь: | BELT FEED |

| Парткод: | -302MV07110 |

| Деталь: | BELT S2M-Z108 |

| Парткод: | -302KV29090 |

| Деталь: | BELT S2M 230 |

| Парткод: | -303J131270 |

| Деталь: | PARTS ROLLER DU SP |

| Парткод: | -302K394250 |

| Деталь: | PARTS ROLLER DU B SP |

| Парткод: | -302K094390 |

| Деталь: | STOPPER 3 /2BT1107 A4 |

| Парткод: | -5MVX111DN007 |

| Деталь: | BUSH DU |

| Парткод: | -302K329270 |

| Деталь: | SPONGE RIGHT COVER |

| Парткод: | -302K029100 |

| Деталь: | JOINT JUNCTION HOOK |

| Парткод: | -302K304571 |

| Деталь: | WIRE EARTH DU B |

| Парткод: | -302K029070 |

| Деталь: | WIRE EARTH DU A |

| Парткод: | -302K029060 |

| Деталь: | COVER RIGHT MIDDLE |

| Парткод: | -302MV04271 |

| Деталь: | LABEL COVER CAUTION |

| Парткод: | -302MV34250 |

| Деталь: | LABEL BYPASS CAUTION |

| Парткод: | -302MV34260 |

| Деталь: | HOOK RIGHT COVER |

| Парткод: | -302K304520 |

| Деталь: | COVER RIGHT HOOK |

| Парткод: | -302MV04300 |

| Деталь: | NUT FUSER A /FS-1800/3800 A4 |

| Парткод: | -5MMS111SL002 |

| Деталь: | STRAP RIGHT COVER |

| Парткод: | -302K304591 |

| Деталь: | LABEL HIGH TEMP |

| Парткод: | -302MV34400 |

| Деталь: | GUIDE EXIT RIGHT |

| Парткод: | -302K029050 |

| Деталь: | SPONGE GUIDE |

| Парткод: | -302K029090 |

| Деталь: | PULLEY DU |

| Парткод: | -302K329020 |

| Деталь: | SPRING DU FEED |

| Парткод: | -302K029080 |

| Деталь: | LABEL COVER CAUTION 9NATIONS |

| Парткод: | -302MV34410 |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | WASHER M3X10X0.8T |

| Парткод: | 7BC00030A080H01 |

| Деталь: | PARTS COVER RIGHT ASSY SP |

| Парткод: | 302MV94450 |

| Деталь: | Электромагнитная муфта |

| Парткод: | 302KV44041 |

| Цена: | 900 ₽ |

| Деталь: | Жидкокристаллический дисплей панели управления |

| Парткод: | 302N494090 |

| Деталь: | PARTS MOTOR-BL W30 SP |

| Парткод: | -302K994331 |

| Деталь: | PLATE MOTOR DLP |

| Парткод: | -302K031090 |

| Деталь: | PARTS MOTOR-BL W20 DRUM SP |

| Парткод: | -302LC94301 |

| Деталь: | PLATE MOTOR MAIN |

| Парткод: | -302K031080 |

| Деталь: | BASE MAIN DRIVE R |

| Парткод: | -302K031020 |

| Деталь: | SPRING MAIN DRIVE B |

| Парткод: | -302K031420 |

| Деталь: | BUSH 6 EW |

| Парткод: | -302H024370 |

| Деталь: | SHAFT DLP |

| Парткод: | -302K031350 |

| Деталь: | RING STOPPER /A-49 FEED A4 |

| Парткод: | -5MVX111DN003 |

| Деталь: | PARTS CLUTCH 50 Z45L SP |

| Парткод: | -302K094320 |

| Деталь: | HOLDER CLUTCH |

| Парткод: | -302K031450 |

| Деталь: | PLATE MAIN DRIVE R |

| Парткод: | -302K031060 |

| Деталь: | PIN DRIVE B |

| Парткод: | -302HN31680 |

| Деталь: | PIN DRIVE A |

| Парткод: | -302HN31670 |

| Деталь: | PIN DRIVE MT |

| Парткод: | -302HN31640 |

| Деталь: | PARTS GEAR DRUM Z180L SP |

| Парткод: | -302MV94360 |

| Деталь: | PARTS GEAR DRUM Z100R SP |

| Парткод: | -302MV94370 |

| Деталь: | PARTS GEAR DRUM Z120L SP |

| Парткод: | -302MV94380 |

| Деталь: | SPRING MAIN DRIVE A |

| Парткод: | -302K031410 |

| Деталь: | COLLAR MIDDLE CLN A |

| Парткод: | -302K031380 |

| Деталь: | GEAR CLN Z30R-Z32 |

| Парткод: | -302K031290 |

| Деталь: | PULLEY MIDDLE CLN Z30 |

| Парткод: | -302K031330 |

| Деталь: | PULLEY MIDDLE CLN IDLE |

| Парткод: | -302K031340 |

| Деталь: | BASE TENSION R |

| Парткод: | -302K031440 |

| Деталь: | BASE TENSION F |

| Парткод: | -302K031431 |

| Деталь: | BELT S2M Z371 |

| Парткод: | -302KV02A90 |

| Деталь: | BUSH SCREW |

| Парткод: | -302H702590 |

| Деталь: | GEAR MIDDLE CLN Z37R |

| Парткод: | -302K031320 |

| Деталь: | SHAFT MIDDLE CLN |

| Парткод: | -302K031370 |

| Деталь: | GEAR MIDDLE CLN Z27L-Z21L |

| Парткод: | -302K031300 |

| Деталь: | GEAR MIDDLE CLN Z30R |

| Парткод: | -302K031310 |

| Деталь: | PLATE MAIN DRIVE F |

| Парткод: | -302K031050 |

| Деталь: | GEAR DLP Z45R |

| Парткод: | -302K031140 |

| Деталь: | GEAR DLP Z37L |

| Парткод: | -302K031170 |

| Деталь: | GEAR DLP Z31R |

| Парткод: | -302K031180 |

| Деталь: | GEAR DLP Z87R-Z66L |

| Парткод: | -302K031150 |

| Деталь: | GEAR DLP Z53R-Z45R |

| Парткод: | -302K031160 |

| Деталь: | GEAR DLP Z45L |

| Парткод: | -302K031190 |

| Деталь: | BASE MAIN DRIVE F |

| Парткод: | -302K031010 |

| Деталь: | COLLAR MIDDLE CLN B |

| Парткод: | -302K031390 |

| Деталь: | SPRING MIDDLE CLN |

| Парткод: | -302K031480 |

| Деталь: | JOINT SHAFT CASSETTE |

| Парткод: | -302HN31660 |

| Деталь: | SHIELD GASKET |

| Парткод: | -7ZGSSTG47023H01 |

| Деталь: | WIRE DRUM-DLP MOT |

| Парткод: | 302K046140 |

| Деталь: | + BIND M SCREW 3X4 |

| Парткод: | 7BB000304H |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | DR-895A |

| Парткод: | 302K093122 |

| Деталь: | RAIL FEED |

| Парткод: | 303NN02370 |

| Деталь: | PULLEY CASSETTE RAIL |

| Парткод: | 302NL09030 |

| Деталь: | PIN CASSETTE RAIL |

| Парткод: | 2FB06710 |

| Деталь: | STAY FRONT FRAME |

| Парткод: | 302MV02040 |

| Деталь: | GUIDE ACTUATOR |

| Парткод: | 302K002590 |

| Деталь: | HOLDER SENSOR |

| Парткод: | 302MV06020 |

| Деталь: | BUSH SCREW |

| Парткод: | 302H702590 |

| Деталь: | WIRE LIMIT JUNCTION UPPER |

| Парткод: | 303NN46130 |

| Деталь: | STAY UPPER FEED |

| Парткод: | 303NN02143 |

| Деталь: | GUIDE PRIMARY FEED |

| Парткод: | 303NN02450 |

| Деталь: | ACTUATOR PAPER EMPTY |

| Парткод: | 302K002230 |

| Деталь: | WIRE LIFT FULL |

| Парткод: | 302K046300 |

| Деталь: | HOLDER CORD SENSOR |

| Парткод: | 302K002980 |

| Деталь: | RAIL DRUM R |

| Парткод: | 302K002340 |

| Деталь: | RAIL DRUM L |

| Парткод: | 302K002350 |

| Деталь: | RAIL DRUM BK |

| Парткод: | 302K002360 |

| Деталь: | SENSOR OPT. |

| Парткод: | 7NXGP1S173LCH01 |

| Деталь: | BUSH 6 EW |

| Парткод: | 302H024370 |

| Цена: | 190 ₽ |

| Деталь: | SHAFT BELT CLEANING DRIVE |

| Парткод: | 302K031730 |

| Деталь: | GEAR BELT CLEANING DRIVE Z30L |

| Парткод: | 302K031720 |

| Деталь: | GEAR BELT CLEANING DRIVE Z20L |

| Парткод: | 302K031740 |

| Деталь: | HOLDER CORD |

| Парткод: | 302NP39130 |

| Деталь: | WIRE DF POWER |

| Парткод: | 302NP46060 |

| Деталь: | ACCESS SADDLE |

| Парткод: | 7YZM610003++H01 |

| Деталь: | STAY HANDLE LEFT |

| Парткод: | 302K002110 |

| Деталь: | HANDLE COVER LEFT |

| Парткод: | 302MV02160 |

| Деталь: | ACCESS.SADDLE |

| Парткод: | 7YZM610009++H01 |

| Деталь: | HOLDER CORD REAR |

| Парткод: | 302K002820 |

| Деталь: | PARTS PIPE TRANSFER CLEANING ASSY SP |

| Парткод: | 302K094041 |

| Деталь: | HOLDER CORD FRONT |

| Парткод: | 302K002C40 |

| Деталь: | MOUNT INTERLOCK SW |

| Парткод: | 302NP02060 |

| Деталь: | INTER LOCK SWITCH |

| Парткод: | 2FB27160 |

| Деталь: | WIRE FRONT/RIGHT SW |

| Парткод: | 302NP46160 |

| Деталь: | SHAFT TRANSFER CLEANING DRIVE |

| Парткод: | 302MV21110 |

| Деталь: | HOLDER CORD SENSOR SUB |

| Парткод: | 302K002770 |

| Деталь: | PIN FRONT CASSETTE RAIL |

| Парткод: | 302GR02240 |

| Деталь: | MOUNT DF CONNECTOR |

| Парткод: | 302NP39080 |

| Деталь: | SW.PUSH |

| Парткод: | 7SP01000004+H01 |

| Деталь: | PAD RAIL |

| Парткод: | 303MH06010 |

| Деталь: | SEAL WIRE A |

| Парткод: | 302H012330 |

| Деталь: | RAIL CASSETTE LEFT |

| Парткод: | 302NP02050 |

| Деталь: | RAIL CASSETTE RIGHT |

| Парткод: | 302NL02210 |

| Деталь: | LEVER LIFT CASSETTE |

| Парткод: | 302K302760 |

| Деталь: | HOLDER CASSETTE HOOK |

| Парткод: | 302NL09020 |

| Деталь: | LEVER CASSETTE HOOK |

| Парткод: | 302K909640 |

| Деталь: | PULLEY EJECT |

| Парткод: | 303LW24060 |

| Деталь: | SHAFT HOOK FULCRUM |

| Парткод: | 303NF02280 |

| Деталь: | SHAFT HOOK PULLEY |

| Парткод: | 302K909630 |

| Деталь: | SPRING CASSETTE HOOK |

| Парткод: | 302NL09060 |

| Деталь: | RING STOPPER /A-49 FEED A4 |

| Парткод: | 5MVX111DN003 |

| Деталь: | STOPPER 3 /2BT1107 A4 |

| Парткод: | 5MVX111DN007 |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | PARTS CLEANING REGIST ASSY SP |

| Парткод: | 302MV94030 |

| Деталь: | SPRING RETAINER L |

| Парткод: | 302K002460 |

| Деталь: | COVER INNER FRONT |

| Парткод: | 302NP02040 |

| Деталь: | BKT COVER INNER FRONT |

| Парткод: | 302K002990 |

| Деталь: | COVER INNER DUCT |

| Парткод: | 302K002D30 |

| Деталь: | PIECE CONTAINER K |

| Парткод: | 302K002B10 |

| Деталь: | LABEL BLACK |

| Парткод: | 302K034090 |

| Деталь: | PIECE CONTAINER M |

| Парткод: | 302K002B20 |

| Деталь: | LABEL MAGENTA |

| Парткод: | 302K034100 |

| Деталь: | PIECE CONTAINER C |

| Парткод: | 302K002B30 |

| Деталь: | LABEL CYAN |

| Парткод: | 302K034110 |

| Деталь: | PIECE CONTAINER Y |

| Парткод: | 302K002B40 |

| Деталь: | LABEL YELLOW |

| Парткод: | 302K034120 |

| Деталь: | HOOK LEVER Y |

| Парткод: | 302NP03040 |

| Деталь: | PIECE RAIL BK |

| Парткод: | 302K002830 |

| Деталь: | PIECE RAIL M |

| Парткод: | 302K002840 |

| Деталь: | PIECE RAIL C |

| Парткод: | 302K002850 |

| Деталь: | PIECE RAIL Y |

| Парткод: | 302K002680 |

| Деталь: | PARTS PWB THERMISTOR ASSY SP |

| Парткод: | 302NP94120 |

| Деталь: | WIRE HUMIT 2 |

| Парткод: | 302K046830 |

| Деталь: | LID GUIDE FFC LED |

| Парткод: | 302K317490 |

| Деталь: | HOLDER RETAINER |

| Парткод: | 302K002371 |

| Деталь: | SPRING DRUM EARTH A |

| Парткод: | 302K002440 |

| Деталь: | SPRING DRUM EARTH B |

| Парткод: | 302K002640 |

| Деталь: | SPRING DRUM EARTH C |

| Парткод: | 302K002730 |

| Деталь: | REINFORCEMENT RETAINER |

| Парткод: | 302K002611 |

| Деталь: | PLATE RETAINER |

| Парткод: | 302NP03020 |

| Деталь: | BUSH RETAINER |

| Парткод: | 302K002630 |

| Деталь: | SHAFT RETAINER |

| Парткод: | 302K002420 |

| Деталь: | LEVER RETAINER |

| Парткод: | 302MV02280 |

| Деталь: | HOOK RETAINER L |

| Парткод: | 302K002430 |

| Деталь: | HOOK RETAINER R |

| Парткод: | 302K002390 |

| Деталь: | SPRING RETAINER R |

| Парткод: | 302K002451 |

| Деталь: | SPRING RETAINER L2 |

| Парткод: | 302K002E80 |

| Деталь: | SEAL WASTE |

| Парткод: | 302K002560 |

| Деталь: | LABEL E |

| Парткод: | 302MV34110 |

| Деталь: | PIN RETAINER |

| Парткод: | 302K002400 |

| Деталь: | SEAL ADJUST BK |

| Парткод: | 302K002240 |

| Деталь: | SEAL RETAINER |

| Парткод: | 302MV03030 |

| Деталь: | HOOK LEVER |

| Парткод: | 302NP03030 |

| Деталь: | +TP-FLAT T.T S SCREW 3X8 SR(BLACK) |

| Парткод: | 7BB782308H |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | +TP-CUP M SCREW 3X6 R |

| Парткод: | 7BB607306H |

| Деталь: | +BIND T.T S SCREW 3X10 SR |

| Парткод: | 7BB700310H |

| Деталь: | Ремень подачи бумаги в автоподатчике документов |

| Парткод: | 303LL07531 |

| Цена: | 1 900 ₽ |

| Деталь: | Ролик захвата бумаги в узле автоматической подачи документов |

| Парткод: | 36211110 |

| Цена: | 750 ₽ |

| Деталь: | HOLDER TRANSFER |

| Парткод: | -302K024050 |

| Деталь: | PLATE SEPARATION |

| Парткод: | -302K324150 |

| Деталь: | HOLDER SEPARATION |

| Парткод: | -302K024060 |

| Деталь: | LEVER HOOK F |

| Парткод: | -302MV24010 |

| Деталь: | SPRING TRANSFER R |

| Парткод: | -302MV24050 |

| Деталь: | BUSH TRANSFER ROLL R |

| Парткод: | -302K324430 |

| Деталь: | SPRING TRANSFER F |

| Парткод: | -302K024170 |

| Деталь: | BUSH TRANSFER ROLL F |

| Парткод: | -302K324240 |

| Деталь: | SPRING GUIDE |

| Парткод: | -302K024200 |

| Деталь: | SPRING GUIDE R |

| Парткод: | -302K024340 |

| Деталь: | GUIDE TRANSFER RIGHT |

| Парткод: | -302K024120 |

| Деталь: | PARTS ROLLER TRANSFER SP |

| Парткод: | -302MV94330 |

| Деталь: | LEVER TRANSFER |

| Парткод: | -302K024091 |

| Деталь: | SHEET TRANSFER |

| Парткод: | -302K024350 |

| Деталь: | GEAR TRANSFER Z25 |

| Парткод: | -302K024410 |

| Деталь: | HOOK TRANSFER F |

| Парткод: | -302K024070 |

| Деталь: | LABEL I |

| Парткод: | -302MV34180 |

| Деталь: | TERMINAL TRANSFER A |

| Парткод: | -302K024130 |

| Деталь: | HOOK TRANSFER R |

| Парткод: | -302K024080 |

| Деталь: | LEVER HOOK R |

| Парткод: | -302MV24020 |

| Деталь: | TR-8315B |

| Парткод: | 302MV93080 |

| Деталь: | DUCT INPUT DLP A |

| Парткод: | 302K033060 |

| Деталь: | PARTS FAN COOLING LSU 60 SP |

| Парткод: | 302LC94380 |

| Деталь: | PARTS,FAN COOLING CONVEYING SP |

| Парткод: | 302FZ94420 |

| Деталь: | WIRE FAN MOT DLP/LSU |

| Парткод: | 302K046370 |

| Деталь: | DUCT INPUT DLP B |

| Парткод: | 302K033070 |

| Деталь: | SPRING DUCT |

| Парткод: | 302K033090 |

| Деталь: | DUCT INPUT DLP C |

| Парткод: | 302K033080 |

| Деталь: | PARTS DUCT OUTPUT DLP IN ASSY SP |

| Парткод: | 302MV94050 |

| Деталь: | STAY SHIELD IH |

| Парткод: | 302K002740 |

| Деталь: | DUCT EXIT |

| Парткод: | 302K033012 |

| Деталь: | DUCT HIGH VOLTAGE |

| Парткод: | 302K002C21 |

| Деталь: | GUIDE FUSER |

| Парткод: | 302MV02360 |

| Деталь: | SPRING IH |

| Парткод: | 302K926220 |

| Деталь: | CAP SPRING |

| Парткод: | 302LK26050 |

| Деталь: | PIN READING GUIDE |

| Парткод: | 303LL24250 |

| Деталь: | DUCT IH COIL |

| Парткод: | 302K002C70 |

| Деталь: | SPONGE IH COIL |

| Парткод: | 302K002D00 |

| Деталь: | DUCT CONTAINER B |

| Парткод: | 302MV33020 |

| Деталь: | DUCT CONTAINER C |

| Парткод: | 302MV33030 |

| Деталь: | BRACKET FAN DLP |

| Парткод: | 302K002261 |

| Деталь: | PARTS,FAN COOLING DLP 70 SP |

| Парткод: | 302FZ94380 |

| Деталь: | PARTS FAN COOLING LSU 60 SP |

| Парткод: | 302K994360 |

| Деталь: | SEAL DLP FAN |

| Парткод: | 302K002D60 |

| Деталь: | DUCT CONTAINER A |

| Парткод: | 302K002790 |

| Деталь: | WIRE IH-DLP FAN |

| Парткод: | 302MV46680 |

| Деталь: | DUCT IH |

| Парткод: | 302K002191 |

| Деталь: | DUCT IH COVER |

| Парткод: | 302K002781 |

| Деталь: | DUCT OUT DLP C |

| Парткод: | 302K033040 |

| Деталь: | PARTS FAN MOTOR SP |

| Парткод: | 302NG94220 |

| Деталь: | WIRE FAN MOT LVU |

| Парткод: | 302MV46070 |

| Деталь: | PARTS FAN MOTOR SET SP |

| Парткод: | 302MV94560 |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | + BIND T.T P SCREW 3X12 |

| Парткод: | 7BB200312H |

| Деталь: | +BIND T.T S SCREW 3X20 SR |

| Парткод: | 7BB700320H |

| Деталь: | HOLDER FEED DRIVE A |

| Парткод: | -302K031501 |

| Деталь: | SPRING EARTH F |

| Парткод: | -302K031570 |

| Деталь: | PARTS MOTOR-BL W20 SP |

| Парткод: | -302K994321 |

| Деталь: | PLATE FEED DRIVE |

| Парткод: | -302K031560 |

| Деталь: | CONNECTOR 292254-2 |

| Парткод: | -7YCC02B1003+H01 |

| Деталь: | BUSH DRIVE |

| Парткод: | -302HN31590 |

| Деталь: | SOLENOID MPF |

| Парткод: | -302HN44160 |

| Деталь: | PIN DRIVE MT |

| Парткод: | -302HN31640 |

| Деталь: | PIN DRIVE A |

| Парткод: | -302K331260 |

| Деталь: | CLUTCH 50 Z35R |

| Парткод: | -302KV44041 |

| Деталь: | SHAFT CLUTCH FEED |

| Парткод: | -302K331240 |

| Деталь: | GEAR Z30L OUTPUT CL |

| Парткод: | -302K031550 |

| Деталь: | GEAR Z32L |

| Парткод: | -302K331130 |

| Деталь: | GEAR Z84R-Z27L |

| Парткод: | -302K031520 |

| Деталь: | GEAR Z61R-Z32R |

| Парткод: | -302K031530 |

| Деталь: | GEAR Z32L IDLE |

| Парткод: | -302K031540 |

| Деталь: | GEAR Z40R IDLE |

| Парткод: | -302K331081 |

| Деталь: | GEAR Z43L IDLE |

| Парткод: | -302K331090 |

| Деталь: | GEAR Z30R IDLE |

| Парткод: | -302K331140 |

| Деталь: | GEAR MIDDLE CLN Z27L-Z21L |

| Парткод: | -302K031300 |

| Деталь: | GEAR Z48R-Z22S |

| Парткод: | -302K331160 |

| Деталь: | GEAR Z42R-Z36R |

| Парткод: | -302K331150 |

| Деталь: | GEAR Z45S INPUT MPF A |

| Парткод: | -302K331180 |

| Деталь: | SPRING INPUT MPF |

| Парткод: | -302HN31650 |

| Деталь: | GEAR Z45S INPUT MPF B |

| Парткод: | -302K331190 |

| Деталь: | HOLDER FEED DRIVE B |

| Парткод: | -302K031511 |

| Деталь: | BUSH DRIVE 8 |

| Парткод: | -302K331230 |

| Деталь: | GEAR Z28S |

| Парткод: | -302K331170 |

| Деталь: | SPRING FEED |

| Парткод: | -302HN31410 |

| Деталь: | JOINT SHAFT CASSETTE |

| Парткод: | -302HN31660 |

| Деталь: | CAM MPF |

| Парткод: | -302K331200 |

| Деталь: | WIRE FEED UNIT 2 |

| Парткод: | -302K046020 |

| Деталь: | + BIND M SCREW 3X4 |

| Парткод: | 7BB000304H |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | DR-895C |

| Парткод: | 302K093142 |

| Деталь: | CASE WASTE A |

| Парткод: | 302K003022 |

| Деталь: | SEAL CASE WASTE C |

| Парткод: | 302K003280 |

| Деталь: | SEAL CASE WASTE D |

| Парткод: | 302K003331 |

| Деталь: | BUSH WASTE |

| Парткод: | 302K003160 |

| Деталь: | SHAFT WASTE DRIVE |

| Парткод: | 302K003170 |

| Деталь: | JOINT WASTE C |

| Парткод: | 302K003140 |

| Деталь: | GEAR WASTE Z13L |

| Парткод: | 302K003110 |

| Деталь: | SCREW WASTE |

| Парткод: | 302K003050 |

| Деталь: | GEAR SCREW WASTE Z13L |

| Парткод: | 302K003060 |

| Деталь: | BUSH SCREW WASTE |

| Парткод: | 302K003290 |

| Деталь: | CASE WASTE B |

| Парткод: | 302K003031 |

| Деталь: | SEAL CASE WASTE B |

| Парткод: | 302K003270 |

| Деталь: | SEAL CASE WASTE A |

| Парткод: | 302K003260 |

| Деталь: | COVER SENSOR |

| Парткод: | 302K003320 |

| Деталь: | PLATE WASTE |

| Парткод: | 302MV03020 |

| Деталь: | LOCK WASTE A |

| Парткод: | 302K003092 |

| Деталь: | LOCK WASTE B |

| Парткод: | 302K003102 |

| Деталь: | SPRING LOCK WASTE |

| Парткод: | 302K003231 |

| Деталь: | SEAL SHUTTER WASTE |

| Парткод: | 302K003250 |

| Деталь: | CASE SENSOR |

| Парткод: | 302K003041 |

| Деталь: | PARTS TONER FULL DETECT ASSY SP |

| Парткод: | 302K094280 |

| Деталь: | SPACER LED /43587J2063 A4 |

| Парткод: | 5MVS313SB002 |

| Деталь: | SHUTTER WASTE TONER |

| Парткод: | 302K003070 |

| Деталь: | SPRING SHUTTER WASTE |

| Парткод: | 302K003200 |

| Деталь: | HOUSING WASTE |

| Парткод: | 302NP03010 |

| Деталь: | PLATE HOUSING WASTE |

| Парткод: | 302K003620 |

| Деталь: | LEVER WASTE |

| Парткод: | 302MV03040 |

| Деталь: | LABEL D |

| Парткод: | 302MV34100 |

| Деталь: | SPRING LEVER WASTE |

| Парткод: | 302K003220 |

| Деталь: | LABEL PUSH |

| Парткод: | 302MV34240 |

| Деталь: | ARM WASTE |

| Парткод: | 302K002B50 |

| Деталь: | SPRING ARM WASTE |

| Парткод: | 302K002B60 |

| Деталь: | STRAP COVER FRONT R |

| Парткод: | 302K304230 |

| Деталь: | STRAP COVER FRONT L |

| Парткод: | 302K304320 |

| Деталь: | WT-895 |

| Парткод: | 302K093110 |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | ACCESS.SPACER |

| Парткод: | 7YZM510007++H01 |

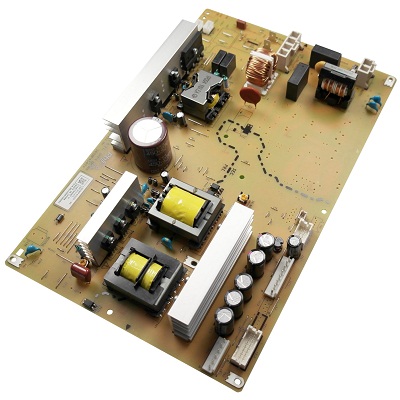

| Деталь: | PARTS UNIT LOW VOLTAGE 200 SP |

| Парткод: | 302NP94090 |

| Цена: | 21 400 ₽ |

| Деталь: | PARTS UNIT LOW VOLTAGE 100 SP |

| Парткод: | 302NP94080 |

| Деталь: | BOX POWER |

| Парткод: | 302NP39020 |

| Деталь: | SHEET BOX POWER |

| Парткод: | 302MV39320 |

| Деталь: | BRACKET FAN POWER |

| Парткод: | 302MV39250 |

| Деталь: | PARTS,FAN COOLING CONVEYING SP |

| Парткод: | 302FZ94420 |

| Деталь: | ACCESS.SADDLE |

| Парткод: | 7YZM610010++H01 |

| Деталь: | ACCESS.SADDLE |

| Парткод: | 7YZM610012++H01 |

| Деталь: | LID POWER |

| Парткод: | 302MV39220 |

| Деталь: | CONNECTOR |

| Парткод: | 7YCC02B1111 + H01 |

| Деталь: | ACCESS.SPACER |

| Парткод: | 7YZM510021++H01 |

| Деталь: | SEAL MOTOR DC |

| Парткод: | 302LC31511 |

| Деталь: | WIRE DP |

| Парткод: | 302NP46360 |

| Деталь: | SPACER,SFS-2.6S-B1WM(JST) |

| Парткод: | M0208010 |

| Деталь: | MOUNT DP CONNECTOR |

| Парткод: | 302NP39150 |

| Деталь: | ACCESS.EDGING |

| Парткод: | 7YZM210005++H01 |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | ELA UNIT-TRANSFER |

| Парткод: | TR-8315B |

| Цена: | 4 200 ₽ |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325C |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325K |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325M |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325Y |

| Деталь: | Formatter, exchange, HP Color LaserJet 3000dn and 3000dtn Series only (256 MB) |

| Парткод: | 302NP94151 |

| Цена: | 81 100 ₽ |

| Деталь: | LASER SCANNER ASSY |

| Парткод: | LK-8325 |

| Цена: | 22 600 ₽ |

| Деталь: | Правая часть узла термозакрепления, в сборе (220В) |

| Парткод: | FK-8325 |

| Цена: | 28 900 ₽ |

| Деталь: | Левая часть узла термозакрепления, в сборе (220В) |

| Парткод: | FK-8507 |

| Цена: | 15 900 ₽ |

| Деталь: | Комплект для технического обслуживания |

| Парткод: | MK-8325B |

| Деталь: | Комплект для технического обслуживания |

| Парткод: | MK-8325A |

| Деталь: | DV-8325K |

| Парткод: | 302NP93050 |

| Деталь: | DV-8325M |

| Парткод: | 302NP93060 |

| Деталь: | DV-8325C |

| Парткод: | 302NP93040 |

| Деталь: | DV-8325Y |

| Парткод: | 302NP93070 |

| Деталь: | BASE CONVEYING |

| Парткод: | -302K024014 |

| Деталь: | TERMINAL TRANSFER B |

| Парткод: | -302K024140 |

| Деталь: | TERMINAL SEPARATION A |

| Парткод: | -302K024151 |

| Деталь: | GUIDE CONVEYING |

| Парткод: | -302K024110 |

| Деталь: | SPRING EARTH CONVEYING |

| Парткод: | -302K024160 |

| Деталь: | SENSOR,CONVEYING |

| Парткод: | -3H327410 |

| Деталь: | WIRE CONVEYING UNIT PI |

| Парткод: | -302K046890 |

| Деталь: | HOLDER SENSOR |

| Парткод: | -302K024380 |

| Деталь: | LEVER CONVEYING F |

| Парткод: | -302K024232 |

| Деталь: | SPRING CONVEYING F |

| Парткод: | -302K324110 |

| Деталь: | LEVER CONVEYING R |

| Парткод: | -302K024242 |

| Деталь: | SPRING CONVEYING R |

| Парткод: | -302K324360 |

| Деталь: | FRAME DU |

| Парткод: | -302K024271 |

| Деталь: | ACTUATOR DU |

| Парткод: | -302K329040 |

| Деталь: | RETAINER ACTUATOR |

| Парткод: | -302K329060 |

| Деталь: | SENSOR OPT. |

| Парткод: | -7NXGP1S173LCH01 |

| Деталь: | PARTS FAN MOTOR SET SP |

| Парткод: | -302MV94560 |

| Деталь: | COVER DUCT FRONT |

| Парткод: | -302K024310 |

| Деталь: | COVER DUCT REAR |

| Парткод: | -302K024320 |

| Деталь: | SHEET FAN PRESS |

| Парткод: | -302K024330 |

| Деталь: | PULLEY DU |

| Парткод: | -302K329020 |

| Деталь: | SPRING DU FEED |

| Парткод: | -302K329030 |

| Деталь: | WIRE CONVEYING UNIT |

| Парткод: | -302K046041 |

| Деталь: | FRAME DU B |

| Парткод: | -302K024280 |

| Деталь: | BASE CONVEYING SUB |

| Парткод: | -302K024300 |

| Деталь: | PARTS ROLLER REGIST RIGHT SP |

| Парткод: | -302K094420 |

| Деталь: | BUSH REGIST F |

| Парткод: | -302K324180 |

| Деталь: | BUSH REGIST R |

| Парткод: | -302K324270 |

| Деталь: | SHEET REGIST R |

| Парткод: | -302K024220 |

| Деталь: | SHEET REGIST LOW |

| Парткод: | -302K024431 |

| Деталь: | SPRING REGIST F |

| Парткод: | -302K024440 |

| Деталь: | PARTS GEAR REGIST Z24R SP |

| Парткод: | -302K394330 |

| Деталь: | COLLAR TRANS ROLLER |

| Парткод: | -302H722470 |

| Деталь: | BUSH SPRING FEED |

| Парткод: | -302KV24090 |

| Деталь: | SPRING MIDDLE PULLEY |

| Парткод: | -302K024190 |

| Деталь: | SHAFT FEED |

| Парткод: | -302K324460 |

| Деталь: | PULLEY MIDDLE |

| Парткод: | -302MV24030 |

| Деталь: | COVER HARNESS |

| Парткод: | -302K024250 |

| Деталь: | SPRING REGIST R |

| Парткод: | -302K024450 |

| Деталь: | SHAFT RIGHT COVER F |

| Парткод: | 302K304550 |

| Деталь: | SHAFT RIGHT COVER R |

| Парткод: | 302K304560 |

| Деталь: | FILM CONVEYING SHAFT |

| Парткод: | 302K304630 |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | +TP-CUP M SCREW 3X12 R |

| Парткод: | 7BB607312H |

| Деталь: | PARTS CONVEYING UNIT SP |

| Парткод: | 302MV94431 |

| Деталь: | ACTUATOR SIZE DETECTION |

| Парткод: | -302K908211 |

| Деталь: | SPRING-TORSION SIZE DETECTION |

| Парткод: | -302K908220 |

| Деталь: | HOLDER SIZE DETECTION |

| Парткод: | -302K908580 |

| Деталь: | SENSOR OPT. |

| Парткод: | -7NXGP1S173LCH01 |

| Деталь: | WIRE MPF SIZE UNIT 2 |

| Парткод: | -302MV46510 |

| Деталь: | TABLE MPF B |

| Парткод: | -302MV08430 |

| Деталь: | SPONGE WIRE MPT |

| Парткод: | -302H708150 |

| Деталь: | TABLE MPF A |

| Парткод: | -302MV08420 |

| Деталь: | TABLE MPF |

| Парткод: | -302MV08410 |

| Деталь: | CURSOR FRONT MPF |

| Парткод: | -302MV08440 |

| Деталь: | CURSOR REAR MPF |

| Парткод: | -302MV08450 |

| Деталь: | GEAR 18 BYPASS |

| Парткод: | -2C906080 |

| Деталь: | TERMINAL PAPER SIZE |

| Парткод: | -2C906090 |

| Деталь: | PCB MPF SIZE ASSY |

| Парткод: | -2C901050 |

| Деталь: | GUIDE FRONT MPF WIRE |

| Парткод: | -302MV08460 |

| Деталь: | ORIGINAL SIZE SWITCH |

| Парткод: | -76727010 |

| Деталь: | GUIDE REAR MPF WIRE |

| Парткод: | -302MV08470 |

| Деталь: | STOPPER BYPASS TABLE |

| Парткод: | -2FB07330 |

| Деталь: | SPRING MPF |

| Парткод: | -302MV08500 |

| Деталь: | COVER MPF |

| Парткод: | -302MV08400 |

| Деталь: | STRAP LINK MPF |

| Парткод: | -302K308460 |

| Деталь: | STOPPER STRAP |

| Парткод: | -302K308470 |

| Деталь: | LABEL BYPASS TABLE |

| Парткод: | -302MV34270 |

| Деталь: | SHEET MPF WIRE A |

| Парткод: | -302MV08520 |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | PARTS MPF TABLE ASSY SP |

| Парткод: | 302MV94080 |

| Деталь: | PARTS PRIMARY FEED ASSY SP |

| Парткод: | 302MV94061 |

| Деталь: | MC-8325 |

| Парткод: | -302NP93020 |

| Деталь: | DK-8325 |

| Парткод: | 302NP93030 |

| Деталь: | GUIDE FEED OUT |

| Парткод: | 302MV07011 |

| Деталь: | PARTS ROLLER FEED UPPER SP |

| Парткод: | 302MV94310 |

| Деталь: | BUSH DU |

| Парткод: | 302K329270 |

| Деталь: | STOPPER 3 /2BT1107 A4 |

| Парткод: | 5MVX111DN007 |

| Деталь: | BUSH 6 EW |

| Парткод: | 302H024370 |

| Цена: | 190 ₽ |

| Деталь: | PULLEY 26-6 DUPLEX |

| Парткод: | 303MR29040 |

| Деталь: | PULLEY PA |

| Парткод: | 302HN24400 |

| Деталь: | ACTUATOR DECK FEED |

| Парткод: | 302K302831 |

| Деталь: | SPRING EARTH FEED |

| Парткод: | 302MV07120 |

| Деталь: | GUIDE FEED LOW |

| Парткод: | 302MV07020 |

| Деталь: | PARTS ROLLER FEED LOWER SP |

| Парткод: | 302MV94320 |

| Деталь: | JOINT PULLEY 26-6 |

| Парткод: | 303NN24110 |

| Деталь: | ACTUATOR REGIST |

| Парткод: | 302K306140 |

| Деталь: | SPRING ACTUATOR REGIST |

| Парткод: | 302K306150 |

| Деталь: | GUIDE FEED |

| Парткод: | 302MV07030 |

| Деталь: | GUIDE TRANSFER LEFT |

| Парткод: | 302K002A20 |

| Деталь: | PARTS ROLLER REGIST LEFT SP |

| Парткод: | 302K394230 |

| Деталь: | BUSH 8 |

| Парткод: | 302H024830 |

| Деталь: | BUSH 8 EW |

| Парткод: | 302H024360 |

| Цена: | 30 ₽ |

| Деталь: | PARTS GEAR REGIST Z28L-Z18L SP |

| Парткод: | 302K394310 |

| Деталь: | STOPPER 6 |

| Парткод: | 2BC06910 |

| Деталь: | SPRING EARTH REG C |

| Парткод: | 302K002D40 |

| Деталь: | GUIDE REGIST FRONT |

| Парткод: | 302K002271 |

| Деталь: | VARISTOR TC |

| Парткод: | 302K345120 |

| Деталь: | SPRING EARTH REG D |

| Парткод: | 302K002490 |

| Деталь: | SPRING EARTH REG B |

| Парткод: | 302K002480 |

| Деталь: | SPRING EARTH REG A |

| Парткод: | 302K002470 |

| Деталь: | GUIDE REGIST REAR |

| Парткод: | 302K002280 |

| Деталь: | TERMINAL SEPARATION B |

| Парткод: | 302K002520 |

| Деталь: | TERMINAL TRANSFER C |

| Парткод: | 302K002510 |

| Деталь: | BELT FEED |

| Парткод: | 302MV07110 |

| Деталь: | SHEET GUIDE CASSETTE |

| Парткод: | 302K002E00 |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | PLATE NUMBER |

| Парткод: | 2BL04310 |

| Деталь: | PLATE NUMBER 2 |

| Парткод: | 2BL04370 |

| Деталь: | SHEET CASSETTE C |

| Парткод: | 302MV34300 |

| Деталь: | SHEET CASSETTE I |

| Парткод: | 302MV34430 |

| Деталь: | LABEL OPERATION L |

| Парткод: | -302MV34330 |

| Деталь: | EMBLEM CASSETTE |

| Парткод: | -302NL09070 |

| Деталь: | COVER CASSETTE |

| Парткод: | -302NL09050 |

| Деталь: | HANDLE CASSETTE |

| Парткод: | -302NL09080 |

| Деталь: | CASSETTE |

| Парткод: | -302NL09010 |

| Деталь: | LABEL OPERATION S |

| Парткод: | -302MV34340 |

| Деталь: | LABEL CASSETTE SIZE A |

| Парткод: | -302MV34310 |

| Деталь: | LABEL CASSETTE SIZE B |

| Парткод: | -302MV34360 |

| Деталь: | LABEL OPERATION CURSOR |

| Парткод: | -302MV34320 |

| Деталь: | PLATE SIDE SWITCH |

| Парткод: | -302MV09050 |

| Деталь: | SPRING SIDE SWITCH |

| Парткод: | -302K309220 |

| Деталь: | ARM SIZE DETECTION |

| Парткод: | -302MV09040 |

| Деталь: | CURSOR END |

| Парткод: | -302K309270 |

| Деталь: | SPRING CURSOR R |

| Парткод: | -2C907360 |

| Деталь: | SLIDER CURSOR END |

| Парткод: | -302K309141 |

| Деталь: | SPRING SIZE SET |

| Парткод: | -302K309360 |

| Деталь: | STOPPER SIZE SET |

| Парткод: | -302K309350 |

| Деталь: | CURSOR CASSETTE REAR |

| Парткод: | -302MV09080 |

| Деталь: | LEVER CURSOR SET |

| Парткод: | -302K309190 |

| Деталь: | SPRING CURSOR SET |

| Парткод: | -302K309370 |

| Деталь: | LABEL PAPER LIMIT |

| Парткод: | -302MV34370 |

| Деталь: | CURSOR CASSETTE FRONT |

| Парткод: | -302MV09090 |

| Деталь: | LEVER RELEASE CURSOR F |

| Парткод: | -302K309200 |

| Деталь: | SPRING RELEASE CURSOR F |

| Парткод: | -302K309210 |

| Деталь: | SPRING SIZE SET F |

| Парткод: | -302K309380 |

| Деталь: | SIZE FIX |

| Парткод: | -302HN09240 |

| Деталь: | PARTS GEAR Z18 SP |

| Парткод: | -302K394380 |

| Деталь: | SHAFT DRIVE LIFT |

| Парткод: | -302K309180 |

| Деталь: | PLATE LIFT BASE CASSETTE |

| Парткод: | -302K309170 |

| Деталь: | STOPPER 6 |

| Парткод: | -2BC06910 |

| Деталь: | SPRING CASSETTE LIFT EARTH |

| Парткод: | -302K309300 |

| Деталь: | BASE CASSETTE |

| Парткод: | -302MV09021 |

| Деталь: | PAD CASSETTE |

| Парткод: | -2C907140 |

| Деталь: | LABEL PAPER SET |

| Парткод: | -302MV34350 |

| Деталь: | LIFT BASE CASSETTE SUB |

| Парткод: | -302K309150 |

| Деталь: | SPRING LEVER LIFT CASSETTE SUB |

| Парткод: | -302K309160 |

| Деталь: | PLATE CASSETTE LEFT |

| Парткод: | -302NL09090 |

| Деталь: | PLATE CASSETTE RIGHT |

| Парткод: | -302NL09100 |

| Деталь: | PULLEY MPT BYPASS |

| Парткод: | -302FZ07020 |

| Деталь: | PULLEY,CASSETTE RAIL |

| Парткод: | -302FG07020 |

| Деталь: | RING STOPPER /A-49 FEED A4 |

| Парткод: | -5MVX111DN003 |

| Деталь: | +TP-FLAT T.T P SCREW 4X10 |

| Парткод: | 7BB202410H |

| Деталь: | SPRING PIN |

| Парткод: | 5MBP2514WXSP |

| Деталь: | +FLAT HEAD T.T P SCREW 3X8 |

| Парткод: | 7BB203308H |

| Деталь: | CT-8325 |

| Парткод: | 302NP93010 |

| Деталь: | WIRE BRIDGE 1 |

| Парткод: | 302NP46140 |

| Деталь: | ACCESS.CLAMP |

| Парткод: | 7YZM390002++H01 |

| Деталь: | MOUNT ENGINE PWB B |

| Парткод: | 302NP39100 |

| Деталь: | FRAME REAR UPPER |

| Парткод: | 302K002151 |

| Деталь: | SLIDER ASSY |

| Парткод: | 302K026090 |

| Деталь: | SPRING EARTH EXIT |

| Парткод: | 302K002671 |

| Деталь: | FRAME FRONT UPPER |

| Парткод: | 302K002141 |

| Деталь: | ADJUSTER FUSER |

| Парткод: | 302K325350 |

| Деталь: | MOUNT FUSER FRONT |

| Парткод: | 302K002290 |

| Деталь: | COVER FUSER MOUNT REAR |

| Парткод: | 302K026030 |

| Деталь: | WIRE FUSER UNIT 1 |

| Парткод: | 302NP46260 |

| Деталь: | HOLDER DRAWER FUSER |

| Парткод: | 302K002660 |

| Деталь: | LEVER FUSER RELEASE FRONT |

| Парткод: | 302MV26010 |

| Деталь: | COVER FUSER MOUNT FRONT |

| Парткод: | 302K026020 |

| Деталь: | SHAFT RAIL |

| Парткод: | 302K026130 |

| Деталь: | GEAR IDLE Z20S |

| Парткод: | 302K026120 |

| Деталь: | SPRING EARTH FUSER RAIL |

| Парткод: | 302K026080 |

| Деталь: | LEVER FUSER RELEASE REAR |

| Парткод: | 302MV26020 |

| Деталь: | SPRING FUSER LOCK LEVER |

| Парткод: | 302K026060 |

| Деталь: | SPRING FUSER LOCK LEVER R |

| Парткод: | 302K026180 |

| Деталь: | LABEL H2 |

| Парткод: | 302MV34170 |

| Деталь: | LABEL PUSH |

| Парткод: | 302MV34240 |

| Деталь: | SHEET RAIL |

| Парткод: | 302K026190 |

| Деталь: | LEVER TRANSFER SHIELD |

| Парткод: | 302K026150 |

| Деталь: | BASE FUSER MOUNT |

| Парткод: | 302K026010 |

| Деталь: | BRACKET DRAWER |

| Парткод: | 302NL02080 |

| Деталь: | WIRE RFID PWB |

| Парткод: | 302NP46240 |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | +TP-FLAT T.T P SCREW 3X8 |

| Парткод: | 7BB202308H |

| Деталь: | SENSOR OPT |

| Парткод: | 7NXGP1S173LCH01 |

| Деталь: | SWITCH RELEASE |

| Парткод: | 302NL17020 |

| Деталь: | MOUNT ISC |

| Парткод: | 302NL17040 |

| Деталь: | GUIDE FFC CCD |

| Парткод: | 302MV17040 |

| Деталь: | SENSOR ORIGINAL |

| Парткод: | 302H044110 |

| Деталь: | WIRE CCD POWER |

| Парткод: | 302MV46600 |

| Деталь: | WIRE ORIGINAL SENSOR |

| Парткод: | 302K946750 |

| Деталь: | ACCESS.CLAMP |

| Парткод: | 7YZM390002++H01 |

| Деталь: | WIRE FFC LED |

| Парткод: | 302MV46630 |

| Деталь: | GUIDE FFC LED C |

| Парткод: | 302K317172 |

| Деталь: | SHEET FFC LED |

| Парткод: | 302K317791 |

| Деталь: | WIRE FFC CCD |

| Парткод: | 302NL46380 |

| Деталь: | FERRITE CORE |

| Парткод: | 7YBFZZ65C001H01 |

| Деталь: | PARTS PWB ISC ASSY SP |

| Парткод: | 302NP94180 |

| Деталь: | MOTOR REVERSE |

| Парткод: | 302HN44100 |

| Деталь: | PARTS GEAR Z18-Z63R SP |

| Парткод: | 302K394370 |

| Деталь: | GEAR Z54 |

| Парткод: | 302K317350 |

| Деталь: | MOUNT DRIVE |

| Парткод: | 302NL17010 |

| Деталь: | WIRE SCANNER MOT |

| Парткод: | 302NP46500 |

| Деталь: | WIRE HP SENSOR |

| Парткод: | 302NP46490 |

| Деталь: | HOLDER SWITCH |

| Парткод: | 302NL17030 |

| Деталь: | WIRE OPEN SENSOR |

| Парткод: | 302NP46480 |

| Деталь: | MOUNT JUNCTION PWB |

| Парткод: | 302NL17070 |

| Деталь: | PARTS ISU |

| Парткод: | 302NP93130 |

| Деталь: | PARTS PWB DP JUNCTION ASSY SP |

| Парткод: | 302NP94160 |

| Деталь: | WIRE DP JUNCTION |

| Парткод: | 302NP46420 |

| Деталь: | FILM FFC CCD |

| Парткод: | 302MV17110 |

| Деталь: | COVER LENS |

| Парткод: | 302MV17030 |

| Деталь: | SHIELD GASKET |

| Парткод: | 7ZG65TSV+010H01 |

| Деталь: | STOPPER 5 |

| Парткод: | 2BC06980 |

| Деталь: | MOUNT DP |

| Парткод: | 302NL17050 |

| Деталь: | PIN FUSER COVER |

| Парткод: | 2FB20860 |

| Деталь: | PARTS CONTACT-GLASS ASSY(C) SP |

| Парткод: | 302MV94110 |

| Деталь: | PARTS CONTACT-GLASS ASSY(I) SP |

| Парткод: | 302MV94100 |

| Деталь: | FILM FFC CCD B |

| Парткод: | 302MV17130 |

| Деталь: | PARTS PWB SCANNER LED ASSY SP |

| Парткод: | -302NP94170 |

| Деталь: | MOUNT LED |

| Парткод: | -302K317470 |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | +PAN M SCREW WITH SW W 3X8 R |

| Парткод: | 7BB606308H |

| Деталь: | PARTS MOUNT LED ASSY SP |

| Парткод: | 302NP93090 |

| Деталь: | Пружина |

| Парткод: | 302HN31650 |

| Цена: | 150 ₽ |

| Деталь: | MOUNT SCANNER REAR |

| Парткод: | 302NP02110 |

| Деталь: | ACCESS.EDGING |

| Парткод: | 7YZM210003++H01 |

| Деталь: | HOLDER CORD RIGHT |

| Парткод: | 302MV02341 |

| Деталь: | SW. SEESAW |

| Парткод: | 7SC020403+++H01 |

| Деталь: | MOUNT SCANNER RIGHT |

| Парткод: | 302MV02092 |

| Деталь: | MOUNT OPTION |

| Парткод: | 302MV02131 |

| Деталь: | MOUNT SCANNER FRONT |

| Парткод: | 302NL02240 |

| Деталь: | COVER EXIT FRONT TOP |

| Парткод: | 302MV04290 |

| Деталь: | ACCESS.CLAMP |

| Парткод: | 7YZM390002++H01 |

| Деталь: | SHEET SCANNER FRONT |

| Парткод: | 302NL02360 |

| Деталь: | MOUNT RIGHT INTERLOCK |

| Парткод: | 302K002210 |

| Деталь: | SW.MICRO |

| Парткод: | 7SM010101+++H01 |

| Деталь: | SPRING BYPASSFFED |

| Парткод: | 302H008140 |

| Деталь: | PIN FUSER COVER |

| Парткод: | 2FB20860 |

| Деталь: | WIRE MAIN SWITCH |

| Парткод: | 302NP46120 |

| Деталь: | WIRE AC CASSETTE SW |

| Парткод: | 302NP46110 |

| Деталь: | COVER EXIT HARNESS |

| Парткод: | 302K002A00 |

| Деталь: | PUSH SWITCH 03 SN /SW-192 N |

| Парткод: | 5ESP03090001+01 |

| Деталь: | MOUNT INLET (CHN) |

| Парткод: | 302MV39380 |

| Деталь: | WIRE DF |

| Парткод: | 302NP46330 |

| Деталь: | SPACER,SFS-2.6S-B1WM(JST) |

| Парткод: | M0208010 |

| Деталь: | SW. SEESAW |

| Парткод: | 7SC010105+++H01 |

| Деталь: | LID VENDOR |

| Парткод: | 302FB26290 |

| Деталь: | ACCESS.EDGING |

| Парткод: | 7YZM210005++H01 |

| Деталь: | ACCESS.SADDLE |

| Парткод: | 7YZM610009++H01 |

| Деталь: | ACCESS.SADDLE |

| Парткод: | 7YZM610010++H01 |

| Деталь: | WIRE CASSETTE SIZE SW |

| Парткод: | 302K046280 |

| Деталь: | WIRE INLET |

| Парткод: | 302NP46100 |

| Деталь: | STAY SHIELD POWER |

| Парткод: | 302K002750 |

| Деталь: | WIRE MPF SIZE 2 |

| Парткод: | 302MV46440 |

| Деталь: | MOUNT SCANNER ADJUST |

| Парткод: | 302K302210 |

| Деталь: | MOUNT MAIN SW |

| Парткод: | 302NP39050 |

| Деталь: | LID DEHUMIDIFIER SW |

| Парткод: | 302K302890 |

| Деталь: | SPACER SCANNER ADJUST |

| Парткод: | 302K302200 |

| Деталь: | COVER WIRE EJECT |

| Парткод: | 303JY28390 |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | +TP-FLAT T.T S SCREW 3X8 SR |

| Парткод: | 7BB702308H |

| Деталь: | ELA UNIT-TRANSFER |

| Парткод: | TR-8315B |

| Цена: | 4 200 ₽ |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325C |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325K |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325M |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325Y |

| Деталь: | Formatter, exchange, HP Color LaserJet 3000dn and 3000dtn Series only (256 MB) |

| Парткод: | 302NP94151 |

| Цена: | 81 100 ₽ |

| Деталь: | LASER SCANNER ASSY |

| Парткод: | LK-8325 |

| Цена: | 22 600 ₽ |

| Деталь: | Правая часть узла термозакрепления, в сборе (220В) |

| Парткод: | FK-8325 |

| Цена: | 28 900 ₽ |

| Деталь: | Левая часть узла термозакрепления, в сборе (220В) |

| Парткод: | FK-8507 |

| Цена: | 15 900 ₽ |

| Деталь: | Комплект для технического обслуживания |

| Парткод: | MK-8325B |

| Деталь: | Комплект для технического обслуживания |

| Парткод: | MK-8325A |

| Деталь: | Вал переноса заряда |

| Парткод: | 302MV94330 |

| Цена: | 7 300 ₽ |

| Деталь: | FK-8507 IH |

| Парткод: | 302LC93090 |

| Деталь: | FK-8506 IH |

| Парткод: | 302LC93080 |

| Деталь: | FK-8325 |

| Парткод: | 302NP93080 |

| Деталь: | Ролик подачи бумаги |

| Парткод: | 302F906230 |

| Цена: | 750 ₽ |

| Деталь: | Ролик отделения бумаги |

| Парткод: | 302F909171 |

| Цена: | 900 ₽ |

| Деталь: | Ролик захвата бумаги |

| Парткод: | 302HN06080 |

| Цена: | 480 ₽ |

| Деталь: | Резина ролика отделения бумаги |

| Парткод: | CET4322PT |

| Цена: | 110 ₽ |

| Деталь: | Резина ролика захвата бумаги |

| Парткод: | CET7806BPT |

| Цена: | 110 ₽ |

| Деталь: | Резина ролика подачи бумаги |

| Парткод: | CET7829 |

| Цена: | 150 ₽ |

| Деталь: | STAY RIGHT HANDLE |

| Парткод: | 302K302140 |

| Деталь: | GUIDE FEED INNER |

| Парткод: | 302MV07040 |

| Деталь: | SENSOR OPT |

| Парткод: | -7NXGP1S173LCH01 |

| Деталь: | BASE MPF |

| Парткод: | -302MV08010 |

| Деталь: | PARTS GEAR MPF Z28 SP |

| Парткод: | -302K394320 |

| Деталь: | SEAL SIDE MPF |

| Парткод: | -302K308480 |

| Деталь: | WIRE MPF SIZE UNIT 1 |

| Парткод: | -302MV46450 |

| Деталь: | WIRE MPF |

| Парткод: | -302MV46580 |

| Деталь: | ACTUATOR MPF |

| Парткод: | -302K308020 |

| Деталь: | SPRING ACTUATOR |

| Парткод: | -302K308250 |

| Деталь: | SPRING LIFT R |

| Парткод: | -302K308120 |

| Деталь: | SPRING LIFT F |

| Парткод: | -302K308130 |

| Деталь: | LIFT PLATE |

| Парткод: | -302K308101 |

| Деталь: | PAD LIFT |

| Парткод: | -302K308110 |

| Деталь: | SEAL GUIDE PAD |

| Парткод: | -302K308340 |

| Деталь: | ARM LIFT |

| Парткод: | -302K308140 |

| Деталь: | SPRING EARTH |

| Парткод: | -302K308240 |

| Деталь: | GUIDE UPPER MPF |

| Парткод: | -302K308030 |

| Деталь: | WIRE EARTH MPF |

| Парткод: | -302K308260 |

| Деталь: | BUSH 10 |

| Парткод: | -302K308070 |

| Деталь: | LABEL J |

| Парткод: | -302MV34190 |

| Деталь: | SHAFT MPF |

| Парткод: | -302K308080 |

| Деталь: | PARTS PAD SEPARATION ASSY SP |

| Парткод: | -302MV94010 |

| Деталь: | ROLLER MPF |

| Парткод: | - -302K308150 |

| Деталь: | PULLEY MPF |

| Парткод: | - -302MV08030 |

| Деталь: | SPRING MPF ROLL |

| Парткод: | - -302K308270 |

| Деталь: | PIN FEED ROLL |

| Парткод: | - -302MV08020 |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | PARTS MPF UNIT SP |

| Парткод: | 302MV94070 |

| Деталь: | PARTS ROLLER MPF ASSY SP |

| Парткод: | -302MV94020 |

| Деталь: | TR-8315A |

| Парткод: | 302MV93070 |

| Деталь: | SPRING HV SLEEVE Y |

| Парткод: | 302K039280 |

| Деталь: | SPRING HV MAG Y |

| Парткод: | 302K039240 |

| Деталь: | SPRING HV MAIN Y |

| Парткод: | 302K039200 |

| Деталь: | SPRING HV SLEEVE C |

| Парткод: | 302K039270 |

| Деталь: | SPRING HV MAG C |

| Парткод: | 302K039230 |

| Деталь: | SPRING HV MAIN C |

| Парткод: | 302K039190 |

| Деталь: | SPRING HV SLEEVE M |

| Парткод: | 302K039260 |

| Деталь: | SPRING HV MAG M |

| Парткод: | 302K039220 |

| Деталь: | SPRING HV MAIN M |

| Парткод: | 302K039180 |

| Деталь: | SPRING HV SLEEVE BK |

| Парткод: | 302K039250 |

| Деталь: | SPRING HV MAG BK |

| Парткод: | 302K039210 |

| Деталь: | SPRING HV MAIN BK |

| Парткод: | 302K039170 |

| Деталь: | SPRING HV TRANSFER |

| Парткод: | 302K039290 |

| Деталь: | SPRING HV SEPARATION |

| Парткод: | 302K039300 |

| Деталь: | SPRING DRUM PWB |

| Парткод: | 302K039160 |

| Деталь: | LID TERMINAL |

| Парткод: | 302K039140 |

| Деталь: | PIN TONER SUPPLY |

| Парткод: | 302K015250 |

| Деталь: | GEAR IDLE Z22S |

| Парткод: | 302K015230 |

| Деталь: | GEAR JOINT Z26S |

| Парткод: | 302K015240 |

| Деталь: | COVER GEAR SUPPLY |

| Парткод: | 302K015460 |

| Деталь: | PARTS PWB DRUM DLP CONNECT ASSY SP |

| Парткод: | 302NP94190 |

| Деталь: | RAIL MIDDLE TRANSFER R |

| Парткод: | 302K002601 |

| Деталь: | SLIDER MIDDLE TRANSFER R |

| Парткод: | 302K002940 |

| Деталь: | SPRING MIDDLE TRANSFER SLIDER |

| Парткод: | 302K002960 |

| Деталь: | LABEL MIDDLE TRANSFER |

| Парткод: | 302MV34080 |

| Деталь: | WORK-PLATE MIDDLE TRANSFER COUPLING |

| Парткод: | 302K002950 |

| Деталь: | SPRING MIDDLE TRANSFER COUPLING |

| Парткод: | 302K002970 |

| Деталь: | PARTS TONER SUPPLY ASSY SP |

| Парткод: | 302K094050 |

| Деталь: | SEAL TONER SUPPLY A |

| Парткод: | 302K015350 |

| Деталь: | BASE CONTAINER |

| Парткод: | 302K002050 |

| Деталь: | SEAL TONER |

| Парткод: | 302K002D51 |

| Деталь: | RAIL CONTAINER L |

| Парткод: | 302K002A40 |

| Деталь: | DAMPER CONTAINER |

| Парткод: | 302K002A60 |

| Деталь: | SPRING DAMPER CONT |

| Парткод: | 302K002B70 |

| Деталь: | RAIL CONTAINER R |

| Парткод: | 302K002A50 |

| Деталь: | SHUTTER TONER SUPPLY A |

| Парткод: | 302K015200 |

| Деталь: | SEAL SHUTTER SUPPLY |

| Парткод: | 302K015340 |

| Деталь: | BALL TN FEED |

| Парткод: | 302K015500 |

| Деталь: | SPRING TN FEED |

| Парткод: | 302K015490 |

| Деталь: | SPRING SHUTTER SUPPLY A |

| Парткод: | 302K015320 |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | ELA UNIT-TRANSFER |

| Парткод: | TR-8315B |

| Цена: | 4 200 ₽ |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325C |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325K |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325M |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325Y |

| Деталь: | Formatter, exchange, HP Color LaserJet 3000dn and 3000dtn Series only (256 MB) |

| Парткод: | 302NP94151 |

| Цена: | 81 100 ₽ |

| Деталь: | LASER SCANNER ASSY |

| Парткод: | LK-8325 |

| Цена: | 22 600 ₽ |

| Деталь: | Правая часть узла термозакрепления, в сборе (220В) |

| Парткод: | FK-8325 |

| Цена: | 28 900 ₽ |

| Деталь: | Левая часть узла термозакрепления, в сборе (220В) |

| Парткод: | FK-8507 |

| Цена: | 15 900 ₽ |

| Деталь: | Комплект для технического обслуживания |

| Парткод: | MK-8325B |

| Деталь: | Комплект для технического обслуживания |

| Парткод: | MK-8325A |

| Деталь: | COVER ISU REAR |

| Парткод: | 302NL04150 |

| Деталь: | COVER ISU RIGHT |

| Парткод: | 302NL04140 |

| Деталь: | COVER ISU LEFT |

| Парткод: | 302NL04131 |

| Деталь: | COVER ISU LEFT SUB |

| Парткод: | 302LC04340 |

| Деталь: | LABEL OPERATION CAUTION B |

| Парткод: | -302LC34031 |

| Деталь: | COVER ISU FRONT |

| Парткод: | 302NP04120 |

| Деталь: | CASE CLIP |

| Парткод: | 302N404130 |

| Деталь: | SEAL MAGNET |

| Парткод: | 302GR04380 |

| Деталь: | MAGNET CLIP DISH |

| Парткод: | 302GR04370 |

| Деталь: | LID USB FRONT |

| Парткод: | 302N404241 |

| Деталь: | LID ISU FRONT |

| Парткод: | 302NL04220 |

| Деталь: | LID CARD |

| Парткод: | 302N404040 |

| Деталь: | MOUNT USB |

| Парткод: | 302NL04230 |

| Деталь: | BUSH SLIDE OPE |

| Парткод: | 302H005340 |

| Деталь: | WIRE USB CARD READER |

| Парткод: | 302NP46520 |

| Деталь: | SPRING USB HOLD |

| Парткод: | 302K905900 |

| Деталь: | LID DP |

| Парткод: | 302NL04210 |

| Деталь: | WIRE USB KEY BOARD |

| Парткод: | 302NP46510 |

| Деталь: | PIN COVER |

| Парткод: | 303MH04040 |

| Деталь: | +TP-FLAT T.T S SCREW 3X8 SR(BLACK) |

| Парткод: | 7BB782308H |

| Деталь: | + BIND M SCREW 3X6 |

| Парткод: | 7BB000306H |

| Деталь: | +BIND T.T S SCREW 3X12 SR |

| Парткод: | 7BB700312H |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | PARTS COVER ISU FRONT A ASSY E SP |

| Парткод: | 302NP94200 |

| Деталь: | COVER INNER FRONT LOWER |

| Парткод: | 302MV04230 |

| Деталь: | LID CONTROLLER |

| Парткод: | 302NL04200 |

| Деталь: | COVER EXIT REAR |

| Парткод: | 302NP04040 |

| Деталь: | COVER TRAY |

| Парткод: | 302NP04030 |

| Деталь: | STOPPER PAPER |

| Парткод: | 302H004560 |

| Деталь: | COVER TRAY LEFT |

| Парткод: | 302NP04180 |

| Деталь: | COVER LEFT TOP |

| Парткод: | 302NP04110 |

| Деталь: | LID COVER LEFT |

| Парткод: | 302FZ04240 |

| Деталь: | COVER RIGHT TOP |

| Парткод: | 302NL04090 |

| Деталь: | COVER LEFT LOW |

| Парткод: | 302NP04100 |

| Деталь: | FOOT |

| Парткод: | 302MV02190 |

| Деталь: | COVER FRONT TOP |

| Парткод: | 302MV04020 |

| Деталь: | LABEL DEHUMIDIFIER SWITCH |

| Парткод: | -302NL34090 |

| Деталь: | COVER MAIN SW |

| Парткод: | -302H704170 |

| Деталь: | LABEL SW CAUTION EN |

| Парткод: | -302LC34620 |

| Деталь: | STOPPER PAPER C |

| Парткод: | -302K317820 |

| Деталь: | LID DF CONNECTOR |

| Парткод: | 302MN04100 |

| Деталь: | LID AK |

| Парткод: | 302NL04250 |

| Деталь: | LABEL SW CAUTION SET A |

| Парткод: | 302LC34630 |

| Деталь: | +TP-FLAT T.T S SCREW 3X8 SR(BLACK) |

| Парткод: | 7BB782308H |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | PARTS COVER REAR ASSY E SP |

| Парткод: | 302NP94010 |

| Деталь: | PARTS COVER RIGHT REAR ASSY EN SP |

| Парткод: | 302NP94050 |

| Деталь: | PARTS TRAY EJECT ASSY SP |

| Парткод: | 302MV94550 |

| Деталь: | Крышка планшетного сканера |

| Парткод: | 1202H70UN0 |

| Цена: | 4 200 ₽ |

| Деталь: | Ограничитель формата бумаги в кассете на 500 листов |

| Парткод: | 302K309270 |

| Цена: | 120 ₽ |

| Деталь: | STOPPER BYPASS TABLE |

| Парткод: | 2FB07330 |

| Деталь: | SPRING FRONT COVER L |

| Парткод: | 302MV04320 |

| Деталь: | HOLDER SWITCH |

| Парткод: | 302NP04200 |

| Деталь: | EMBLEM |

| Парткод: | 302LC04272 |

| Деталь: | SHEET EMBLEM |

| Парткод: | 302NP34010 |

| Деталь: | SHEET COVER FRONT |

| Парткод: | 302NP34040 |

| Деталь: | COVER INNER BASE |

| Парткод: | 302K302260 |

| Деталь: | PARTS COVER FRONT ASSY 25 SP |

| Парткод: | 302NP940 |

| Деталь: | SHEET GUIDE FEED |

| Парткод: | 302K002D70 |

| Деталь: | SENSOR OPT |

| Парткод: | 7NXGP1S173LCH01 |

| Деталь: | SW.PUSH |

| Парткод: | 7SP01000001+H01 |

| Деталь: | PLATE SIZE DETECTION |

| Парткод: | 302K309410 |

| Деталь: | STAY FRONT RIGHT |

| Парткод: | 302MV02200 |

| Деталь: | RAIL MIDDLE TRANSFER F |

| Парткод: | 302K002531 |

| Деталь: | LABEL MIDDLE TRANSFER |

| Парткод: | 302MV34080 |

| Деталь: | HANDLE |

| Парткод: | 302JF02160 |

| Деталь: | SEAL HANDLE |

| Парткод: | 302FZ03110 |

| Деталь: | CAP HANDLE |

| Парткод: | 302FZ02580 |

| Деталь: | PIN FRONT HANDLE |

| Парткод: | 302MV02240 |

| Деталь: | STOPPER 4 |

| Парткод: | 302FZ25740 |

| Деталь: | HEATER DEHUMIDIFIER 240 |

| Парткод: | 302K302440 |

| Деталь: | HEATER DEHUMIDIFIER 120 |

| Парткод: | 302K302430 |

| Деталь: | LABEL HIGH TEMPERATURE CAUTION |

| Парткод: | 302KP34220 |

| Деталь: | CAP DECK PIN |

| Парткод: | 302K302920 |

| Деталь: | GUIDE WIRE MAIN SW |

| Парткод: | 302NL39060 |

| Деталь: | MOUNT DECK PI |

| Парткод: | 302K302840 |

| Деталь: | MOUNT DECK DRAWER |

| Парткод: | 302K302910 |

| Деталь: | WIRE PF DRAWER 200 |

| Парткод: | 302K346660 |

| Деталь: | WIRE PF DRAWER |

| Парткод: | 302K346470 |

| Деталь: | INTER LOCK SWITCH |

| Парткод: | 2FB27160 |

| Деталь: | ACCESS.CLAMP |

| Парткод: | 7YZM390002++H01 |

| Деталь: | ACCESS.SADDLE |

| Парткод: | 7YZM610009++H01 |

| Деталь: | ACCESS.SADDLE |

| Парткод: | 7YZM610010++H01 |

| Деталь: | GUIDE WIRE LVU B |

| Парткод: | 302MV39270 |

| Деталь: | STAY POWER |

| Парткод: | 302MV39230 |

| Деталь: | SPRING MAIN DRIVE B |

| Парткод: | 302K031420 |

| Деталь: | SHAFT HANDLE |

| Парткод: | 302MV02220 |

| Деталь: | MOUNT REAR HANDLE |

| Парткод: | 302MV02231 |

| Деталь: | DUCT CORD |

| Парткод: | 302K002650 |

| Деталь: | WIRE PAPER EMPTY/BOTTOM UP |

| Парткод: | 302K046290 |

| Деталь: | WIRE PF SIG |

| Парткод: | 302MV46320 |

| Деталь: | WIRE CASSETTE2 PI |

| Парткод: | 302NP46080 |

| Деталь: | ACCESS.SPACER |

| Парткод: | 7YZM510006++H01 |

| Деталь: | WIRE FEED UNIT PI2 |

| Парткод: | 302MV46560 |

| Деталь: | SLIDER MIDDLE TRANSFER F |

| Парткод: | 302K002930 |

| Деталь: | SPRING MIDDLE TRANSFER SLIDER |

| Парткод: | 302K002960 |

| Деталь: | ACCESS SADDLE |

| Парткод: | 7YZM610003++H01 |

| Деталь: | ACCESS.EDGING |

| Парткод: | 7YZM210002++H01 |

| Деталь: | ACCESS.SADDLE |

| Парткод: | 7YZM610011++H01 |

| Деталь: | SPONGE LOWER RIGHT SP |

| Парткод: | 302LF33B10 |

| Деталь: | PARTS AC CORD EU SP |

| Парткод: | 302AR94050 |

| Деталь: | AC CORD ASSY AS |

| Парткод: | 7AAACCAS+10H001 |

| Деталь: | POWER CORD(120) |

| Парткод: | 3019527401 |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | + BIND T.T S SCREW 4X6 |

| Парткод: | 7BB100406H |

| Деталь: | BOX CONTROLLER |

| Парткод: | 302NP39010 |

| Деталь: | ACCESS.EDGING |

| Парткод: | 7YZM210002++H01 |

| Деталь: | ACCESS.SADDLE |

| Парткод: | 7YZM610011++H01 |

| Деталь: | LID CONTROLLER |

| Парткод: | 302NL39100 |

| Деталь: | LID DP |

| Парткод: | 302NL39110 |

| Деталь: | LID FAX BOARD |

| Парткод: | 302NL39120 |

| Деталь: | LID WIRE GUIDE |

| Парткод: | 303LT02020 |

| Деталь: | FAN BOX COOLING |

| Парткод: | 302FZ44040 |

| Деталь: | BUSHING FAN |

| Парткод: | 302JD19140 |

| Деталь: | PLATE OPTION |

| Парткод: | 302K339050 |

| Деталь: | RAIL PWB |

| Парткод: | 302K939030 |

| Деталь: | SEAL MOTOR DC |

| Парткод: | 302LC31511 |

| Деталь: | Holder FFC |

| Парткод: | 302LF02380 |

| Деталь: | GUIDE WIRE FRONT PWB |

| Парткод: | 302LF39050 |

| Деталь: | BRACKET HDD |

| Парткод: | 302MV39040 |

| Деталь: | HOLDER FAN MAIN |

| Парткод: | 302MV39050 |

| Деталь: | PIN HDD |

| Парткод: | 302MV39340 |

| Деталь: | SPRING EARTH HDD |

| Парткод: | 302MV39350 |

| Деталь: | WIRE EARTH |

| Парткод: | 302MV46640 |

| Деталь: | BRACKET MAIN |

| Парткод: | 302NL39090 |

| Деталь: | WIRE KUIO POWER |

| Парткод: | 302NP46460 |

| Деталь: | WIRE FFC KUIO |

| Парткод: | 302NP46470 |

| Деталь: | SCREW OP / M3 X 8 CRFREE A4 |

| Парткод: | 5MMT263SN012++R |

| Деталь: | ACCESS.EDGING |

| Парткод: | 7YZM210005++H01 |

| Деталь: | ACCESS.CLAMP |

| Парткод: | 7YZM390011++H01 |

| Деталь: | DUCT OUT DLP D |

| Парткод: | 302MV33010 |

| Деталь: | WIRE HDD POWER |

| Парткод: | 302MV46210 |

| Деталь: | WIRE LVU-MAIN POWER |

| Парткод: | 302NP46040 |

| Деталь: | WIRE HDD SIG |

| Парткод: | 302NP46530 |

| Деталь: | PARTS PWB KUIO ASSY SP |

| Парткод: | 302K994270 |

| Деталь: | PARTS STORAGE DEVICE SP |

| Парткод: | 302MV93130 |

| Деталь: | PARTS PWB MAIN ASSY SP |

| Парткод: | 302NP94140 |

| Деталь: | PARTS PWB MAIN ASSY EU SP |

| Парткод: | 302NP94150 |

| Деталь: | PARTS MEMORY MODULE SP |

| Парткод: | 302LC94390 |

| Деталь: | ACCESS.SADDLE |

| Парткод: | 7YZM610010++H01 |

| Деталь: | HOLDER WIRE D |

| Парткод: | 303LL02330 |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | ACCESS.SADDLE |

| Парткод: | 7YZM610009++H01 |

| Деталь: | SHUTTER ID SENSOR CLEANING |

| Парткод: | 302K002870 |

| Деталь: | FELT CLEANER ID |

| Парткод: | 302HN02970 |

| Деталь: | SPRING ID CLEANING |

| Парткод: | 302K002C60 |

| Деталь: | CASE ID SENSOR CLEANING |

| Парткод: | 302K002860 |

| Деталь: | SENSOR OPT. |

| Парткод: | 7NXGP1S173LCH01 |

| Деталь: | WIRE ID SENS MOT/PI |

| Парткод: | 302K046420 |

| Деталь: | WORM-WHEEL ID SENSOR CLEANING |

| Парткод: | 302K002880 |

| Деталь: | GEAR ID SENSOR CLEANING Z71R |

| Парткод: | 302K002890 |

| Деталь: | ARM ID SENSOR CLEANING |

| Парткод: | 302K002900 |

| Деталь: | PARTS MOTOR-DC ASSY C SP |

| Парткод: | 302K094090 |

| Деталь: | CONNECTOR |

| Парткод: | 7YCC02B1202+H01 |

| Деталь: | PARTS ID SENSOR ASSY SP |

| Парткод: | 302K094290 |

| Деталь: | BUSH 6 EW |

| Парткод: | 302H024370 |

| Цена: | 190 ₽ |

| Деталь: | ACTUATOR REGIST |

| Парткод: | 302K306140 |

| Деталь: | SPRING ACTUATOR REGIST |

| Парткод: | 302K306150 |

| Деталь: | GUIDE FEED CASSETTE |

| Парткод: | 302K002172 |

| Деталь: | SPRING EARTH MIDDLE |

| Парткод: | 302K002540 |

| Деталь: | BUSH MIDDLE |

| Парткод: | 302K002C00 |

| Деталь: | PARTS ROLLER MIDDLE SP |

| Парткод: | 302K094330 |

| Деталь: | GEAR Z27L CLUTCH |

| Парткод: | 302HS31120 |

| Деталь: | RING STOPPER /A-49 FEED A4 |

| Парткод: | 5MVX111DN003 |

| Деталь: | SHEET GUIDE FEED |

| Парткод: | 302K002D70 |

| Деталь: | SHEET REGIST |

| Парткод: | 302K002500 |

| Деталь: | WIRE RESIST |

| Парткод: | 302K046380 |

| Деталь: | WIRE ID SENSOR |

| Парткод: | 302K046310 |

| Деталь: | PLATE ID SENSOR |

| Парткод: | 302K002130 |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | ELA UNIT-TRANSFER |

| Парткод: | TR-8315B |

| Цена: | 4 200 ₽ |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325C |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325K |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325M |

| Деталь: | MEA UNIT-DEV Y |

| Парткод: | DV-8325Y |

| Деталь: | Formatter, exchange, HP Color LaserJet 3000dn and 3000dtn Series only (256 MB) |

| Парткод: | 302NP94151 |

| Цена: | 81 100 ₽ |

| Деталь: | LASER SCANNER ASSY |

| Парткод: | LK-8325 |

| Цена: | 22 600 ₽ |

| Деталь: | Правая часть узла термозакрепления, в сборе (220В) |

| Парткод: | FK-8325 |

| Цена: | 28 900 ₽ |

| Деталь: | Левая часть узла термозакрепления, в сборе (220В) |

| Парткод: | FK-8507 |

| Цена: | 15 900 ₽ |

| Деталь: | Комплект для технического обслуживания |

| Парткод: | MK-8325B |

| Деталь: | Комплект для технического обслуживания |

| Парткод: | MK-8325A |

| Деталь: | GEAR Z27S Z27R |

| Парткод: | 302K902401 |

| Деталь: | GEAR Z14R |

| Парткод: | 302K902391 |

| Деталь: | PARTS MOTOR-DC ASSY C SP |

| Парткод: | 302K094090 |

| Деталь: | PARTS GEAR Z32L SP |

| Парткод: | 302K994520 |

| Деталь: | PARTS PWB LSU CONNECT ASSY SP |

| Парткод: | 302K094170 |

| Деталь: | ACCESS.SADDLE |

| Парткод: | 7YZM610007++H01 |

| Деталь: | LK-8325 |

| Парткод: | 302NP93120 |

| Деталь: | SPRING-COMPRESSION LSU RETAINING |

| Парткод: | 302K902480 |

| Деталь: | PIN LSU RETAINING |

| Парткод: | 302K902470 |

| Деталь: | ACCESS.CLAMP |

| Парткод: | 7YZM390003++H01 |

| Деталь: | WIRE ENGINE MAIN-LSU CONNECT 2 |

| Парткод: | 302K046200 |

| Деталь: | WIRE MAIN-LSU CONNECT 2 |

| Парткод: | 302K046220 |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | + BIND M SCREW 3X4 |

| Парткод: | 7BB000304H |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | PARTS HVU1 SP |

| Парткод: | 302K094260 |

| Цена: | 11 600 ₽ |

| Деталь: | HOLDER RFID |

| Парткод: | 302K002B00 |

| Деталь: | PARTS PWB RFID ASSY SP |

| Парткод: | 302K094200 |

| Деталь: | HOLDER PWB MIDDLE |

| Парткод: | 302K002551 |

| Деталь: | PARTS PWB TRANSFER CONNECT ASSY SP |

| Парткод: | 302K094190 |

| Деталь: | WIRE ENGINE2 - TC CONNECT |

| Парткод: | 302K046350 |

| Деталь: | WIRE WT SENS 1 |

| Парткод: | 302K046400 |

| Деталь: | WIRE HUMIT 1 |

| Парткод: | 302NP46270 |

| Деталь: | WIRE HIGH VOL1 |

| Парткод: | 302NP46230 |

| Деталь: | SHIELD HI VOLTAGE TC1 |

| Парткод: | 302K039050 |

| Деталь: | BRACKET HV |

| Парткод: | 302K039070 |

| Деталь: | SPRING CONTACT TC1 |

| Парткод: | 302K039150 |

| Деталь: | PARTS HVU2 SP |

| Парткод: | 302K094270 |

| Деталь: | WIRE ENGINE MAIN-LSU CONNECT 1 |

| Парткод: | 302NP46280 |

| Деталь: | PARTS PWB ENGINE ASSY SP |

| Парткод: | 302NP94100 |

| Деталь: | WIRE SUB PWB |

| Парткод: | 302K046090 |

| Деталь: | WIRE EXIT UNIT1 |

| Парткод: | 302NP46070 |

| Деталь: | ACCESS.SADDLE |

| Парткод: | 7YZM610010++H01 |

| Деталь: | WIRE RELAY |

| Парткод: | 302K046640 |

| Деталь: | SHIELD PWB IH |

| Парткод: | -302K039030 |

| Деталь: | ACCESS.SPACER |

| Парткод: | -7YZM510018++H01 |

| Деталь: | COVER PWB IH |

| Парткод: | -302NP39040 |

| Деталь: | SHIELD GASKET |

| Парткод: | -7ZGSSTG34070H01 |

| Деталь: | WIRE LVU-IH PRIMARY |

| Парткод: | 302NP46350 |

| Деталь: | WIRE ENGINE-IH |

| Парткод: | 302K046620 |

| Деталь: | WIRE OPTION CONNECT |

| Парткод: | 302NP46170 |

| Деталь: | PARTS FAN MOTOR SP |

| Парткод: | 302K094300 |

| Деталь: | WIRE FFC ENGINE-MAIN SIG |

| Парткод: | 302NP46010 |

| Деталь: | WIRE ENGINE POWER1 |

| Парткод: | 302NP46030 |

| Деталь: | WIRE FEED UNIT PI 1 |

| Парткод: | 302K046030 |

| Деталь: | WIRE FEED UNIT 1 |

| Парткод: | 302K046010 |

| Деталь: | WIRE MPF SIZE 1 |

| Парткод: | 302MV46430 |

| Деталь: | WIRE FFC ENGINE 1-2 SIG |

| Парткод: | 302NP46020 |

| Деталь: | PARTS PWB OPTION CONNECT ASSY SP |

| Парткод: | 302NP94130 |

| Деталь: | FERRITE CORE |

| Парткод: | 7YBER0R0E001H01 |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | +BIND T.T S SCREW 3X30 SR |

| Парткод: | 7BB700330H |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | PARTS PWB IH 200 ASSY SP |

| Парткод: | 302MV94420 |

| Деталь: | PARTS PWB IH 100 ASSY SP |

| Парткод: | 302MV94410 |

| Деталь: | BASE MIDDLE DRIVE R |

| Парткод: | -302K031040 |

| Деталь: | SPRING MAIN DRIVE B |

| Парткод: | -302K031420 |

| Деталь: | PLATE MIDDLE DRIVE |

| Парткод: | -302K031070 |

| Деталь: | PARTS MOTOR-BL W20 SP |

| Парткод: | -302K994321 |

| Деталь: | PLATE MOTOR MIDDLE |

| Парткод: | -302K031100 |

| Деталь: | BUSH 6 EW |

| Парткод: | -302H024370 |

| Деталь: | POLYSLIDER WASHER |

| Парткод: | -2FT18370 |

| Деталь: | RING STOPPER /A-49 FEED A4 |

| Парткод: | -5MVX111DN003 |

| Деталь: | GUIDE WIRE MIDDLE DRIVE |

| Парткод: | -302K031470 |

| Деталь: | PARTS GEAR MIDDLE TRANS Z89R SP |

| Парткод: | -302MV94390 |

| Деталь: | ONE WAY CLUTCH /A-49 MPFz A4 |

| Парткод: | -5AAVCLTCH018 |

| Деталь: | PARTS GEAR MIDDLE TRANS Z90R-Z37L SP |

| Парткод: | -302MV94400 |

| Деталь: | GEAR FUSER Z74R-Z24 |

| Парткод: | -302K031260 |

| Деталь: | SPRING FUSER |

| Парткод: | -302K031610 |

| Деталь: | GEAR FUSER Z45 |

| Парткод: | -302K031270 |

| Деталь: | GEAR FUSER Z24 |

| Парткод: | -302K031600 |

| Деталь: | GEAR FUSER Z25 |

| Парткод: | -302K031280 |

| Деталь: | GEAR DLP Z45R |

| Парткод: | -302K031210 |

| Деталь: | GEAR DLP Z87R-Z66L |

| Парткод: | -302K031150 |

| Деталь: | GEAR DLP Z53R |

| Парткод: | -302K031200 |

| Деталь: | BASE MIDDLE DRIVE F |

| Парткод: | -302K031030 |

| Деталь: | PARTS DRIVE MIDDLE TRANS SP |

| Парткод: | -302K094640 |

| Деталь: | WIRE BELT-FUSER MOT |

| Парткод: | 302K046180 |

| Деталь: | HOLDER TONER DRIVE B |

| Парткод: | 302K015022 |

| Деталь: | PARTS DC MOTOR SP |

| Парткод: | 302NP94220 |

| Деталь: | CONNECTOR 292254-2 |

| Парткод: | 7YCC02B1003+H01 |

| Деталь: | SHEET HOLDER TONER DRIVE |

| Парткод: | 302K015540 |

| Деталь: | PARTS DC MOTOR SP |

| Парткод: | 302K094100 |

| Цена: | 6 300 ₽ |

| Деталь: | WIRE TONER SUPPLY MOT |

| Парткод: | 302K046130 |

| Деталь: | GEAR Z50S |

| Парткод: | 302K015040 |

| Деталь: | SPRING JOINT CONTAINER |

| Парткод: | 302K015270 |

| Деталь: | GEAR Z20S-Z26L |

| Парткод: | 302K015030 |

| Деталь: | HOLDER TONER DRIVE A |

| Парткод: | 302K015010 |

| Деталь: | LID WIRE GUIDE |

| Парткод: | 303LT02020 |

| Деталь: | + BIND M SCREW 3X4 |

| Парткод: | 7BB000304H |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | DR-895B |

| Парткод: | 302K093131 |

| Деталь: | COVER SW FEED |

| Парткод: | 302MV07080 |

| Деталь: | GUIDE COVER INNER |

| Парткод: | -302MV07051 |

| Деталь: | COVER RIGHT LOW |

| Парткод: | -302NL04340 |

| Деталь: | HOLDER SPRING |

| Парткод: | -302MV07070 |

| Деталь: | Cover Handle |

| Парткод: | -302NL06060 |

| Деталь: | CAP SPRING /B-11 ENCLOSURE A4 |

| Парткод: | -2FM04150 |

| Деталь: | SPRING FEED LOW |

| Парткод: | -303NN24180 |

| Деталь: | SHAFT FEED B |

| Парткод: | -302BG06152 |

| Деталь: | PULLEY 15 DUPLEX |

| Парткод: | -3HY07120 |

| Деталь: | SPRING LID |

| Парткод: | -302FZ20021 |

| Деталь: | HOOK FEED LOW |

| Парткод: | -302K906670 |

| Деталь: | SHAFT FEED LOW HOOK |

| Парткод: | -302NL06070 |

| Деталь: | HANDLE FEED LOW |

| Парткод: | -303PC06060 |

| Деталь: | HOLDER HOOK F |

| Парткод: | 302NL06040 |

| Деталь: | HOLDER HOOK R |

| Парткод: | 302NL06050 |

| Деталь: | BAND B |

| Парткод: | 2BG06480 |

| Деталь: | SW.PUSH |

| Парткод: | 7SP01000001+H01 |

| Деталь: | SENSOR OPT. |

| Парткод: | 7NXGP1S173LCH01 |

| Деталь: | SPRING EARTH SW |

| Парткод: | 303NN24250 |

| Деталь: | WIRE RIGHT COVER SW |

| Парткод: | 302MV46520 |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | + BIND T.T P SCREW 4X10 |

| Парткод: | 7BB200410H |

| Деталь: | +BIND M SCREW 3X6 R |

| Парткод: | 7BB600306H |

| Деталь: | PARTS COVER RIGHT LOW ASSY SP |

| Парткод: | 302NP94230 |

| Деталь: | FILM LCD WIRE |

| Парткод: | -302N405210 |

| Деталь: | CUSHION LCD |

| Парткод: | -302H705610 |

| Деталь: | SPONGE LCD B |

| Парткод: | -302K505280 |

| Деталь: | PARTS PWB OPERATION ASSY SP |

| Парткод: | -302N494180 |

| Деталь: | KEY MENU |

| Парткод: | -302N405080 |

| Деталь: | PARTS LCD OPERATION SP |

| Парткод: | -302N494090 |

| Деталь: | PARTS PWB PANEL MAIN ASSY SP |

| Парткод: | -302N494150 |

| Деталь: | COVER OPERATION A |

| Парткод: | -302NL05010 |

| Деталь: | KEY 10 |

| Парткод: | -302LC05050 |

| Деталь: | KEY COLOR |

| Парткод: | -302N405060 |

| Деталь: | KEY FUNCTION |

| Парткод: | -302N405070 |

| Деталь: | SHEET WIRE CONV E |

| Парткод: | -302H722690 |

| Деталь: | KEY START |

| Парткод: | -302LC05090 |

| Деталь: | KEY STOP |

| Парткод: | -302LC05100 |

| Деталь: | KEY RESET |

| Парткод: | -302LC05110 |

| Деталь: | KEY POWER |

| Парткод: | -302N405090 |

| Деталь: | LID OPERATION SHEET A |

| Парткод: | -302N405140 |

| Деталь: | LID OPERATION SHEET B |

| Парткод: | -302N405150 |

| Деталь: | PARTS TABLET OPERATION SP |

| Парткод: | -302N494100 |

| Деталь: | SHEET COLOR |

| Парткод: | -302N405520 |

| Деталь: | KEY HOME |

| Парткод: | -302N405100 |

| Деталь: | KEY DISPLAY |

| Парткод: | -302N405110 |

| Деталь: | KEY RIGHT SIDE |

| Парткод: | -302N405120 |

| Деталь: | HOLDER LCD |

| Парткод: | -302LC05270 |

| Деталь: | PARTS SPEAKER SP |

| Парткод: | -302LC94370 |

| Деталь: | WIRE FFC KEY PWB |

| Парткод: | -302N446050 |

| Деталь: | LENS LED |

| Парткод: | -302N405200 |

| Деталь: | MOUNT MAIN PWB |

| Парткод: | -302NL05030 |

| Деталь: | GUIDE WIRE OPERATION |

| Парткод: | -302NL05040 |

| Деталь: | WIRE PANEL JOINT |

| Парткод: | -302NP46450 |

| Деталь: | WIRE PANEL DATA |

| Парткод: | -302NP46390 |

| Деталь: | HOLDER WIRE D |

| Парткод: | -303LL02330 |

| Деталь: | FILM FFC |

| Парткод: | -302LC05420 |

| Деталь: | WIRE USB HOST |

| Парткод: | 302NP46400 |

| Деталь: | SPRING USB HOLD |

| Парткод: | 302K905900 |

| Деталь: | COVER OPERATION B |

| Парткод: | 302NL05020 |

| Деталь: | PANEL OPERATION |

| Парткод: | 302N405130 |

| Деталь: | SHEET OPERATION EN |

| Парткод: | 302N405510 |

| Деталь: | SHEET OPERATION KDA EN |

| Парткод: | 302N405630 |

| Деталь: | MOUNT USB |

| Парткод: | 302MV05050 |

| Деталь: | MOUNT OPERATION |

| Парткод: | 302NL05050 |

| Деталь: | PLATE EARTH ISU |

| Парткод: | 302K302A50 |

| Деталь: | WIRE MAIN-OPERATION |

| Парткод: | 302NP46380 |

| Деталь: | FILM COVER LOW |

| Парткод: | 302MV05090 |

| Деталь: | CLAMP,EMT-3N(TAKEUCHI) |

| Парткод: | M7005010 |

| Деталь: | +TP-FLAT T.T S SCREW 3X8 SR(BLACK) |

| Парткод: | 7BB782308H |

| Деталь: | +BIND T.T S SCREW 3X8 SR |

| Парткод: | 7BB700308H |

| Деталь: | + BIND T.T P SCREW 3X8 |

| Парткод: | 7BB200308H |

| Деталь: | + BIND M SCREW 3X6 |

| Парткод: | 7BB000306H |

| Деталь: | PARTS OPERATION UNIT SP |

| Парткод: | 302NP94070 |

| Деталь: | PARTS MOTOR LIFT ASSY SP |

| Парткод: | 302K394190 |

| Цена: | 6 000 ₽ |

| Деталь: | PARTS MOTOR-BL W10 SP |

| Парткод: | -302LC94291 |

| Деталь: | PLATE MOTOR LOW |

| Парткод: | -302MV31030 |

| Деталь: | HOLDER DRIVE LOW A |

| Парткод: | -302MV31010 |

| Деталь: | SPRING EARTH FEED LOW |

| Парткод: | -302MV31040 |

| Деталь: | BUSH DRIVE |

| Парткод: | -302HN31590 |

| Деталь: | CLUTCH 50 Z35R |

| Парткод: | -302KV44041 |

| Деталь: | SHAFT CLUTCH FEED |

| Парткод: | -302K331240 |

| Деталь: | SHAFT GEAR |

| Парткод: | -303NN31060 |

| Деталь: | GEAR Z27L IDLE |

| Парткод: | -303NN31050 |

| Деталь: | GEAR Z40R IDLE |

| Парткод: | -302K331081 |