Canon Color imageCLASS LBP622Cdw

Рейтинг

Модули

102B INTERNAL COMPONENTS 2 120V

100B EXTERNAL COVERS, PANELS, ETC. LBP622Cdw

101C INTERNAL COMPONENTS 1

100D EXTERNAL COVERS, PANELS, ETC. LBP623Cdw

103B INTERNAL COMPONENTS 3

102C INTERNAL COMPONENTS 2 230V

Детали 100B EXTERNAL COVERS, PANELS, ETC. LBP622Cdw

| Деталь: | FIXING ASSY (220-240V) |

| Парткод: | FM1-W285-000 |

| Деталь: | PLATE, USB, GROUNDING |

| Парткод: | FE8-0014-000 |

| Цена: | 950 ₽ |

| Деталь: | USB RELAY PCB ASSEMBLY |

| Парткод: | FM1-R870-000 |

| Цена: | 3 400 ₽ |

| Деталь: | MOTOR, STEPPING |

| Парткод: | RK2-9471-000 |

| Деталь: | FAN |

| Парткод: | RK2-6425-000 |

| Деталь: | MAIN MOTOR ASSY |

| Парткод: | RM2-8054-000 |

| Деталь: | L.V. POWER SUPPLY PCB ASSY |

| Парткод: | FM2-G952-000 |

| Деталь: | CARTRIDGE TRAY ASSY |

| Парткод: | FM1-V317-000 |

| Деталь: | POWER SUPPLY SWITCH ASSY |

| Парткод: | FM1-N656-000 |

| Деталь: | MICROSWITCH |

| Парткод: | RK2-0534-000 |

| Деталь: | SCREW, D, M3X6 |

| Парткод: | XA9-1835-000 |

| Деталь: | SCREW, D, M3X8 |

| Парткод: | XA9-1671-000 |

| Цена: | 170 ₽ |

| Деталь: | COVER, LEFT |

| Парткод: | FE2-A771-000 |

| Деталь: | COVER, RIGHT |

| Парткод: | FE2-A770-000 |

| Деталь: | DUPLEXING DOOR ASSY |

| Парткод: | FM1-N654-020 |

| Деталь: | COVER, BOTTOM, REAR |

| Парткод: | FL1-7033-000 |

| Деталь: | REAR DOOR ASSY |

| Парткод: | RM2-5580-000 |

| Деталь: | ROLLER, SECONDARY TRANSFER |

| Парткод: | RM2-5906-000 |

| Деталь: | FRONT DOOR ASSY |

| Парткод: | FM1-N648-000 |

| Деталь: | TOP COVER ASSY |

| Парткод: | FM1-N680-010 |

| Деталь: | CONTROL PANEL ASSEMBLY |

| Парткод: | FM1-N692-000 |

| Деталь: | LID, MODULAR |

| Парткод: | FE8-3017-000 |

| Цена: | 340 ₽ |

| Деталь: | SCREW, D, M3X8 |

| Парткод: | XA9-1671-000 |

| Цена: | 170 ₽ |

| Деталь: | SHEET, HANDSET |

| Парткод: | FL1-0525-000 |

| Цена: | 800 ₽ |

| Деталь: | LID, USB, UPPER |

| Парткод: | FE8-3189-000 |

| Цена: | 410 ₽ |

| Деталь: | COVER, USB |

| Парткод: | FE8-3224-000 |

| Цена: | 1 400 ₽ |

| Деталь: | SEPARATION ROLLER ASSY |

| Парткод: | RM2-5881-000 |

| Деталь: | FEED ROLLER ASSY |

| Парткод: | RM2-5577-000 |

| Деталь: | CASE, ROLLER |

| Парткод: | RC5-1975-000 |

| Деталь: | CASSETTE ASSY |

| Парткод: | FM1-V312-000 |

| Деталь: | MULTI FEED TRAY ASSY |

| Парткод: | FM1-V315-000 |

| Деталь: | ENVIRONMENT SENSOR PCB ASSY |

| Парткод: | RM2-9510-000 |

| Деталь: | ARM, LOCK, LEFT |

| Парткод: | RC4-3848-000 |

| Деталь: | ARM, LOCK, RIGHT |

| Парткод: | RC4-3847-000 |

| Деталь: | PAPER PICK-UP ROLLER ASSY |

| Парткод: | RM2-5576-000 |

| Деталь: | SCREW, D, M3X6 |

| Парткод: | XA9-1835-000 |

| Деталь: | SCREW, D, M3X8 |

| Парткод: | XA9-1671-000 |

| Цена: | 170 ₽ |

| Деталь: | DUPLEXING DRIVE ASSY |

| Парткод: | RM2-5872-000 |

| Деталь: | COVER, LEFT |

| Парткод: | FE2-A771-000 |

| Деталь: | COVER, RIGHT |

| Парткод: | FE2-A770-000 |

| Деталь: | DUPLEXING DOOR ASSY |

| Парткод: | FM1-N654-020 |

| Деталь: | COVER, BOTTOM, REAR |

| Парткод: | FL1-7033-000 |

| Деталь: | REAR DOOR ASSY |

| Парткод: | RM2-5580-000 |

| Деталь: | ROLLER, SECONDARY TRANSFER |

| Парткод: | RM2-5906-000 |

| Деталь: | FRONT DOOR ASSY |

| Парткод: | FM1-N648-000 |

| Деталь: | TOP COVER ASSY |

| Парткод: | FM1-N680-010 |

| Деталь: | CONTROL PANEL ASSEMBLY |

| Парткод: | FM1-N692-000 |

| Деталь: | LID, MODULAR |

| Парткод: | FE8-3017-000 |

| Цена: | 340 ₽ |

| Деталь: | SCREW, D, M3X8 |

| Парткод: | XA9-1671-000 |

| Цена: | 170 ₽ |

| Деталь: | SHEET, HANDSET |

| Парткод: | FL1-0525-000 |

| Цена: | 800 ₽ |

| Деталь: | LID, USB, UPPER |

| Парткод: | FE8-3189-000 |

| Цена: | 410 ₽ |

| Деталь: | COVER, USB |

| Парткод: | FE8-3224-000 |

| Цена: | 1 400 ₽ |

| Деталь: | CABLE, FLAT |

| Парткод: | RK2-6383-000 |

| Деталь: | CABLE, FLAT |

| Парткод: | RK2-8980-000 |

| Деталь: | MAIN CONTROLLER PCB ASSEMBLY |

| Парткод: | FM2-G968-000 |

| Деталь: | MAIN CONTROLLER PCB ASSEMBLY |

| Парткод: | FM2-G969-000 |

| Деталь: | CABLE, GROUNDING |

| Парткод: | FM1-X968-000 |

| Деталь: | DENSITY DETECT SENSOR ASSY |

| Парткод: | RM2-5874-000 |

| Деталь: | ENGINE CONTROLLER PCB ASSY |

| Парткод: | FM2-G958-000 |

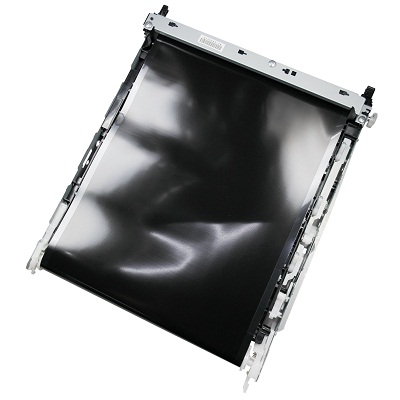

| Деталь: | INTERMEDIATE TRANS. BELT ASSY |

| Парткод: | RM2-5907-000 |

| Цена: | 8 000 ₽ |

| Деталь: | MOTOR, STEPPING |

| Парткод: | RK2-9730-000 |

| Деталь: | SCREW, D, M3X8 |

| Парткод: | XA9-1671-000 |

| Цена: | 170 ₽ |

| Деталь: | CABLE, FLAT |

| Парткод: | FL0-8148-000 |

| Деталь: | SCREW, D, M3X6 |

| Парткод: | XA9-1835-000 |

| Деталь: | MODULE, WLAN |

| Парткод: | FK4-4651-000 |

| Деталь: | CABLE, FLAT |

| Парткод: | FL0-8219-000 |

| Деталь: | FIXING ASSY (220-240V) |

| Парткод: | FM1-W286-000 |

| Деталь: | PLATE, USB, GROUNDING |

| Парткод: | FE8-0014-000 |

| Цена: | 950 ₽ |

| Деталь: | USB RELAY PCB ASSEMBLY |

| Парткод: | FM1-R870-000 |

| Цена: | 3 400 ₽ |

| Деталь: | MOTOR, STEPPING |

| Парткод: | RK2-9471-000 |

| Деталь: | FAN |

| Парткод: | RK2-6425-000 |

| Деталь: | MAIN MOTOR ASSY |

| Парткод: | RM2-8054-000 |

| Деталь: | L.V. POWER SUPPLY PCB ASSY |

| Парткод: | FM2-G956-000 |

| Деталь: | CARTRIDGE TRAY ASSY |

| Парткод: | FM1-V317-000 |

| Деталь: | POWER SUPPLY SWITCH ASSY |

| Парткод: | FM1-N656-000 |

| Деталь: | MICROSWITCH |

| Парткод: | RK2-0534-000 |

| Деталь: | SCREW, D, M3X6 |

| Парткод: | XA9-1835-000 |

| Деталь: | SCREW, D, M3X8 |

| Парткод: | XA9-1671-000 |

| Цена: | 170 ₽ |

Коды ошибок

0901

0902

0903

0907

0908

0909

090C

090D

0A01

0A03

0A07

0A08

0A09

0A0C

0A0D

10-0100

10-0401

10-0402

10-0403

10-0404

1101

1103

1107

1108

1109

110C

110D

1901

1903

1907

1908

1909

190C

190D

2101

2103

2107

2108

2109

210C

210D

2901

2903

2907

2908

2909

290C

290D

3101

3103

3107

3108

3109

310A

310D

3901

3903

3907

3908

3909

390C

390D

4101

4103

4107

4108

4109

410C

410D

4901

4903

4907

4908

4909

490C

490D

5901

5903

5907

5908

5909

590C

590D

590E

6101

6103

6107

6108

6109

610C

610D

6201

6203

6207

6208

6209

620C

620D

7101

7102

7103

7107

7108

7109

710C

710D

710E

7201

7202

7203

7207

7208

7209

720C

720D

720E

7901

7902

7903

7907

7908

7909

790C

790D

790E

E000-0000

E001-0000

E003-0000

E004-0000

E012-0000

E012-0001

E015-0000

E020-0000

E052-0000

E066-0000

E100-0000

E100-0001

E100-0002

E100-0003

E110-0000

E196-0000

E196-1000

E196-2000

E196-3000

E196-3001

E198-0000

E202-0001

E202-0002

E225-0001

E246-0000

E247-0000

E248-0001

E350-0000

E351-0000

E354-0000 ... E355-0005

E719-0000

E732-0000

E733-0000

E736-0000

E736-0001

E743-0000

E744-0001

E744-0002

E744-1001

E744-4000

E744-5000

E744-6000

E744-7000

E746-0000

E766-8000

E766-9000

E806-0000

E840-0000

Описание

| Error code: | 0901 |

| Description: | Pickup Delay Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Pickup Cassette of the host machine |

| Error code: | 0902 |

| Description: | Pickup Delay Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Multi-purpose Tray |

| Error code: | 0903 |

| Description: | Pickup Delay Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Cassette Feeding Module |

| Error code: | 0907 |

| Description: | Pickup Delay Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Registration to Drum Area |

| Error code: | 0908 |

| Description: | Pickup Delay Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Drum to Fixing Area |

| Error code: | 0909 |

| Description: | Pickup Delay Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Fixing to Delivery Area |

| Error code: | 090C |

| Description: | Pickup Delay Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Duplex Reverse Area |

| Error code: | 090D |

| Description: | Pickup Delay Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Duplex Feed Area |

| Error code: | 0A01 |

| Display: | Print Unable 0A Turn the power off and then back on again. |

| Description: | Pickup Delay Jam |

| Causes: | Cassette Feed Sensor SR31 |

| Remedy: | Pickup Cassette of the host machine |

| Error code: | 0A03 |

| Description: | Pickup Delay Jam |

| Causes: | Cassette Feed Sensor SR31 |

| Remedy: | Cassette Feeding Module |

| Error code: | 0A07 |

| Description: | Pickup Delay Jam |

| Causes: | Cassette Feed Sensor SR31 |

| Remedy: | Registration to Drum Area |

| Error code: | 0A08 |

| Description: | Pickup Delay Jam |

| Causes: | Cassette Feed Sensor SR31 |

| Remedy: | Drum to Fixing Area |

| Error code: | 0A09 |

| Description: | Pickup Delay Jam |

| Causes: | Cassette Feed Sensor SR31 |

| Remedy: | Fixing to Delivery Area |

| Error code: | 0A0C |

| Description: | Pickup Delay Jam |

| Causes: | Cassette Feed Sensor SR31 |

| Remedy: | Duplex Reverse Area |

| Error code: | 0A0D |

| Description: | Pickup Delay Jam |

| Causes: | Cassette Feed Sensor SR31 |

| Remedy: | Duplex Feed Area |

| Error code: | 10-0100 |

| Description: | Unidentified Toner Cartridge replacement notification alarm (C) |

| Causes: | Detail Code: 0184 |

| Remedy: | When the replacement with a non-genuine Toner Cartridge was detected. |

| Error code: | 10-0401 |

| Description: | Toner Cartridge empty alarm (Y) |

| Causes: | Alarm to be generated once the Toner Cartridge becomes empty. |

| Error code: | 10-0402 |

| Description: | Toner Cartridge empty alarm (M) |

| Causes: | Alarm to be generated once the Toner Cartridge becomes empty. |

| Error code: | 10-0403 |

| Description: | Toner Cartridge empty alarm (C) |

| Causes: | Alarm to be generated once the Toner Cartridge becomes empty. |

| Error code: | 10-0404 |

| Description: | Toner Cartridge empty alarm (Bk) |

| Causes: | Alarm to be generated once the Toner Cartridge becomes empty. |

| Error code: | 1101 |

| Display: | Replace part soon. |

| Description: | Data transmission did not finish within the specified time. |

| Causes: | An incompatible loop-back connector is connected to the parallel port, or the loop-back connector is not connected. Use the correct loop-back connector (P/#: G0219350) before the test. |

| Remedy: | Load paper. If the problem remains, then check the paper sensor. |

| Error code: | 1103 |

| Description: | Missing Printhead |

| Causes: | Registration Sensor SR1 |

| Remedy: | Install a printhead. |

| Error code: | 1107 |

| Description: | Carriage Interface Error The Carriage Interface is not connect correctly. |

| Causes: | Registration Sensor SR1 |

| Remedy: | • Reconnect the Trailing Cable to the Carriage PCA and the Main PCA. • Make sure that the Trailing Cable is not damaged. • Replace the Carriage PCA. • If the error continues, replace the Main PCA. • If the error continues after replacing the Main PCA and the Carriage PCA, replace the Trailing Cable. |

| Error code: | 1108 |

| Description: | USB Error USB communication is not performed correctly. |

| Causes: | Registration Sensor SR1 |

| Remedy: | • Replace the Main PCA. |

| Error code: | 1109 |

| Description: | EEPROM Error The parameters saved in the EEPROM on the Main PCA cannot be read correctly. |

| Causes: | Registration Sensor SR1 |

| Remedy: | • Replace the EEPROM. • Replace the Main PCA. |

| Error code: | 110C |

| Description: | Pickup Stationary Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Duplex Reverse Area |

| Error code: | 110D |

| Description: | Pickup Stationary Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Duplex Feed Area |

| Error code: | 1901 |

| Description: | Fixing Delivery Delay Jam |

| Causes: | Fixing Delivery Sensor SR3 |

| Remedy: | Pickup Cassette of the host machine |

| Error code: | 1903 |

| Description: | An abnormally high temperature of the PLATEN HEATER(64) on the HEATER RELAY BOARD ASSY An abnormally high temperature of the PLATEN HEATER(64) is detected. |

| Causes: | Fixing Delivery Sensor SR3 |

| Remedy: | Check whether the THERMISTOR, PLATEN(s) is correctly installed. Replace the HEATER RELAY BOARD ASSY . |

| Error code: | 1907 |

| Description: | An abnormally low temperature of the AFTER HEATER(64) on the HEATER RELAY BOARD ASSY An abnormally low temperature of the AFTER HEATER(64) is detected. |

| Causes: | Fixing Delivery Sensor SR3 |

| Remedy: | Check whether the AFTER HEATER(s)(64) is properly connected. Check whether the THERMISTOR, AFTER(s) is correctly installed. Check whether the THERMISTOR, AFTER(s) is properly connected. Check whether the FUSE has blown. If so, replace the FUSE. Replace the HEATER RELAY BOARD ASSY . |

| Error code: | 1908 |

| Description: | An abnormal voltage of the heater on the HEATER CONT BOARD ASSY The voltage of the HEATER CONT BOARD ASSY is abnormally changed.d |

| Causes: | Fixing Delivery Sensor SR3 |

| Remedy: | Replace the HEATER CONT BOARD ASSY . Replace the P/S BOARD ASSY . |

| Error code: | 1909 |

| Description: | Serial communication failure between the HEATER CONT BOARD ASSY and SUB-B/C BOARD The serial communication between the HEATER CONT BOARD ASSY and the SUB_B BOARD ASSY/SUB_C BOARD ASSY cannot be made. |

| Causes: | Fixing Delivery Sensor SR3 |

| Remedy: | Check whether the serial cable is properly connected. If not, connect it properly. |

| Error code: | 190C |

| Description: | Fixing Delivery Delay Jam |

| Causes: | Fixing Delivery Sensor SR3 |

| Remedy: | Duplex Reverse Area |

| Error code: | 190D |

| Description: | Fixing Delivery Delay Jam |

| Causes: | Fixing Delivery Sensor SR3 |

| Remedy: | Duplex Feed Area |

| Error code: | 2101 |

| Description: | Developer motor error After developer motor is driven, the ready signal does not turn to L within 2 s. After developer motor is stabilized, the ready signal is at the H level for 1 s continuously. |

| Causes: | Defective connector cable or poor contact in the connector. Defective drive transmission system of motor. Defective developer motor. Defective engine PWB. |

| Remedy: | Developer unit 1. Check that the developer waste lock has been released and, if not, release the lock. 2. Check that the gears and spiral screw of the developer unit are not damaged. 3. Confirm that the developer roller can rotate. 4. If it won`t rotate, replace the developer unit. Developer motor 1. To check the motor operation, execute DLP(K) by U030. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Developer motor and Feed PWB 1 (YC8) Feed PWB 1 (YC2) and Engine PWB (YC5) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the Developer motor. Engine PWB. 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB. |

| Error code: | 2103 |

| Description: | Developer motor M error After developer motor M is driven, the ready signal does not turn to L within 5 s. After developer motor M is stabilized, the ready signal is at the H level for 5 s continuously. |

| Causes: | Defective connector cable or poor contact in the connector. Defective drive transmission system of motor. Defective developer motor M. Defective engine PWB. |

| Remedy: | Developer unit M 1. Check that the developer waste lock has been released and, if not, release the lock. 2. Check that the gears and spiral screw of the developer unit are not damaged. 3. Confirm that the developer roller can rotate. 4. If it won`t rotate, replace the developer unit. Developer motor M 1. To check the motor operation, execute DLP(M) by U030. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Developer motor M and Motor control PWB (YC7) Motor control PWB (YC3) and Engine PWB (YC9) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the Developer motor M. Motor control PWB Replace the Motor control PWB Engine PWB. 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB. |

| Error code: | 2107 |

| Description: | Fixing Delivery Stationary Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Registration to Drum Area |

| Error code: | 2108 |

| Description: | Fixing Delivery Stationary Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Drum to Fixing Area |

| Error code: | 2109 |

| Description: | Fixing Delivery Stationary Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Fixing to Delivery Area |

| Error code: | 210C |

| Description: | Fixing Delivery Stationary Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Duplex Reverse Area |

| Error code: | 210D |

| Description: | Fixing Delivery Stationary Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Duplex Feed Area |

| Error code: | 2901 |

| Display: | Mail box nearly full. Delete unwanted data. The mail box is nearly full. Delete |

| Description: | Delivery Delay Jam |

| Causes: | Fixing Delivery Sensor SR3 |

| Remedy: | Pickup Cassette of the host machine |

| Error code: | 2903 |

| Description: | Delivery Delay Jam |

| Causes: | Fixing Delivery Sensor SR3 |

| Remedy: | Cassette Feeding Module |

| Error code: | 2907 |

| Display: | Mail box full. Delete unwanted data. Maximum jobs stored. Delete unwanted data. |

| Description: | Delivery Delay Jam |

| Causes: | Fixing Delivery Sensor SR3 |

| Remedy: | Registration to Drum Area |

| Error code: | 2908 |

| Display: | Hard disk error. Press OK to reformat |

| Description: | Delivery Delay Jam |

| Causes: | Fixing Delivery Sensor SR3 |

| Remedy: | Drum to Fixing Area |

| Error code: | 2909 |

| Display: | File read error. Turn off printer, wait a while, and turn it on again. Invalid files will be deleted. |

| Description: | Delivery Delay Jam |

| Causes: | Fixing Delivery Sensor SR3 |

| Remedy: | Fixing to Delivery Area |

| Error code: | 290C |

| Description: | Delivery Delay Jam |

| Causes: | Fixing Delivery Sensor SR3 |

| Remedy: | Duplex Reverse Area |

| Error code: | 290D |

| Description: | Delivery Delay Jam |

| Causes: | Fixing Delivery Sensor SR3 |

| Remedy: | Duplex Feed Area |

| Error code: | 3101 |

| Description: | Delivery Stationary Jam |

| Causes: | Delivery Sensor SR4 |

| Remedy: | Pickup Cassette of the host machine |

| Error code: | 3103 |

| Description: | Delivery Stationary Jam |

| Causes: | Delivery Sensor SR4 |

| Remedy: | Cassette Feeding Module |

| Error code: | 3107 |

| Description: | Delivery Stationary Jam |

| Causes: | Delivery Sensor SR4 |

| Remedy: | Registration to Drum Area |

| Error code: | 3108 |

| Description: | Delivery Stationary Jam |

| Causes: | Delivery Sensor SR4 |

| Remedy: | Drum to Fixing Area |

| Error code: | 3109 |

| Description: | Delivery Stationary Jam |

| Causes: | Delivery Sensor SR4 |

| Remedy: | Fixing to Delivery Area |

| Error code: | 310A |

| Description: | Centre Output Tray Poor Stacking RAP Use this RAP to identify the cause of poor stacking in the centre output tray. |

| Causes: | Delivery Sensor SR4 |

| Remedy: | Perform the steps that follow: • Ensure that all paper or other copy stock being used is within the size and weight specifications. Refer to GP 20 Paper and Media Size Specifications. • Ensure that the edge guides of all paper trays are adjusted correctly for the paper size and that the trays are fully closed. • Ensure that the paper stack in each paper tray has been fanned. • Turn over the paper stack in each paper tray. • Use a new ream of paper, if available. • Check the output copies/prints for curl. Refer to the IQ5 Print Damage RAP. • Check the offset motor, PL 10.11 Item 14. Refer to 310-702-00 Offset Motor Fault RAP. • Check the inverter assembly, PL 10.10 Item 1 for wear or damage. • Check the bail arm assembly, PL 10.11 Item 25 for wear or damage. |

| Error code: | 310D |

| Description: | Delivery Stationary Jam |

| Causes: | Delivery Sensor SR4 |

| Remedy: | Duplex Feed Area |

| Error code: | 3901 |

| Description: | Reverse Delay Jam |

| Causes: | Duplex Reverse Sensor R21 |

| Remedy: | Pickup Cassette of the host machine |

| Error code: | 3903 |

| Description: | Reverse Delay Jam |

| Causes: | Duplex Reverse Sensor R21 |

| Remedy: | Cassette Feeding Module |

| Error code: | 3907 |

| Description: | Reverse Delay Jam |

| Causes: | Duplex Reverse Sensor R21 |

| Remedy: | Registration to Drum Area |

| Error code: | 3908 |

| Description: | Reverse Delay Jam |

| Causes: | Duplex Reverse Sensor R21 |

| Remedy: | Drum to Fixing Area |

| Error code: | 3909 |

| Description: | Reverse Delay Jam |

| Causes: | Duplex Reverse Sensor R21 |

| Remedy: | Fixing to Delivery Area |

| Error code: | 390C |

| Description: | Photoreceptor Fan RAP Use this RAP to check the photoreceptor fan. NOTE: A faulty photoreceptor fan can cause image quality problems and xerographic module failure. |

| Causes: | Duplex Reverse Sensor R21 |

| Remedy: | Ensure that the machine is switched on, GP 14. Check the airflow by holding a piece of paper over the fan intake, PL 90.25 Item 7. The fan is working. Y↓N→Go to Flag 1. Check the photoreceptor fan motor. Refer to GP 10, How to Check a Motor. Check the following: • +11V to+15V is available at PJ42 pin 1 (red wire). • 0V is available at PJ42 pin 2 (black wire). • +11V to+15V is available at P/J17 (red wire). • Continuity between PJ42 and P/J17. If necessary repair the harness. Perform the following as necessary. • Install a new photoreceptor fan assembly, PL 90.25 Item 6. • 301L LVPS Checkout RAP. Ensure that the fan is installed correctly. If the fan is installed correctly air will be drawn into the air intake. Refer to the OF6 Ozone and Air Systems RAP. The fault may be intermittent. Go to Flag 1. Check the harness and the connectors, GP 7. |

| Error code: | 390D |

| Description: | Reverse Delay Jam |

| Causes: | Duplex Reverse Sensor R21 |

| Remedy: | Duplex Feed Area |

| Error code: | 4101 |

| Description: | BD initialization error K After Polygon motor is driven, the BD signal is not detected for 1 s. |

| Causes: | Defective connector cable or poor contact in the connector. Defective PD PWB. Defective engine PWB. |

| Remedy: | PD PWB K (LSU) 1. Confirm that the FFC wiring connector is not distorted and connect the FFC wiring all the way in. Laser scanner unit and LSU relay PWB (YC3) LSU relay PWB (YC2) and Engine PWB (YC11) 2. If the FFC wiring is disconnected, replace the FFC wiring. 3. Replace the laser scanner unit. Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB. |

| Error code: | 4103 |

| Description: | BD initialization error M After polygon motor M is driven, the BD signal is not detected for 1 s. |

| Causes: | Defective connector cable or poor contact in the connector. Defective PD PWB M. Defective engine PWB. |

| Remedy: | PD PWB M (LSU) 1. Confirm that the FFC wiring connector is not distorted and connect the FFC wiring all the way in. Laser scanner unit and LSU relay PWB (YC8) LSU relay PWB (YC3) and Engine PWB (YC12) 2. If the FFC wiring is disconnected, replace the FFC wiring. 3. Replace the laser scanner unit. Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB. |

| Error code: | 4107 |

| Description: | Reverse Stationary Jam |

| Causes: | Duplex Reverse Sensor R21 |

| Remedy: | Registration to Drum Area |

| Error code: | 4108 |

| Description: | Reverse Stationary Jam |

| Causes: | Duplex Reverse Sensor R21 |

| Remedy: | Drum to Fixing Area |

| Error code: | 4109 |

| Description: | Reverse Stationary Jam |

| Causes: | Duplex Reverse Sensor R21 |

| Remedy: | Fixing to Delivery Area |

| Error code: | 410C |

| Description: | Reverse Stationary Jam |

| Causes: | Duplex Reverse Sensor R21 |

| Remedy: | Duplex Reverse Area |

| Error code: | 410D |

| Description: | Reverse Stationary Jam |

| Causes: | Duplex Reverse Sensor R21 |

| Remedy: | Duplex Feed Area |

| Error code: | 4901 |

| Description: | FW/OS integrity verification error • NG results from verification of the hash value of the controller FW. • Faulty, damaged, or illegally written ROM data |

| Causes: | • MFP board (MFPB) • SSD board (SSDB) |

| Remedy: | 1 Reboot the machine. - - 2 Update the firmware. - - 3 Check the MFPB for proper connection and correct as necessary. - - 4 Check the SSDB for proper connection and correct as necessary. 5 Replace SSD 6 Replace MFPB |

| Error code: | 4903 |

| Description: | Duplex Feed Delay Jam |

| Causes: | Duplex Re-pickup Sensor SR22 |

| Remedy: | Cassette Feeding Module |

| Error code: | 4907 |

| Description: | Duplex Feed Delay Jam |

| Causes: | Duplex Re-pickup Sensor SR22 |

| Remedy: | Registration to Drum Area |

| Error code: | 4908 |

| Description: | Duplex Feed Delay Jam |

| Causes: | Duplex Re-pickup Sensor SR22 |

| Remedy: | Drum to Fixing Area |

| Error code: | 4909 |

| Description: | Duplex Feed Delay Jam |

| Causes: | Duplex Re-pickup Sensor SR22 |

| Remedy: | Fixing to Delivery Area |

| Error code: | 490C |

| Description: | Duplex Feed Delay Jam |

| Causes: | Duplex Re-pickup Sensor SR22 |

| Remedy: | Duplex Reverse Area |

| Error code: | 490D |

| Description: | Duplex Feed Delay Jam |

| Causes: | Duplex Re-pickup Sensor SR22 |

| Remedy: | Duplex Feed Area |

| Error code: | 5901 |

| Description: | Duplex Re-pickup Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Pickup Cassette of the host machine |

| Error code: | 5903 |

| Description: | Duplex Re-pickup Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Cassette Feeding Module |

| Error code: | 5907 |

| Description: | Duplex Re-pickup Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Registration to Drum Area |

| Error code: | 5908 |

| Description: | Duplex Re-pickup Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Drum to Fixing Area |

| Error code: | 5909 |

| Description: | Duplex Re-pickup Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Fixing to Delivery Area |

| Error code: | 590C |

| Description: | Duplex Re-pickup Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Duplex Reverse Area |

| Error code: | 590D |

| Description: | Duplex Re-pickup Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Duplex Feed Area |

| Error code: | 590E |

| Description: | Duplex Re-pickup Jam |

| Causes: | Registration Sensor SR1 |

| Remedy: | Duplex Pickup Area |

| Error code: | 6101 |

| Display: | No Toner Open the Front Cover, then install Toner Cartridge. Black (BK). |

| Description: | Wrapping Jam |

| Causes: | Fixing Delivery Sensor SR3, Duplex Reverse Sensor SR21 |

| Remedy: | Pickup Cassette of the host machine |

| Error code: | 6103 |

| Display: | No Toner Open the Front Cover, then install Toner Cartridge. Magenta (M). |

| Description: | Wrapping Jam |

| Causes: | Fixing Delivery Sensor SR3, Duplex Reverse Sensor SR21 |

| Remedy: | Cassette Feeding Module |

| Error code: | 6107 |

| Description: | Wrapping Jam |

| Causes: | Fixing Delivery Sensor SR3, Duplex Reverse Sensor SR21 |

| Remedy: | Registration to Drum Area |

| Error code: | 6108 |

| Description: | Wrapping Jam |

| Causes: | Fixing Delivery Sensor SR3, Duplex Reverse Sensor SR21 |

| Remedy: | Drum to Fixing Area |

| Error code: | 6109 |

| Description: | Wrapping Jam |

| Causes: | Fixing Delivery Sensor SR3, Duplex Reverse Sensor SR21 |

| Remedy: | Fixing to Delivery Area |

| Error code: | 610C |

| Description: | Wrapping Jam |

| Causes: | Fixing Delivery Sensor SR3, Duplex Reverse Sensor SR21 |

| Remedy: | Duplex Reverse Area |

| Error code: | 610D |

| Description: | Wrapping Jam |

| Causes: | Fixing Delivery Sensor SR3, Duplex Reverse Sensor SR21 |

| Remedy: | Duplex Feed Area |

| Error code: | 6201 |

| Description: | Wrapping Jam |

| Causes: | Fixing Delivery Sensor SR3, Duplex Reverse Sensor SR21 |

| Remedy: | Pickup Cassette of the host machine |

| Error code: | 6203 |

| Description: | Wrapping Jam |

| Causes: | Fixing Delivery Sensor SR3, Duplex Reverse Sensor SR21 |

| Remedy: | Cassette Feeding Module |

| Error code: | 6207 |

| Description: | Wrapping Jam |

| Causes: | Fixing Delivery Sensor SR3, Duplex Reverse Sensor SR21 |

| Remedy: | Registration to Drum Area |

| Error code: | 6208 |

| Display: | Drum ! Slide the Green tab on Drum Unit. |

| Description: | Wrapping Jam |

| Causes: | Fixing Delivery Sensor SR3, Duplex Reverse Sensor SR21 |

| Remedy: | Drum to Fixing Area |

| Error code: | 6209 |

| Display: | Drum ! Slide the Green tab on Drum Unit. |

| Description: | Wrapping Jam |

| Causes: | Fixing Delivery Sensor SR3, Duplex Reverse Sensor SR21 |

| Remedy: | Fixing to Delivery Area |

| Error code: | 620C |

| Description: | Wrapping Jam |

| Causes: | Fixing Delivery Sensor SR3, Duplex Reverse Sensor SR21 |

| Remedy: | Duplex Reverse Area |

| Error code: | 620D |

| Description: | Wrapping Jam |

| Causes: | Fixing Delivery Sensor SR3, Duplex Reverse Sensor SR21 |

| Remedy: | Duplex Feed Area |

| Error code: | 7101 |

| Description: | Toner sensor error Sensor output value of 60 or less or 944 or more continued for 3 s. |

| Causes: | Defective connector cable or poor contact in the connector. Defective toner sensor. Defective engine PWB. |

| Remedy: | Failure of locking the developer waste slot at setup. If an abnormal noise is heard, check that the developer ejection outlet is released and, if not, release the outlet. Toner sensor 1. Check the toner sensor output by U155. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Toner sensor and Front PWB (YC7) Front PWB (YC2) and Engine PWB (YC8) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Check that the gears of the Developer unit are not damaged and the spiral can rotate. 5. Replace the Developer unit. Toner motor 1. Draw out the toner container and execute U135 to check the toner motor operation. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Toner motor and Engine PWB (YC27) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the Toner motor. Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB. |

| Error code: | 7102 |

| Description: | Toner sensor C error Sensor output value of 60 or less or 944 or more continued for 3 s. |

| Causes: | Defective connector cable or poor contact in the connector. Defective engine PWB. |

| Remedy: | Failure of locking the developer waste slot at setup. If an abnormal noise is heard, check that the developer ejection outlet is released and, if not, release the outlet. Toner sensor C 1. Check the toner sensor output by U155. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Toner sensor C and Front PWB (YC13) Front PWB (YC2) and Engine PWB (YC10) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Check that the gears of the developer unit C are not damaged and the spiral can rotate. 5. Replace the Developer unit C. Toner motor C 1. Draw out the toner container and execute U135 to check the toner motor operation. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Toner motor C and Engine PWB (YC27) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the Toner motor C. Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB. |

| Error code: | 7103 |

| Description: | Toner sensor M error Sensor output value of 60 or less or 944 or more continued for 3 s. |

| Causes: | Defective connector cable or poor contact in the connector. Defective engine PWB. |

| Remedy: | Failure of locking the developer waste slot at setup. If an abnormal noise is heard, check that the developer ejection outlet is released and, if not, release the outlet. Toner sensor M 1. Check the toner sensor output by U155. 2. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Toner sensor M and Front PWB (YC11) Front PWB (YC2) and Engine PWB (YC10) 3. If the wiring is disconnected, shorted or grounded, replace the wiring. 4. Check that the gears of the developer unit M are not damaged and the spiral can rotate. 5. Replace the Developer unit M. Toner motor M 1. Draw out the toner container and execute U135 to check the toner motor operation. 2. Check the drive gear can rotate or they are not unusually loaded and, if necessary, replace. 3. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. Toner motor M and and Engine PWB (YC27) 4. If the wiring is disconnected, shorted or grounded, replace the wiring. 5. Replace the Toner motor M. Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB. |

| Error code: | 7107 |

| Description: | Internal residual jam |

| Causes: | Registration Sensor Fixing Delivery Sensor Arch Sensor SR1 SR3 SR2 |

| Remedy: | Registration to Drum Area |

| Error code: | 7108 |

| Description: | Internal residual jam |

| Causes: | Registration Sensor Fixing Delivery Sensor Arch Sensor SR1 SR3 SR2 |

| Remedy: | Drum to Fixing Area |

| Error code: | 7109 |

| Description: | Internal residual jam |

| Causes: | Registration Sensor Fixing Delivery Sensor Arch Sensor SR1 SR3 SR2 |

| Remedy: | Fixing to Delivery Area |

| Error code: | 710C |

| Description: | Internal residual jam |

| Causes: | Registration Sensor Fixing Delivery Sensor Arch Sensor SR1 SR3 SR2 |

| Remedy: | Duplex Reverse Area |

| Error code: | 710D |

| Description: | Internal residual jam |

| Causes: | Registration Sensor Fixing Delivery Sensor Arch Sensor SR1 SR3 SR2 |

| Remedy: | Duplex Feed Area |

| Error code: | 710E |

| Description: | Internal residual jam |

| Causes: | Registration Sensor Fixing Delivery Sensor Arch Sensor SR1 SR3 SR2 |

| Remedy: | Duplex Pickup Area |

| Error code: | 7201 |

| Description: | Short-circuited inner thermistor (Developer) The sensor input sampling is less than the reference value. (After detection, controlled at 25 °C/77.0 °F) |

| Remedy: | Developer unit K 1. Confirm that the connector of developer unit K is firmly connected, and if necessary, push the unit all the way in. Developer unit K (toner sensor) and Drum relay PWB (YC6) Drum relay PWB (YC1) and Main/Engine PWB (YC15) 2. If the wire is disconnected, short-circuited or has ground fault, or the connector pin is deformed, replace the wire. 3. Replace the developer unit K. Drum relay PWB Replace the drum relay PWB. Main/Engine PWB 1. Check the engine firmware and upgrade to the latest version if necessary. 2. Replace the Main/Engine PWB. |

| Error code: | 7202 |

| Description: | Internal residual jam |

| Causes: | Registration Sensor Fixing Delivery Sensor Arch Sensor SR1 SR3 SR2 |

| Remedy: | Multi-purpose Tray |

| Error code: | 7203 |

| Description: | Internal residual jam |

| Causes: | Registration Sensor Fixing Delivery Sensor Arch Sensor SR1 SR3 SR2 |

| Remedy: | Cassette Feeding Module |

| Error code: | 7207 |

| Description: | Internal residual jam |

| Causes: | Registration Sensor Fixing Delivery Sensor Arch Sensor SR1 SR3 SR2 |

| Remedy: | Registration to Drum Area |

| Error code: | 7208 |

| Description: | Internal residual jam |

| Causes: | Registration Sensor Fixing Delivery Sensor Arch Sensor SR1 SR3 SR2 |

| Remedy: | Drum to Fixing Area |

| Error code: | 7209 |

| Description: | Internal residual jam |

| Causes: | Registration Sensor Fixing Delivery Sensor Arch Sensor SR1 SR3 SR2 |

| Remedy: | Fixing to Delivery Area |

| Error code: | 720C |

| Description: | Internal residual jam |

| Causes: | Registration Sensor Fixing Delivery Sensor Arch Sensor SR1 SR3 SR2 |

| Remedy: | Duplex Reverse Area |

| Error code: | 720D |

| Description: | Internal residual jam |

| Causes: | Registration Sensor Fixing Delivery Sensor Arch Sensor SR1 SR3 SR2 |

| Remedy: | Duplex Feed Area |

| Error code: | 720E |

| Description: | Internal residual jam |

| Causes: | Registration Sensor Fixing Delivery Sensor Arch Sensor SR1 SR3 SR2 |

| Remedy: | Duplex Pickup Area |

| Error code: | 7901 |

| Description: | Drum EEPROM error No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs 8 times successively. Mismatch between writing data and reading data occurs 8 times successively. |

| Causes: | Defective connector cable or poor contact in the connector. Defective drum PWB. |

| Remedy: | DR PWB 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. DR PWB and Front PWB (YC6) Front PWB (YC2) and Engine PWB (YC8) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Drum unit. Front PWB Replace the front PWB Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB. |

| Error code: | 7902 |

| Description: | Drum C EEPROM error No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs 8 times successively. Mismatch between writing data and reading data occurs 8 times successively. |

| Causes: | Defective connector cable or poor contact in the connector. Defective drum PWB C. |

| Remedy: | DR PWB- C 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. DR PWB- C and Front PWB (YC12) Front PWB (YC2) and Engine PWB (YC10) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Drum unit C. Front PWB Replace the front PWB Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB. |

| Error code: | 7903 |

| Description: | Drum M EEPROM error No response is issued from the device in reading/writing for 5 ms or more and this problem is repeated five times successively. Mismatch of reading data from two locations occurs 8 times successively. Mismatch between writing data and reading data occurs 8 times successively. |

| Causes: | Defective connector cable or poor contact in the connector. Defective drum PWB M. |

| Remedy: | DR PWB- M 1. Confirm that the wiring connector is firmly connected and, if necessary, connect the connector all the way in. DR PWB- M and Front PWB (YC10) Front PWB (YC2) and Engine PWB (YC10) 2. If the wiring is disconnected, shorted or grounded, replace the wiring. 3. Replace the Drum unit M. Front PWB Replace the front PWB Engine PWB 1. Check the engine software and upgrade to the latest, if necessary. 2. Replace the engine PWB. |

| Error code: | 7907 |

| Description: | Door Open Jam |

| Causes: | Registration Sensor Multi-purpose Tray Paper Sensor Fixing Delivery Sensor Delivery Sensor Duplex Re-pickup Sensor SR1 SR6 SR3 SR4 SR22 |

| Remedy: | Registration to Drum Area |

| Error code: | 7908 |

| Description: | Door Open Jam |

| Causes: | Registration Sensor Multi-purpose Tray Paper Sensor Fixing Delivery Sensor Delivery Sensor Duplex Re-pickup Sensor SR1 SR6 SR3 SR4 SR22 |

| Remedy: | Drum to Fixing Area |

| Error code: | 7909 |

| Description: | Door Open Jam |

| Causes: | Registration Sensor Multi-purpose Tray Paper Sensor Fixing Delivery Sensor Delivery Sensor Duplex Re-pickup Sensor SR1 SR6 SR3 SR4 SR22 |

| Remedy: | Fixing to Delivery Area |

| Error code: | 790C |

| Description: | Door Open Jam |

| Causes: | Registration Sensor Multi-purpose Tray Paper Sensor Fixing Delivery Sensor Delivery Sensor Duplex Re-pickup Sensor SR1 SR6 SR3 SR4 SR22 |

| Remedy: | Duplex Reverse Area |

| Error code: | 790D |

| Description: | Door Open Jam |

| Causes: | Registration Sensor Multi-purpose Tray Paper Sensor Fixing Delivery Sensor Delivery Sensor Duplex Re-pickup Sensor SR1 SR6 SR3 SR4 SR22 |

| Remedy: | Duplex Feed Area |

| Error code: | 790E |

| Description: | Door Open Jam |

| Causes: | Registration Sensor Multi-purpose Tray Paper Sensor Fixing Delivery Sensor Delivery Sensor Duplex Re-pickup Sensor SR1 SR6 SR3 SR4 SR22 |

| Remedy: | Duplex Pickup Area |

| Error code: | E000-0000 |

| Description: | Startup error The temperature detected by the main or sub thermistor does not rise to the specified value during startup control. |

| Causes: | The detection temperature of the main thermistor did not increase after start of the power distribution to the heater. |

| Remedy: | - Check the fixing film connector. - Replace the fixing film unit. - Replace the DC controller PCB. |

| Error code: | E001-0000 |

| Description: | Abnormally high temperature (detected by main thermistor) The main thermistor detected an abnormally high temperature 235 deg C) during temperature control |

| Causes: | The main thermistor detected a temperature of higher than 255 degree C. |

| Remedy: | - Check the connector of the fixing film unit. - Replace the fixing film unit. - Replace the DC controller PCB. |

| Error code: | E003-0000 |

| Description: | Abnormally low temperature (detected by main thermistor) After the temperature detected by the main thermistor has reached the specified value, it does not reach the specified value during initial rotation. |

| Causes: | The main thermistor detected a temperature of lower than 120 degree C for more than 1 second when 20 seconds elapsed after start of the power distribution to the heater. |

| Remedy: | - Check the connector of the fixing film unit. - Replace the fixing film unit. - Replace the DC controller PCB. |

| Error code: | E004-0000 |

| Description: | Fixing power supply drive circuit error |

| Causes: | 43 to 57Hz could not be detected continuously for more than 5 seconds when zero cross detection started. |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Replace the DC Controller Board. (2) Replace the Fixing Assembly. |

| Error code: | E012-0000 |

| Description: | Error in ITB motor activation. |

| Causes: | The cycle of ITB motor speed detection signal does not move in the specified cycle after ITB motor drive is started. Cause Failure in ITB motor, failure in DC controller PCB |

| Remedy: | - Check the connectors of ITB motor and DC controller PCB - Replace the ITB motor - Replace the DC controller PCB |

| Error code: | E012-0001 |

| Description: | Error in ITB motor activation. |

| Causes: | If the ITB motor speed detection signal comes off the specified cycle after it turned once to the specified cycle. Cause Failure in ITB motor, failure in DC controller PCB. |

| Remedy: | - Check the connectors of ITB motor and DC controller PCB - Replace the ITB motor - Replace the DC controller PCB |

| Error code: | E015-0000 |

| Description: | Developing disengagement motor failure |

| Causes: | Developing disengagement motor failure The standard flag was not detected even when driving was performed for 1000ms after rotation of the motor. The standard flag was not detected even when driving was performed for 8000ms at the time of switching from the full-color position to "all disengagement". The standard flag was not detected even when driving was performed for 3000ms at the time of switching from the monochrome position to "all disengagement". |

| Remedy: | Reconnect the connector J518 of the developing disengagement motor, the connector J1005 on the driver PCB, and the connector J91 on the DC controller PCB. Check the condition of the developing disengagement sensor in the sensor monitor mode. If a failure is found, replace the developing disengagement sensor assembly. Execute the developing assembly engagement/disengagement drive test in the actuator drive mode. If the developing assembly does not perform engagement/disengagement, replace the developing disengagement motor. |

| Error code: | E020-0000 |

| Description: | Density sensor failure warning |

| Error code: | E052-0000 |

| Description: | Erroneous connection to duplex unit Disconnection of the duplex unit was detected after power-on, detection of normal connection to the duplex unit, and start of communication. |

| Causes: | Failed to detect 2-sided unit Cause: improper 2-sided unit connection |

| Remedy: | - Check the connectors of the duplex unit and DC controller PCB. - Replace the duplex controller PCB. - Replace the DC controller PCB. |

| Error code: | E066-0000 |

| Description: | Environment sensor failure |

| Causes: | Environment sensor failure |

| Remedy: | Replace the environment sensor. |

| Error code: | E100-0000 |

| Description: | BD detection PCB failure The BD detection PCB is faulty. |

| Causes: | Yellow optical assembly failure |

| Remedy: | - Check the connector of the BD detection PCB. - Replace the laser scanner unit. - Replace the DC controller PCB. |

| Error code: | E100-0001 |

| Description: | Error detection on any of scanner motor, laser unit, and BD detection at scanner area. |

| Causes: | Magenta optical assembly failure |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Replace the Laser Scanner Unit. (2) Replace the DC Controller Board. |

| Error code: | E100-0002 |

| Description: | Optical assembly error (Laser) |

| Causes: | Cyan optical assembly failure |

| Remedy: | Check the contact of the connector between the laser scanner unit and the DC controller. Replace the laser scanner unit. |

| Error code: | E100-0003 |

| Description: | Optical assembly error (Laser) |

| Causes: | Black optical assembly failure |

| Remedy: | Check the contact of the connector between the laser scanner unit and the DC controller. Replace the laser scanner unit. |

| Error code: | E110-0000 |

| Description: | Optical assembly error (Scanner motor) |

| Causes: | Optical assembly error (Scanner motor initial operation failure) |

| Remedy: | Check the contact of the connector between the laser scanner unit and the DC controller. Replace the laser scanner unit. |

| Error code: | E196-0000 |

| Description: | Invalid RFU execution requested |

| Causes: | D-con update for the host machine or the optional cassette is not completed. |

| Error code: | E196-1000 |

| Description: | Main Controller PCB reading/writing error Error in reading/writing of main program in the Main Controller PCB |

| Causes: | Error in writing in / reading from ROM (main) Cause: Problem in main controller PCB |

| Remedy: | 1. Install the set of the controller firmware. 2. Replace the Main Controller PCB. |

| Error code: | E196-2000 |

| Description: | ROM read/write error (Error in storing each setting values for user mode / service mode / factory mode) |

| Causes: | Error in writing in/reading from ROM (storing settings) Cause: Problem in main controller PCB |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Update the set of the Controller Firmware (2) Replace the Main Controller Board. |

| Error code: | E196-3000 |

| Description: | ROM writing/reading error (eMMC) |

| Causes: | Unable to read/write data from the eMMC. The eMMC failure occurred. |

| Remedy: | 1. Update the firmware. 2. Replace the Main Controller PCB (UN30). |

| Error code: | E196-3001 |

| Description: | ROM-ID mismatch (eMMC) |

| Causes: | The eMMC was replaced incorrectly. The eMMC failure occurred. |

| Remedy: | 1. Update the firmware. 2. Replace the Main Controller PCB (UN30). |

| Error code: | E198-0000 |

| Description: | DC controller memory failure |

| Causes: | A checksum failure is found in the block where specific information of the DC controller PCB is saved. A communication error occurred when reading the specific information of the DC controller PCB from the NVRAM at power-on. |

| Remedy: | If the failure cannot be removed by turning the power OFF/ON, replace the DC controller PCB. |

| Error code: | E202-0001 |

| Description: | Reader HP sensor fault |

| Causes: | Reader HP outward fault The CCD unit moves backward, but does not move to the home position. |

| Remedy: | - Replace reader HP sensor. - Replace reader motor sensor. - Replace reader unit. |

| Error code: | E202-0002 |

| Description: | Contact Sensor HP error, Failure in return |

| Causes: | Reader HP homeward fault - Replace reader unit. The CCD unit moves forward, but does not move to the home position. |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Check the connection of Flat Cable between Main Controller Board (J5) and Contact Sensor. (2) Replace the Flat Cable between Main Controller Board (J5) and Contact Sensor. (3) Replace the Contact Sensor. (4) Replace the Main Controller Board. |

| Error code: | E225-0001 |

| Description: | Light intensity of a lamp is less or equal to the criteria |

| Causes: | When the light intensity is at the reference level or below at shading. |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Check the connection of Flat Cable between Main Controller Board (J5) and Contact Sensor. (2) Replace the Flat Cable between Main Controller Board (J5) and Contact Sensor. (3) Replace the Contact Sensor. (4) Replace the Main Controller Board. |

| Error code: | E246-0000 |

| Description: | System error |

| Causes: | System error |

| Remedy: | Contact the sales company. |

| Error code: | E247-0000 |

| Description: | System error |

| Causes: | System error |

| Remedy: | Contact the sales company. |

| Error code: | E248-0001 |

| Description: | EEPROM access error |

| Causes: | Error at EEPROM power-on EEPROM data cannot be read at power-on. |

| Remedy: | Replace reader unit. |

| Error code: | E350-0000 |

| Description: | System error |

| Causes: | System error |

| Remedy: | Contact the sales company. |

| Error code: | E351-0000 |

| Description: | Main controller PCB fault |

| Causes: | Internal error of the main controller PCB Cause Main controller PCB fault. |

| Remedy: | - Check the connection of main controller PCB. - Replace main controller PCB. |

| Error code: | E354-0000 ... E355-0005 |

| Description: | System error |

| Causes: | System error |

| Remedy: | Contact the sales company. |

| Error code: | E719-0000 |

| Description: | Erroneous communication with card reader (serial communication) - Disconnection from the card reader has been detected since communication started after confirmation of normal connection to the card reader (after power-on). - A serial communication error has occurred. (The serial communication error cannot be recovered.) |

| Causes: | Erroneous communication with card reader (serial communication) - Disconnection from the card reader has been detected since communication started after confirmation of normal connection to the card reader (after power-on). - A serial communication error has occurred. (The serial communication error cannot be recovered.) |

| Remedy: | - Check the connectors of the card reader and image processor PCB. - Replace the card reader for normal connection. - Replace the image processor PCB. |

| Error code: | E732-0000 |

| Description: | Scanner communication error. |

| Causes: | Scanner communication error |

| Remedy: | 1. Install the set of the controller firmware. 2.Replace the Main Controller PCB (UN30). |

| Error code: | E733-0000 |

| Description: | Erroneous communication between controller and printer Cannot communicate with the printer at startup. |

| Causes: | Printer communication error (communication error at initial communication and negotiation packet error) |

| Remedy: | - Check the connectors of the DC controller PCB and image processor PCB for normal connection. - Check the power supply of the printer (Check whether initialization is performed at startup). - Replace the DC controller PCB or image processor PCB. |

| Error code: | E736-0000 |

| Description: | CCU communication error The installed modem PCB is incompatible. |

| Causes: | Error in CCU-modem communication Cause: Problem in FAX-NCU PCB / main controller PCB |

| Remedy: | - Check the connectors of the image processor PCB and modem. - Replace the modem PCB. - Replace the image processor PCB. |

| Error code: | E736-0001 |

| Description: | Error in ROM for backing up fax data |

| Causes: | An error occurred in ROM for backing up fax data. |

| Remedy: | 1. Check the connection of the NCU PCB (UN38). 2. Replace the NCU PCB (UN38). 3. Replace the Main Controller PCB (UN30). |

| Error code: | E743-0000 |

| Description: | Error in main controller communication An error in reading of/writing to the Flash ROM in the Main Controller occurred. |

| Causes: | Software sequence error |

| Remedy: | 1. Turn OFF and then ON the main power. 2. Replace the Main Controller PCB. |

| Error code: | E744-0001 |

| Description: | Language file/boot ROM/USB memory error The language file version does not match Bootable. |

| Causes: | Language file version error The language file version does not match Bootable. |

| Remedy: | Download a language file of the correct version. |

| Error code: | E744-0002 |

| Description: | Language file/boot ROM/USB memory error The language file is longer than the permitted size. |

| Causes: | Language file size error The language file is longer than the permitted size. |

| Remedy: | Download a language file of the correct version. |

| Error code: | E744-1001 |

| Description: | Firmware version error Version of the main program and the version of the start-up program was not matched. |

| Causes: | Versions of Bootable and BootRom do not match |

| Remedy: | Install the set of the controller firmware. |

| Error code: | E744-4000 |

| Description: | Engine ID error (Invalid engine connection is detected) |

| Causes: | Error in engine ID Detected illegal engine connection |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Check the DC Controller Board. (2) Update the Engine Firmware. (3) Update the set of the Controller Firmware |

| Error code: | E744-5000 |

| Description: | Error in the Control Panel PCB Error in the Control Panel PCB (microcomputer). |

| Causes: | Error in panel microcomputer |

| Remedy: | 1. Check the Control Panel PCB, and install the firmware (PANEL). 2. Install the set of the controller firmware. 3. Replace the Main Controller PCB. |

| Error code: | E744-6000 |

| Description: | Communication error with Wireless LAN board. |

| Causes: | Communication with the Wireless LAN PCB could not be established. |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Replace the Wireless LAN Board. (4) Replace the Main Controller Board. |

| Error code: | E744-7000 |

| Description: | Main Controller PCB error An error in the microcomputer which retains fax job information of the Main Controller PCB. |

| Causes: | An error in the microcomputer which retains fax job information of the Main Controller PCB. |

| Remedy: | 1. Install the firmware of BKUP. 2. Install the set of the controller firmware. 3. Replace the Main Controller PCB. |

| Error code: | E746-0000 |

| Description: | Main Controller PCB error Main Controller communication error occurred (other than scan). |

| Causes: | Communication error occurred in main controller PCB (other than scannerrelated) Cause: Problem in main controller PCB |

| Remedy: | 1. Install the set of the controller firmware. 2. Replace the Main Controller PCB. |

| Error code: | E766-8000 |

| Description: | Digital registration error Information at digital registration could not be obtained. |

| Causes: | Incorrect digital registration 3 point information Cause: Problem in firmware |

| Remedy: | 1. Install the Engine Controller firmware. 2. Install the set of the controller firmware. 3. Replace the Engine Controller PCB. |

| Error code: | E766-9000 |

| Description: | Scanner power state error An error was detected in power state of the Laser Scanner Unit. |

| Causes: | Error in laser scanner unit power supply Cause: Problem in firmware |

| Error code: | E806-0000 |

| Description: | Fan Motor cannot rotate at specified revolution speed. |

| Causes: | Fixing / fixing power supply cooling fan does not rotate in the specified rotation speed. Cause: Problem in fixing / fixing power supply cooling fan / DC controller PCB |

| Remedy: | When the same error repeatedly occurs after several times of turning the power OFF/ON, execute the following remedies. (1) Replace the Main Fan Unit. (2) Replace the DC Controller Board. |

| Error code: | E840-0000 |

| Description: | Pressure release mechanism failure |

| Causes: | The target pressure position was not reached even when 3.5 seconds (approximately 1.5 rotation of the cam) elapsed after start of the fixing motor reverse rotation. |

| Remedy: | Check the gears and detection flags related to fixing pressure release mechanism. Replace the fixing pressure release sensor (PS9). Replace the fixing motor. Replace the fixing assembly. |