Samsung ML-5510N

Рейтинг

Снят с производства

Снят с производства

Тип устройства

Принтер

Технология печати

лазерная

Макс. формат

A4

Число страниц в месяц

250000

Скорость печати

A4

52

Цветность печати

черно-белая

Общие характеристики |

|

|---|---|

Число страниц в месяц |

250 000 |

Тип устройства |

Принтер |

Макс. формат |

A4 |

Печать фотографий |

|

Сканер |

|

Факс |

|

Телефон |

|

Копир |

|

Размещение |

настольный |

Цветность печати |

|

Область применения |

большой офис |

Тип |

лазерный/светодиодный |

Технология печати |

лазерная |

Принтер |

|

Печать без полей |

|

Прямая печать |

|

Пигментные чернила |

|

Система непрерывной подачи чернил |

|

Двусторонняя печать |

|

Макс, разрешение для ч/б печати |

|

| По Y | 1 200 |

| По X | 1 200 |

Скорость ч/б печати |

|

| A4 | 52 |

Время выхода первого отпечатка |

|

| Ч/б | 7,8 |

Сканер |

|

Стандарт TWAIN |

|

Стандарт WIA |

|

Отправка изображения по e-mail |

|

Расходные материалы |

|

Ресурс фотобарабана |

80 000 |

Ресурс ч/б картриджа/тонера |

10 000 |

Количество картриджей |

1 |

Печать на: |

|

| Рулоне |

|

| CD/DVD |

|

| Фотобумаге |

|

| Матовой бумаге |

|

| Конвертах |

|

| Глянцевой бумаге |

|

| Этикетках |

|

| Пленках |

|

| Карточках |

|

Факс |

|

PC Fax |

|

Цветной |

|

Телефон |

|

Беспроводная трубка |

|

Спикерфон |

|

Стандарт DECT |

|

Автоответчик |

|

Caller ID |

|

АОН |

|

Проводная трубка |

|

Языки управления |

|

|

|

|

| PCL 6 |

|

| PCL 5e |

|

| PostScript 3 |

|

| PostScript |

|

| PostScript 2 |

|

| PCL 5c |

|

| PPDS |

|

Лотки |

|

Емкость лотка ручной подачи |

100 |

Подача бумаги |

|

| Стандартная | 620 |

| Максимальная | 3 140 |

Вывод бумаги |

|

| Стандартный | 500 |

Финишер |

|

Электронная сортировка |

|

Сортировка со сдвигом |

|

Степлер |

|

Сортер |

|

Брошюровщик |

|

Интерфейсы |

|

Устройство для чтения карт памяти |

|

USB |

|

Ethernet (RJ-45) |

|

Веб-интерфейс |

|

RS-232 |

|

Инфракрасный порт |

|

AirPrint |

|

LPT |

|

Bluetooth |

|

Wi-Fi 802.11n |

|

Wi-Fi |

|

FireWire (IEEE 1394) |

|

Версия USB |

2,0 |

Память/Процессор |

|

Объем памяти |

256 |

Процессор |

Samsung |

Макс, объем памяти |

768 |

Частота процессора |

700 |

Дополнительная информация |

|

Экран |

|

Работа от аккумулятора |

|

Поддержка ОС |

|

| Linux |

|

| DOS |

|

| Windows |

|

| Mac OS |

|

Потребляемая мощность |

|

| В режиме ожидания | 100 |

| При работе | 820 |

Уровень шума |

|

| В режиме ожидания | 30 |

| При работе | 56 |

Габариты |

|

Ширина |

464 |

Вес |

34,2 |

Высота |

420 |

Глубина |

540 |

Модули

Frame Pick-up

Exit

Frame-Middle

Cover Top

Drive Fuser

Power Supply and FDB

COVER

Frame Base

Fuser

FRAME

Cover Rear

DUPLEX

CASSETTE

DRIVE MAIN

FRAME MAIN

DRIVE FEED

MP

MAIN

Детали MP

| Деталь: | FRAME-PICKUP |

| Парткод: | JC93-00240A |

| Деталь: | PLATE-PICKUP_BASE |

| Парткод: | JC61-03850A |

| Деталь: | HOLDER-PICK_UP |

| Парткод: | JC61-03823A |

| Деталь: | HOUSING-PICK_UP |

| Парткод: | JC61-03846A |

| Деталь: | ACTUATOR-PAPER_EMPTY |

| Парткод: | JC66-02613A |

| Деталь: | ACTUATOR-FEED_DUPLEX |

| Парткод: | JC66-02614A |

| Деталь: | GEAR-DRY_PICKUP |

| Парткод: | JC66-02632A |

| Деталь: | PLATE-GUIDE_PAPER |

| Парткод: | JC61-03849A |

| Деталь: | SHAFT-PICK_UP |

| Парткод: | JC66-02653A |

| Деталь: | BRUSH-PICK |

| Парткод: | JC67-00468A |

| Деталь: | MEA UNIT-ROLLER PU |

| Парткод: | JC97-02259A |

| Цена: | 240 ₽ |

| Деталь: | MEA UNIT-IDLE FORWARD |

| Парткод: | JC97-02292A |

| Деталь: | MEA UNIT-GEAR ONE WAY |

| Парткод: | JC97-02291A |

| Деталь: | GEAR-M_IDLE PU |

| Парткод: | JC66-00940A |

| Деталь: | GEAR-M_PU JOINT |

| Парткод: | JC66-00943A |

| Деталь: | BUSH-6_D(L) |

| Парткод: | JC61-00884A |

| Деталь: | PHOTO-INTERRUPTER |

| Парткод: | 0604-001325 |

| Деталь: | Ring-E |

| Парткод: | 6044-000125 |

| Деталь: | SCREW-TAPPING |

| Парткод: | 6002-000440 |

| Деталь: | Spring-TS |

| Парткод: | 6107-001261 |

| Деталь: | HARNESS-PICKUP |

| Парткод: | JC39-01382A |

| Деталь: | FRAME-EXIT |

| Парткод: | JC61-03862B |

| Деталь: | FRAME-CAP_EXIT |

| Парткод: | JC61-03878A |

| Деталь: | LEVER-STACKING |

| Парткод: | JC66-02621A |

| Деталь: | GUIDE-DEFLECTOR |

| Парткод: | JC61-03891A |

| Деталь: | GROUND-EXIT_ROLLER |

| Парткод: | JC63-02657A |

| Деталь: | GROUND-EXIT |

| Парткод: | JC63-02658A |

| Деталь: | ROLLER-EXIT_UPPER |

| Парткод: | JC66-02663A |

| Деталь: | ROLLER-EXIT_LOWER |

| Парткод: | JC66-02664A |

| Деталь: | PHOTO-INTERRUPTER |

| Парткод: | 0604-001325 |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6003-000196 |

| Деталь: | Ring-E |

| Парткод: | 6044-000125 |

| Деталь: | Ring-C |

| Парткод: | 6044-000159 |

| Деталь: | BUSH-4 |

| Парткод: | JC61-00424A |

| Цена: | 500 ₽ |

| Деталь: | BUSH-6_D |

| Парткод: | JC61-00423A |

| Деталь: | BUSH-8/5 |

| Парткод: | JC61-00426A |

| Деталь: | Ring-E |

| Парткод: | 6044-000129 |

| Деталь: | Spring-TS |

| Парткод: | 6107-001500 |

| Деталь: | EXIT-ROLLER DUPLEX |

| Парткод: | JC90-01017A |

| Деталь: | HARNESS-REAR_JOINT_FR |

| Парткод: | JC39-00992A |

| Деталь: | BRACKET-MALE_REAR |

| Парткод: | JC61-02634A |

| Деталь: | CAP-ROLLER_EXIT |

| Парткод: | JC67-00477A |

| Деталь: | BRUSH-ANTISTATIC |

| Парткод: | JC67-00295A |

| Деталь: | SPONGE-LEVER_STACKING |

| Парткод: | JC72-01582A |

| Деталь: | DAMPER-PAD ADF_R2 |

| Парткод: | JC66-00738A |

| Деталь: | HARNESS-SENS T1 ENGA |

| Парткод: | JC39-00710A |

| Деталь: | DRIVE EXIT |

| Парткод: | JC93-00227A |

| Деталь: | Gear-M-Exit DUP Z21 |

| Парткод: | JC66-00854A |

| Деталь: | GEAR-M_EXIT LOWER |

| Парткод: | JC66-01018A |

| Деталь: | GEAR-M_EXIT UPPER |

| Парткод: | JC66-01017A |

| Деталь: | FRAME-SHAFT |

| Парткод: | JC93-00258A |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6003-000196 |

| Деталь: | SHEET-GUTDE_PLATE_TR |

| Парткод: | JC63-02963A |

| Деталь: | GUTDE-PLATE_TR |

| Парткод: | JC61-03904A |

| Деталь: | GUTDE-TRANSFER_REAR |

| Парткод: | JC61-04321A |

| Деталь: | GROUND-STDE_SAW |

| Парткод: | JC63-02671A |

| Деталь: | SHEET-FAN-SMPS |

| Парткод: | JC63-02872A |

| Деталь: | FRAME-REGT |

| Парткод: | JC93-00239A |

| Деталь: | GROUND-EARTH_TR |

| Парткод: | JC63-03083A |

| Деталь: | FRAME-SENSOR CTD |

| Парткод: | JC93-00279A |

| Деталь: | SHEET-FEED CTD |

| Парткод: | JC63-02825A |

| Деталь: | CAP-ACTUATOR |

| Парткод: | JC67-00456A |

| Деталь: | ELA HOU-VARTSTOR |

| Парткод: | JC96-01772A |

| Деталь: | GROUND-VARTSTOR |

| Парткод: | JC63-03086A |

| Деталь: | FRAME-HOLDER CONNECTOR |

| Парткод: | JC93-00260A |

| Деталь: | GROUND-TR |

| Парткод: | JC63-02685A |

| Деталь: | SHAFT-M BELT_GEAR |

| Парткод: | JC66-00888A |

| Деталь: | PMO-BEARTNG SHAFT |

| Парткод: | JC72-41191B |

| Цена: | 430 ₽ |

| Деталь: | GEAR-M-EXTT Z17 |

| Парткод: | JC66-00674A |

| Деталь: | FRAME-ACTUATOR |

| Парткод: | JC93-00257A |

| Деталь: | Saddle |

| Парткод: | 6502-001132 |

| Деталь: | FRAME-BASE_FEED |

| Парткод: | JC61-03832A |

| Деталь: | Gear-Feed |

| Парткод: | JC66-01262A |

| Деталь: | BUSH-6_D(L) |

| Парткод: | JC61-00884A |

| Деталь: | RTNG-E |

| Парткод: | 6044-000125 |

| Деталь: | ROLLER-FEED2 |

| Парткод: | JC66-02656A |

| Деталь: | FRAME-FEED TDLE |

| Парткод: | JC93-00259A |

| Деталь: | GROUND-REGT |

| Парткод: | JC63-02666A |

| Деталь: | TCT-SHAFT HV LARGE |

| Парткод: | JC70-40912A |

| Деталь: | GROUND-TRANSFER_REAR |

| Парткод: | JC63-03079A |

| Деталь: | SHEET-GUTDE_PLATE_TR_SMALL |

| Парткод: | JC63-02964A |

| Деталь: | KEY-CIRCLE |

| Парткод: | JC64-0060 A |

| Деталь: | OPE |

| Парткод: | JC97-03868D |

| Деталь: | KEY-ECO |

| Парткод: | JC64-00600A |

| Деталь: | Cover-OPE |

| Парткод: | JC63-02866D |

| Деталь: | KEY-NUMERICAL |

| Парткод: | JC64-00599A |

| Деталь: | PBA-COVER_OPEN SENSOR |

| Парткод: | JC92-02057A |

| Деталь: | LENS-STATUS |

| Парткод: | JC67-00495A |

| Деталь: | SPONGE-LCD |

| Парткод: | JC72-0 529A |

| Деталь: | HOLDER-LCD |

| Парткод: | JC6 -02792A |

| Деталь: | KEY-OK |

| Парткод: | JC64-00566B |

| Деталь: | GROUND-LCD |

| Парткод: | JC63-02697A |

| Деталь: | KEY-STOP |

| Парткод: | JC64-00564B |

| Деталь: | LCD |

| Парткод: | JC07-000 2A |

| Деталь: | PBA-OPE |

| Парткод: | JC92-02285A |

| Деталь: | KEY-MENU |

| Парткод: | JC64-00598A |

| Деталь: | COVER-OPE_HARNESS |

| Парткод: | JC63-02868A |

| Деталь: | KEY-POWER_B |

| Парткод: | JC64-00443A |

| Деталь: | COVER-OPE_LOWER |

| Парткод: | JC63-02867A |

| Деталь: | KEY-POWER |

| Парткод: | JB64-00 4E |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6003-000 96 |

| Деталь: | PMO-Stacker_RX |

| Парткод: | JC72-0 367E |

| Деталь: | LEVER-EXPANDER |

| Парткод: | JC66-0 966A |

| Деталь: | Stopper-M-Hinge Open |

| Парткод: | JC6 -00656A |

| Деталь: | Cover-Top |

| Парткод: | JC63-02860A |

| Деталь: | COVER-TOP_DUMMY |

| Парткод: | JC63-0286 A |

| Деталь: | DRIVE FUSER |

| Парткод: | JC93-00226A |

| Деталь: | SCREW-MACHINE |

| Парткод: | 6001-000130 |

| Деталь: | Motor BLDC |

| Парткод: | JC31-00090A |

| Цена: | 2 900 ₽ |

| Деталь: | GEAR-RDCN_3X5 |

| Парткод: | JC66-02652A |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6003-000301 |

| Деталь: | Washer-Plain |

| Парткод: | 6031-001255 |

| Деталь: | Ring-E |

| Парткод: | 6044-000125 |

| Деталь: | BRACKET-FUSER_SWING |

| Парткод: | JC61-03807A |

| Деталь: | SUPPORT-GAP_RING |

| Парткод: | JC61-03914A |

| Деталь: | GEAR-RDCN_FUSER |

| Парткод: | JC66-02634A |

| Деталь: | GEAR-DRV_OPC |

| Парткод: | JC66-02633A |

| Деталь: | BRACKET-SWING_INNER |

| Парткод: | JC61-03961A |

| Деталь: | BRACKET-DRIVE FUSER |

| Парткод: | JC61-03808A |

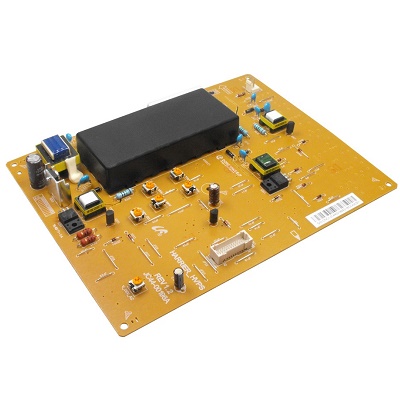

| Деталь: | FRAME-POWER SUPPLY |

| Парткод: | JC93-00270A |

| Деталь: | HVPS |

| Парткод: | JC44-00196A |

| Деталь: | SMPS-V1 |

| Парткод: | JC44-00093B |

| Деталь: | HARNESS-FUSER_FR |

| Парткод: | JC39-01393A |

| Деталь: | FRAME-BOARD FUSER DRIVE |

| Парткод: | JC93-00277A |

| Деталь: | COVER-FUSER DRIVE BOARD |

| Парткод: | JC95-01292A |

| Деталь: | FDB-MULTI TRIAC V1 |

| Парткод: | JC44-00191A |

| Деталь: | HARNESS-FUSER_AC |

| Парткод: | JC39-01390A |

| Деталь: | Harness-Inlet |

| Парткод: | JC39-01389A |

| Деталь: | Cover-Top |

| Парткод: | JC95-01297D |

| Деталь: | COVER-OPTION |

| Парткод: | JC95-01322A |

| Деталь: | Cover-Front |

| Парткод: | JC95-01328A |

| Деталь: | COVER-MP |

| Парткод: | JC63-03063A |

| Деталь: | MP-TRAY |

| Парткод: | JC90-01016B |

| Деталь: | STACKER-MP |

| Парткод: | JC61-02804C |

| Деталь: | TRAY-EXTENSION_MP |

| Парткод: | JC63-02096C |

| Деталь: | Cover-Front |

| Парткод: | JC63-03060A |

| Деталь: | PBA-USB HOST |

| Парткод: | JC92-02284A |

| Деталь: | HOLDER-USB_HOST |

| Парткод: | JC61-03912A |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6003-000196 |

| Деталь: | COVER-RIGHT |

| Парткод: | JC95-01329A |

| Деталь: | COVER-RIGHT |

| Парткод: | JC63-03064A |

| Деталь: | COVER-RIGHT_DUMMY |

| Парткод: | JC63-02863A |

| Деталь: | COVER-CONTROL_BOX DUMMY |

| Парткод: | JC63-02852A |

| Деталь: | COVER-CONTROL_BOX |

| Парткод: | JC63-03067A |

| Деталь: | COVER-RIGHT_FAN |

| Парткод: | JC63-03065A |

| Деталь: | SEAL-FILTER RIGHT |

| Парткод: | JC62-00759A |

| Деталь: | COVER-HANDLE |

| Парткод: | JC63-03061A |

| Деталь: | COVER-LEFT |

| Парткод: | JC95-01330A |

| Деталь: | SHAFT-EXIT IDLE |

| Парткод: | JC66-00661A |

| Деталь: | COVER-WTB |

| Парткод: | JC63-03066A |

| Деталь: | COVER-LEFT |

| Парткод: | JC63-03062A |

| Деталь: | Cover-Rear |

| Парткод: | JC95-01295A |

| Деталь: | FRAME-RIGHT |

| Парткод: | JC93-00248A |

| Деталь: | FRAME-LEFT |

| Парткод: | JC93-00242A |

| Деталь: | FRAME-BOTTOM |

| Парткод: | JC93-00253A |

| Деталь: | FRAME-PICKUP |

| Парткод: | JC93-00240A |

| Деталь: | FRAME-MIDDLE |

| Парткод: | JC93-00256A |

| Деталь: | FRAME-UPPER |

| Парткод: | JC93-00255A |

| Деталь: | FRAME-FRONT |

| Парткод: | JC93-00261A |

| Деталь: | FRAME-FUSER_UPPER |

| Парткод: | JC61-03825A |

| Деталь: | SCREW-SPECIAL |

| Парткод: | 6009-001717 |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6003-000196 |

| Деталь: | MOTOR GEARED-P LIFT |

| Парткод: | JC31-00045A |

| Деталь: | FRAME-RIGHT |

| Парткод: | JC61-03810A |

| Деталь: | DRIVE-PICK UP |

| Парткод: | JC93-00225A |

| Деталь: | HOLDER-CASSETTE_LIFT |

| Парткод: | JC61-03962A |

| Деталь: | GEAR-IDLE_LIFT |

| Парткод: | JC66-02710A |

| Деталь: | FRAME-LSU_LOWER |

| Парткод: | JC61-03824A |

| Деталь: | PBA-ERASER |

| Парткод: | JC92-02287A |

| Деталь: | HOLDER-PBA_LED |

| Парткод: | JC61-03843A |

| Деталь: | COVER-UPPER |

| Парткод: | JC63-02651A |

| Деталь: | THERMISTOR-NTC ASSY |

| Парткод: | 1404-001567 |

| Деталь: | FUSER-BRACKET UPPER |

| Парткод: | JC91-00998A |

| Деталь: | LAMP-HALOGEN |

| Парткод: | 4713-001521 |

| Деталь: | ROLLER-HEAT |

| Парткод: | JC66-02727A |

| Цена: | 6 200 ₽ |

| Деталь: | BUSH-HR |

| Парткод: | JC61-03883A |

| Деталь: | Bearing-Ball |

| Парткод: | 6601-001726 |

| Деталь: | Roller-Pressure |

| Парткод: | JC66-02718A |

| Цена: | 5 700 ₽ |

| Деталь: | Guide-INPUT |

| Парткод: | JC61-03920A |

| Деталь: | FUSER-COVER RIGHT |

| Парткод: | JC91-00999A |

| Деталь: | FUSER-BRACKET GEAR |

| Парткод: | JC91-00995A |

| Деталь: | BRACKET-LAMP_R |

| Парткод: | JC61-03836A |

| Деталь: | HOLDER-SHAFT_ENCORD |

| Парткод: | JC61-03859A |

| Деталь: | CAM-RELEASE-L |

| Парткод: | JC66-02619A |

| Деталь: | SPRING-ETC |

| Парткод: | 6107-002620 |

| Деталь: | Spring-ES |

| Парткод: | 6107-002624 |

| Деталь: | BRACKET-PR-R |

| Парткод: | JC61-03826A |

| Деталь: | HARNESS-FUSER_FU |

| Парткод: | JC39-01394A |

| Деталь: | FUSER-BRACKET LOWER |

| Парткод: | JC91-01020A |

| Деталь: | FUSER-CAM SHAFT |

| Парткод: | JC91-01015A |

| Деталь: | FUSER-ROLLER CLEAN |

| Парткод: | JC91-00994A |

| Деталь: | HOLDER-HARNESS_AC_SUB |

| Парткод: | JC61-03856A |

| Деталь: | FUSER-GUIDE EXIT UPPER |

| Парткод: | JC91-00996A |

| Деталь: | FUSER-GUIDE EXIT LOWER |

| Парткод: | JC91-00997A |

| Деталь: | FUSER-COVER DUPLEX |

| Парткод: | JC91-01001A |

| Деталь: | BRACKET-PR_L |

| Парткод: | JC61-03829A |

| Деталь: | HOLDER-HARNESS_DC |

| Парткод: | JC61-03857A |

| Деталь: | HOLDER-HARNESS_AC |

| Парткод: | JC61-03855A |

| Деталь: | FUSER-COVER LEFT |

| Парткод: | JC91-01021A |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6006-001078 |

| Деталь: | SCREW-SPECIAL |

| Парткод: | 6009-001711 |

| Деталь: | SCREW-MACHINE |

| Парткод: | 6006-001193 |

| Деталь: | BRACKET-FUSER_UPPER |

| Парткод: | JC61-03820A |

| Деталь: | HOLDER-THERMOSTAT |

| Парткод: | JC61-03860A |

| Деталь: | CONNECTOR-HEADER |

| Парткод: | 3711-007521 |

| Деталь: | THERMISTOR-NTC ASSY |

| Парткод: | 1404-001453 |

| Деталь: | CONNECTOR-HEADER |

| Парткод: | 3711-007520 |

| Деталь: | THERMISTOR-NTC ASSY |

| Парткод: | 1404-001565 |

| Деталь: | THERMOSTAT |

| Парткод: | 4712-001085 |

| Деталь: | SPRING-ETC |

| Парткод: | 6107-002670 |

| Деталь: | Actuator-Exit |

| Парткод: | JC66-02625A |

| Деталь: | HOLDER-ACTUATOR |

| Парткод: | JC61-03851A |

| Деталь: | Holder-M_Rear_Lever |

| Парткод: | JC61-01625A |

| Деталь: | GUIDE-EXIT_LOWER |

| Парткод: | JC61-03921A |

| Деталь: | PMO-Bushing Feed |

| Парткод: | JC72-00382B |

| Цена: | 260 ₽ |

| Деталь: | FUSER-ROLLER EXIT |

| Парткод: | JC91-01022A |

| Деталь: | Spring-ES |

| Парткод: | 6107-001237 |

| Деталь: | GEAR-FUSER |

| Парткод: | JC66-02615A |

| Деталь: | FRAME MAIN |

| Парткод: | JC93-00273B |

| Деталь: | BRACKET-RIGHT_LOWER |

| Парткод: | JC6l-038l7A |

| Деталь: | HARNESS-SCF |

| Парткод: | JC39-0l375A |

| Деталь: | BRACKET-ENGINE_CONTROLLER |

| Парткод: | JC6l-038l8A |

| Деталь: | Saddle |

| Парткод: | 6502-00ll32 |

| Деталь: | FRAME-ROLLER TRANSFER |

| Парткод: | JC93-0027lB |

| Деталь: | FRAME-TERMINAL |

| Парткод: | JC93-00247A |

| Деталь: | SPONGE-SMPS |

| Парткод: | JC72-0l587A |

| Деталь: | HOUSING-TERMINAL |

| Парткод: | JC6l-03907A |

| Деталь: | PHOTO-INTERRUPTER |

| Парткод: | 0604-00l325 |

| Деталь: | PBA-WASTE SENSOR TX |

| Парткод: | JC92-02340A |

| Деталь: | Spring-TS |

| Парткод: | 6l07-002693 |

| Деталь: | ROLLER-SLIDE B |

| Парткод: | JC66-0ll43A |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6003-000l96 |

| Деталь: | SCREW-HEX |

| Парткод: | 6009-00l664 |

| Деталь: | GUIDE-EXIT |

| Парткод: | JC61-03911A |

| Деталь: | DAMPER-PAD ADF_R2 |

| Парткод: | JC66-00738A |

| Деталь: | ROLLER |

| Парткод: | JC72-20902A |

| Цена: | 500 ₽ |

| Деталь: | SHAFT |

| Парткод: | JC70-20901A |

| Деталь: | Spring-TS |

| Парткод: | 6107-001160 |

| Деталь: | Guide-Rear |

| Парткод: | JC61-03910A |

| Деталь: | FAN |

| Парткод: | JC31-00141A |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6003-000196 |

| Деталь: | BRACKET-FEMALE |

| Парткод: | JC61-02622A |

| Деталь: | HARNESS-REAR_JOINT_FN |

| Парткод: | JC39-00993A |

| Деталь: | HOLDER-LOCKER |

| Парткод: | JC61-03909B |

| Деталь: | Cover-Rear |

| Парткод: | JC63-02676B |

| Деталь: | LOCKER-REAR L |

| Парткод: | JC64-00547A |

| Деталь: | Spring-TS |

| Парткод: | 6107-001268 |

| Деталь: | BRACKET-P-HANDLE SCF |

| Парткод: | JC61-01404A |

| Деталь: | HANDLE-REAR COVER |

| Парткод: | JC64-00420C |

| Деталь: | LOCKER-REAR R |

| Парткод: | JC64-00548A |

| Деталь: | LABEL-FUNCTION |

| Парткод: | JC68-02563A |

| Деталь: | DUPLEX |

| Парткод: | JC90-0101SB |

| Деталь: | FRAME-DUPLEX_LOWER |

| Парткод: | JC61-03S42B |

| Деталь: | FRAME-DUPLEX_UPPER |

| Парткод: | JC61-03S44A |

| Деталь: | GROUND-DUPLEX_GASKET |

| Парткод: | JC63-02656A |

| Деталь: | GASKET-CONDUCTIVE |

| Парткод: | JC63-021S9A |

| Деталь: | GUIDE-PAPER_DUPLEX |

| Парткод: | JC61-04153A |

| Деталь: | GUIDE-DUPLEX_ALIGN |

| Парткод: | JC61-04154A |

| Деталь: | BRUSH-DUPLEX |

| Парткод: | JC67-00205A |

| Деталь: | Shaft-Idle Roll, Dup |

| Парткод: | JC66-00444A |

| Деталь: | LEVER-ALIGN_DUPLEX |

| Парткод: | JC66-02S37A |

| Деталь: | ROLLER-IDLE_DUPLEX |

| Парткод: | JC66-02S16A |

| Деталь: | PCT-SILP WASHER |

| Парткод: | JK72-0005SA |

| Деталь: | Spring-TS |

| Парткод: | 6107-001667 |

| Деталь: | Bush-M-Feed, Dup |

| Парткод: | JC61-00665A |

| Деталь: | Terminal-P-GND DUP |

| Парткод: | JC65-00017A |

| Деталь: | DUPLEX FEEDER-LOWER |

| Парткод: | JC90-01051A |

| Деталь: | DUPLEX FEEDER-LOWER |

| Парткод: | JC90-01052A |

| Деталь: | PULLEY-1S_DUP |

| Парткод: | JC66-00S99A |

| Деталь: | PULLEY-M-1S-DUMMY_DUP |

| Парткод: | JC66-00900A |

| Деталь: | Belt-Timing Gear |

| Парткод: | 6602-0010S4 |

| Деталь: | GEAR-EXIT F/DOWN |

| Парткод: | JC66-0003SA |

| Деталь: | COVER-CASSETTE |

| Парткод: | JC63-01942C |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6003-000196 |

| Деталь: | CSP-HANDLE CASSETTE |

| Парткод: | JC81-09315A |

| Деталь: | CSP-CST PAPER INDICATOR |

| Парткод: | JC81-08891A |

| Деталь: | CSP-FRAME GUIDE PAPER DUMMY |

| Парткод: | JC81-08591B |

| Деталь: | CASSETTE-RETARD |

| Парткод: | JC90-01049A |

| Деталь: | CASSETTE-SIDE RIGHT |

| Парткод: | JC90-01047A |

| Деталь: | CSP-FRAME CASSETTE |

| Парткод: | JC81-08488B |

| Деталь: | CASSETTE-SIDE LEFT |

| Парткод: | JC90-01048A |

| Деталь: | CSP-CAP RETARD |

| Парткод: | JC81-08479B |

| Деталь: | CASSETTE-GUIDE REAR PAPER |

| Парткод: | JC90-01050B |

| Деталь: | CSP-DETECTOR PAPER SIZE |

| Парткод: | JC81-08485A |

| Деталь: | ROLLER-SUPPORT_CST |

| Парткод: | JC61-03882A |

| Деталь: | CSP-SPRING GROUND CASSETTE |

| Парткод: | JC81-08486A |

| Деталь: | CSP-GEAR LIFTING |

| Парткод: | JC81-08478A |

| Деталь: | CSP-LOCKER GUIDE REAR |

| Парткод: | JC81-08602A |

| Деталь: | CSP-LOCKER CASSETTE |

| Парткод: | JC81-08494A |

| Деталь: | CSP-PLATE KNOCK UP |

| Парткод: | JC81-08519A |

| Деталь: | PLATE-LEVER |

| Парткод: | JC61-03206A |

| Деталь: | GEAR-M_PINION 24 |

| Парткод: | JC66-01020A |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6003-000196 |

| Деталь: | SCREW-TAPPING |

| Парткод: | 6002-000440 |

| Деталь: | Ring-E |

| Парткод: | 6044-000125 |

| Деталь: | MEA UNIT-ROLLER PU |

| Парткод: | JC97-02259A |

| Цена: | 240 ₽ |

| Деталь: | CSP-SHAFT HINGE RETARD |

| Парткод: | JC81-08638A |

| Деталь: | CSP-SHAFT RETARD |

| Парткод: | JC81-08639A |

| Деталь: | SPRING ETC-PAD |

| Парткод: | JC61-00387A |

| Деталь: | CSP-GEAR IDLE RETARD |

| Парткод: | JC81-08477A |

| Деталь: | GEAR-PICKUP DRIVE |

| Парткод: | JC66-01676A |

| Деталь: | BUSH-D6IL4 |

| Парткод: | JC61-00699A |

| Деталь: | JOINT-M_RETARD |

| Парткод: | JC66-00976A |

| Деталь: | COUPLER-TORQUELIMITER |

| Парткод: | JC67-00126A |

| Деталь: | DRIVE MAIN |

| Парткод: | JC93-00230A |

| Деталь: | COUPLER-CARTRIDGE_OPC |

| Парткод: | JC67-00461A |

| Деталь: | HOLDER-CAM_COUPLING |

| Парткод: | JC61-03865A |

| Деталь: | LINK-COUPLING_RACK |

| Парткод: | JC66-02629A |

| Деталь: | LINK-TONER_SHUTTER |

| Парткод: | JC66-02631A |

| Деталь: | COUPLER-CARTRIDGE_MAG |

| Парткод: | JC67-00460A |

| Деталь: | GEAR-COUPLING |

| Парткод: | JC66-02641A |

| Деталь: | Spring-CS |

| Парткод: | 6107-002662 |

| Деталь: | MOTOR DC |

| Парткод: | JC31-00078A |

| Цена: | 1 600 ₽ |

| Деталь: | GEAR-DRV_TONER_1 |

| Парткод: | JC66-02638A |

| Деталь: | GEAR-RDCN DEVE |

| Парткод: | JC66-01051A |

| Деталь: | GEAR-DRV SUPPLY |

| Парткод: | JC66-02650A |

| Деталь: | GEAR-RDCN_MAG |

| Парткод: | JC66-02646A |

| Деталь: | GEAR-COUPLING-OPC |

| Парткод: | JC66-02642A |

| Деталь: | Motor BLDC |

| Парткод: | JC31-00090A |

| Цена: | 2 900 ₽ |

| Деталь: | Saddle |

| Парткод: | 6502-001132 |

| Деталь: | COVER-COUPLING |

| Парткод: | JC63-02653A |

| Деталь: | LINK-COUPLING_PINION |

| Парткод: | JC66-02630A |

| Деталь: | BRACKET-DRIVE CARTRIDGE INNER |

| Парткод: | JC61-03802A |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6003-000301 |

| Деталь: | GEAR-DRV_OPC |

| Парткод: | JC66-02633A |

| Деталь: | Ring-E |

| Парткод: | 6044-000231 |

| Деталь: | BRACKET-P-TONER MOTOR |

| Парткод: | JC61-01370A |

| Деталь: | FRAME BASE |

| Парткод: | JC93-00272A |

| Деталь: | FRAME-DUCT WASTE TONER |

| Парткод: | JC93-00269A |

| Деталь: | FRAME-GUIDE OPC LEFT |

| Парткод: | JC93-00246A |

| Деталь: | FRAME-GUIDE CASSETTE RIGHT |

| Парткод: | JC93-00250A |

| Деталь: | FRAME-GUIDE CASSETTE LEFT |

| Парткод: | JC93-00243A |

| Деталь: | FRAME-GUIDE OPC RIGHT |

| Парткод: | JC93-00252A |

| Деталь: | MP |

| Парткод: | JC90-01020A |

| Деталь: | HOLDER-CONNECTOR_TONER |

| Парткод: | JC61-03905A |

| Деталь: | PBA-ZENER |

| Парткод: | JC92-02376A |

| Деталь: | PBA-JOINT |

| Парткод: | JC92-02282A |

| Деталь: | DRIVE FUSER-RELEASE |

| Парткод: | JC93-00232A |

| Деталь: | FAN |

| Парткод: | JC31-00141A |

| Деталь: | HOLDER-FAN_SMPS |

| Парткод: | JC61-03835A |

| Деталь: | SENSOR-HUMIDITY |

| Парткод: | JC32-00005A |

| Деталь: | HOLDER-SENSOR HUMIDITY |

| Парткод: | JC61-03217A |

| Деталь: | GUIDE-WTB |

| Парткод: | JC61-03941A |

| Деталь: | GUIDE-COVER_OPEN_L |

| Парткод: | JC61-03877A |

| Деталь: | BRACKET-SUPPORT_REAR |

| Парткод: | JC61-03815A |

| Деталь: | GUIDE-COVER_OPEN_R |

| Парткод: | JC61-03876A |

| Деталь: | GUIDE-FUSER_SIDE_R |

| Парткод: | JC61-03873A |

| Деталь: | GUIDE-FUSER_SIDE_L |

| Парткод: | JC61-03869A |

| Деталь: | FRAME-GUIDE DUPLEX LEFT |

| Парткод: | JC93-00244A |

| Деталь: | Exit |

| Парткод: | JC90-01013B |

| Деталь: | CLUTCH-SPUR |

| Парткод: | JC66-00994C |

| Деталь: | DRIVE-FEED |

| Парткод: | JC93-00229A |

| Деталь: | DRIVE FUSER |

| Парткод: | JC93-00226A |

| Деталь: | DRIVE-DUPLEX |

| Парткод: | JC93-00228A |

| Деталь: | HOLDER-FAN_LSU |

| Парткод: | JC61-03840A |

| Деталь: | FAN-DC |

| Парткод: | JC31-00086A |

| Деталь: | DRIVE MAIN |

| Парткод: | JC93-00230A |

| Деталь: | GUIDE-HARNESS_FRAME |

| Парткод: | JC61-03879A |

| Деталь: | SCREW-HEX |

| Парткод: | 6009-001664 |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6003-000196 |

| Деталь: | DRIVE-FEED |

| Парткод: | JC93-00229A |

| Деталь: | GEAR-IDLE OPC |

| Парткод: | JC66-01376A |

| Деталь: | Motor BLDC |

| Парткод: | JC31-00090A |

| Цена: | 2 900 ₽ |

| Деталь: | Washer-Plain |

| Парткод: | 6031-001255 |

| Деталь: | GEAR-FEED_IDLE |

| Парткод: | JC66-02643A |

| Деталь: | BRACKET-DRIVE FEED 1 |

| Парткод: | JC61-03801A |

| Деталь: | GEAR-RDCN_FORWARD |

| Парткод: | JC66-02645A |

| Деталь: | GEAR-RDCN_FEED |

| Парткод: | JC66-02649A |

| Деталь: | GEAR-RDCN_REGI |

| Парткод: | JC66-02644A |

| Деталь: | GEAR-M-MP DRV |

| Парткод: | JC66-00861A |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6003-000301 |

| Деталь: | MP |

| Парткод: | JC90-01020A |

| Деталь: | MP-LOWER RETARD |

| Парткод: | JC90-01014A |

| Цена: | 1 000 ₽ |

| Деталь: | FRAME-MP_BOTTOM |

| Парткод: | JC61-03893A |

| Деталь: | BUSH-D6/L4 |

| Парткод: | JC61-00699A |

| Деталь: | GROUND-MP |

| Парткод: | JC63-02663A |

| Деталь: | BUSH-6_D |

| Парткод: | JC61-00423A |

| Деталь: | CLUTCH-FEED |

| Парткод: | JC47-00023A |

| Цена: | 1 100 ₽ |

| Деталь: | GROUND-MP_TOP |

| Парткод: | JC63-02665A |

| Деталь: | RTNG-E |

| Парткод: | 6044-000125 |

| Деталь: | MP-PTCK UP |

| Парткод: | JC90-01012A |

| Цена: | 1 300 ₽ |

| Деталь: | BRUSH-PTCK_MP |

| Парткод: | JC67-00507A |

| Деталь: | STOPPER-PAPER_MP |

| Парткод: | JC61-03892A |

| Деталь: | PHOTO-TNTERRUPTER |

| Парткод: | 0604-001325 |

| Деталь: | LATCH-M_ARM REAR |

| Парткод: | JC66-00958B |

| Деталь: | FRAME-MP_TOP |

| Парткод: | JC61-03894A |

| Деталь: | GROUND-MP_RELEASE |

| Парткод: | JC63-02664A |

| Деталь: | GUTDE-MP_RELEASE |

| Парткод: | JC61-03871A |

| Деталь: | GUTDE-ENVELOPE |

| Парткод: | JC61-03864A |

| Деталь: | ABSORBER-ENVELOPE |

| Парткод: | JC63-02973A |

| Деталь: | SCREW-TAPTYPE |

| Парткод: | 6003-000196 |

| Деталь: | CASSETTE |

| Парткод: | JC90-01026A |

| Деталь: | Cover-Front |

| Парткод: | JC95-01328A |

| Деталь: | COVER-LEFT |

| Парткод: | JC95-01330A |

| Деталь: | FRAME |

| Парткод: | JC93-00241B |

| Деталь: | LSU |

| Парткод: | JC97-03777A |

| Деталь: | Cover-Top |

| Парткод: | JC95-01297D |

| Деталь: | COVER-OPTION |

| Парткод: | JC95-01322A |

| Деталь: | HANDLE-M_FIX FUSER |

| Парткод: | JC64-00186C |

| Деталь: | Fuser |

| Парткод: | JC91-01014A |

| Деталь: | BRACKET-BOTTOM_FUSER |

| Парткод: | JC61-03811A |

| Деталь: | FRAME-POWER SUPPLY |

| Парткод: | JC93-00270A |

| Деталь: | SHIELD-MAIN_CTRL |

| Парткод: | JC63-02643A |

| Деталь: | PBA-ENGINE |

| Парткод: | JC92-02281A |

| Деталь: | HOLDER-HARNESS_DRIVE |

| Парткод: | JC61-03845A |

| Деталь: | LEVER-COUPLER |

| Парткод: | JC66-02628A |

| Деталь: | PBA-Main |

| Парткод: | JC92-02280B |

| Деталь: | FRAME-BOARD FUSER DRIVE |

| Парткод: | JC93-00277A |

| Деталь: | COVER-RIGHT |

| Парткод: | JC95-01329A |

| Деталь: | DUPLEX |

| Парткод: | JC90-01018B |

| Деталь: | Cover-Rear |

| Парткод: | JC95-01295A |

Коды ошибок

A1-1110

A1-1210

A1-1310

A1-3110

A2-1910

A2-1920

A2-2410

A3-2110

A3-5110

C1-1110

C1-1120

C1-1140

C1-1311, C1-1412, C1-1413

C1-1330, C1-1411

C1-1512

C3-1110, C3-1120, C3-1140

C3-1312, C3-1315

C3-1320, C3-1330

C3-1321

C3-1411, C3-1412

C3-1512, C3-1514

C6-1110, C6-1120

C7-1110, C7-1120

C7-1310

H1-1210, H1-1310

H1-1222, H1-1322

H1-1252, H1-1352

H1-1253, H1-1353

H1-1410, H1-1510

H1-1422, H1-1522

H1-1452, H1-1552

H1-1453, H1-1553

H1-2210, H1-2310, H1-2410

H1-2222, H1-2322, H1-2422

H1-2252, H1-2352, H1-2452

H1-2253, H1-2353, H1-2453

H2-1100

H2-1101

H2-1102

H2-1200

H2-1300

H2-1302

H2-1710, H2-1711

H2-1720, H2-1721

H2-1730, H2-1731

H2-1751, H2-1753

H2-1752

H2-1760, H2-1A80

H2-1800

H2-1A20

H2-1A32

H2-1A50

H2-1A62

H2-1A63

H2-1A70, H2-1750

H2-4100

H2-4101

H2-4102

H2-4200

H2-4201

H2-4202

H2-4300

H2-4301

H2-4302

H2-4400

H2-4401

H2-4402

H2-4500

H2-4501

H2-4502

H2-4700, H2-4701

H2-4710, H2-4711

H2-4A20

H2-4A32

H2-4A35

H2-4A38

H2-4A3C

M1-1110

M1-1610

M1-3122

M1-4111

M1-5112

M1-5612

M2-1110

M2-2110

M2-2310

M2-3120

M3-1110

M3-2130

S1-2111

S2-4110

S2-4610

S6-3123

S6-3128

U1-2115

U1-2117

U1-2320

U1-2330

U1-2340

U2-1111

U2-1113

Описание

| Error code: | A1-1110 |

| Display: | Error #A1-1110 Turn off then on |

| Description: | Main Motor Failure: #A1-1110. Turn off then on. Call for service if the problem persists |

| Causes: | After working the main BLDC motor, the Ready signal has not occurred within 1 sec. |

| Remedy: | 1) Turn the machine off then on. If the error persists, refer to the following. 2) Check if the motor connector on the main board is connected properly. Reconnect it. 3) OPC coupler has overloaded. After removing the imaging unit, rotate the OPC coupler. (Spec : 6 kgf.cm) If there is any damage, the OPC coupler can’t rotate well. Replace the imaging unit. 4) The main BLDC motor is defective. • Unplug the connector from the motor carefully. • Replace the main BLDC motor with new one. 5) If the problem persists, replace the main board. |

| Error code: | A1-1210 |

| Display: | Actuator Motor Failure #A1-1210: Turn off then on. |

| Description: | Error #A1-1210 Call for service |

| Causes: | The fuser motor does not operate. / The fuser motor is operating but is recognized as stop status. |

| Remedy: | 1) Turn the machine off then on. If the error persists, turn the machine off again. 2) Remove the rear and right cover. 3) Check if there are any obstacles or paper around the fuser unit. 4) Check if the connection between main board and fuser motor are correct. 5) If the connection is OK, replace the fuser motor. 6) If the problem persists, replace the main board. |

| Error code: | A1-1310 |

| Display: | Actuator Motor Failure #A1-1310: Turn off then on. |

| Description: | After working the Pick-up BLDC motor, the Ready signal has not occurred within 1 sec. 1. Harness is defective. Connector is not connected properly. 2. Pick up/ Regi. clutch is defective. 3. Main BLDC motor is defective. 4. Engine board is defective. |

| Remedy: | First, turn the machine off then on. If the error persists, refer to the following. 1. Check if the connector is connected properly. Reconnect it. 2. Pick up/ Regi clutch is defective. - Remove the Regi. clutch then warm up the machine. If the corresponding error has disappeared, Regi. clutch is defective. Replace the Regi. clutch. - Remove the pick up clutch then warm up the machine. If the corresponding error has disappeared, pick up clutch is defective. Replace the pick up clutch. 3. Pick up BLDC motor is defective. - Unplug all connectors on the Engine Board. - Remove the Engine board with the bracket. - Replace the BLDC motor with new one. 4. Engine Board is defective. - Unplug all connectors. - Replace the Engine board with new one after removing 4 screws. |

| Error code: | A1-3110 |

| Display: | Actuator Motor Failure #A1-3110 |

| Description: | After working the Deve BLDC motor, the Ready signal has not occurred within 1 sec. 1. Harness is defective. Connector is not connected properly. 2. Mag. Roller is overloaded. 3. Deve BLDC motor is defective. 4. Engine board is defective. |

| Remedy: | First, turn the machine off then on. If the error persists, refer to the following. 1. Check if the connector is connected properly. Reconnect it. 2. Mag roller in the imaging unit is overloaded. - Rotate the Mag roller. If there is any damage, the Mag roller can’t be rotated well. (Spec : 4kgf.cm) Replace the imaging unit. 3. Deve BLDC motor is defective. - Replace the BLDC motor with new one. 4. Engine Board is defective. - Unplug all connectors. - Replace the Engine board with new one after removing 4 screws. |

| Error code: | A2-1910 |

| Display: | Actuator Fan Failure: #A2-1910. Turn off then on. |

| Description: | The Main(SMPS) Fan does not work normally. 1. Fan Harness connection is bad. 2. Harness is defective or GND is short. 3. Fan is defective. |

| Remedy: | 1. Check if the Fan Relay connector is connected properly. 2. Connect the Harness Housing correctly. 3. Check if the Fan harness is normal. If it is defective, replace it. 4. Enter the Tech mode and execute the Main Fan test (EDC code : 100-0260 (SMPS FAN). To enter the Tech mode, press the button in this order. (Menu - # - 1 - 9 -3 -4 - OK ) |

| Error code: | A2-1920 |

| Display: | Actuator Fan Failure: #A2-1920. Turn off then on |

| Description: | The Rear Fan does not work normally. 1. Fan Harness connection is bad. 2. Harness is defective or GND is short. 3. Fan is defective. |

| Remedy: | 1. Check if the Fan Relay connector is connected properly. 2. Connect the Harness Housing correctly. 3. Check if the Fan harness is normal. If it is defective, replace it. 4. Enter the Tech mode and execute the Main Fan test (EDC code : 109-0042 (Rear FAN). To enter the Tech mode, press the button in this order. (Menu - # - 1 - 9 -3 -4 - OK ) |

| Error code: | A2-2410 |

| Display: | Actuator Fan Failure: #A2-2410. |

| Description: | The LSU Fan does not work. |

| Remedy: | 1. Check if there is any obstacle in LSU Fan. 2. Check if the harness is connected properly. 3. Check if the joint connector is connected properly. 4. Check if the harness is defective. 5. Enter the tech mode and execute the LSU fan test. 6. If the fan is defective, replace it. |

| Error code: | A3-2110 |

| Display: | Actuator Sensor Failure: #A3-2110. |

| Description: | ID control algorithm to control the density finds the ID Sensor value input in an abnormal state. 1. The image density of the imaging unit is abnormal. 2. ID sensor (CTD sensor) is defective. |

| Remedy: | 1. In case of density defect. Print the sample page. If the density is too low or dark, replace the imaging unit. 2. In case of ID sensor defect. Print the sample page. If the density is normal, replace the ID sensor or the sensor cleaning part. |

| Error code: | A3-5110 |

| Display: | Actuator Sensor Failure: #A3-5110. |

| Description: | The signal level of the Toner Empty sensor is 0V. |

| Remedy: | 1. Remove the Left cover. Check if the sensor connector of the WTB Pipe unit is connected properly. 2. If the harness is defective, replace it. |

| Error code: | C1-1110 |

| Display: | Prepare new yellow toner cartridge. |

| Description: | Toner remained is 5 - 30% of its life. |

| Causes: | Toner cartridge is almost empty. |

| Remedy: | 1) Open the front cover. 2) Remove the toner cartridge(MLT-D709S). (Toner cartridge with level of “Low” will be exhausted soon.) |

| Error code: | C1-1120 |

| Display: | Replace with new toner cartridge. |

| Description: | A toner cartridge has almost reached its estimated cartridge life. Status LED – Red is on. |

| Remedy: | 1. Turn the machine off and turn it on again. 2. Print the supply information report. Check the life remaining of the toner cartridge. If its life is at the end, turn the machine off and replace the toner cartridge with new one. |

| Error code: | C1-1140 |

| Display: | C1-1140 Replace with new toner cartridge |

| Description: | The toner cartridge is at the end of its life. |

| Remedy: | Replace the toner cartridge with new one. |

| Error code: | C1-1311, C1-1412, C1-1413 |

| Display: | Toner Failure: #C1-1311: Install toner again Did not supply enough toner. Reinstall it Shake toner cartridge and then install. Imaging Unit Failure #C3-1312: Install IMG. unit. Imaging Unit Failure #C3-1315: Install IMG. unit. |

| Description: | The imaging unit does not get enough toner from the toner cartridge. 1. The toner cartridge shutter does not work normally. 2. The imaging unit shutter does not work normally. 3. The toner cartridge seal is not removed. 4. The toner cartridge is not installed properly. 5. The toner is consumed quickly due to a defective image (Background etc.) |

| Remedy: | 1. Turn the machine off then on. 2. Remove the toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3. Try to print out the sample page more than 20 pages. 4. Check the toner cartridge. - Check if the toner supply shutter between the toner cartridge and the imaging unit works normally. - Remove the seal. Check if the auger rotates normally. - Reinstall the toner cartridge. 5. Replace the toner cartridge. Print out the sample page. 6. Check if the toner supply motor works normally. |

| Error code: | C1-1330, C1-1411 |

| Display: | Toner Failure: #C1-1330: Install toner again Toner cartridge is not installed. Install it |

| Description: | 1. The toner cartridge is not installed. 2. The toner cartridge is not installed properly. |

| Remedy: | 1. Install the genuine samsung toner cartridge. 2. If the toner cartridge is already installed, check the following. a. Reinstall the toner cartridge and imaging unit. b. Check If the CRUM contact is normal. c. After reinstallation, turn the machine off then on. |

| Error code: | C1-1512 |

| Display: | Toner cartridge is not compatible. Check users guide. |

| Description: | Toner cartridge is not compatible. Check users guide. |

| Causes: | Toner cartridge is not compatible. |

| Remedy: | 1) Print the supply information report. Check information of the toner cartridge. 2) If the toner cartridge is not a Samsung genuine toner cartridge, replace with new one. |

| Error code: | C3-1110, C3-1120, C3-1140 |

| Display: | Prepare new imaging unit Replace with new imaging unit Replace with new imaging unit |

| Description: | The remaining life of the imaging unit is less than 10% of its life. The remaining life of the imaging unit is less than 0% of its life. |

| Remedy: | Prepare the new imaging unit. |

| Error code: | C3-1312, C3-1315 |

| Display: | Toner Failure: #C1-1311: Install toner again Did not supply enough toner. Reinstall it Shake toner cartridge and then install. Imaging Unit Failure #C3-1312: Install IMG. unit. Imaging Unit Failure #C3-1315: Install IMG. unit. |

| Description: | The imaging unit does not get enough toner from the toner cartridge. 1. The toner cartridge shutter does not work normally. 2. The imaging unit shutter does not work normally. 3. The toner cartridge seal is not removed. 4. The toner cartridge is not installed properly. 5. The toner is consumed quickly due to a defective image (Background etc.) |

| Remedy: | 1. Turn the machine off then on. 2. Remove the toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3. Try to print out the sample page more than 20 pages. 4. Check the toner cartridge. - Check if the toner supply shutter between the toner cartridge and the imaging unit works normally. - Remove the seal. Check if the auger rotates normally. - Reinstall the toner cartridge. 5. Replace the toner cartridge. Print out the sample page. 6. Check if the toner supply motor works normally. |

| Error code: | C3-1320, C3-1330 |

| Display: | Imaging Unit Failure #C3-1320: Install IMG. unit. Imaging Unit Failure #C3-1330: Install IMG. unit. Imaging unit is not installed. Install the unit. Did not supply enough toner. Reinstall Toner |

| Description: | 1. The imaging unit is not installed. 2. The imaging unit is not installed properly. |

| Remedy: | 1. Install the samsung genuine imaging unit. 2. If the imaging unit is already installed, check the following. a. Reinstall the toner cartridge and imaging unit. b. Check If the CRUM contact is normal. c. After reinstallation, turn the machine off then on. |

| Error code: | C3-1321 |

| Display: | Imaging Unit Failure #C3-1321: Install IMG. unit. |

| Description: | The position of imaging unit is not normal position, or the imaging unit could not get the normal high voltage. 1. The imaging unit is not installed properly. 2. The contact between the machine and the imaging unit is bad. 3. The imaging unit is defective. 4. The high voltage power circuit or high voltage control circuit of machine is defective. |

| Remedy: | 1. Remove the imaging unit. Check if the contact terminal is contaminated. Reinstall the imaging unit, and turn the machine of then on. Print 10 sample pages for test. 2. If the problem persists, replace the imaging unit. 3. If the problem persists reinstall or replace the imaging unit, replace the HVPS board or the engine board. |

| Error code: | C3-1411, C3-1412 |

| Display: | Imaging Unit Failure #C3-1320: Install IMG. unit. Imaging Unit Failure #C3-1330: Install IMG. unit. Imaging unit is not installed. Install the unit. Did not supply enough toner. Reinstall Toner |

| Description: | 1. The imaging unit is not installed. 2. The imaging unit is not installed properly. |

| Remedy: | 1. Install the samsung genuine imaging unit. 2. If the imaging unit is already installed, check the following. a. Reinstall the toner cartridge and imaging unit. b. Check If the CRUM contact is normal. c. After reinstallation, turn the machine off then on. |

| Error code: | C3-1512, C3-1514 |

| Display: | Imaging unit is not compatible. Check guide Imaging unit is not compatible. Check guide |

| Description: | The imaging unit is not compatible. |

| Remedy: | 1. Check information of the imaging unit. 2. If the imaging unit is not a Samsung genuine imaging unit, replace with new one. |

| Error code: | C6-1110, C6-1120 |

| Display: | Prepare new fuser unit. Replace with new fuser unit. |

| Description: | Replace Fuser Soon Replace new Fuser unit |

| Causes: | The fuser unit is at the end of its life. |

| Remedy: | 1) Print the supply information report. Check the life remaining of the fuser unit. 2) If its life is at the end, turn the machine off and replace the fuser unit with new one. |

| Error code: | C7-1110, C7-1120 |

| Display: | Waste toner container is almost full. Replace with new one Waste toner container is almost full. Replace with new one |

| Description: | The waste toner container is full. |

| Remedy: | Replace the waste toner container with new one. |

| Error code: | C7-1310 |

| Display: | Install waste toner container. |

| Description: | The waste toner container is full. |

| Remedy: | Install the waste toner container. If the waste toner container is already installed, remove and reinstall it. |

| Error code: | H1-1210, H1-1310 |

| Display: | Paper Jam in Tray2 Paper Jam in Tray3 Paper Jam in Tray4 Paper Jam in Tray5 |

| Description: | A jammed paper has occurred in the option cassette. (SCF unit) |

| Remedy: | 1. Remove the jammed paper. If the problem persists, check the followings. 2. Check if the paper is loaded in the SCF tray properly. 3. Check if the roller is defective or worn out. 4. Check if the Empty/ Pick up/ Regi-Act sensor is working properly. 5. Check if the main board/ motor/ clutch connector are connected properly. 6. Check if the AS-SPRING_ES is deforemd or assembled properly. 7. Check if the Press D-cut of the Gear-Lifting is broken. 8. If the problem persists after checking No. 1-7, replace the SCF main board. 9. If the probelm persists, replace the Drop connector harness. |

| Error code: | H1-1222, H1-1322 |

| Display: | Tray2 cassette is pulled out. Insert it properly. Tray3 cassette is pulled out. Insert it properly. Tray4 cassette is pulled out. Insert it properly. Tray5 cassette is pulled out. Insert it properly. |

| Description: | A optional cassette (SCF) is pulled out. |

| Remedy: | 1. Check if the optional cassette is inserted propelry. Remove the cassette then re-install it. 2. Check if the Signal-Switch is deformed or broken. If it is defective, replace it. |

| Error code: | H1-1252, H1-1352 |

| Display: | Paper Empty in Tray# |

| Description: | Paper in the optional cassette is empty. |

| Remedy: | 1. Check if the paper in optional cassette is loaded. Load the paper. 2. Check if the empty actuator and empty senosr are assembled properly. 3. If the empty actuator is defective, replace it. 4. If the problem persists after replacing the empty actuator, replace the empty sensor. |

| Error code: | H1-1253, H1-1353 |

| Display: | Error : # |

| Description: | The paper in the optional cassette is not picked up. |

| Remedy: | 1. Check if the Gear-Idle Lift is broken. 2. Check if the Signal-Swtich is operated properly. If it is defective, replace it. 3. Check if the Lift-Motor connector is connected properly. 4. Check if the Press D-Cut of the Gear-Lifting is deformed or broken. 5. If the problem persists, replace the Lift-Motor. |

| Error code: | H1-1410, H1-1510 |

| Display: | Paper Jam in Tray2 Paper Jam in Tray3 Paper Jam in Tray4 Paper Jam in Tray5 |

| Description: | A jammed paper has occurred in the option cassette. (SCF unit) |

| Remedy: | 1. Remove the jammed paper. If the problem persists, check the followings. 2. Check if the paper is loaded in the SCF tray properly. 3. Check if the roller is defective or worn out. 4. Check if the Empty/ Pick up/ Regi-Act sensor is working properly. 5. Check if the main board/ motor/ clutch connector are connected properly. 6. Check if the AS-SPRING_ES is deforemd or assembled properly. 7. Check if the Press D-cut of the Gear-Lifting is broken. 8. If the problem persists after checking No. 1-7, replace the SCF main board. 9. If the probelm persists, replace the Drop connector harness. |

| Error code: | H1-1422, H1-1522 |

| Display: | Tray2 cassette is pulled out. Insert it properly. Tray3 cassette is pulled out. Insert it properly. Tray4 cassette is pulled out. Insert it properly. Tray5 cassette is pulled out. Insert it properly. |

| Description: | A optional cassette (SCF) is pulled out. |

| Remedy: | 1. Check if the optional cassette is inserted propelry. Remove the cassette then re-install it. 2. Check if the Signal-Switch is deformed or broken. If it is defective, replace it. |

| Error code: | H1-1452, H1-1552 |

| Display: | Paper Empty in Tray# |

| Description: | Paper in the optional cassette is empty. |

| Remedy: | 1. Check if the paper in optional cassette is loaded. Load the paper. 2. Check if the empty actuator and empty senosr are assembled properly. 3. If the empty actuator is defective, replace it. 4. If the problem persists after replacing the empty actuator, replace the empty sensor. |

| Error code: | H1-1453, H1-1553 |

| Display: | Error : # |

| Description: | The paper in the optional cassette is not picked up. |

| Remedy: | 1. Check if the Gear-Idle Lift is broken. 2. Check if the Signal-Swtich is operated properly. If it is defective, replace it. 3. Check if the Lift-Motor connector is connected properly. 4. Check if the Press D-Cut of the Gear-Lifting is deformed or broken. 5. If the problem persists, replace the Lift-Motor. |

| Error code: | H1-2210, H1-2310, H1-2410 |

| Display: | Paper Jam in HCF# |

| Description: | A jammed paper has occurred in the option cassette. (HCF unit) |

| Remedy: | 1. Remove the jammed paper. If the problem persists, check the followings. 2. Check if the paper is loaded in the HCF tray properly. 3. Check if the roller is defective or worn out. 4. Check if the Empty/ Pick up/ Regi-Act sensor is working properly. 5. Check if the main board/ motor/ clutch connector are connected properly. 6. PICK-UP-SPRING is deformed or assembled properly. 7. If the problem persists after checking No. 1-6, replace the HCF main board. 8. If the probelm persists, replace the Drop connector harness. |

| Error code: | H1-2222, H1-2322, H1-2422 |

| Display: | HCF 2 cassette Out HCF 3 cassette Out HCF 4 cassette Out |

| Description: | A optional cassette (HCF) is pulled out. |

| Remedy: | 1. Check if the Cover-Front Door is closed propelry. Open and Close it. 2. Check if the connector of the PBA-SUB Cover Open is connected properly. If it is defective, replace it. 3. If the connection is OK, replace the PBA-SUB Cover Open. |

| Error code: | H1-2252, H1-2352, H1-2452 |

| Display: | Paper Empty in HCF# |

| Description: | Paper in the optional cassette (HCF) is empty. |

| Remedy: | 1. Check if the paper in HCF Unit is loaded. Load the paper. 2. Check if the empty actuator and empty sensor are assembled properly. 3. If the empty actuator is defective, replace it. 4. If the problem persists after replacing the empty actuator, replace the empty sensor. |

| Error code: | H1-2253, H1-2353, H1-2453 |

| Display: | Error : # |

| Description: | The paper in the optional cassette is not picked up. |

| Remedy: | 1. Check if the Gear-Coupling and Gear-Lift are broken. 2. Check if the SPRING-ES and SPRING-CS are assembled propelry. 3. Check if the Lift-Motor connector is connected properly. 4. Check if the Press D-Cut of the Gear-Lifting is deformed or broken. 5. If the problem persists, replace the Lift-Motor. |

| Error code: | H2-1100 |

| Display: | Paper jam inside of finisher. Remove paper |

| Description: | Finisher Entrance sensor actuator does not return after a paper covers it IOT Exit Roller grabs the paper. Or Finisher Feeding Motors Stopped. Or Finisher Entrance Sensor damaged or harness damaged. Or Finisher Main Board damaged |

| Remedy: | 1. Check Jam Occurrence in IOT. - If the IOT roller is grabbing the paper, it’s IOT fault 2. Check the Main Board Harness Connection. 3. Check Finisher Entrance operation & harness connection. 4. Check Finisher Feeding Entrance Motor Harness Connection and operation. 5. Check Finisher Feeding Exit Motor Harness Connection and operation. 6. If the same problem happens after checking 1-5, Replace the Finisher main board. 7. If the same problem happens after checking 5, replace the Finisher harnesses. |

| Error code: | H2-1101 |

| Display: | Paper jam in front of finisher. Remove paper |

| Description: | Paper doesn’t reach Finisher’s Entrance Sensor. Paper jam in IOT. Or Finisher Diverter operation not well. Or IOT Defl ector Damaged. Or Finisher Entrance Sensor not working (Finisher Entrance Sensor Damaged, Harness connection not well, Main Board damaged) |

| Remedy: | 1. Check Jam Occurrence in IOT. 2. Check IOT Defl ector part’s operation. 3. Check the Main Board Harness Connection. 4. Check Finisher’s Entrance operation & harness connection 5. Referring to H2-1800, Check the Finisher Diverter operation. 6. If the same problem happens after checking 1-5, Replace the Finisher main board. 7. If the same problem happens after checking 6, replace the Finisher harnesses. |

| Error code: | H2-1102 |

| Display: | Paper jam inside of finisher. Remove paper |

| Description: | Initialization started with Jammed paper covering Finisher Entrance Sensor. Paper exists covering Finisher Entrance Sensor. Or Finisher Entrance Sensor Damaged or harness connection not well. Or Finisher Main Board damaged |

| Remedy: | 1. Check if there is a jammed paper inside Finisher. 2. Check the Main Board Harness Connection. 3. Check Finisher Entrance operation & harness connection. 4. If the same problem happens after checking 1-3, Replace the Finisher main board. 5. If the same problem happens after checking 4, replace the Finisher harnesses. |

| Error code: | H2-1200 |

| Display: | Paper jam inside of finisher. Remove paper |

| Description: | Finisher Exit Sensor doesn’t turn on after a paper entered Finisher. IOT Exit Roller grabs the paper. Or Finisher Feeding Motors Stopped. Or Finisher Exit Sensor damaged or harness damaged. Or Finisher Main Board damaged |

| Remedy: | 1. Check Jam Occurrence in IOT. - If the IOT roller is grabbing the paper, it’s IOT fault. 2. Check the Main Board Harness Connection. 3. Check Finisher Exit Sensor operation & harness connection. 4. Check Finisher Feeding Entrance Motor Harness Connection and operation. 5. Check Finisher Feeding Exit Motor Harness Connection and operation. 6. If the same problem happens after checking 1-5, Replace the Finisher main board. 7. If the same problem happens after checking 6, replace the Finisher harnesses. |

| Error code: | H2-1300 |

| Display: | Paper jam inside of finisher. Remove paper |

| Description: | Finisher Exit Sensor doesn’t turn off after the sensor turned on IOT Exit Roller grabs the paper. Or Finisher Feeding Motors Stopped. Or Finisher Exit Sensor damaged or harness damaged. Or Finisher Main Board damaged |

| Remedy: | 1. Check Jam Occurrence in IOT. - If the IOT roller is grabbing the paper, it’s IOT fault. 2. Check the Main Board Harness Connection. 3. Check Finisher Exit Sensor operation & harness connection. 4. Check Finisher Feeding Entrance Motor Harness Connection and operation. 5. Check Finisher Feeding Exit Motor Harness Connection and operation. 6. If the same problem happens after checking 1-5, Replace the Finisher main board. 7. If the same problem happens after checking 6, replace the Finisher harnesses. |

| Error code: | H2-1302 |

| Display: | Paper jam inside of finisher. Remove paper |

| Description: | Initialization started with Jammed paper covering Finisher Exit Sensor. Paper exists covering Finisher Exit Sensor. Or Finisher Exit Sensor Damaged or harness connection not well. Or Finisher Main Board damaged |

| Remedy: | 1. Check if there is a jammed paper on the feeding path of Finisher. 2. Check the Main Board Harness Connection. 3. Check Finisher Exit sensors’ operation & harness connection. 4. If the same problem happens after checking 1-3, Replace the Finisher main board. 5. If the same problem happens after checking 4, replace the Finisher harnesses. |

| Error code: | H2-1710, H2-1711 |

| Display: | Finisher Failure: #H2-1710. Check fi nisher Finisher Failure: #H2-1711. Check fi nisher |

| Description: | Front Jogger is not working well. Front Jogger Home Sensor, Front Jogger Motor Harness Connection not well or damaged, Main Board damaged. |

| Remedy: | 1. Check the Main Board Harness Connection. 2. Check the Finisher Front Jogger Home Sensor’s Harness Connection. 3. Check the Finisher Front Jogger Motor’s Harness Connection and operation. 4. Check if Front jogger part is contaminated. 5. If the same problem happens after checking 1-4, Replace the Finisher main board. 6. If the same problem happens after checking 5, Replace the Finisher harnesses. |

| Error code: | H2-1720, H2-1721 |

| Display: | Finisher Failure: #H2-1720. Check fi nisher Finisher Failure: #H2-1721. Check fi nisher |

| Description: | Rear Jogger is not working well. Rear Jogger Home Sensor, Rear Jogger Motor Harness Connection not well or damaged, Main Board damaged. |

| Remedy: | 1. Check the Main Board Harness Connection. 2. Check the Finisher Rear Jogger Home Sensor’s Harness Connection. 3. Check the Finisher Rear Jogger Motor’s Harness Connection and operation. 4. Check if Rear jogger part is contaminated. 5. If the same problem happens after checking 1-4, Replace the Finisher main board. 6. If the same problem happens after checking 5, Replace the Finisher harnesses. |

| Error code: | H2-1730, H2-1731 |

| Display: | Finisher Failure: #H2-1730. Check fi nisher Finisher Failure: #H2-1731. Check fi nisher |

| Description: | Support Finger (Extension Tray) is not working well. Support Finger Home Sensor, Support Finger Motor Harness Connection not well or damaged, Main Board damaged |

| Remedy: | 1. Check the Main Board Harness Connection. 2. Check the Finisher Support Finger Home Sensor’s Harness Connection. 3. Check the Finisher Support Finger Motor’s Harness Connection and operation. 4. If the same problem happens after checking 1-3, Replace the Finisher main board. 5. If the same problem happens after checking 4, Replace the Finisher harnesses. |

| Error code: | H2-1751, H2-1753 |

| Display: | Finisher Failure: #. Check fi nisher |

| Description: | Stapler is not working well. Stapler Harness Connection not well. Or Cartridge set sensors damaged, Or Main Board damaged. |

| Remedy: | NOTE - Make sure that the staple strips on top of the stack are complete and fl at. Remove any partial strips and any strips that are bent. 1. Check the Main Board Harness Connection. 2. Check the Stapler harness connection. 3. Check if staples are stuck in Stapler Head area and damage of Stapler itself. 4. If the same problem happens after checking 1-3, Replace the Finisher main board. 5. If the same problem happens after checking 4, Replace the Finisher Stapler. 6. If the same problem happens after checking 5, Replace the Finisher harnesses. |

| Error code: | H2-1752 |

| Display: | Finisher Failure: #H2-1752. Check finisher |

| Description: | Finisher compiles all the papers and moves them to stapling position and do nothing. the message “Stapler Safety Fault” pops up. Safety Switch Harness connection not well. Main Board damaged. |

| Remedy: | 1. Check the Main Board Harness Connection. 2. Check the Safety Switch Harness Connection. 3. Check the Safety Unit’s operation. Check the switch is clicked when the Safety Link moves. 4. Check the Safety Unit’s operation using Rear Jogger. The same “switch ON/OFF” operation should be followed. 5. Check the Safety Unit’s operation. When Rear Jogger stands at the position having the Shield and Rear Jogger met, the Safety Switch should be ON. 6. If the same problem happens after checking 1-5, Replace the Finisher main board. 7. If the same problem happens after checking 6, Replace the Finisher harnesses. |

| Error code: | H2-1760, H2-1A80 |

| Display: | Finisher Failure: #H2-1760. Check fi nisher Finisher Failure: #H2-1A80. Check fi nisher |

| Description: | Stacker Unit is not working. Stacker Level sensor, Stack Full sensor, Stacker Motor Harness Connection not well or damaged, Main Board damaged. |

| Remedy: | 1. Check the Main Board Harness Connection. 2. Check the Stacker Level Sensor’s Harness Connection and Actuator’s operation & its Spring behind the wall. 3. Check the Stacker Motor Harness Connection and operation. 4. Check the Stack Full Sensor Connection and operation. 5. If the same problem happens after checking 1-3, Replace the Finisher main board. 6. If the same problem happens after checking 4, replace the Finisher harnesses. |

| Error code: | H2-1800 |

| Display: | Finisher Failure: #H2-1800. Check fi nisher sens |

| Description: | Diverter is not working. Diverter Motor, Sensor Harness Connection not well or damaged. Main Board Damaged. IOT’s Defl ector damaged. |

| Remedy: | 1. Check the Main Board Harness Connection. 2. Check the IOT’s Defl ector operation. 3. Check Diverter sensor harness connection. 4. Diverter Motor Harness Connection and operation. 5. Check if Diverter Unit is not contaminated. 6. If the same problem happens after checking 1-5, Replace the Finisher main board. 7. If the same problem happens after checking 6, replace the Finisher harnesses. |

| Error code: | H2-1A20 |

| Display: | Finisher door is open. Close it |

| Description: | Finisher Motors doesn’t work. Jam Cover Opened, Jam Cover not assembled well or Jam Cover Flag damaged, Stapler Door Opened, Stapler Door Micro Switch not assembled well or Stapler Door Flag damaged, Harness Damaged. Main Board Damaged, door fl ag damaged. |

| Remedy: | 1. Check the Jam Cover and Stapler Door Closed fi rmly. 2. Check if Mounting Part not damaged - Male part in Finisher - Female part in IOT 3. Check the Main Board Harness Connection. 4. Check the Stapler Door Switch Harness Connection. 5. Check the Stapler Door fl ag damaged. 6. Check the Jam Cover Sensor Harness connection. 7. Check the Jam Cover fl ag damaged 8. If the same problem happens after checking 1-7, Replace the Finisher main board. 9. If the same problem happens after checking 8, replace the Finisher harnesses. |

| Error code: | H2-1A32 |

| Display: | Too much paper in finisher stacker. Remove printed paper |

| Description: | Finisher Full message pops when papers on the Stacker Tray are stacked fully or the full sensor detecting mechanism is out of order Finisher Full detecting sensor damaged, harness connection not well or damaged, Main Board damaged. |

| Remedy: | 1. Check the Stacker Tray’s Full Sensor Connection and check if Flag is damaged - The sensor must not be covered besides the full detecting fl ag. 2. Check Finisher Main Board Harness Connection. 3. If the same problem happens after checking 1-2, Replace the Finisher main board. 4. If the same problem happens after checking 3, Replace the Finisher harnesses. |

| Error code: | H2-1A50 |

| Display: | Finisher Failure: #H2-1A50. Check finisher |

| Description: | Finisher doesn’t work because of Communication error between finisher and IOT. Interface Cable Connection not well or Interface Cable(Harness) damaged, Main Board damaged. |

| Remedy: | 1. Check if Mounting Part not damaged - Male part in Finisher - Female part in IOT 2. Check the Main Board Harness Connection. 3. If the same problem happens after checking 1-2, Replace the Finisher main board.. 4. If the same problem happens after checking 3, Replace the Finisher harnesses |

| Error code: | H2-1A62 |

| Display: | Staple cartridge is low. Replace it |

| Description: | No more stapling job will not be performed if the near empty Stapler Cartridge will not be replaced soon. The staples in Staple Cartridge are going to a shortage. Or Stapler harness connection now well. Or Stapler set sensors damaged, Main Board damaged. |

| Remedy: | 1. Check if staples in cartridge are in some level. - With such level like the below picture during jobs, The sensor detects it as “Low”. Only twenty more stapling jobs can be performed normally. NOTE - Make sure that the staple strips on top of the stack are complete and fl at. Remove any partial strips and any strips that are bent. 2. If the Cartridge is not low after checking with your naked eyes, Check the Stapler Harness connection 3. Check the Cartridge Set sensor’s operation. 4. Check the Main Board Harness connection. 5. If the same problem happens after checking 1-4, replace the Finisher main board. 6. If the same problem happens after checking 5, replace the Finisher Stapler. 7. If the same problem happens after checking 6, replace the Finisher harnesses. |

| Error code: | H2-1A63 |

| Display: | Staple cartridge is empty. Replace it |

| Description: | Finisher doesn’t staple. Staple Cartridge is not inserted Or Staples are in short supply. Or Stapler Harness connection not well. Or Cartridge set sensor damaged, Or Main Board damaged. |

| Remedy: | 1. Check if Cartridge exists. 2. Check if Cartridge is inserted fi rmly. 3. Check if staples in cartridge are in some level. - With such level like the below picture or lower during POPO(Power off power on), The sensor detects it “empty”. NOTE - Make sure that the staple strips on top of the stack are complete and fl at. Remove any partial strips and any strips that are bent. 4. Check the Stapler harness connection. 5. Check the Cartridge Set sensors’ operation. 6. Check the Main Board Harness Connection. 7. If the same problem happens after checking 1-6, replace the Finisher main board. 8. If the same problem happens after checking 7, replace the Finisher Stapler. 9. If the same problem happens after checking 8, replace the Finisher harnesses. |

| Error code: | H2-1A70, H2-1750 |

| Display: | Finisher Failure: #. Check fi nisher |

| Description: | Stapler is not working well. Stapler Harness Connection not well. Or Cartridge set sensors damaged, Or Main Board damaged. |

| Remedy: | NOTE - Make sure that the staple strips on top of the stack are complete and fl at. Remove any partial strips and any strips that are bent. 1. Check the Main Board Harness Connection. 2. Check the Stapler harness connection. 3. Check if staples are stuck in Stapler Head area and damage of Stapler itself. 4. If the same problem happens after checking 1-3, Replace the Finisher main board. 5. If the same problem happens after checking 4, Replace the Finisher Stapler. 6. If the same problem happens after checking 5, Replace the Finisher harnesses. |

| Error code: | H2-4100 |

| Display: | Paper jam in front of mailbox. Remove paper. |

| Description: | Paper doesn’t reach Mailbox’s Entrance Sensor. Paper jam in IOT. Or Mailbox Lower Diverter operation not well. Or IOT Defl ector Damaged. Or Mailbox Entrance Sensor not working (Mailbox Entrance Sensor Damaged, Harness connection not well, MainBoard damaged) |

| Remedy: | 1. Check Jam Occurrence in IOT. 2. Check IOT Defl ector part’s operation. 3. Check Mailbox Main Board Harness connection. 4. Check Mailbox Entrance operation & harness connection. 5. Refer to the Lower Diverter fault. 6. If the same problem happens after checking 1-5, Replace the mailbox main board. 7. If the same problem happens after checking 6, Replace the mailbox harnesses. |

| Error code: | H2-4101 |

| Display: | Paper jam inside of mailbox. Remove paper |

| Description: | Mailbox Entrance sensor actuator does not return after a paper covers it. IOT Exit Roller grabs the paper. Or Mailbox Feeding Motor Stops. Or Mailbox Entrance Sensor damaged or harness damaged. Or Mailbox Main Board damaged. |

| Remedy: | 1. Check Jam Occurrence in IOT. - If the IOT roller is grabbing the paper, it’s IOT fault. 2. Check Mailbox Main Board Harness connection. 3. Check Mailbox Entrance operation & harness connection. 4. Check Mailbox Feeding Motor Harness connection and operation. 5. If the same problem happens after checking 1-4, replace the mailbox main board. 6. If the same problem happens after checking 5, replace the mailbox harnesses. |

| Error code: | H2-4102 |

| Display: | Paper jam inside of mailbox. Remove paper |

| Description: | Initialization started with Jammed paper covering Mailbox Entrance Sensor. Paper exists covering Mailbox Entrance Sensor. Or Mailbox Entrance Sensor Damaged or harness connection not well. Or Mailbox Main Board damaged. |

| Remedy: | 1. Check if there is a jammed paper inside Mailbox. 2. Check Mailbox Main Board Harness connection. 3. Check Mailbox Entrance operation & harness connection. 4. If the same problem happens after checking 1-3, replace the mailbox main board. 5. If the same problem happens after checking 4, replace the mailbox harnesses. |

| Error code: | H2-4200 |

| Display: | Paper jam in front of bin 1. Remove paper |

| Description: | Mailbox Bin 1 Exit Sensor doesn’t turn on after a paper entered Mailbox. IOT Exit Roller grabs the paper. Or Mailbox Feeding Motor Stops. Or Mailbox Entrance Exit Sensor damaged or Mailbox Gate doesn’t work or harness damaged. Or Mailbox Main Board damaged. |

| Remedy: | 1. Check Jam Occurrence in IOT. - If the IOT roller is grabbing the paper, it’s IOT fault. 2. Check Mailbox Main Board Harness connection. 3. Check Mailbox Exit-related Sensors operation & harness connection. 4. Check Mailbox Feeding Motor Harness Connection and operation. 5. Referring to Upper Diverter Fault, check the Upper Diverter’s operation. 6. Referring to Lower Diverter Fault, check the Lower Diverter’s operation 7. If the same problem happens after checking 1-6, replace the mailbox main board. 8. If the same problem happens after checking 7, replace the mailbox harnesses. |

| Error code: | H2-4201 |

| Display: | Paper jam at mailbox bin 1. Remove paper |

| Description: | Mailbox Bin 1 Exit Sensor doesn’t turn off after the sensor turned on. IOT Exit Roller grabs the paper. Or Mailbox Feeding Motor Stops. Or Mailbox Entrance Exit Sensor damaged or Mailbox Gate doesn’t work or harness damaged. Or Mailbox Main Board damaged. |

| Remedy: | 1. Check Jam Occurrence in IOT. - If the IOT roller is grabbing the paper, it’s IOT fault. 2. Check Mailbox Main Board Harness connection. 3. Check Mailbox Exit-related Sensors operation & harness connection. 4. Check Mailbox Feeding Motor Harness Connection and operation. 5. Referring to Upper Diverter Fault, check the Upper Diverter’s operation. 6. Referring to Lower Diverter Fault, check the Lower Diverter’s operation 7. If the same problem happens after checking 1-6, replace the mailbox main board. 8. If the same problem happens after checking 7, replace the mailbox harnesses. |

| Error code: | H2-4202 |

| Display: | Paper jam at mailbox bin 1. Remove paper |

| Description: | Initialization started with Jammed paper covering Mailbox Bin1 Exit Sensor. Paper exists covering Mailbox Exit Sensor. Or Mailbox Exit Sensor Damaged or harness connection not well. Or Mailbox Main Board damaged. |

| Remedy: | 1. Check if there is a jammed paper on the feeding path of Mailbox. 2. Check Mailbox Main Board Harness connection. 3. Check Mailbox Bin1 Exit-related sensors’ operation & harness connection. 4. If the same problem happens after checking 1-3, replace the mailbox main board. 5. If the same problem happens after checking 4, replace the mailbox harnesses. |

| Error code: | H2-4300 |

| Display: | Paper jam in front of bin 2. Remove paper |

| Description: | Mailbox Bin 2 Exit Sensor doesn’t turn on after a paper entered Mailbox. IOT Exit Roller grabs the paper. Or Mailbox Feeding Motor Stops. Or Mailbox Entrance Exit Sensor damaged or Mailbox Gate doesn’t work or harness damaged. Or Mailbox Main Board damaged. |

| Remedy: | 1. Check Jam Occurrence in IOT. - If the IOT roller is grabbing the paper, it’s IOT fault. 2. Check Mailbox Main Board Harness connection. 3. Check Mailbox Exit-related Sensors operation & harness connection. 4. Check Mailbox Feeding Motor Harness Connection and operation. 5. Referring to Upper Diverter Fault, check the Upper Diverter’s operation. 6. Referring to Lower Diverter Fault, check the Lower Diverter’s operation 7. If the same problem happens after checking 1-6, replace the mailbox main board. 8. If the same problem happens after checking 7, replace the mailbox harnesses. |

| Error code: | H2-4301 |

| Display: | Paper jam in front of bin 2. Remove paper |

| Description: | Mailbox Bin 2 Exit Sensor doesn’t turn off after the sensor turned on. IOT Exit Roller grabs the paper. Or Mailbox Feeding Motor Stops. Or Mailbox Entrance Exit Sensor damaged or Mailbox Gate doesn’t work or harness damaged. Or Mailbox Main Board damaged. |

| Remedy: | 1. Check Jam Occurrence in IOT. - If the IOT roller is grabbing the paper, it’s IOT fault. 2. Check Mailbox Main Board Harness connection. 3. Check Mailbox Exit-related Sensors operation & harness connection. 4. Check Mailbox Feeding Motor Harness Connection and operation. 5. Referring to Upper Diverter Fault, check the Upper Diverter’s operation. 6. Referring to 12-945, 12-955 Check the Lower Diverter’s operation 7. If the same problem happens after checking 1-6, replace the mailbox main board. 8. If the same problem happens after checking 7, replace the mailbox harnesses. |

| Error code: | H2-4302 |

| Display: | Paper jam at mailbox bin 2. Remove paper |

| Description: | Initialization started with Jammed paper covering Mailbox Bin2 Exit Sensor. Paper exists covering Mailbox Exit Sensor. Or Mailbox Exit Sensor Damaged or harness connection not well. Or Mailbox Main Board damaged. |

| Remedy: | 1. Check if there is a jammed paper on the feeding path of Mailbox. 2. Check Mailbox Main Board Harness connection. 3. Check Mailbox Bin2 Exit-related sensors’ operation & harness connection. 4. If the same problem happens after checking 1-3, replace the mailbox main board. 5. If the same problem happens after checking 4, replace the mailbox harnesses. |

| Error code: | H2-4400 |

| Display: | Paper jam in front of bin 3. Remove paper |

| Description: | Mailbox Bin 3 Exit Sensor doesn’t turn on after a paper entered Mailbox. IOT Exit Roller grabs the paper. Or Mailbox Feeding Motor Stops. Or Mailbox Entrance Exit Sensor damaged or Mailbox Gate doesn’t work or harness damaged. Or Mailbox Main Board damaged. |