Samsung MultiXpress M4370LX

Рейтинг

Снят с производства

Снят с производства

Тип устройства

МФУ

Технология печати

лазерная

Макс. формат

A4

Число страниц в месяц

250000

Скорость печати

A4

43

Цветность печати

черно-белая

Общие характеристики |

|

|---|---|

Технология печати |

лазерная |

Тип |

лазерный/светодиодный |

Цветность печати |

|

Область применения |

большой офис |

Число страниц в месяц |

250 000 |

Размещение |

настольный |

Макс. формат |

A4 |

Факс |

|

Телефон |

|

Печать фотографий |

|

Сканер |

|

Копир |

|

Тип устройства |

МФУ |

Принтер |

|

Прямая печать |

|

Двусторонняя печать |

|

Пигментные чернила |

|

Печать без полей |

|

Макс, разрешение для ч/б печати |

|

| По X | 1 200 |

| По Y | 1 200 |

Скорость ч/б печати |

|

| A4 | 43 |

Время выхода первого отпечатка |

|

| Ч/б | 8 |

Копир |

|

Макс, количество копий за цикл |

9 999 |

Время выхода первой копии |

5 |

Значение масштаба |

|

| Минимальное | 0,25 |

| Максимальное | 4 |

Макс, разрешение (ч/б) |

|

| По X | 1 200 |

| По Y | 600 |

| По Y | 1 200 |

Сканер |

|

Тип сканера |

планшетный/протяжный |

Устройство автоподачи оригиналов |

двустороннее |

Стандарт WIA |

|

Слайд-адаптер |

|

Отправка изображения по e-mail |

|

Стандарт TWAIN |

|

Емкость устройства автоподачи оригиналов |

100 |

Макс. формат оригинала |

A4 |

Разрешение сканера |

|

| По Y (улучшенное) | 4 800 |

| По Х (улучшенное) | 4 800 |

| По Х | 600 |

Расходные материалы |

|

Количество картриджей |

1 |

Ресурс фотобарабана |

100 000 |

Ресурс ч/б картриджа/тонера |

30 000 |

Печать на: |

|

| Карточках |

|

| Матовой бумаге |

|

| Конвертах |

|

| Глянцевой бумаге |

|

| Этикетках |

|

| Фотобумаге |

|

| CD/DVD |

|

| Рулоне |

|

| Пленках |

|

Плотность бумаги |

|

| Максимальная | 163 |

| Минимальная | 60 |

Факс |

|

PC Fax |

|

Цветной |

|

Телефон |

|

Проводная трубка |

|

Беспроводная трубка |

|

Стандарт DECT |

|

Спикерфон |

|

Автоответчик |

|

Caller ID |

|

АОН |

|

Языки управления |

|

| PostScript |

|

| PostScript 3 |

|

|

|

|

| PCL 5c |

|

| PCL 6 |

|

| PostScript 2 |

|

| PCL 5e |

|

| PPDS |

|

Лотки |

|

Емкость лотка ручной подачи |

100 |

Подача бумаги |

|

| Максимальная | 3 240 |

| Стандартная | 620 |

Финишер |

|

Степлер |

|

Сортер |

|

Электронная сортировка |

|

Сортировка со сдвигом |

|

Брошюровщик |

|

Интерфейсы |

|

Версия USB |

2,0 |

Ethernet (RJ-45) |

|

USB |

|

AirPrint |

|

Веб-интерфейс |

|

LPT |

|

Устройство для чтения карт памяти |

|

FireWire (IEEE 1394) |

|

Bluetooth |

|

Wi-Fi 802.11n |

|

Wi-Fi |

|

RS-232 |

|

Инфракрасный порт |

|

Память/Процессор |

|

Емкость жесткого диска |

320 |

Макс, объем памяти |

2 048 |

Объем памяти |

2 048 |

Дополнительная информация |

|

Диагональ дисплея |

10,1 |

Экран |

|

Работа от аккумулятора |

|

Поддержка ОС |

|

| Linux |

|

| Windows |

|

| Mac OS |

|

| DOS |

|

Потребляемая мощность |

|

| В режиме ожидания | 1,5 |

| При работе | 800 |

Уровень шума |

|

| При работе | 58 |

| В режиме ожидания | 37 |

Габариты |

|

Глубина |

506 |

Высота |

636 |

Вес |

49 |

Ширина |

630 |

Модули

COVER

COVER-HOUSING SIDE

FRAME-HOUSING PLATE UPPER

FRAME-HOUSING MAIN

ELA HOU-DUPLEX

DSDF-FRAME MAIN

DUPLEX SUB-SIDE

CASSETTE

Frame-Base

Fuser

Exit

DSDF

MAIN

PLATEN

DRIVE-FUSER

FRAME-HOUSING MP

FRAME-HOUSING BASE

DRIVE-MAIN

DSDF-OPEN

DSDF-PLATEN

FRAME

Детали ELA HOU-DUPLEX

| Деталь: | COVER-UNIT TOP, M5370,SEC |

| Парткод: | JC95-01915A |

| Деталь: | COVER-LEFT TOP, M5370,HIPS,Split Gray,HIP |

| Парткод: | JC63-04458A |

| Деталь: | COVER-EXIT BOTTOM, M5370,SEC |

| Парткод: | JC95-01914A |

| Деталь: | COVER-FRONT TOP, M5370,ABS,Split Brown Bl |

| Парткод: | JC63-04457A |

| Деталь: | COVER-FRONT, M5370,SEC |

| Парткод: | JC95-01897A |

| Деталь: | COVER-INNER FRONT, M5370,SEC |

| Парткод: | JC95-01917A |

| Деталь: | COVER-PORT, M5370,SEC |

| Парткод: | JC95-01918A |

| Деталь: | COVER-REAR, M5370,SEC |

| Парткод: | JC95-01916A |

| Деталь: | MEA UNIT-COVER UPPER, SCX-6345N/XRX,SEC,- |

| Парткод: | JC97-02274B |

| Деталь: | ELA HOU-GUIDE SIDE, SCX-6555N,SEC,-,-,-,- |

| Парткод: | JC96-04897A |

| Деталь: | FAN-TYPE 5, Type5,24,170mA,4.0mmH20,0.433 |

| Парткод: | JC31-00160A |

| Деталь: | FAN-TYPE 8, Type8,24,220mA,1.388m3/mi |

| Парткод: | JC31-00162A |

| Деталь: | LOCKER-M_FRONT, SCX-6345N/XRX,POM,BLACK,H |

| Парткод: | JC64-00198A |

| Деталь: | SPRING ETC-LOCKER TORSION, SCX-5100,SUS30 |

| Парткод: | JC61-00479A |

| Деталь: | SHAFT-HANDLE, SCX-6345N/XRX,POSCUT,L356.2 |

| Парткод: | JC66-00935A |

| Деталь: | LOCKER-M_REAR, SCX-6345N/XRX,POM,BLACK,HB |

| Парткод: | JC64-00199A |

| Деталь: | BRACKET-COVER DUP, ML-9400W,PC/ABS |

| Парткод: | JC61-00175A |

| Деталь: | ROLLER-DUPLEX, SCX-6345N,EPDM,SUM22,6 |

| Парткод: | JC66-00969A |

| Деталь: | BRACKET-P-DUPLEX, SCX-6345N/XRX,SECC,0.50 |

| Парткод: | JC61-01334A |

| Деталь: | ROLLER-DUPLEX READY, SCX-6345N,EPDM,SUM22 |

| Парткод: | JC66-00970A |

| Деталь: | GROUND-P-DUPLEX, SCX-6345N/XRX,STAINLESS- |

| Парткод: | JC63-00784A |

| Деталь: | BELT-TIMING GEAR, RUBBER,T1.36,40S2M338,3 |

| Парткод: | 6602-001092 |

| Деталь: | CLUTCH-2.5K Z24, CLX-8380ND/XAA,POM+METAL |

| Парткод: | JC66-01837A |

| Деталь: | OTHER MECHA-M COLLAR DP, SCX-6345N/XRX,PO |

| Парткод: | JC67-00116A |

| Деталь: | COVER-SIDE, M5370,HIPS,Split Gray,HIPS-51 |

| Парткод: | JC63-04472A |

| Деталь: | MOTOR DC, HF283LG,DC24V,CLX-8380ND/XAA,79 |

| Парткод: | JC31-00094A |

| Деталь: | GEAR-IDLE ENV, SCX-6555N,POM,0.4/0.7,70/1 |

| Парткод: | JC66-01665A |

| Деталь: | GEAR-CAM REAR, SCX-6555N,PC,0.7,14,BLK,SP |

| Парткод: | JC66-01684A |

| Деталь: | GEAR-DRIVE REAR, SCX-6555N,POM,0.4/0.6,20 |

| Парткод: | JC66-01685A |

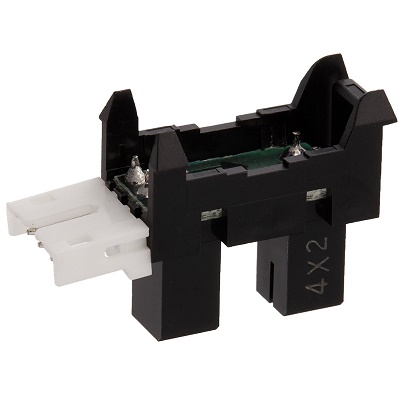

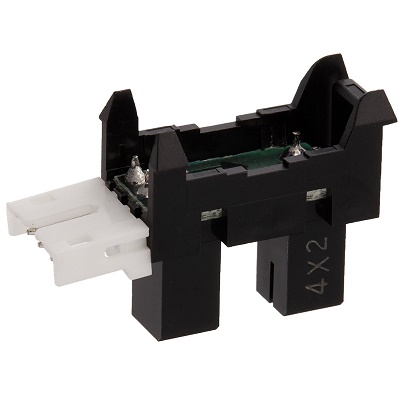

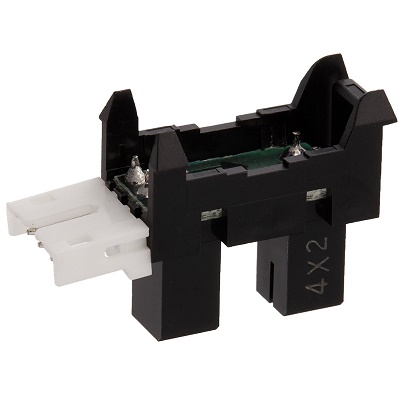

| Деталь: | PHOTO-INTERRUPTER, TR,DIP-4,BK |

| Парткод: | 0604-001415 |

| Цена: | 240 ₽ |

| Деталь: | LEG-M_ACTUATOR DUPLEX, SCX-6345N/XRX,PC,2 |

| Парткод: | JC61-01336A |

| Деталь: | LEVER-GEAR FRONT, SCX-6555N,PC,BLACK,LINK |

| Парткод: | JC66-01686A |

| Деталь: | GUIDE-M_SIDE, SCX-6345N/XRX,ABS+PC,T2.5,2 |

| Парткод: | JC61-01289A |

| Деталь: | PLATE-P-BEAM BASE, SCX-6345N/XRX,EGI-SECC |

| Парткод: | JC61-01312A |

| Деталь: | HOUSING-BASE LEFT, ABS,split gray,HF-0660 |

| Парткод: | JC61-01342C |

| Деталь: | ELA HOU-PICK UP, SCX-6555N,SEC,ASSY SPEAK |

| Парткод: | JC96-05046A |

| Деталь: | HARNESS-SCF_EMPTY, Rushmore,UL10272,8P,3P |

| Парткод: | JC39-00794A |

| Деталь: | PHOTO-INTERRUPTER, TR,DIP-4,BK |

| Парткод: | 0604-001415 |

| Цена: | 240 ₽ |

| Деталь: | HARNESS-MOTOR_SW, Rushmore,UL10272,2P,300 |

| Парткод: | JC39-00833A |

| Деталь: | LEG-M_ACT NO PAPER, SCX-6345N/XRX,ABS,2,3 |

| Парткод: | JC61-01350A |

| Деталь: | MEA UNIT-ROLLER PU, SCX-6345N/XRX,XEROX,- |

| Парткод: | JC97-02259A |

| Цена: | 240 ₽ |

| Деталь: | GEAR-M_PU JOINT, SCX-6345N/XRX,POM,0.7,21 |

| Парткод: | JC66-00943A |

| Деталь: | GEAR-M_IDLE PU, SCX-6345N/XRX,POM,0.7,22, |

| Парткод: | JC66-00940A |

| Деталь: | MEA UNIT-IDLE FORWARD, SCX-6345N/XRX,XERO |

| Парткод: | JC97-02292A |

| Деталь: | MEA UNIT-GEAR ONE WAY, SCX-6345N/XRX,XERO |

| Парткод: | JC97-02291A |

| Деталь: | GUIDE-M_UPPER PICK UP, SCX-6345N/XRX,PC,T |

| Парткод: | JC61-01299A |

| Деталь: | FAN, SCX-6555N,PBT+GF,HNS100mm,24,150mA |

| Парткод: | JC31-00099A |

| Деталь: | DUCT-M_FAN LSU, SCX-6345N/XRX,ABS ,T1.5,W |

| Парткод: | JC67-00127A |

| Деталь: | HOLDER-FUSER LAMP, SCX-6555N,PC,T2,BLK |

| Парткод: | JC61-02257A |

| Деталь: | FRAME-M_COVER REAR, SCX-6345N/XRX,ABS,HB, |

| Парткод: | JC61-01316A |

| Деталь: | MEA UNIT-DAMPER,L, SCX-6345N/XRX,XEROX,DA |

| Парткод: | JC97-02301A |

| Деталь: | ROLLER-IDLE REGI, SCX-6345N,SUM22,15 |

| Парткод: | JC66-01028A |

| Деталь: | ROLLER FEED-REGI, M5370,EPDM,SUM22,6 |

| Парткод: | JC66-04242A |

| Деталь: | FRAME-HOUSING CVR OPN, M5370,SEC |

| Парткод: | JC93-00888A |

| Деталь: | FRAME-HOUSING TERMINAL, M5370,SEC |

| Парткод: | JC93-00899A |

| Деталь: | PBA-TCRUM_IF, SCX-6555N,SEC,EXPORT,-,-,-, |

| Парткод: | JC92-01963A |

| Деталь: | HOLDER-TONER CRUM, SCX-6555N,PC+ABS,BLK,V |

| Парткод: | JC61-02422A |

| Деталь: | GROUND-P-P FUSER, SCX-6345N/XRX,STS301,0. |

| Парткод: | JC63-00797A |

| Деталь: | GROUND-P-MAIN DRIVE L, SCX-6345N/XRX,STS3 |

| Парткод: | JC63-00799A |

| Деталь: | GROUND-P-OPC CONTACT, SCX-6345N/XRX,PBS-C |

| Парткод: | JC63-00802A |

| Деталь: | GROUND-P-OPE REAR, SCX-6345N/XRX,PBS-C521 |

| Парткод: | JC63-00800A |

| Деталь: | MEA UNIT-REGI F, SCX-6345N/XRX,XEROX,-,RE |

| Парткод: | JC97-02262A |

| Деталь: | MEA UNIT-REGI R, SCX-6345N/XRX,XEROX,-,RE |

| Парткод: | JC97-02261A |

| Деталь: | GUIDE-P-TR, SCX-6345N/XRX,SECC,T0.5,233mm |

| Парткод: | JC61-01290A |

| Деталь: | GUIDE-M_FEED, SCX-6345N/XRX,ABS,T2.5,287m |

| Парткод: | JC61-01292A |

| Деталь: | HOLDER-M_SAW, SCX-6345N/XRX,PC,T1.5,243,1 |

| Парткод: | JC61-01407A |

| Деталь: | CORE ROTOR, SCX-6320F,STAINLESS-STS304,0. |

| Парткод: | JC70-10232D |

| Деталь: | GUIDE-EARTH TR, SCX-6555N,SECC,T1,PATH |

| Парткод: | JC61-02760A |

| Деталь: | SPRING ETC-SPRING ETC FEED, ML-5000A,SUS3 |

| Парткод: | JC61-70959A |

| Деталь: | FRAME-ID SENSOR, SCX-6555N,SEC |

| Парткод: | JC96-05348B |

| Деталь: | BRUSH-ANTISTATIC, SCX-6445,SUS FIBER,0.05 |

| Парткод: | JC67-00694A |

| Деталь: | GUIDE-M_DUPLEX, SCX-6345N/XRX,ABS+PC,T2.5 |

| Парткод: | JC61-01293A |

| Деталь: | ROLLER-M IDLE JF, SCX-6345N,POM |

| Парткод: | JC66-01013A |

| Деталь: | TERMINAL-S_IDLE, SCX-6345N/XRX,SUS304WPB, |

| Парткод: | JC65-00012A |

| Деталь: | SENSOR-CTD, SENSOR-CTD,0 60,5V,6.62mA,r |

| Парткод: | JC32-00014A |

| Деталь: | HOLDER, SCX-6555N,PC,BLK,NH-1035 |

| Парткод: | JC61-02753A |

| Деталь: | HARNESS-CTD, Rushmore,UL10272,4p, 5P,GRAY |

| Парткод: | JC39-00797A |

| Деталь: | SPRING-TS, STAINLESS-STS304,0.35,ID4.6,OD |

| Парткод: | 6107-001261 |

| Деталь: | HOLDER-CTD, SCX-6555N,ABS,BLK |

| Парткод: | JC61-02259A |

| Деталь: | DADF-PICK UP, M5370 |

| Парткод: | JC97-04428A |

| Деталь: | DADF-GUIDE PICK UP, CLX-8650ND,SEE |

| Парткод: | JC97-04103A |

| Деталь: | DSDF-CCDM, M5370,SEC |

| Парткод: | JC97-04571A |

| Деталь: | BELT-TIMING GEAR, 40S2M326,RUBBER,0.6,326 |

| Парткод: | 6602-003273 |

| Деталь: | CLUTCH-ELECTRIC, 2.5,24,1,120mA,200Ohm |

| Парткод: | JC47-00033A |

| Цена: | 1 200 ₽ |

| Деталь: | BELT-TIMING GEAR, 80S2M264,RUBBER,0.6,264 |

| Парткод: | 6602-003272 |

| Деталь: | BELT-TIMING GEAR, 60S2M138,RUBBER,0.6,138 |

| Парткод: | 6602-003271 |

| Деталь: | BELT-TIMING GEAR, 40S2M134,RUBBER,0.6,134 |

| Парткод: | 6602-003274 |

| Деталь: | PHOTO-INTERRUPTER, TR,DIP-4,BK |

| Парткод: | 0604-001415 |

| Цена: | 240 ₽ |

| Деталь: | MOTOR STEP 1P, 24V,1.3A |

| Парткод: | JC31-00163A |

| Деталь: | GUIDE-EXIT UPPER, CLX-8650ND,ABS,2,44.7,2 |

| Парткод: | JC61-05292A |

| Деталь: | DADF-GUIDE FEED IN, CLX-8650ND,SEE |

| Парткод: | JC97-04102A |

| Деталь: | FRAME-BRIDGE EXIT, CLX-8650ND,EGI-SECC,1. |

| Парткод: | JC61-05307A |

| Деталь: | GUIDE-REGI, CLX-8650ND,ABS,77.1,235.5,BLA |

| Парткод: | JC61-05295A |

| Деталь: | DADF-GUIDE EXIT LOWER, CLX-8650ND,SEE |

| Парткод: | JC97-04104A |

| Деталь: | DSDF-PICK UP ROLLER, CLX-8650ND,SEC |

| Парткод: | JC97-04099A |

| Деталь: | PAD-GUIDE PICKUP, SCX-6555N,Urethan Spong |

| Парткод: | JC69-01326A |

| Деталь: | DAMPER-RETARD MP, CLX-8650ND,NBR,1.1,21.1 |

| Парткод: | JC66-03759A |

| Деталь: | DADF-RETARD ROLLER, CLX-8650ND,SEE |

| Парткод: | JC97-04135A |

| Деталь: | STOPPER-PICK UP, CLX-8650ND,ABS+PC,37.6,1 |

| Парткод: | JC61-05363A |

| Деталь: | DSDF-SEPARATION SUB ROLLER, CLX-8650ND,SE |

| Парткод: | JC97-04148A |

| Деталь: | CAP-M_SIDE, SCX-6345N/XRX,ABS,T2,354.9mm, |

| Парткод: | JC67-00112A |

| Деталь: | MP SUB-SIDE, M5370,SEC |

| Парткод: | JC90-01269A |

| Деталь: | COVER-HOUSING SIDE, M5370,SEC |

| Парткод: | JC95-01922A |

| Деталь: | ELA HOU-DUPLEX, SCX-6555N,SEC,-,-,- |

| Парткод: | JC96-04982A |

| Деталь: | MEA UNIT-TR, SCX-6345N/XRX,XEROX,-,TR,-,- |

| Парткод: | JC97-02287A |

| Деталь: | TRAY-ASF IN MP, M5370,HIPS,235,SPILIT GRA |

| Парткод: | JC63-00447H |

| Деталь: | TRAY-ASF IN TOP, M5370,ABS,1.5,SPILIT GRA |

| Парткод: | JC63-00745C |

| Деталь: | ADJUST-SIDE GUIDE MP R, M5370,HIPS,SHG85, |

| Парткод: | JC72-01006D |

| Деталь: | GEAR-PINION, SF4000,POM,1,Z16,WHT |

| Парткод: | JG66-40003A |

| Цена: | 260 ₽ |

| Деталь: | COVER-TRAY LOWER, M5370,HIPS,SPLIT GRAY,H |

| Парткод: | JC63-04487A |

| Деталь: | ADJUST-SIDE GUIDE MP L, M5370,HIPS,SHG85, |

| Парткод: | JC72-01005E |

| Деталь: | MEA UNIT-TR SUB, SCX-6345N/XRX,XEROX,-,-, |

| Парткод: | JC97-02375A |

| Деталь: | BAND, SCX-5312F,PC+ABS,EMBER GOLD |

| Парткод: | JC72-00883A |

| Деталь: | BAND, SCX-5312F,PC+ABS,EMBER GOLD |

| Парткод: | JC72-00884A |

| Деталь: | SPRING ETC-TR_R, ML-165,SUS304WPB,PI0.5,O |

| Парткод: | JC61-70906A |

| Деталь: | ROLLER-TRANSFER, Rushmore,18.4 (mm),EPDM |

| Парткод: | JC66-01023A |

| Деталь: | CASSETTE SUB-MAIN, M5370,SEC |

| Парткод: | JC90-01268A |

| Деталь: | COVER-CASSETTE, M5370,HIPS,SPLIT GRAY,HIP |

| Парткод: | JC63-04486A |

| Деталь: | CAP-M_HANDLE LEFT, SCX-6345N/XRX,PC,T2,12 |

| Парткод: | JC67-00123A |

| Деталь: | GUIDE-P-SIDE LEFT, SCX-6345N/XRX,SECC,T1. |

| Парткод: | JC61-01413A |

| Деталь: | PLATE-P-LEVER, SCX-6345N/XRX,EGI-SECC,T1. |

| Парткод: | JC61-01322A |

| Деталь: | FRAME-CASSETTE, M5370,HIPS,SPILIT GRAY,3, |

| Парткод: | JC61-01411C |

| Деталь: | GEAR-M_RACK, SCX-6345N/XRX,POM,1,24,NTR |

| Парткод: | JC66-00956A |

| Деталь: | GEAR-M_PINION 24, SCX-6345N/XRX,POM,1,24, |

| Парткод: | JC66-01020A |

| Деталь: | GUIDE-P-SIDE RIGHT, SCX-6345N/XRX,SECC,T1 |

| Парткод: | JC61-01414A |

| Деталь: | STOPPER-M_KNOCK UP, M4580,ABS,HF-0660I,SP |

| Парткод: | JC61-00832G |

| Деталь: | SHAFT-PLATE LEVER, SCX-6345N/XRX,POSCUT,L |

| Парткод: | JC66-00953A |

| Деталь: | GEAR-M_LIFT COUPLING, SCX-6345N/XRX,POM,1 |

| Парткод: | JC66-00955A |

| Деталь: | GEAR-M_LIFTING, SCX-6345N/XRX,POM,1.5,46, |

| Парткод: | JC66-00954A |

| Деталь: | BRACKET-P-LIFTING, SCX-6345N/XRX,SECC,1.6 |

| Парткод: | JC61-01394A |

| Деталь: | SUPPORT-M_PUSH PAPER, SCX-6345N/XRX,PC,T2 |

| Парткод: | JC61-01417A |

| Деталь: | SUPPORT-M_BAR PAPER, SCX-6345N/XRX,PC,T2. |

| Парткод: | JC61-01416A |

| Деталь: | GUIDE-REAR, M5370,ABS,47.2,59.8,HF-0660I, |

| Парткод: | JC61-01395C |

| Деталь: | LEVER-LENTH HANDLE, SCX-6345N,HIPS HB,2,4 |

| Парткод: | JC66-00202B |

| Деталь: | GUIDE-M_HOOK, SCX-6345N/XRX,HIPS,GREEN,PA |

| Парткод: | JC61-01304A |

| Деталь: | PLATE-P-KNOCK UP, SCX-6345N/XRX,EGI-SECC, |

| Парткод: | JC61-01412A |

| Деталь: | PAD-MP(PLUS), SCX-5315F,Urethan Sponge,90 |

| Парткод: | JC69-00494A |

| Деталь: | FRAME-HOUSING MAIN, M5370 |

| Парткод: | JC93-00877A |

| Деталь: | FRAME-SUPPORT SCAN, M5370,SEC |

| Парткод: | JC93-00879A |

| Деталь: | GROUND-P-FUSER DRV, SCX-6345N/XRX,STS301, |

| Парткод: | JC63-00790A |

| Деталь: | GROUND-P-MAIN DRV, SCX-6345N/XRX,STS301,0 |

| Парткод: | JC63-00789A |

| Деталь: | GEAR-M_RETARD, SCX-6345N/XRX,POM,0.6,57,H |

| Парткод: | JC66-00975A |

| Деталь: | GEAR-M_FORWARD, SCX-6345N/XRX,POM,1,31,H9 |

| Парткод: | JC66-00974A |

| Деталь: | GEAR-M_PICKUP IDLE B, SCX-6345N/XRX,POM,A |

| Парткод: | JC66-00973A |

| Деталь: | CAP-M_INLET, SCX-6345N/XRX,PC+ABS,T2.5,W8 |

| Парткод: | JC67-00113A |

| Деталь: | FAN-DC, CLX-8380ND/XAA,UL10272 AWG26, AM |

| Парткод: | JC31-00086A |

| Деталь: | FRAME-HOUSING BASE, M5370,SEC |

| Парткод: | JC93-00878A |

| Деталь: | MEA UNIT-ACT FEED, SCX-6345N,XEROX,-,-,- |

| Парткод: | JC97-02702A |

| Деталь: | MEA UNIT-ACT REGI, SCX-6345N,XEROX,GB,-,- |

| Парткод: | JC97-02703A |

| Деталь: | PLATE-M_FEED UPPER, SCX-6345N/XRX,ABS,T2, |

| Парткод: | JC61-01295A |

| Деталь: | LEG-M_ACT FEED BASE, SCX-6345N/XRX,POM,2, |

| Парткод: | JC61-01426A |

| Деталь: | SPRING-TS, STAINLESS-STS304,0.35,ID4.6,OD |

| Парткод: | 6107-001261 |

| Деталь: | HOLDER-M_ACT_FEED, SCX-6345N/XRX,PC,T2,W1 |

| Парткод: | JC61-01421A |

| Деталь: | LEG-M_ACTUATOR REGI, SCX-6345N/XRX,POM,2, |

| Парткод: | JC61-01408A |

| Деталь: | FUSER, M5370,SEC,WORLD,110V |

| Парткод: | JC91-01159A |

| Деталь: | FUSER, M5370,SEC,WORLD,220V |

| Парткод: | JC91-01160A |

| Деталь: | HARNESS-FUSER_FU, SCX-6555N,UL3122,3P/1P, |

| Парткод: | JC39-00831A |

| Деталь: | THERMOSTAT, 125/250VAC,200,170+-5C,200,10 |

| Парткод: | 4712-001028 |

| Деталь: | PBA-FUSER_CRUM, SCX-6555N,SEC,EXPORT,-,-, |

| Парткод: | JC92-02008A |

| Деталь: | THERMISTOR-NTC ASSY, 7Kohm,3370K |

| Парткод: | 1404-001453 |

| Деталь: | LAMP-HALOGEN, 115V,1300W,13x9.8x276 |

| Парткод: | 4713-001521 |

| Деталь: | LAMP-HALOGEN, 230V,1300W,13x9.8x276 |

| Парткод: | 4713-001522 |

| Цена: | 3 900 ₽ |

| Деталь: | LEG-M ACTUATOR EXIT, SCX-6345N/XRX,PA,3,2 |

| Парткод: | JC61-01384B |

| Деталь: | GEAR-M DRV Z2228, SCX-6345N/XRX,NYLON66,A |

| Парткод: | JC66-01011A |

| Деталь: | GEAR-FUSER, SCX-6555N,PPS+GF40%,1.0,51,BR |

| Парткод: | JC66-01666A |

| Деталь: | ROLLER-PRESSURE, SCX-6555N,38,SUM22, STKM |

| Парткод: | JC66-01825A |

| Деталь: | GUIDE-M_INPUT JF, SCX-6345N/XRX,PET+GF,T3 |

| Парткод: | JC61-01419A |

| Деталь: | LEVER-JAM R, SCX-6555N,NYLON,T2,V0,BLK |

| Парткод: | JC66-01687A |

| Деталь: | LEVER-JAM L, SCX-6555N,NYLON66,T2,V0,BLK |

| Парткод: | JC66-01859A |

| Деталь: | GROUND-PR2, SCX-6555N,SUS,0.2,GROUND/UNC |

| Парткод: | JC63-01640A |

| Деталь: | COVER-M_GROUND, SCX-6345N/XRX,PET+GF30%,T |

| Парткод: | JC63-00761A |

| Деталь: | GROUND-P-PR, SCX-6345N/XRX,SUS 301 1/2H,0 |

| Парткод: | JC63-00819A |

| Деталь: | ROLLER FUSER-HEAT, M5370,22.43,AL,0.7T,PF |

| Парткод: | JC66-04148A |

| Деталь: | ELA HOU-EXIT, SCX-6555N,SEC,-,-,- |

| Парткод: | JC96-04892A |

| Деталь: | HOLDER-M_ACT OUTBIN, SCX-6345N/XRX,PC,T2. |

| Парткод: | JC61-01392A |

| Деталь: | LEG-M LIMIT STACKING, SCX-6345N/XRX,PC,3, |

| Парткод: | JC61-01391A |

| Деталь: | ADJUST, SUS,L23,PI1.8,ADJUST/UNC |

| Парткод: | JC70-00064A |

| Деталь: | GUIDE-M_EXIT UPPER, SCX-6345N/XRX,ABS+PC, |

| Парткод: | JC61-01301A |

| Деталь: | GEAR-M_EXIT LOWER, SCX-6345N/XRX,POM,0.8, |

| Парткод: | JC66-01018A |

| Деталь: | GEAR-M_EXIT UPPER, SCX-6345N/XRX,POM,0.8, |

| Парткод: | JC66-01017A |

| Деталь: | BRUSH-ANTISTATIC, SCX-6445,SUS FIBER,0.05 |

| Парткод: | JC67-00694A |

| Деталь: | ROLLER-EXIT UPPER, SCX-6345N,EPDM |

| Парткод: | JC66-01015A |

| Деталь: | ROLLER-EXIT_LOWER, SCX-6345N,EPDM |

| Парткод: | JC66-01016A |

| Деталь: | ROLLER-EXIT DRV, SCX-6345N,EPDM |

| Парткод: | JC66-01014A |

| Деталь: | SPRING-TS, SWP B,PI0.5,D3.55,L12.93/6.5,W |

| Парткод: | 6107-001540 |

| Деталь: | ROLLER-M IDLE JF, SCX-6345N,POM |

| Парткод: | JC66-01013A |

| Деталь: | HARNESS-EXIT, SCX-6555N,UL10272,8P/3P,2P, |

| Парткод: | JC39-00788A |

| Деталь: | ELA HOU-SOLENOID DP, CLX-8380ND/XAA,-,KOR |

| Парткод: | JC96-03749B |

| Деталь: | GUIDE-M_EXIT DUPLEX, SCX-6345N/XRX,ABS,T2 |

| Парткод: | JC61-01303A |

| Деталь: | MEA-GATE SPONGE, SCX-6555N,SEC,-,-,- |

| Парткод: | JC97-03208A |

| Деталь: | GEAR-M_EXIT, SCX-6345N/XRX,POM,1,15,W10,B |

| Парткод: | JC66-01012A |

| Деталь: | GUIDE-M_EXIT LOWER, SCX-6345N/XRX,ABS+GF, |

| Парткод: | JC61-01302A |

| Деталь: | DADF-OPEN, M5370 |

| Парткод: | JC97-04423A |

| Деталь: | DADF-SUB, M5370 |

| Парткод: | JC97-04424A |

| Деталь: | COVER-SIDE R, M5370,ABS,G32690,HF-0660I,S |

| Парткод: | JC63-04426A |

| Деталь: | DADF-PLATEN, M5370 |

| Парткод: | JC97-04426A |

| Деталь: | COVER-SIDE F, M5370,ABS,G32690,HF-0660I,S |

| Парткод: | JC63-04425A |

| Деталь: | DADF-HINGE L, M5370,SEC |

| Парткод: | JC97-04446A |

| Деталь: | DADF-HINGE R, M5370,SEC |

| Парткод: | JC97-04445A |

| Деталь: | DADF-FRAME MAIN, M5370 |

| Парткод: | JC97-04427A |

| Деталь: | DADF-STACKER, M5370 |

| Парткод: | JC97-04425A |

| Деталь: | GUIDE-TX STACKER, M5370,ABS,HF-0660I,GUID |

| Парткод: | JC61-06086A |

| Деталь: | GUIDE-RACK DOCU TX, M5370,POM,F20-02,GUID |

| Парткод: | JC61-06082A |

| Деталь: | PHOTO-INTERRUPTER, TR,DIP-4,BK |

| Парткод: | 0604-001415 |

| Цена: | 240 ₽ |

| Деталь: | ACTUATOR-PAPER_LENGTH, CLX-9201,ABS,22,65 |

| Парткод: | JC66-03209A |

| Деталь: | GUIDE-STACKER LOWER, M5370,ABS,HF-0660I,G |

| Парткод: | JC61-06087A |

| Деталь: | GUIDE-STACKER WIRE, SCX-6345N/XRX,STS304, |

| Парткод: | JC61-01438A |

| Деталь: | HVPS, 24V,21.6V26.4V,MAX 5KV,MAX-2.5KV,6 |

| Парткод: | JC44-00234A |

| Деталь: | HOLDER-HVPS, M5370,ABS+PC,BLACK,NH-1000T |

| Парткод: | JC61-06099A |

| Деталь: | SMPS-V1, CLX-9201,PSPN TYPE5-V1,AC-DC,275 |

| Парткод: | JC44-00093C |

| Деталь: | SHIELD-SMPS LOWER, M5370,EGI-SECC,0.8,SHI |

| Парткод: | JC63-04483A |

| Деталь: | OPE, M5370,SEC |

| Парткод: | JC97-04499A |

| Деталь: | CASSETTE SUB-MAIN, M5370,SEC |

| Парткод: | JC90-01268A |

| Деталь: | SMPS-FDB V1, M5370-FDB-V1,JC44-00159B,AC/ |

| Парткод: | JC44-00159B |

| Деталь: | SHIELD-BD FUSER, SCX-6555N,EGI-SECC,0.8,N |

| Парткод: | JC63-01645A |

| Деталь: | HINGE-OPE, SUM22 |

| Парткод: | JC61-06103A |

| Деталь: | COVER-SCAN HINGE, M5370,ABS,Split Brown B |

| Парткод: | JC63-04464A |

| Деталь: | PLATEN, M5370,SEC |

| Парткод: | JC97-04418A |

| Деталь: | SPONGE-WHITE, M5370,Polyurethane Form,Bla |

| Парткод: | JC63-04419A |

| Деталь: | LSU, SCX-6555FN,SEC,SEE,55,600DPI,4Beam,- |

| Парткод: | JC97-03624A |

| Деталь: | ELA HOU-EXIT, SCX-6555N,SEC,-,-,- |

| Парткод: | JC96-04892A |

| Деталь: | FRAME-BASE, M5370,SEC |

| Парткод: | JC93-00876A |

| Деталь: | FUSER, M5370,SEC,WORLD,110V |

| Парткод: | JC91-01159A |

| Деталь: | FUSER, M5370,SEC,WORLD,220V |

| Парткод: | JC91-01160A |

| Деталь: | DRIVE MAIN, SCX-6555N,SEC |

| Парткод: | JC93-00168A |

| Деталь: | DRIVE FUSER, SCX-6555N,SEC |

| Парткод: | JC93-00169A |

| Деталь: | FRAME-FAN DUCT, SCX-6555N,SEC,100MOHM |

| Парткод: | JC93-00173A |

| Деталь: | CLUTCH-5K Z32, SCX-6345N/XRX,POM+METAL,5k |

| Парткод: | JC66-00994A |

| Деталь: | CLUTCH-5K Z32, CLX-8380ND/XAA,POM+METAL,5 |

| Парткод: | JC66-00994B |

| Деталь: | DUPLEX SUB-SIDE, M5370,SEC |

| Парткод: | JC90-01270A |

| Деталь: | COVER, M5370,SEC |

| Парткод: | JC95-01896A |

| Деталь: | DADF, M5370 |

| Парткод: | JC97-04422A |

| Деталь: | PBA-MAIN, SCX-6555N,SEC,FR-4,6Layer |

| Парткод: | JC92-02661A |

| Деталь: | HDD, 320G,HTS543232A7A384,S63,H16,C16383, |

| Парткод: | JC59-00035A |

| Деталь: | HOLDER-M_HDD, SCX-6345N/XRX,ABS,T2,W114.1 |

| Парткод: | JC61-01389A |

| Деталь: | SENSOR, HSU-07F1V2-N,CLX-9201,045C,+3.3 |

| Парткод: | JC32-00015A |

| Деталь: | HOLDER-LIU, M5370,PC,BLACK,NH-1035 |

| Парткод: | JC61-06098A |

| Деталь: | COVER-REAR DUMMY, CLX-8650,ABS,HF-0660I |

| Парткод: | JC63-03623A |

| Деталь: | PLATEN-UPPER, M5370,SEC |

| Парткод: | JC97-04419A |

| Деталь: | PLATEN-LOWER, M5370,SEC |

| Парткод: | JC97-04420A |

| Деталь: | PLATEN-DUMMY UPPER, M5370,SEC |

| Парткод: | JC97-04421A |

| Деталь: | CCDM, CLX-8650,SEC,600dpi,LED |

| Парткод: | JC97-04021A |

| Деталь: | PLATEN-HOLDER FFC, M5370 |

| Парткод: | JC97-04448A |

| Деталь: | ACTUATOR, SCX-5100,POM,HB,NTR,ACTUATOR |

| Парткод: | JC72-00755A |

| Деталь: | PHOTO-INTERRUPTER, TR,75mW,BGA,TR |

| Парткод: | 0604-001393 |

| Деталь: | PBA-SCAN JOINT, M5370,SEC,FR-4,2Layer |

| Парткод: | JC92-02673A |

| Деталь: | PLATEN-SENSOR APS, M5370,SEC |

| Парткод: | JC97-04573B |

| Деталь: | PLATEN-MOTOR SUB, CLX-8650ND,SEE |

| Парткод: | JC97-04120A |

| Деталь: | BELT-TIMING GEAR, 950-2GT-3,3 |

| Парткод: | 6602-003266 |

| Деталь: | COVER-SCAN LOWER, M5370,ABS,G32690,HF-066 |

| Парткод: | JC63-04434A |

| Деталь: | BRACKET-SCAN LOWER, STAINLESS-STS304,PRES |

| Парткод: | JC61-06080A |

| Деталь: | PBA-APS_IF, SCX-6555N,SEC,EXPORT,-,-,-,30 |

| Парткод: | JC92-02009A |

| Деталь: | PHOTO-INTERRUPTER, Infrared light,BULK |

| Парткод: | 0604-001464 |

| Деталь: | DRIVE FUSER, SCX-6555N,SEC |

| Парткод: | JC93-00169A |

| Деталь: | MOTOR STEP, M42SP-4NK,CLX-8380ND/XAA,0.6A |

| Парткод: | JC31-00077A |

| Деталь: | PMO-IMPELLER_DRV, ML-6200,PA66,18,5mm,VO, |

| Парткод: | JC72-00825A |

| Деталь: | MOTOR STEP, M49SP-2NK,SCX-6555N,1.2A,1150 |

| Парткод: | JC31-00100A |

| Деталь: | GEAR-EXIT IDLE C, SCX-6555N,L1724KH,0.5/1 |

| Парткод: | JC66-01987A |

| Деталь: | GEAR-M_EXIT IDLE A, SCX-6345N/XRX,POM,A:1 |

| Парткод: | JC66-00996A |

| Деталь: | GEAR-M_FUSER IDLE A, SCX-6345N/XRX,POM,A: |

| Парткод: | JC66-00995A |

| Деталь: | FRAME-M_MP TOP, M5370,ABS,SPLIT GRAY,HF-0 |

| Парткод: | JC61-01352C |

| Деталь: | SPONGE-DAMPER MP, SCX-6345N/XRX,POLYURETH |

| Парткод: | JC72-01375A |

| Деталь: | GEAR-M_MP FEED, SCX-6345N/XRX,POM,1,24,H2 |

| Парткод: | JC66-00936A |

| Деталь: | ROLLER-MP DRV, SCX-6345N,EPDM,SUM22,6 |

| Парткод: | JC66-01026A |

| Деталь: | STOPPER-M_PAPER FRT, SCX-6345N/XRX,POM,T2 |

| Парткод: | JC61-01307A |

| Деталь: | ELA HOU-MP PICK UP, SCX-6345N/XRX,-,-,MP |

| Парткод: | JC96-03533A |

| Деталь: | LATCH-M_ARM REAR, SCX-6345N/XRX,POM,T1.5, |

| Парткод: | JC66-00958B |

| Деталь: | PHOTO-INTERRUPTER, TR,DIP-4,BK |

| Парткод: | 0604-001415 |

| Цена: | 240 ₽ |

| Деталь: | FRAME-M MP LOWER, ABS,SPLIT GRAY,HF-0660I |

| Парткод: | JC61-01351C |

| Деталь: | MEC-ADF ROLLER ASSY, SCX-1110F/XRX,XEROX, |

| Парткод: | JB75-00299A |

| Цена: | 330 ₽ |

| Деталь: | MEC-PICK UP ROLLER ASSY, SCX-1110F/XRX,XE |

| Парткод: | JB75-00300A |

| Цена: | 220 ₽ |

| Деталь: | GEAR-ADF IDLE 34, SCX-1110F,POM,0.6,34,20 |

| Парткод: | JB66-00104A |

| Деталь: | GEAR-PICK UP IDEL 38, SCX-1110F,POM,0.6,3 |

| Парткод: | JB66-00102A |

| Деталь: | GEAR-PICK UP 26, SCX-1110F,POM,0.6,26,15. |

| Парткод: | JB66-00105A |

| Деталь: | FRAME-HOUSING PLATE UPPER, M5370,SEC |

| Парткод: | JC93-00898A |

| Деталь: | GUIDE-M_FEED UPPER, SCX-6345N/XRX,ABS,T2, |

| Парткод: | JC61-01296A |

| Деталь: | GUIDE-P-SHIELD SMPS, M5370,EGI-SECC,T 1.0 |

| Парткод: | JC61-06100A |

| Деталь: | BRUSH-ANTISTATIC, SCX-6445,SUS FIBER,0.2, |

| Парткод: | JC67-00055C |

| Деталь: | FRAME, M5370,SEC |

| Парткод: | JC93-00928A |

| Деталь: | FRAME-HOUSING MP, M5370,SEC |

| Парткод: | JC93-00927A |

| Деталь: | ELA HOU-SIZE SENSOR, SCX-6555N,SEC,korea, |

| Парткод: | JC96-04906A |

| Деталь: | ELA HOU-UPPER DP, SCX-6555N,SEC,-,-,- |

| Парткод: | JC96-04907A |

| Деталь: | ELA HOU-BASE PLATE R, SCX-6555N,SEC,-,-,- |

| Парткод: | JC96-04908A |

| Деталь: | FRAME-HOLDER PAD, M5370,SEC |

| Парткод: | JC93-00937A |

| Деталь: | PBA SUB-CASSETTE, CLX-8380ND,SEC,SEC,CASS |

| Парткод: | JC92-01913A |

| Деталь: | PHOTO-INTERRUPTER, TR,DIP-4,BK |

| Парткод: | 0604-001415 |

| Цена: | 240 ₽ |

| Деталь: | CORE ROTOR, ML-7250,STAINLESS-STS301,0.2T |

| Парткод: | JC70-00192A |

| Деталь: | BRACKET, ML-7250,EGI-SECC,1.6T,PRESS |

| Парткод: | JC70-00195A |

| Деталь: | HOUSING-M_SIZE SENSOR, SCX-6345N/XRX,ABS, |

| Парткод: | JC61-01343A |

| Деталь: | MEA UNIT-ACT READY, SCX-6345N,XEROX,GB,-, |

| Парткод: | JC97-02704A |

| Деталь: | GUIDE-M_FEED DP, SCX-6345N/XRX,ABS,T 2.5, |

| Парткод: | JC61-01294A |

| Деталь: | MOTOR GEARED-P LIFT, 2.1rpm,1.5N.m,1/1513 |

| Парткод: | JC31-00045A |

| Деталь: | HARNESS-SCF_MAIN, Rushmore,UL10272,18p,GR |

| Парткод: | JC39-00780A |

| Деталь: | RMO-ADF RUBBER, SCX-1110F,Si Rubber,50,G3 |

| Парткод: | JB73-00052A |

| Цена: | 70 ₽ |

| Деталь: | SHEET-GUIDE MP, M5370,PET,0.125,TRANSPARE |

| Парткод: | JC63-04751A |

| Деталь: | HOLDER-M-ADF RUBBER UPPER, SCX-6320F,HIPS |

| Парткод: | JC61-00744A |

| Деталь: | RPR-PAD CASSETTE, ML-1510,Urethan Sponge, |

| Парткод: | JC73-00141A |

| Цена: | 80 ₽ |

| Деталь: | GUIDE-M_PAD LOWER, SCX-6345N/XRX,HIPS,T2. |

| Парткод: | JC61-01415A |

| Деталь: | DRIVE MAIN, SCX-6555N,SEC |

| Парткод: | JC93-00168A |

| Деталь: | MOTOR BLDC, 2220 RPM,1400gf.cm,DC24V,2.1A |

| Парткод: | JC31-00090A |

| Цена: | 2 900 ₽ |

| Деталь: | CABLE CLAMP, DAWS-3NE,ID11L34.8,NYLON66, |

| Парткод: | 6502-001093 |

| Деталь: | CABLE CLAMP, DAWS-1NE,ID11,L21.0,NTR,NYLO |

| Парткод: | 6502-000132 |

| Деталь: | MOTOR DC, NF213G-1020515,DC24V,CLX-8380ND |

| Парткод: | JC31-00078A |

| Цена: | 1 600 ₽ |

| Деталь: | GEAR-AGI IDLE B, SCX-6555N,POM,0.5/1,86/1 |

| Парткод: | JC66-01679A |

| Деталь: | CAP-GEAR, SCX-6555N,HIPS,T2.0,BLK |

| Парткод: | JC67-00276A |

| Деталь: | COUPLER, SCX-5100,DE8903,BLK |

| Парткод: | JC72-00743A |

| Деталь: | GEAR-M_AGI IDLE, SCX-6345N/XRX,POM,1,31/5 |

| Парткод: | JC66-00989A |

| Деталь: | GEAR-M_SUPPLY IDLE, SCX-6345N/XRX,POM,A:0 |

| Парткод: | JC66-00993A |

| Деталь: | GEAR-M_MIXER, SCX-6345N/XRX,POM,1,27,D34. |

| Парткод: | JC66-00985A |

| Деталь: | MEA UNIT-GEAR SUPPLY, SCX-6345N/XRX,XEROX |

| Парткод: | JC97-02681A |

| Деталь: | GEAR-M_OPC BASE, SCX-6345N/XRX,POM,0.5,79 |

| Парткод: | JC66-00982A |

| Деталь: | OTHER MECHA-M CPL OPC, SCX-6345,POM M90-4 |

| Парткод: | JC67-00115A |

| Деталь: | GEAR-MIDDLE, SCX-6555N,POM,1,21,NTR,HELIC |

| Парткод: | JC66-01678A |

| Деталь: | GEAR-REGI IDLE C, SCX-6555N,POM,1/1,19/31 |

| Парткод: | JC66-01677A |

| Деталь: | GEAR-PICK UP HELICAL, SCX-6555N,POM,1/1,3 |

| Парткод: | JC66-01682A |

| Деталь: | GEAR-MP HELICAL, SCX-6555N,PA66,1/1,17/18 |

| Парткод: | JC66-01680A |

| Деталь: | GEAR-M_MP IDLE B, SCX-6345N/XRX,POM,A:1,B |

| Парткод: | JC66-00990A |

| Деталь: | GEAR-M_DUPLEX IDLE, SCX-6345N/XRX,POM,1,3 |

| Парткод: | JC66-00991A |

| Деталь: | OTHER MECHA-M COLLAR DP, SCX-6345N/XRX,PO |

| Парткод: | JC67-00116A |

| Деталь: | COVER-OPEN UPPER, M5370,ABS,G32690,HF-066 |

| Парткод: | JC63-04428A |

| Деталь: | COVER-OPEN HANDLE, M5370,ABS+PC,G32690,23 |

| Парткод: | JC63-04437A |

| Деталь: | HOLDER-REGI SPRING L, CLX-8650ND,ABS,34.8 |

| Парткод: | JC61-05548A |

| Деталь: | PHOTO-INTERRUPTER, TR,DIP-4,BK |

| Парткод: | 0604-001415 |

| Цена: | 240 ₽ |

| Деталь: | ACTUATOR-REGI, CLX-8650ND,PC,18.9,60.8,BL |

| Парткод: | JC66-03531A |

| Деталь: | ROLLER-REGI IDLE, CLX-8650ND,POM,6,19 |

| Парткод: | JC66-03751A |

| Деталь: | ACTUATOR-PICKUP-FEED, CLX-8650ND,PC,24,51 |

| Парткод: | JC66-03529A |

| Деталь: | BRUSH-PICK UP ANTISTATIC, CLX-8650ND,SUS |

| Парткод: | JC67-00667A |

| Деталь: | ACTUATOR-DETECT, CLX-8650ND,PC,45,35.6,BL |

| Парткод: | JC66-03530A |

| Деталь: | ACTUATOR-DETECT B, CLX-8650ND,PC,31.1,35. |

| Парткод: | JC66-03532A |

| Деталь: | COVER-OPEN LOWER, M5370,ABS,G32690,HF-066 |

| Парткод: | JC63-04427A |

| Деталь: | HOLDER-REGI SPRING R, CLX-8650ND,ABS,2,34 |

| Парткод: | JC61-05547A |

| Деталь: | HOLDER-ARM RELEASE, CLX-9350,POM,29.13,55 |

| Парткод: | JC61-03231A |

| Деталь: | ROLLER-IDLE-OD16, CLX-9350,POM,16 |

| Парткод: | JC66-02293A |

| Деталь: | GROUND-HINGE_LEFT, CLX-8650ND,C521P,0.2,4 |

| Парткод: | JC63-03683A |

| Деталь: | PCB-ADF, CLX-8650ND,FR4,2,1.6,13060mm,4, |

| Парткод: | JC41-00776A |

| Деталь: | SHIELD-ADF BOARD, CLX-8650ND,EGI-SECC,0.8 |

| Парткод: | JC63-03685A |

| Деталь: | GROUND-HINGE_RIGHT, CLX-8650ND,PBS-C5210, |

| Парткод: | JC63-03684A |

| Деталь: | GUIDE-EXTENSION_S, CLX-8650ND,ABS,2.5,86. |

| Парткод: | JC61-05297A |

| Деталь: | GUIDE-EXTENSION S, M5370,ABS,HF-0660I,GUI |

| Парткод: | JC61-06083A |

| Деталь: | COVER-DUMMY RIGHT, M5370,ABS,G32690,HF-06 |

| Парткод: | JC63-04430A |

| Деталь: | COVER-DUMMY PLATEN, M5370,ABS,G32690,HF-0 |

| Парткод: | JC63-04431A |

| Деталь: | GUIDE-M_PICKUP BASE, SCX-6345N/XRX,ABS,T2 |

| Парткод: | JC61-01313A |

| Деталь: | SPRING-TS, SUS304-WPB,PI1.2,D11.2,L25/18. |

| Парткод: | 6107-001263 |

| Деталь: | MEA UNIT-RETARD, SCX-6345N/XRX,XEROX,-,RE |

| Парткод: | JC97-02290A |

| Деталь: | GUIDE-M_FEED IDLE MP, SCX-6345N/XRX,ABS,T |

| Парткод: | JC61-01297A |

| Деталь: | MEA UNIT-FEED IDLE MP, SCX-6345N,XEROX,-, |

| Парткод: | JC97-02705A |

| Деталь: | SPEAKER, 0.3W,8Ohm,81dB,400Hz |

| Парткод: | 3001-002207 |

| Деталь: | MEA UNIT-ROLLER PU, SCX-6345N/XRX,XEROX,- |

| Парткод: | JC97-02259A |

| Цена: | 240 ₽ |

| Деталь: | JOINT-M_RETARD, SCX-6345,POM,D18.4, L10.7 |

| Парткод: | JC66-00976A |

| Деталь: | COUPLER-TORQUELIMITER, SCX-6345N/XRX,OTLV |

| Парткод: | JC67-00126A |

| Деталь: | ROLLER-RUBBER IDLE, SCX-6345N,EPDM,SUM22, |

| Парткод: | JC66-01027A |

| Деталь: | HOLDER-M_BUSHING IDLE, SCX-6345N/XRX,POM, |

| Парткод: | JC61-01434A |

| Деталь: | SPRING ETC-TR R HAWK, ML-6060A,SUS 304 WP |

| Парткод: | JC61-00046A |

Коды ошибок

11-2T01, 11-2T11, 11-2T21

11-2T31, 11-2T41, 11-2T61

61-1111

A1-1111, A1-1112, A1-1113

A1-3111, A1-3112, A1-3113

A3-2113

A3-3210, A3-3211, A3-3212

A3-3310, A3-3311, A3-3312

A3-3320, A3-3410

A3-3411, A3-3412

A4-1110

C1-1110

C1-111A, C1-1313, C1-1314

C1-1140, C1-1160, C1-1170

C1-1410

C1-1512

C1-1710, C1-1711, C1-1712

C3-1110

C3-1140 C3-1150 C3-1170

C3-1210

C3-1314, C3-1315, C3-1316

C3-1410, C3-1414, C3-1512

C3-1710, C3-1711, C3-1712

C6-1120

C9-1112, C9-1122

C9-1132, C9-1142

C9-1162

C9-2120

C9-2220

H1-1211, H1-1213

H1-1217, H1-1218, H1-1219

H1-1220

H1-1222, H1-1240

H1-1230

H1-1251, H1-1252

H1-1253

H1-1311, H1-1313

H1-1317, H1-1318, H1-1319

H1-1320

H1-1322, H1-1340

H1-1332

H1-1351, H1-1352

H1-1353

H1-1411, H1-1413

H1-1417, H1-1418, H1-1419

H1-1420

H1-1422

H1-1434

H1-1451, H1-1452

H1-1453

H1-2211, H1-2213

H1-2217, H1-2218, H1-2219

H1-2220

H1-2222, H1-2240

H1-2230

H1-2251, H1-2252

H1-2253

H2-5001, H2-5002, H2-5096

H2-5003, H2-5004, H2-5097

H2-5005, H2-5006, H2-5098

H2-5007, H2-5008, H2-5099

H2-5009, H2-5010

H2-5011, H2-5100

H2-5012, H2-5013, H2-5101

H2-5014, H2-5015, H2-5102

H2-5032

H2-5033, H2-5035, H2-5036

H2-5034, H2-5037

H2-5048

H2-506x, H2-507x, H2-5A50

H2-5080 ... H2-5085

H2-5086, H2-5087

H2-5088

H2-5112, H2-5113

H2-5A21

H2-5A31, H2-5A32

H2-5A34, H2-5A35

H2-5A38 ... H2-5A49

H2-5A50, H2-6A50

H2-5A62, H2-5A63

H2-5A90

H2-6A62, H2-6A63

M1-1113

M1-1613

M1-3122

M1-4111

M1-5111, M1-5112, M1-5120

M1-5612

M2-1111, M2-1114

M2-1117, M2-2111

M2-2112, M2-2114

M2-2311, M2-2312, M2-2314

M3-1111, M3-1112, M3-1114

M3-2130

S1-1313

S1-2411

S1-2433, S1-244x

S1-2434, S1-2435, S1-2436

S1-2437, S1-2438, S1-2439

S1-2510, S1-2521

S1-2523, S1-2530

S2-1211

S2-331D

S2-3321

S2-3421

S2-4120

S3-3121

S3-3211

S5-3111

S6-3122

S6-3123, S6-3229, S6-322A

S6-3128

S6-3224, S6-3225

S6-3226, S6-3227

S7-1110

S7-1210

S7-2110

U1-2115

U1-2117, U1-212x

U1-213x, U1-23xx

U1-234J, U1-234P

U2-1112

U2-1113

U3-3211, U3-3213, U3-3214

U3-3311, U3-3313, U3-3314

U3-3411, U3-3413, U3-3414

U3-3511, U3-3513, U3-3514

U3-3611, U3-3613, U3-3614

U3-3713, U3-3714

Описание

| Error code: | 11-2T01, 11-2T11, 11-2T21 |

| Display: | Tray paper mismatch Tray 1 paper mismatch Tray 2 paper mismatch Tray 3 paper mismatch Tray 4 paper mismatch MP tray paper mismatch |

| Description: | Load tray with [Letter], [Plain] paper Load tray 1 with [Letter], [Plain] paper Load tray 2 with [Letter], [Plain] paper Load tray 3 with [Letter], [Plain] paper Load tray 4 with [Letter], [Plain] paper Load MP with [Letter], [Plain] paper |

| Causes: | Paper in tray is not matched to the machine paper setting. |

| Remedy: | 1) Check and change the paper setting of the corresponding tray properly. |

| Error code: | 11-2T31, 11-2T41, 11-2T61 |

| Display: | Tray paper mismatch Tray 1 paper mismatch Tray 2 paper mismatch Tray 3 paper mismatch Tray 4 paper mismatch MP tray paper mismatch |

| Description: | Load tray with [Letter], [Plain] paper Load tray 1 with [Letter], [Plain] paper Load tray 2 with [Letter], [Plain] paper Load tray 3 with [Letter], [Plain] paper Load tray 4 with [Letter], [Plain] paper Load MP with [Letter], [Plain] paper |

| Causes: | Paper in tray is not matched to the machine paper setting. |

| Remedy: | 1) Check and change the paper setting of the corresponding tray properly. |

| Error code: | 61-1111 |

| Description: | Booting Failure: #61-1111. Turn off then on. Call for service if the problem persists |

| Causes: | Hibernation image creation is failed. |

| Remedy: | 1) Turn the machine on with a normal booting. 2) Enter the SVC mode. Select “Hibernation On” again. |

| Error code: | A1-1111, A1-1112, A1-1113 |

| Description: | Motor Failure: #A1-1111. Turn off then on. Call for service if the problem persists Motor Failure: #A1-1112. Turn off then on. Call for service if the problem persists Motor Failure: #A1-1113. Turn off then on. Call for service if the problem persists |

| Causes: | Main motor operation is abnormal. |

| Remedy: | • A1–1111 : Main motor is stopped but machine recognizes it as operational. • A1–1112 : Main motor is not operated for print-job. • A1–1113 : Main motor is operating but machine recognizes status as "Stopped". 1) Turn the machine off. Check if there are any foreign substances or paper around the paper path. 2) Remove the rear cover after removing 6 screws. 3) Check if the main motor connector is connected correctly. 4) If the connection is OK, turn the machine on. Enter SVC mode. Select the main motor test. (Diagnostics > Engine Diagnostics > Engine Test Routines) Check the motor operation. a) If the motor is not operational, • Check the signal and power with the DVM. • If the checked result is normal, replace the main motor(JC31-00090A) • If the checked result is abnormal, check the following. - If 24V power is not generated, replace the SMPS board(JC44-00100C (220V) / JC44-00093C (110V)). - If the control signal is abnormal, replace the main board(JC92–02661A) b) If the motor is operational, • Check the Pin No 8. If the value is abnormal, replace the main board. If the value is normal, replace the harness. |

| Error code: | A1-3111, A1-3112, A1-3113 |

| Description: | Motor Failure: #A1-3111. Turn off then on. Call for service if the problem persists Motor Failure: #A1-3112. Turn off then on. Call for service if the problem persists Motor Failure: #A1-3113. Turn off then on. Call for service if the problem persists |

| Causes: | Dev motor operation is abnormal. |

| Remedy: | • A1–3111 : Dev motor is stopped but machine recognizes it as operational. • A1–3112 : Dev motor is not operated for print-job. • A1–3113 : Dev motor is operating but machine recognizes status as "Stopped". 1) Turn the machine off. Check if there are any foreign substances or paper around the imaging unit. 2) Remove the rear cover after removing 6 screws. 3) Check if the Dev motor connector is connected correctly. 4) If the connection is OK, turn the machine on. Enter SVC mode. Select the Dev motor test. (Diagnostics > Engine Diagnostics > Engine Test Routines) Check the motor operation. a) If the motor is not operational, • Check the signal and power with the DVM. • If the checked result is normal, replace the Dev motor(JC31-00090A) • If the checked result is abnormal, check the following. - If 24V power is not generated, replace the SMPS board(JC44-00100C (220V) / JC44-00093C (110V)). - If the control signal is abnormal, replace the main board(JC92–02661A) b) If the motor is operational, • Check the Pin No 8. If the value is abnormal, replace the main board. If the value is normal, replace the harness. |

| Error code: | A3-2113 |

| Display: | The CTD sensor is dirty. Please clean it with soft cloth or paper(A3-2113) |

| Description: | The CTD sensor is dirty. Please clean it with soft cloth or paper. |

| Causes: | CTD sensor is defective or CTD sensor calibration is abnormal. |

| Remedy: | 1) Turn the machine off. 2) Open the side cover. 3) Check if the CTD sensor window is contaminated. If yes, clean the window with soft cloth. 4) Close the side cover. 5) Turn the machine on. 6) If the problem persists, replace the CTD sensor (JC32-00014A). |

| Error code: | A3-3210, A3-3211, A3-3212 |

| Display: | Sensor Failure: #. Turn off then on. Call for service if the problem persists. |

| Description: | Sensor Failure: #A3-3210. Turn off then on. Call for service if the problem persists Sensor Failure: #A3-3211. Turn off then on. Call for service if the problem persists Sensor Failure: #A3-3212. Turn off then on. Call for service if the problem persists |

| Causes: | Inner temperature sensor is defective. • A3–3210 : Inner temperature sensor value is abnormal. • A3–3211 : Inner temperature sensor is in short status. • A3–3212 : Inner temperature sensor is in open status. |

| Remedy: | 1) Open the side cover. Check the connection. • If the connection is OK, replace the photo sensor (1404-001417). 2) If the sensor is normal, replace the main board(JC92-02742A). |

| Error code: | A3-3310, A3-3311, A3-3312 |

| Display: | Sensor Failure: #A3-3310. Turn off then on. Call for service if the problem persists. Actuator Fan Failure #: Turn off then on. |

| Description: | Sensor Failure: #A3-3310. Turn off then on. Call for service if the problem persists Sensor Failure: #A3-3311. Turn off then on. Call for service if the problem persists Sensor Failure: #A3-3312. Turn off then on. Call for service if the problem persists |

| Causes: | Outer temperature/humidity sensor is defective. • A3–3310 / A3–3311 / A3–3312 : Temperature function is abnormal. • A3–3410 / A3–3411 / A3–3412 : Humidity function is abnormal. |

| Remedy: | 1) Remove the left cover. Unplug and reconnect the sensor harness. If the error persists, replace the sensor(JC93-00486A). 2) If the harness and sensor are normal, replace the main board (JC92-02742A). |

| Error code: | A3-3320, A3-3410 |

| Description: | The room temperature is not suitable for this set use. Please adjust room temperature Sensor Failure: #A3-3410. Turn off then on. Call for service if the problem persists. |

| Causes: | Outer temperature/humidity sensor is defective. |

| Remedy: | • A3–3310 / A3–3311 / A3–3312 / A3–3320 : Temperature function of the sensor is abnormal. • A3–3410 / A3–3411 / A3–3412 : Humidity function of the sensor is abnormal. 1) Enter SVC mode. Execute sensor test to check its operation. (Diagnostics > Engine Diagnostics > Engine Test Routines > 109-0013 Outer Temperature ) 2) Remove the left cover. Measure the resistance value of the connector at both ends. If the value is not in 47.5KΩ ~ 52.5KΩ (@ 25°C), replace the outer temperature/humidity sensor(JC32–00015A). 3) If the harness and sensor are normal, replace the main board(JC92–02661A). |

| Error code: | A3-3411, A3-3412 |

| Display: | A3-3311, A3-3312, A3-3320, A3-3411, A3-3412 Sensor errors |

| Description: | Sensor Failure: #A3-3411. Turn off then on. Call for service if the problem persists. Sensor Failure: #A3-3412. Turn off then on. Call for service if the problem persists. |

| Causes: | Outer temperature/humidity sensor is defective. |

| Remedy: | • A3–3310 / A3–3311 / A3–3312 / A3–3320 : Temperature function of the sensor is abnormal. • A3–3410 / A3–3411 / A3–3412 : Humidity function of the sensor is abnormal. 1) Enter SVC mode. Execute sensor test to check its operation. (Diagnostics > Engine Diagnostics > Engine Test Routines > 109-0013 Outer Temperature ) 2) Remove the left cover. Measure the resistance value of the connector at both ends. If the value is not in 47.5KΩ ~ 52.5KΩ (@ 25°C), replace the outer temperature/humidity sensor(JC32–00015A). 3) If the harness and sensor are normal, replace the main board(JC92–02661A). |

| Error code: | A4-1110 |

| Display: | Lamp Failure: #A4-1110. Open the door, then close it. Call for service if the problem persists |

| Description: | Erase Lamp does not turn on. |

| Causes: | Erase Lamp does not turn on. |

| Remedy: | 1) Enter SVC mode. Execute the erase lamp test. (Diagnostics > Engine Diagnostics > Engine Test Routines > Erase Lamp) 2) If the erase lamp does not turn on, replace it(JC92-02373A). |

| Error code: | C1-1110 |

| Display: | Prepare new yellow toner cartridge. |

| Description: | Toner remained is 5 - 30% of its life. |

| Causes: | Toner cartridge is almost empty. |

| Remedy: | 1) Open the front cover. 2) Remove the toner cartridge(MLT-D709S). (Toner cartridge with level of “Low” will be exhausted soon.) |

| Error code: | C1-111A, C1-1313, C1-1314 |

| Description: | Shake toner cartridge and then install. Replace toner cartridge if the problem persists. Shake toner cartridge and then install. Call for service if the problem persists. Did not supply enough toner. Remove seal tape of toner cartridge or shake it. Call for service if the problem persists. |

| Causes: | Toner remained of the toner cartridge is low. / Toner supply is abnormal. |

| Remedy: | 1) Open the front cover and side cover. 2) Remove the toner cartridge. 3) Check if the toner cartridge seal is removed. If not, remove it. 4) Shake the toner cartridge horizontally to distribute the toner evenly inside the cartridge. 5) Reinstall the toner cartridge. 6) If the problem persists, replace the toner cartridge. |

| Error code: | C1-1140, C1-1160, C1-1170 |

| Display: | C1-1140, C1-1160, C1-1170 Toner errors |

| Description: | End of life, Replace with new toner cartridge. Replace with new toner cartridge. |

| Causes: | Toner cartridge is at the end of its life. |

| Remedy: | 1) Open the front cover and side cover. 2) Remove the toner cartridge. 3) Install the new toner cartridge. 4) Close the front cover. |

| Error code: | C1-1410 |

| Display: | Toner cartridge is not installed. Install the cartridge. |

| Description: | The toner cartridge is not installed. / The machine can’t detect the toner cartridge. |

| Causes: | Toner cartridge is not installed. |

| Remedy: | 1) Turn the machine off then on. 2) Remove the toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3) Check if the CRUM contact area is contaminated. Clean it. |

| Error code: | C1-1512 |

| Display: | Toner cartridge is not compatible. Check users guide. |

| Description: | Toner cartridge is not compatible. Check users guide. |

| Causes: | Toner cartridge is not compatible. |

| Remedy: | 1) Print the supply information report. Check information of the toner cartridge. 2) If the toner cartridge is not a Samsung genuine toner cartridge, replace with new one. |

| Error code: | C1-1710, C1-1711, C1-1712 |

| Display: | Error: #C1-1710 Call for Service Error: #C1-1711 Call for Service Error: #C1-1712 Call for Service |

| Description: | The machine can’t detect the CRUM chip of the toner cartridge. |

| Causes: | The data of CRUM is not detected. / CRUM is defective. |

| Remedy: | NOTE These errors are for M3325/3825/4025. 1) Open the front cover. 2) Remove the toner cartridge. 3) Check if the CRUM terminal is contaminated. Clean it. 4) If the toner cartridge is not a Samsung genuine toner cartridge, replace with new one. |

| Error code: | C3-1110 |

| Display: | Prepare IMG. Unit / Prepare new imaging unit Replace IMG. Unit / Replace with new imaging unit |

| Description: | The remaining imaging unit is less than 10% / The imaging unit is at the end of its life. |

| Causes: | Imaging unit has almost reached the end of its life. |

| Remedy: | These errors are for M3325/3825/4025. Check the life remaining of the imaging unit. If its life is at the end, turn the machine off and replace the imaging unit with new one. |

| Error code: | C3-1140 C3-1150 C3-1170 |

| Description: | End of life, Replace with new imaging unit. Replace with new imaging unit End of life, Replace with new imaging unit. |

| Causes: | Imaging unit is at the end of its life. |

| Remedy: | 1) Open the front cover and side cover. 2) Remove the toner cartridge. 3) Remove the imaging unit and replace it with new one. 4) Install the toner cartridge. 5) Close the side cover and front cover. |

| Error code: | C3-1210 |

| Description: | Imaging Unit Failure:#C3-1210. Please turn off then on. |

| Causes: | Sensor calibration error that detects the toner density for image stabilization control has occurred. |

| Remedy: | 1) Open the front cover and side cover. 2) Remove the toner cartridge. 3) Remove and reinstall the imaging unit. 4) Install the toner cartridge. 5) Close the side cover and front cover. 6) If the problem persists, replace the imaging unit. |

| Error code: | C3-1314, C3-1315, C3-1316 |

| Description: | Imaging Unit Failure: #C3-1314. Install imaging unit again Imaging Unit Failure: #C3-1315. Install imaging unit again Imaging Unit Failure: #C3-1316. Install imaging unit again |

| Causes: | Toner supply is abnormal. |

| Remedy: | 1) Open the front cover and side cover. 2) Remove the toner cartridge. 3) Remove and reinstall the imaging unit. 4) Install the toner cartridge. 5) Close the side cover and front cover. 6) If the problem persists, replace the imaging unit. 7) Check if the motor related to toner supply is working normally. If not, replace the motor. |

| Error code: | C3-1410, C3-1414, C3-1512 |

| Description: | Imaging unit is not installed. Install the unit. Imaging Unit Failure: #C3-1414. Install imaging unit again. Imaging unit is not compatible. Check users guide. |

| Causes: | Imaging unit is not installed properly. / The machine can’t read the charger resistance value from the imaging unit. / Imaging unit is not compatible. |

| Remedy: | 1) Open the front cover and side cover. 2) Remove the toner cartridge. 3) Remove and reinstall the imaging unit. 4) Install the toner cartridge. 5) Close the side cover and front cover. 6) If the problem persists, replace the imaging unit with new one. |

| Error code: | C3-1710, C3-1711, C3-1712 |

| Description: | Imaging unit Failure: #C3-1710. Call for service. Imaging unit Failure: #C3-1711. Call for service. Imaging unit Failure: #C3-1712. Call for service. |

| Causes: | The data of CRUM is not detected. |

| Remedy: | 1) Open the front cover and side cover. 2) Remove the imaging unit check that its modular jack is contaminated or deformed. 3) If it is defective, replace it with new one. 4) Close the side cover and front cover. |

| Error code: | C6-1120 |

| Display: | Replace new Fuser unit |

| Description: | Replace with new fuser unit |

| Causes: | The life of the fuser unit has expired. |

| Remedy: | 1) Turn the machine off. 2) Replace the fuser unit(JC91-01157A (220V) /JC91-01158A (110V)). 3) Turn the machine on. |

| Error code: | C9-1112, C9-1122 |

| Description: | Replace with new Tray1 pickup roller. Replace with new Tray2 pickup roller. |

| Causes: | The life of the pick up/reverse/forward roller for tray1,2,3,4 has expired. |

| Remedy: | 1) Open the side cover. 2) Remove the cassette. 3) Lift small tap, remove the pick up / reverse/ forward roller. 4) Install the new pick up / reverse/ forward roller. 5) Enter SVC mode. 6) Select “Roller” (INFORMATION > Supply Status > Field Replacement Unit > Roller) 7) Select “P/up roller Kit-tray1~4”. The “RESET” button will be activated. Click “RESET” to clear the corresponding pick up roller. 8) Exit SVC mode by pushing the home button. |

| Error code: | C9-1132, C9-1142 |

| Description: | Replace with new Tray3 pickup roller. Replace with new Tray4 pickup roller. |

| Causes: | The life of the pick up/reverse/forward roller for tray1,2,3,4 has expired. |

| Remedy: | 1) Open the side cover. 2) Remove the cassette. 3) Lift small tap, remove the pick up / reverse/ forward roller. 4) Install the new pick up / reverse/ forward roller. 5) Enter SVC mode. 6) Select “Roller” (INFORMATION > Supply Status > Field Replacement Unit > Roller) 7) Select “P/up roller Kit-tray1~4”. The “RESET” button will be activated. Click “RESET” to clear the corresponding pick up roller. 8) Exit SVC mode by pushing the home button. |

| Error code: | C9-1162 |

| Display: | Replace with new MP pickup roller |

| Description: | Replace new MP Pickup roller |

| Causes: | The MP pick up roller is at the end of its life. |

| Remedy: | 1) Turn the machine off. 2) Replace the MP pick up roller. |

| Error code: | C9-2120 |

| Description: | Replace with new Transfer roller |

| Causes: | The life of the second transfer roller(T2) expires soon or has expired. |

| Remedy: | 1) Open the side cover. 2) Replace the second transfer roller with new one. 3) Close the side cover. 4) Enter SVC mode. 5) Select “TRNASFER” (INFORMATION > Supply Status > Field Replacement Unit > TRNASFER) 6) Select “T2 Roller”. The “RESET” button will be activated. Click “RESET” to clear the T2 roller. 7) Exit SVC mode by pushing the home button. |

| Error code: | C9-2220 |

| Display: | TR Failure: #C9-2220. Install transfer roller again. |

| Description: | TR Failure: #C9-2220. Install transfer roller again |

| Causes: | The life of the second transfer roller(T2) is not installed. |

| Remedy: | 1) Open the side cover. 2) Remove and reinstall the second transfer roller. 3) Close the side cover. 4) If the problem persists, replace the HVPS board(JC44–00212A). |

| Error code: | H1-1211, H1-1213 |

| Description: | Paper jam in Tray 2. Paper jam in tray 2 or tray door is open. |

| Causes: | Paper jam has occurred in tray2. (Pick up unit connection is defective. / Pickup rollers are defective. / Pick up sensor is defective.) |

| Remedy: | 1) Remove the tray2. Remove the jammed paper. And install the tray2. 2) If the problem persists, check the followings. 3) Check if the proper paper is loaded in the tray. If not, replace the paper. 4) Check if the pick up/reverse/forward roller are contaminated or worn out. Replace these rollers. 5) Check the tray 2 pick up unit. • Check if the sensor and actuator are assembled correctly. When the paper or something puts on sensor, check the sensor output. Check if the value is changed to 3.3V width. If not, replace the sensor. • If there is a defective part like a actuator, spring etc., replace it or the tray 2 pick up unit. 6) Check if the tray 2 pick up motor connector is connected correctly. 7) If the pick up motor is defective, replace it. 8) Check if the tray 2 pick up clutch connector is connected correctly. |

| Error code: | H1-1217, H1-1218, H1-1219 |

| Description: | Paper jam in Tray 2. Paper jam in tray 2 or tray door is open. |

| Causes: | Paper jam has occurred in tray2. (Pick up unit connection is defective. / Pickup rollers are defective. / Pick up sensor is defective.) |

| Remedy: | 1) Remove the tray2. Remove the jammed paper. And install the tray2. 2) If the problem persists, check the followings. 3) Check if the proper paper is loaded in the tray. If not, replace the paper. 4) Check if the pick up/reverse/forward roller are contaminated or worn out. Replace these rollers. 5) Check the tray 2 pick up unit. • Check if the sensor and actuator are assembled correctly. When the paper or something puts on sensor, check the sensor output. Check if the value is changed to 3.3V width. If not, replace the sensor. • If there is a defective part like a actuator, spring etc., replace it or the tray 2 pick up unit. 6) Check if the tray 2 pick up motor connector is connected correctly. 7) If the pick up motor is defective, replace it. 8) Check if the tray 2 pick up clutch connector is connected correctly. |

| Error code: | H1-1220 |

| Display: | Tray 2 Door Open. Close it |

| Description: | Optional cassette is not installed properly |

| Causes: | Tray 2 door is open. |

| Remedy: | 1) Remove and reinstall the Tray2 cassette. 2) Check the cassette detection sensor. • Check if the connection between sensor and main board is OK. Reconnect the harness. • If the sensor(JC34-00001A) is defective, replace it. 3) If the problem persists, replace the SCF main board(JC92-02636A). |

| Error code: | H1-1222, H1-1240 |

| Description: | Tray 2 cassette is pulled out. Insert it properly. |

| Causes: | Tray 2 is pulled out or the cassette detection sensor connector is not connected or broken. |

| Remedy: | 1) Remove and insert tray2 correctly. 2) If the problem persists, remove tray2 again. 3) Check if the cassette detection sensor cable is connected correctly. Unplug and reconnect it. 4) If the connection is OK, replace the cassette detection sensor. 5) If the problem persists, replace the SCF board. |

| Error code: | H1-1230 |

| Display: | Error: #H1-1230 / Input System Failure: #H1-1230. Check tray 2 connection |

| Description: | Communication error has occurred. |

| Causes: | The communication error between the tray 2 and the main machine has occurred. |

| Remedy: | 1) Turn the machine off then on. 2) If the problem persists, turn the machine off. 3) Remove the SCF right cover. (Refer to 3.3.23.1) 4) Check if the interface connector is connected to the SCF main board. If the interface connector is defective, replace it. 5) If the problem persists, replace the SCF main board.(JC92-02636A) |

| Error code: | H1-1251, H1-1252 |

| Description: | Paper Low in tray 2 / Paper is low in tray 2. Load paper Paper Empty in tray 2 / Paper is empty in tray 2. Load paper |

| Causes: | Paper in the tray2 is less than 10% of specification or empty. / The photo sensor is defective. |

| Remedy: | 1) Remove tray2. Load the paper in tray2. 2) If paper is loaded but error message has not disappeared, check the following. a) Check if the paper empty sensor is contaminated. If so, clean it. b) If the paper empty sensor is defective, replace it. c) If the empty actuator is defective, replace it. |

| Error code: | H1-1253 |

| Display: | Input System Failure #H1-1253 : Pull Tray 2 out and insert it. |

| Description: | The paper is not fed from tray2. |

| Causes: | The paper is not fed from tray2. |

| Remedy: | 1) Check if the Gear-Idle Lift is broken. 2) Check if the cassette detection sensor cable is connected correctly. Unplug and reconnect it. 3) If the connection is OK, replace the cassette detection sensor(JC34-00001A). 4) Check if the Lift-Motor connector is connected properly. 5) If the problem persists, replace the Lift-Motor(JC81-08705A). |

| Error code: | H1-1311, H1-1313 |

| Description: | Paper jam in Tray 3. Paper jam in tray 3 or tray door is open. |

| Causes: | Paper jam has occurred in tray3. (Pick up unit connection is defective. / Pickup rollers are defective. / Pick up sensor is defective.) |

| Remedy: | 1) Remove the tray3. Remove the jammed paper. And install the tray3. 2) If the problem persists, check the followings. 3) Check if the proper paper is loaded in the tray. If not, replace the paper. 4) Check if the pick up/reverse/forward roller are contaminated or worn out. Replace these rollers. 5) Check the tray 3 pick up unit. • Check if the sensor and actuator are assembled correctly. When the paper or something puts on sensor, check the sensor output. Check if the value is changed to 3.3V width. If not, replace the sensor. • If there is a defective part like a actuator, spring etc., replace it or the tray 3 pick up unit. 6) Check the tray 3 pick up motor. • Check if the tray 3 pick up motor cable is connected correctly. • If the connection is OK, replace the tray 3 pick up drive unit. |

| Error code: | H1-1317, H1-1318, H1-1319 |

| Description: | Paper jam in Tray 3. Paper jam in tray 3 or tray door is open. |

| Causes: | Paper jam has occurred in tray3. (Pick up unit connection is defective. / Pickup rollers are defective. / Pick up sensor is defective.) |

| Remedy: | 1) Remove the tray3. Remove the jammed paper. And install the tray3. 2) If the problem persists, check the followings. 3) Check if the proper paper is loaded in the tray. If not, replace the paper. 4) Check if the pick up/reverse/forward roller are contaminated or worn out. Replace these rollers. 5) Check the tray 3 pick up unit. • Check if the sensor and actuator are assembled correctly. When the paper or something puts on sensor, check the sensor output. Check if the value is changed to 3.3V width. If not, replace the sensor. • If there is a defective part like a actuator, spring etc., replace it or the tray 3 pick up unit. 6) Check the tray 3 pick up motor. • Check if the tray 3 pick up motor cable is connected correctly. • If the connection is OK, replace the tray 3 pick up drive unit. |

| Error code: | H1-1320 |

| Description: | Tray 3 door is open. Close it |

| Causes: | Tray 3 door is open. |

| Remedy: | 1) Check if the tray3 door is closed. If not, close it. 2) If the problem persists, check the door open sensor. If it is defective, replace it. 3) If the sensor is normal, replace the SCF board. |

| Error code: | H1-1322, H1-1340 |

| Description: | Tray 3 cassette is pulled out. Insert it properly. Tray 3 is not installed. Install the tray. |

| Causes: | Tray 3 is pulled out or the cassette detection sensor connector is not connected or broken. |

| Remedy: | 1) Remove and insert tray3 correctly. 2) If the problem persists, remove tray3 again. 3) Check if the cassette detection sensor cable is connected correctly. Unplug and reconnect it. 4) If the connection is OK, replace the cassette detection sensor. 5) If the problem persists, replace the SCF board. |

| Error code: | H1-1332 |

| Description: | Error: #H1-1332 / Tray Failure: #H1-1332. Check tray 3 connection & turn off then on. Call for service if the problem persists |

| Causes: | Connection between the main machine and the SCF unit is abnormal. |

| Remedy: | 1) Check the harness connection between the main machine and the SCF unit. Reconnect the harness. 2) If the problem persists, replace the SCF board. 3) If the SCF board is normal, replace the Main board. |

| Error code: | H1-1351, H1-1352 |

| Display: | Paper is low in Tray 3. Load paper. Paper is empty in Tray 3. Load paper. |

| Description: | Paper in the tray is less than 10%. / The photo sensor is defective.). |

| Causes: | Paper in the tray3 is less than 10% of specification or empty. / The photo sensor is defective. |

| Remedy: | 1) Remove tray3. Load the paper in the tray3. 2) If paper is loaded but error message has not disappeared, check the following. a) Remove the DCF pick up unit1. b) Check if the photo sensor in the DCF pick up unit1 is contaminated. If so, clean it. c) If the photo sensor(0604-001393) is defective, replace it. d) If the actuator(JC66-03199A) is defective, replace it. |

| Error code: | H1-1353 |

| Display: | Input System Failure #H1-1353 : Pull Tray 3 out and insert it. |

| Description: | Input System Failure #H1-1353 : Pull Tray 3 out and insert it. |

| Causes: | The paper is not fed from tray3. |

| Remedy: | 1) Remove and insert tray3 correctly. 2) Turn the machine off then on. 3) If the problem persists, turn the machine off. 4) Remove the Bracket Rear Cover after removing 5 screws. 5) Check if the connection between the DCF pick up drive and DCF board is correct. 6) If the connection is OK, replace the pick up drive unit(JC93-00442A). 7) If the problem persists, check the following. a) Remove the DCF pick up unit1. b) Check if the photo sensor in the DCF pick up unit1 is contaminated, clean it. c) If the photo sensor(0604-001393) is defective, replace it. |

| Error code: | H1-1411, H1-1413 |

| Description: | Paper jam in Tray 4. Paper jam in tray 4 or tray door is open. |

| Causes: | Paper jam has occurred in tray4. (Pick up unit connection is defective. / Pickup rollers are defective. / Pick up sensor is defective.) |

| Remedy: | 1) Remove the tray4. Remove the jammed paper. And install the tray4. 2) If the problem persists, check the followings. 3) Check if the proper paper is loaded in the tray. If not, replace the paper. 4) Check if the pick up/reverse/forward roller are contaminated or worn out. Replace these rollers. 5) Check the tray 4 pick up unit. • Check if the sensor and actuator are assembled correctly. When the paper or something puts on sensor, check the sensor output. Check if the value is changed to 3.3V width. If not, replace the sensor. • If there is a defective part like a actuator, spring etc., replace it or the tray 4 pick up unit. 6) Check the tray 4 pick up motor. • Check if the tray 4 pick up motor cable is connected correctly. • If the connection is OK, replace the tray 4 pick up drive unit. |

| Error code: | H1-1417, H1-1418, H1-1419 |

| Description: | Paper jam in Tray 4. Paper jam in tray 4 or tray door is open. |

| Causes: | Paper jam has occurred in tray4. (Pick up unit connection is defective. / Pickup rollers are defective. / Pick up sensor is defective.) |

| Remedy: | 1) Remove the tray4. Remove the jammed paper. And install the tray4. 2) If the problem persists, check the followings. 3) Check if the proper paper is loaded in the tray. If not, replace the paper. 4) Check if the pick up/reverse/forward roller are contaminated or worn out. Replace these rollers. 5) Check the tray 4 pick up unit. • Check if the sensor and actuator are assembled correctly. When the paper or something puts on sensor, check the sensor output. Check if the value is changed to 3.3V width. If not, replace the sensor. • If there is a defective part like a actuator, spring etc., replace it or the tray 4 pick up unit. 6) Check the tray 4 pick up motor. • Check if the tray 4 pick up motor cable is connected correctly. • If the connection is OK, replace the tray 4 pick up drive unit. |

| Error code: | H1-1420 |

| Description: | Tray 4 door is open. Close it |

| Causes: | Tray 4 door is open. |

| Remedy: | 1) Check if the tray4 door is closed. If not, close it. 2) If the problem persists, check the door open sensor. If it is defective, replace it. 3) If the sensor is normal, replace the SCF board. |

| Error code: | H1-1422 |

| Display: | Tray 4 cassette is pulled out. Insert it properly. |

| Description: | Tray 4 cassette is pulled out. Insert it properly. |

| Causes: | Tray 4 is pulled out or the auto size sensor connector is not connected or is broken. |

| Remedy: | 1) Remove and insert tray4 correctly. 2) If the problem persists, remove tray3 and tray4. Look inside machine. 3) Check if the auto size sensor cable is connected correctly. Unplug and reconnect it. 4) If the connection is OK, replace the auto size sensor(JC93-00018A). 5) If the problem persists, replace the DCF board(JC92-02453A). |

| Error code: | H1-1434 |

| Description: | Error: #H1-1434 / Tray Failure: #H1-1434. Check tray 4 connection & turn off then on. Call for service if the problem persists |

| Causes: | Connection between the main machine and the SCF unit is abnormal. |

| Remedy: | 1) Check the harness connection between the main machine and the SCF unit. Reconnect the harness. 2) If the problem persists, replace the SCF board. 3) If the SCF board is normal, replace the Main board. |

| Error code: | H1-1451, H1-1452 |

| Display: | Paper is low in Tray 4. Load paper. Paper is empty in Tray 4. Load paper. |

| Description: | Paper in tray4 is less than 10%. / The photo sensor is defective. |

| Causes: | Paper in the tray4 is less than 10% of specification. / The photo sensor is defective. |

| Remedy: | 1) Remove the tray4. Load the paper in the tray4. 2) If paper is loaded but error message has not disappeared, check the following. a) Remove the DCF pick up unit2. b) Check if the photo sensor in the DCF pick up unit2 is contaminated. If so, clean it. c) If the photo sensor(0604-001393) is defective, replace it. d) If the actuator(JC66-03199A) is defective, replace it. |

| Error code: | H1-1453 |

| Display: | Input System Failure #H1-1453 : Pull Tray 4 out and insert it. |

| Description: | Input System Failure #H1-1453 : Pull Tray 4 out and insert it. |

| Causes: | The paper is not fed from tray4. |

| Remedy: | 1) Remove and insert tray4 correctly. 2) Turn the machine off then on. 3) If the problem persists, turn the machine off. 4) Remove the Bracket Rear Cover after removing 5 screws. 5) Check if the connection between the DCF pick up drive and DCF board is correct. 6) If the connection is OK, replace the pick up drive unit(JC93-00442A). 7) If the problem persists, check the following. a) Remove the DCF pick up unit2. b) Check if the photo sensor in the DCF pick up unit2 is contaminated. If so, clean it. c) If the photo sensor(0604-001393) is defective, replace it. |

| Error code: | H1-2211, H1-2213 |

| Description: | Paper jam in HCF 2. Paper jam in tray 2 or tray door is open. |

| Causes: | Paper jam has occurred in 1st HCF. (Pick up unit connection is defective. / Pickup rollers are defective. / Pick up sensor is defective.) |

| Remedy: | 1) Remove the 1st HCF cassette. Remove the jammed paper. And install the 1st HCF cassette. 2) If the problem persists, check the followings. 3) Check if the proper paper is loaded in the cassette. If not, replace the paper. 4) Check if the pick up/reverse/forward roller are contaminated or worn out. Replace these rollers. 5) Check the 1st HCF pick up unit. • Check if the sensor and actuator are assembled correctly. When the paper or something puts on sensor, check the sensor output. Check if the value is changed to 3.3V width. If not, replace the sensor. • If there is a defective part like a actuator, spring etc., replace it or the 1st HCF pick up unit. 6) Check the 1st HCF pick up motor. • Check if the 1st HCF pick up motor cable is connected correctly. • If the connection is OK, replace the 1st HCF pick up drive unit. |

| Error code: | H1-2217, H1-2218, H1-2219 |

| Description: | Paper jam in HCF 2. Paper jam in tray 2 or tray door is open. |

| Causes: | Paper jam has occurred in 1st HCF. (Pick up unit connection is defective. / Pickup rollers are defective. / Pick up sensor is defective.) |

| Remedy: | 1) Remove the 1st HCF cassette. Remove the jammed paper. And install the 1st HCF cassette. 2) If the problem persists, check the followings. 3) Check if the proper paper is loaded in the cassette. If not, replace the paper. 4) Check if the pick up/reverse/forward roller are contaminated or worn out. Replace these rollers. 5) Check the 1st HCF pick up unit. • Check if the sensor and actuator are assembled correctly. When the paper or something puts on sensor, check the sensor output. Check if the value is changed to 3.3V width. If not, replace the sensor. • If there is a defective part like a actuator, spring etc., replace it or the 1st HCF pick up unit. 6) Check the 1st HCF pick up motor. • Check if the 1st HCF pick up motor cable is connected correctly. • If the connection is OK, replace the 1st HCF pick up drive unit. |

| Error code: | H1-2220 |

| Description: | HCF 2 door is open. Close it. |

| Causes: | The right door of the 1st HCF is open. / The door open sensor is defective. |

| Remedy: | 1) Open and close the 1st HCF door. 2) If the problem persists, check the door open sensor. • Check if the door open sensor connector is connected correctly. • If the sensor operation is abnormal, replace it. |

| Error code: | H1-2222, H1-2240 |

| Description: | HCF 2 cassette is pulled out. Insert it properly. HCF 2 is not installed. Install the HCF. |

| Causes: | 1st HCF cassette is pulled out or the cassette detection sensor connector is not connected or broken. |

| Remedy: | 1) Remove and insert the 1st HCF cassette correctly. 2) If the problem persists, remove the 1st HCF cassette again. 3) Check if the cassette detection sensor cable is connected correctly. Unplug and reconnect it. 4) If the connection is OK, replace the cassette detection sensor. 5) If the problem persists, replace the HCF board. |

| Error code: | H1-2230 |

| Description: | Input System Failure: #H1-2230. Check HCF 2 connection. |

| Causes: | The communication error between the 1st HCF and the main machine has occurred. |

| Remedy: | 1) Check if the HCF unit connector is connected to the machine correctly. Reconnect it. 2) If the drawer connector is deformed, replace it. |

| Error code: | H1-2251, H1-2252 |

| Description: | Paper is low in HCF 2. Load paper. Paper is empty in HCF 2. Load paper. |

| Causes: | Paper in the 1st HCF cassette is less than 10% of specification. / The photo sensor is defective. |

| Remedy: | 1) Remove 1st HCF cassette. Load the paper in the 1st HCF cassette. 2) If paper is loaded but error message has not disappeared, check the following. a) Remove the 1st HCF pick up unit. b) Check if the paper empty sensor is contaminated. If so, clean it. c) If the paper empty sensor is defective, replace it. d) If the empty actuator is defective, replace it. |

| Error code: | H1-2253 |

| Description: | Input System Failure #H1-2253 : Pull HCF 2 out and insert it. |

| Causes: | The paper is not fed from HCF. |