Samsung ProXpress C4060FX

Рейтинг

Модули

Exit

ADF

COVER

FRAME SUB BRKT MP

MAIN

DRIVE-MAIN

FRAME

Fuser

PLATEN

FRAME SUB-LEFT

Cover-Middle

FRAME SUB-RIGHT

COVER-REAR

CASSETTE

FRAME-SEPARATION

Детали ADF

| Деталь: | EXIT, C3510,NON-MD |

| Парткод: | JC90-01606A |

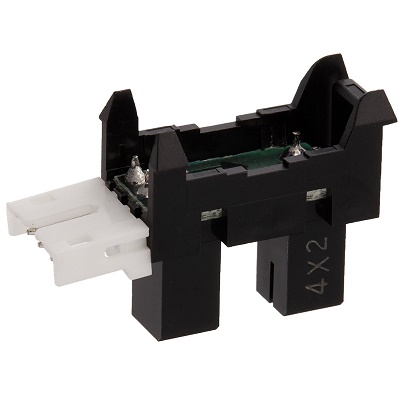

| Деталь: | PHOTO-INTERRUPTER, TR,75mW,BGA,TR |

| Парткод: | 0604-001393 |

| Деталь: | BRACKET-EXIT, C3560,ABS+PC,BLACK,MOLD |

| Парткод: | JC61-07978A |

| Деталь: | GUIDE-EXIT LOWER, C3510,ABS+PC,AC2013,SPL |

| Парткод: | JC61-07993A |

| Деталь: | GUIDE-EXIT UPPER, C3510,ABS+PC,AC2013,SPL |

| Парткод: | JC61-07994A |

| Деталь: | COVER-STACKER, C3510,ABS+PC,SPLIT BROWN B |

| Парткод: | JC63-05500A |

| Деталь: | COVER-STACKER DUMMY, C3510,ABS+PC,SPLIT B |

| Парткод: | JC63-05501A |

| Деталь: | GROUND-EXIT ROLLER, C3510,STS304,0.2,17.3 |

| Парткод: | JC63-05502A |

| Деталь: | GEAR-IDLE FEED B, CLP-770ND,POM(DE8903),0 |

| Парткод: | JC66-02044A |

| Деталь: | GEAR-DRIVE EXIT LOWER, M40,POM,0.8,17,NAT |

| Парткод: | JC66-04917A |

| Деталь: | GEAR-DRIVE EXIT UPPER, M40,POM,0.8,16,NAT |

| Парткод: | JC66-04918A |

| Деталь: | ACTUATOR-EXIT FUSER, C3510,POM,1.3,9.9,10 |

| Парткод: | JC66-05054A |

| Деталь: | GEAR-IDLE EXIT, C3560,POM,0.8,32,NATURAL |

| Парткод: | JC66-05074A |

| Деталь: | ROLLER EXIT-DRIVE, C3510,Shaft-Exit(Steel |

| Парткод: | JC66-05085A |

| Деталь: | ROLLER EXIT-DECURL, C3510,Shaft-Exit(Stee |

| Парткод: | JC66-05086A |

| Деталь: | LEVER-STACKING, C3510,ABS+PC,230NH,BLACK, |

| Парткод: | JC66-05104A |

| Деталь: | LEVER-STACKER, C3510,ABS+PC,230NH,BLACK,G |

| Парткод: | JC66-05105A |

| Деталь: | ROLLER, ML-165,POM |

| Парткод: | JC72-40981A |

| Деталь: | A/S ASSY-FEED MOTOR, M4580,SEC |

| Парткод: | JC82-00374A |

| Деталь: | A/S ASSY-WHITE BAR CIS, M4580,SEC |

| Парткод: | JC82-00375A |

| Деталь: | A/S ASSY-PAPER PATH, M4580,SEC |

| Парткод: | JC82-00376A |

| Деталь: | A/S ASSY-TOP COVER, M4580,SEC |

| Парткод: | JC82-00377A |

| Деталь: | A/S ASSY-PICK UP HOUSING, M4580,SEC |

| Парткод: | JC82-00378A |

| Деталь: | A/S ASSY-INPUT TRAY, M4580,SEC |

| Парткод: | JC82-00379A |

| Деталь: | A/S ASSY-SEPARATE ROLLER, M4580,SEC |

| Парткод: | JC82-00380A |

| Деталь: | A/S ASSY-EXIT STACKER, M4580,SEC |

| Парткод: | JC82-00381A |

| Деталь: | COVER-FRONT INNER |

| Парткод: | JC63-05455A |

| Деталь: | Cover-Front |

| Парткод: | JC95-02060C |

| Деталь: | Cover-Rear |

| Парткод: | JC95-02061A |

| Деталь: | COVER-LEFT |

| Парткод: | JC95-02062A |

| Деталь: | COVER-RIGHT |

| Парткод: | JC95-02063A |

| Деталь: | Cover-Front |

| Парткод: | JC63-03729B |

| Деталь: | LINK-COVER_MP |

| Парткод: | JC66-02086D |

| Деталь: | LOCKER-LATCH_PUSH |

| Парткод: | JC64-00912A |

| Деталь: | BUTTON-FRONT |

| Парткод: | JC64-01020A |

| Деталь: | LINK-SUPPORT R |

| Парткод: | JC66-03640A |

| Деталь: | LINK-SUPPORT L |

| Парткод: | JC66-03639A |

| Деталь: | COVER-MP TRAY |

| Парткод: | JC95-01651D |

| Деталь: | COVER-WTB |

| Парткод: | JC63-03734B |

| Деталь: | COVER-LEFT |

| Парткод: | JC63-05454A |

| Деталь: | COVER-DIMM |

| Парткод: | JC63-05465A |

| Деталь: | COVER-RIGHT |

| Парткод: | JC63-05464A |

| Деталь: | COVER-MP |

| Парткод: | JC63-03730D |

| Деталь: | Gear-Rack_Pinion |

| Парткод: | JC66-00387A |

| Деталь: | TRAY-MP LOWER |

| Парткод: | JC63-02902F |

| Деталь: | ADJUST-MP_LEFT |

| Парткод: | JC70-00561B |

| Деталь: | ADJUST-MP_RIGHT |

| Парткод: | JC70-00562B |

| Деталь: | PHOTO-INTERRUPTER, TR,75mW,BGA,TR |

| Парткод: | 0604-001393 |

| Деталь: | WASHER-PLAIN, M17.5,ID6.1,OD17.5,T0.13,BL |

| Парткод: | 6031-001002 |

| Деталь: | WASHER-PLAIN, POLYSIDER,CUTTING,ID5,OD9,T |

| Парткод: | 6031-001255 |

| Деталь: | CABLE CLAMP, 4,Nylon66 |

| Парткод: | 6502-001131 |

| Деталь: | BELT-TIMING GEAR, S2M250,RUB(CR),L250 |

| Парткод: | 6602-001721 |

| Деталь: | CLUTCH-ELECTRIC, SL-M4030,POM,2.5,41,0.6, |

| Парткод: | JC47-00035C |

| Деталь: | BRACKET-MP, CLP-680DW,EGI-SECC,0.8T |

| Парткод: | JC61-05412A |

| Деталь: | HOLDER-SHAFT MP, CLP-680ND,POM,1.5,12.5,3 |

| Парткод: | JC61-05529A |

| Деталь: | GUIDE-PAPER MP, C2620,POM,F20-02,NATURAL |

| Парткод: | JC61-06377A |

| Деталь: | COVER-ITB SENSOR, CLP-680ND,HIPS,BLACK,HI |

| Парткод: | JC63-03761A |

| Деталь: | SHEET-BRACKET_MP, CLP-680DN,PET,0.125 |

| Парткод: | JC63-03983A |

| Деталь: | MP SUB-GUIDE, C3510 |

| Парткод: | JC90-01604A |

| Деталь: | FRAME-REGI, CLP-680ND |

| Парткод: | JC93-00790A |

| Деталь: | PICK UP, C3510,NON-MD |

| Парткод: | JC93-01340A |

| Деталь: | FRAME SUB-ROLLER MP, C3510 |

| Парткод: | JC93-01357A |

| Деталь: | SPRING ETC-SENSOR, SF-5100,SUS304WPB,0.2, |

| Парткод: | JC61-00018A |

| Деталь: | HOLDER-SHAFT, ML-1660,POM,21.8,BLACK,F25- |

| Парткод: | JC61-03973A |

| Деталь: | GUIDE-MP, C3510,ABS,780U,CREAM WHITE,PATH |

| Парткод: | JC61-07996A |

| Деталь: | ACTUATOR-FEED MP, CLP-680ND,PC,BLACK,ACTU |

| Парткод: | JC66-03608A |

| Деталь: | SHAFT-REGI IDLE, CLP-680ND,SUM22,173.2,5, |

| Парткод: | JC66-03778A |

| Деталь: | GROUND-REGI, CLP-680ND,STS301,0.2,14,37.5 |

| Парткод: | JC63-03773A |

| Деталь: | CLUTCH-ELECTRIC, 2.5,41,0.6,120mA,200Ohm |

| Парткод: | JC47-00035B |

| Деталь: | SPRING-TS, SUS,PI0.15,D3.95,ID3.8,OD4.1 |

| Парткод: | 6107-001164 |

| Цена: | 1 100 ₽ |

| Деталь: | SPRING-CS, SUS304,0.6,14.8,4,RIGHT |

| Парткод: | 6107-003246 |

| Деталь: | ACTUATOR-REGI SENSOR, CLP-680ND,PC+GF,3T, |

| Парткод: | JC66-03611A |

| Деталь: | ROLLER IDLE-REGI, CLP-680ND,EPDM,SUM22,6 |

| Парткод: | JC66-03633A |

| Деталь: | FRAME-REGI, CLP-680ND,ABS+GF20%,BLACK,GR- |

| Парткод: | JC61-05443A |

| Деталь: | HOLDER, CLP-680ND,POM,NATURAL (WHITE),NW- |

| Парткод: | JC61-05448A |

| Деталь: | SPRING-CS, SUS,0.4,5.2,5,5.4,11.25,RIGHT, |

| Парткод: | 6107-003349 |

| Деталь: | FRAME-PICK UP, C3510,ABS,BLACK,780U,FEED |

| Парткод: | JC61-07991A |

| Деталь: | HOLDER-PICK UP, C3510,POM,NATURAL (WHITE) |

| Парткод: | JC61-08004A |

| Деталь: | SHAFT-PICK UP, CLP-680ND,PC+GF20%,6,BLACK |

| Парткод: | JC66-03620A |

| Деталь: | ACTUATOR-EMPTY, C3510,ABS+PC,2,47.94,59.2 |

| Парткод: | JC66-05053A |

| Деталь: | PMO, ML-2150,NTR,POM,NW-02 |

| Парткод: | JC72-41191B |

| Цена: | 430 ₽ |

| Деталь: | PICK UP SUB-ROLLER, C3510,NON-MD |

| Парткод: | JC93-01337A |

| Деталь: | PULLEY-DUPLEX, ML-5015ND,POM |

| Парткод: | JC66-02902A |

| Деталь: | GEAR-MP FEED, CLP-680ND,POM,0.6,24,Natura |

| Парткод: | JC66-03647A |

| Деталь: | ROLLER FEED, C3510,EPDM,CFRP,6 |

| Парткод: | JC66-05087A |

| Деталь: | ROLLER IDLE-REGI, CLP-680ND,POM,F20-02 |

| Парткод: | JC61-05611A |

| Деталь: | HOUSING-PICK UP, C3510,POM,2,41.1,49.85,B |

| Парткод: | JC61-07976A |

| Деталь: | ROLLER IDLE-MAT_RETARD, ML-2950ND,EPDM |

| Парткод: | JC66-02939B |

| Цена: | 350 ₽ |

| Деталь: | CLUTCH-P-ONEWAY, ML-2955ND,POM |

| Парткод: | JC66-03047A |

| Деталь: | GEAR-IDLE FEED, C3510,POM,0.5,30,NATURAL |

| Парткод: | JC66-05063A |

| Деталь: | Scanner |

| Парткод: | JC97-04818A |

| Деталь: | CARTRIDGE-WTB |

| Парткод: | JC96-06367A |

| Деталь: | COVER |

| Парткод: | JC95-02059C |

| Деталь: | FAN |

| Парткод: | JC31-00180A |

| Деталь: | HVPS |

| Парткод: | JC44-00244A |

| Деталь: | HVPS |

| Парткод: | JC44-00243A |

| Деталь: | FRAME-T1 TERMINAL |

| Парткод: | JC93-00658A |

| Деталь: | HOLDER-TERMINAL |

| Парткод: | JC61-07847A |

| Деталь: | LSU |

| Парткод: | JC97-04795A |

| Деталь: | ITB |

| Парткод: | JC93-01348A |

| Деталь: | FRAME SUB-DRAWER |

| Парткод: | JC93-01339A |

| Деталь: | BRACKET-MAIN |

| Парткод: | JC61-07963A |

| Деталь: | PBA MAIN |

| Парткод: | JC92-02795E |

| Деталь: | FAN |

| Парткод: | JC31-00161A |

| Деталь: | DUCT-FAN UPPER |

| Парткод: | JC67-00766A |

| Деталь: | COVER-CONN |

| Парткод: | JC63-03763A |

| Деталь: | CASSETTE |

| Парткод: | JC90-01599A |

| Деталь: | COVER-MIDDLE RIGHT |

| Парткод: | JC95-02058A |

| Деталь: | Cover-Middle |

| Парткод: | JC95-02057A |

| Деталь: | OPE |

| Парткод: | JC97-04798A |

| Деталь: | GUIDE-HDD |

| Парткод: | JC61-07494A |

| Деталь: | HDD |

| Парткод: | JC59-00035A |

| Деталь: | SHEET-WHITE |

| Парткод: | JC63-04347A |

| Деталь: | ADF |

| Парткод: | JC97-04451B |

| Деталь: | PLATEN |

| Парткод: | JC97-04823A |

| Деталь: | HINGE-RIGHT |

| Парткод: | JC97-04912A |

| Деталь: | HINGE-LEFT |

| Парткод: | JC97-04911A |

| Деталь: | COVER-CONNECTOR |

| Парткод: | JC63-04697A |

| Деталь: | DRIVE-MAIN, C3560,SEC,MD |

| Парткод: | JC93-01342A |

| Деталь: | MOTOR BLDC, 48M843M070,11003000,24,2.2,3 |

| Парткод: | JC31-00144G |

| Деталь: | HOLDER-SENSOR OPC, CLP-680ND,ABS,93.5,44, |

| Парткод: | JC61-05573A |

| Деталь: | PHOTO-INTERRUPTER, TR,75mW,BGA,TR |

| Парткод: | 0604-001393 |

| Деталь: | CLUTCH-ELECTRIC, SL-M4030,POM,2.5,41,0.6, |

| Парткод: | JC47-00035C |

| Деталь: | DRIVE-SUB DEVE CLUTCH, C3560,SEC,NON-MD |

| Парткод: | JC93-00772B |

| Деталь: | COUPLER-DRIVE ITB, SMF 4040 |

| Парткод: | JC66-05016A |

| Деталь: | BRACKET-CLUTCH, C3560,EGI-SECC,0.6,PRESS |

| Парткод: | JC61-07984A |

| Деталь: | HOLDER-DRIVE OPC, C3560,POM,D17.0,BLACK,F |

| Парткод: | JC61-08015A |

| Деталь: | GEAR-DRIVE OPC, CLP-680ND,POM,0.5,120,BLA |

| Парткод: | JC66-03695A |

| Деталь: | GEAR-DEVE IDLE 1ST, CLP-680ND,POM,0.5,69, |

| Парткод: | JC66-03701A |

| Деталь: | FRAME SUB-LEFT, C3510,SEC |

| Парткод: | JC93-01334A |

| Деталь: | FRAME SUB-DUCT, C3510,SEC |

| Парткод: | JC93-01329A |

| Деталь: | DUCT-SUB, C30,HIPS,HIPS-5197,BLACK |

| Парткод: | JC67-00836A |

| Деталь: | BRACKET-FRONT_TOP, CLP-680DW,EGI-SECC,1.0 |

| Парткод: | JC61-05407A |

| Деталь: | MP SUB-GUIDE UPPER, C4010,CH,15,300 |

| Парткод: | JC90-01698A |

| Деталь: | LINK-L, CLP-680ND,POM,BLACK |

| Парткод: | JC66-03637A |

| Деталь: | LINK-R, CLP-680ND,POM,BLACK |

| Парткод: | JC66-03638A |

| Деталь: | MP SUB-SEPARATION, C3510 |

| Парткод: | JC90-01605A |

| Деталь: | FRAME SUB-BRKT MP, C3510,SEC |

| Парткод: | JC93-01328A |

| Деталь: | EXIT, C3510,NON-MD |

| Парткод: | JC90-01606A |

| Деталь: | CAP-FUSER AC HARNESS, CLP-470NW,ABS+PC,23 |

| Парткод: | JC67-00647A |

| Деталь: | FUSER, C3510,SEC,115V,IFS3,24,27,MD |

| Парткод: | JC91-01227A |

| Деталь: | BRACKET-BOTTOM_REAR, CLP-680DW,EGI-SECC,1 |

| Парткод: | JC61-05404A |

| Деталь: | DUPLEX SUB-ACTUATOR, C3510 |

| Парткод: | JC90-01607A |

| Деталь: | COVER-PATH, C4010,HIPS,2.5,CREAM WHITE (C |

| Парткод: | JC63-05447A |

| Деталь: | FRAME SUB-SEPARATION, C3510 |

| Парткод: | JC93-01336A |

| Деталь: | FRAME SUB-INLET, SL-C3510ND,SEC |

| Парткод: | JC93-01352A |

| Деталь: | DRIVE-DUPLEX, C3560,SEC,MD |

| Парткод: | JC93-01346A |

| Деталь: | FRAME SUB-RIGHT, C3510,SEC |

| Парткод: | JC93-01327A |

| Деталь: | DRIVE-FEED, C3560,SEC,MD |

| Парткод: | JC93-01344A |

| Деталь: | BRACKET-TR MOTOR DC, CLP-680ND,HIPS,BLACK |

| Парткод: | JC61-05575A |

| Деталь: | DRIVE-CST LIFT, C3560,SEC,MD |

| Парткод: | JC93-01345A |

| Деталь: | DRIVE-T1 ENGAGE, C3560,SEC,MD |

| Парткод: | JC93-01343A |

| Деталь: | DUCT-FAN LOWER, C3510,HIPS,1.5,154,120,HB |

| Парткод: | JC67-00765B |

| Деталь: | DRIVE-FUSER, C3560,DRIVE-FUSER,MD |

| Парткод: | JC93-00767B |

| Деталь: | HOLDER-USB HOST, CLP-680ND,HIPS,2,33,11.8 |

| Парткод: | JC61-05639A |

| Деталь: | DRIVE-MAIN, C3560,SEC,MD |

| Парткод: | JC93-01342A |

| Деталь: | SMPS-V1, C35,PSPN2 Type4H V1,AC-DC,225W,1 |

| Парткод: | JC44-00247A |

| Деталь: | FRAME SUB-SMPS, C3510,SEC |

| Парткод: | JC93-01330A |

| Деталь: | BRACKET-LSU_REAR, CLP-680DW,EGI-SECC,1.0T |

| Парткод: | JC61-05409A |

| Деталь: | BRACKET-FUSER, CLP-680DW,EGI-SECC,0.8T,PR |

| Парткод: | JC61-05406A |

| Деталь: | ROLLER IDLE-RUBBER-PICK_UP, ML-2851ND |

| Парткод: | JC73-00295A |

| Цена: | 380 ₽ |

| Деталь: | SLEEVE-MP, ML-2855ND,6,41.4,10 |

| Парткод: | JC61-02808A |

| Деталь: | HOLDER-SHAFT, CLX-6200FX,POM |

| Парткод: | JC61-02260A |

| Деталь: | GEAR-JOINT2_MP, ML-2855ND,POM,0.5,23,12.5 |

| Парткод: | JC66-02085A |

| Деталь: | COLLAR-MP, ML-6510ND,POM,10.8,13.5,NTR |

| Парткод: | JC61-03898A |

| Деталь: | DRIVE-MOTOR STEP, C3560,SEC,NON-MD |

| Парткод: | JC93-01347A |

| Деталь: | CLUTCH-ELECTRIC, SL-M4030,POM,2.5,41,0.6, |

| Парткод: | JC47-00035C |

| Деталь: | DRIVE-MOTOR STEP, C4060,SEC,NON-MD |

| Парткод: | JC93-00301C |

| Деталь: | FAN, Type4,24,100mA,2.794mmH20,0.374m3/m |

| Парткод: | JC31-00146A |

| Деталь: | FUSER, C3510,SEC,115V,IFS3,24,27,MD |

| Парткод: | JC91-01227A |

| Деталь: | FUSER-FRAME TOP, MD |

| Парткод: | JC91-01231A |

| Деталь: | FUSER-BELT, C3510,110V,MD |

| Парткод: | JC91-01234A |

| Деталь: | ACTUATOR-CAM, CLP-680ND,PA,A50H1,BLACK,AC |

| Парткод: | JC66-03436A |

| Деталь: | SPRING ES, C3510,SWPB,1.3,6.9,9.5,35.3,13 |

| Парткод: | JC61-08046A |

| Деталь: | WIRE HARNESS-FUSER AC, C40,UL3122,2p,60, |

| Парткод: | JC39-02506A |

| Деталь: | FUSER-BIAS, C3510,MD |

| Парткод: | JC91-01232A |

| Деталь: | ROLLER FUSER-PRESSURE, C3510,19,SUM23,PFA |

| Парткод: | JC66-05096A |

| Деталь: | BEARING BALL, 688ZZ,ID8,OD16,L5,SUJ2/SUS3 |

| Парткод: | 6601-001341 |

| Деталь: | GEAR-CAM, CLP-680ND,PA,1,22,BLACK,24,A50H |

| Парткод: | JC66-03437A |

| Деталь: | GUIDE WIRE-GEAR, C3510,PET+GF,5V,LV2250GN |

| Парткод: | JC61-08045A |

| Деталь: | GEAR DRIVE-FUSER, C3510,PA66+GF25%,1.0,23 |

| Парткод: | JC66-05183A |

| Деталь: | FUSER-FRAME BOTTOM, MD |

| Парткод: | JC91-01230A |

| Деталь: | FUSER-GUIDE DUP, C3510,110V,MD |

| Парткод: | JC91-01233A |

| Деталь: | ACTUATOR-EXIT FUSER, C3510,PA66,2413GW,BL |

| Парткод: | JC66-05097A |

| Деталь: | PLATEN-UPPER, M4580,SEC |

| Парткод: | JC97-04454A |

| Деталь: | PLATEN LOWER-FRAME, C3562,CH,35,No,Module |

| Парткод: | JC97-04826A |

| Деталь: | PLATEN LOWER, C3562,NON-MD |

| Парткод: | JC97-04824A |

| Деталь: | COVER-SCAN UPPER, M4580,ABS,SEC,SPLIT BRO |

| Парткод: | JC63-04556A |

| Деталь: | GLASS TEMPERED-ADF, 26228.5,2.8,Scanner |

| Парткод: | JC01-00103A |

| Деталь: | GLASS TEMPERED-PLATEN, 254.4420,2.8,Scan |

| Парткод: | JC01-00104A |

| Деталь: | CBF FLAT CABLE-CIS, C4062,24P,900,AWM2062 |

| Парткод: | JC39-02534A |

| Деталь: | CORE-FERRITE, 33x30x6.5mm,2800,1500Gauss |

| Парткод: | 3301-001877 |

| Деталь: | FRAME-PLATEN, M4580,ABS,HF-0660I,SPLIT BR |

| Парткод: | JC61-06108A |

| Деталь: | PLATEN-MAIN, C3562,CH,35,No,Module Transf |

| Парткод: | JC97-04827A |

| Деталь: | GROUND-SCAN LOWER, SL-C2680FX,STS304,0.2, |

| Парткод: | JC63-05103A |

| Деталь: | COVER-SCAN LOWER, C3562,ABS,SPLIT BROWN B |

| Парткод: | JC63-05478A |

| Деталь: | CONTACT IMAGE SENSOR, 219mm,5184DOT,0.121 |

| Парткод: | 0605-001237 |

| Деталь: | PLATEN-GUIDE CIS REAR, C2680,SEC,NON-MD |

| Парткод: | JC97-04717A |

| Деталь: | BELT-TIMING GEAR, 932,poly urethan,black |

| Парткод: | 6602-003602 |

| Деталь: | PLATEN-DRIVETRAIN, CLX-6260ND |

| Парткод: | JC97-04170A |

| Цена: | 2 000 ₽ |

| Деталь: | BRACKET-CIS, M4580,ABS+PC,BLACK,MOLD |

| Парткод: | JC61-06361A |

| Деталь: | PHOTO-INTERRUPTER, TR,75mW,BGA,TR |

| Парткод: | 0604-001393 |

| Деталь: | FRAME SUB-LEFT, C3510,SEC |

| Парткод: | JC93-01334A |

| Деталь: | LINK-CRUM HV, C4010,ABS,BLACK |

| Парткод: | JC66-05178A |

| Деталь: | FRAME SUB-GUIDE CST L, C3510,SEC |

| Парткод: | JC93-01335A |

| Деталь: | FRAME SUB-HOLDER HVPS, C3510,SEC |

| Парткод: | JC93-01349A |

| Деталь: | FRAME SUB-HOLDER HVPS, C3510,SEC |

| Парткод: | JC93-01350A |

| Деталь: | FRAME SUB-CRUM, C4010,SEC |

| Парткод: | JC93-01463A |

| Деталь: | GUIDE-TRAY LEFT, CLP-680DW,ABS+GF,344.2,G |

| Парткод: | JC61-05426A |

| Деталь: | FRAME-HOLDER WTB SENSOR, SL-C3010ND,SEC |

| Парткод: | JC93-01297A |

| Деталь: | SENSOR, HSU-07F1V2-N,CLX-9201,045C,+3.3 |

| Парткод: | JC32-00015A |

| Деталь: | HOLDER-T2 HV, CLP-680ND,ABS+PC,BLACK,NH-1 |

| Парткод: | JC61-05563A |

| Деталь: | HOLDER-ACTUATOR REAR, CLP-680ND,ABS,BLACK |

| Парткод: | JC61-05559A |

| Деталь: | PHOTO-INTERRUPTER, TR,DIP-4,BK |

| Парткод: | 0604-001415 |

| Цена: | 240 ₽ |

| Деталь: | PBA SUB-WTB SEN, C3010,C3060,FR1,1L,19.6 |

| Парткод: | JC92-02936A |

| Деталь: | HOLDER-WTB SENSOR, CLP-680ND,HIPS,ICE GRE |

| Парткод: | JC61-05483A |

| Деталь: | COVER-MIDDLE, C4062,SEC |

| Парткод: | JC95-02057A |

| Деталь: | COVER-MIDDLE, C3560,ABS,SPLIT BROWN BLACK |

| Парткод: | JC63-05466A |

| Деталь: | COVER-MIDDLE LEFT, C3562,ABS,SPLIT BROWN |

| Парткод: | JC63-05469A |

| Деталь: | COVER-DUMMY USB, SL-C2680FX,ABS,SEC,SPLIT |

| Парткод: | JC63-05110A |

| Деталь: | TRAY-ASF OUT, M4530,ABS,91.2,SPLIT BROWN |

| Парткод: | JC63-05086A |

| Деталь: | GROUND-EXIT, C3510,STS304,0.2,GROUND |

| Парткод: | JC63-05459A |

| Деталь: | GROUND-MIDDLE, C3560,STS304,0.2,GROUND |

| Парткод: | JC63-05461A |

| Деталь: | GROUND-FAX, C3560,STS304,0.2,GROUND |

| Парткод: | JC63-05460A |

| Деталь: | COVER-LIU, CLX-6200FX,ABS+PC,V0 |

| Парткод: | JC63-01518A |

| Деталь: | PBA SUB-FAX, C3060,FR4, 2L,9050mm |

| Парткод: | JC92-02552C |

| Деталь: | SPEAKER, 0.3W,8ohm,81dB,400Hz,50x16.4mm |

| Парткод: | 3001-002262 |

| Деталь: | BRUSH-ANTISTATIC, CLX-6260ND,Al,100,16.5, |

| Парткод: | JC67-00693A |

| Деталь: | FLAT CABLE-FAX_FFC, C3060,16,0.05,350,AWM |

| Парткод: | JC39-02459A |

| Деталь: | WIRE HARNESS-USB HOST NFC, C40,UL2725,5P, |

| Парткод: | JC39-02513A |

| Деталь: | GROUND-MIDDLE L, C3562,STS304,0.2,GROUND |

| Парткод: | JC63-05463A |

| Деталь: | FRAME SUB-RIGHT, C3510,SEC |

| Парткод: | JC93-01327A |

| Деталь: | DRIVE-DEVE NIP, C3510,SEC,MD |

| Парткод: | JC93-00773C |

| Деталь: | DRIVE EXIT, C4010,SEC,MD |

| Парткод: | JC93-01451A |

| Деталь: | LEVER-DEVE PUSHER, CLP-680ND,POM,LINK/UNC |

| Парткод: | JC66-03604A |

| Деталь: | LEVER-LINK DEVE PUSHER, CLP-680ND,POM,LIN |

| Парткод: | JC66-03605A |

| Деталь: | LINK-DEVE PUSHER, CLP-680ND,POM |

| Парткод: | JC66-03603A |

| Деталь: | GEAR-IDLE MP, CLP-680ND,POM,0.6,28,18.00, |

| Парткод: | JC66-03715A |

| Деталь: | LINK-MAIN COUPLER UPPER, CLP-680ND,ABS,31 |

| Парткод: | JC66-03740A |

| Деталь: | FRAME SUB-GUIDE CST R, C3510,SEC |

| Парткод: | JC93-01326A |

| Деталь: | DUCT-MAIN, C3510,HIPS,1.5,HIPS-5197,BLACK |

| Парткод: | JC67-00844A |

| Деталь: | GUIDE-TRAY RIGHT, CLP-680DW,ABS+GF,341.3, |

| Парткод: | JC61-05427A |

| Деталь: | SOLENOID, SL-C4010ND,24,100,27.54 X 27.75 |

| Парткод: | JC33-00035C |

| Деталь: | BELT-TIMING GEAR, 40S2M152,RUBBER,W4.0,L1 |

| Парткод: | 6602-001729 |

| Деталь: | BELT-TIMING GEAR, RUBBER,T1.36,L168MM,BLK |

| Парткод: | 6602-001581 |

| Деталь: | SOLENOID, CLP-680ND,DC 24V,70,21.314.8 |

| Парткод: | JC33-00028D |

| Деталь: | GEAR-PULLEY MP FEED, CLP-680ND,POM,0.6/S2 |

| Парткод: | JC66-03716A |

| Деталь: | ROLLER IDLE-PRESSURE_CASSETTE, ML-6510ND, |

| Парткод: | JC61-03882A |

| Деталь: | COVER-REAR, C4010,SEC |

| Парткод: | JC95-02061A |

| Деталь: | COVER-REAR, C30,HIPS,Cream White |

| Парткод: | JC63-03793B |

| Деталь: | GUIDE-GATE DUPLEX, C3510,ABS+GF20%,C2110, |

| Парткод: | JC61-08001A |

| Деталь: | GUIDE-SIDE REAR, C3510,ABS,780U,SPLIT BRO |

| Парткод: | JC61-07939A |

| Деталь: | DUPLEX GUIDE-LOWER, CLP-680ND |

| Парткод: | JC90-01203A |

| Деталь: | DUPLEX GUIDE-UPPER, CLP-680ND |

| Парткод: | JC90-01204A |

| Деталь: | COVER-REAR TRANSFER, C3010,SEC,WORLD |

| Парткод: | JC95-02044A |

| Деталь: | GUIDE-TRANSFER, CLP-680ND,HIPS,HIPS-5197, |

| Парткод: | JC61-05421A |

| Деталь: | ROLLER TR-TRANSFER2, Rousseau,-,KOREA,SCF |

| Парткод: | JC66-03756A |

| Цена: | 1 300 ₽ |

| Деталь: | LOCKER-T2 L, CLP-680ND,POM,BLACK,42.9x15. |

| Парткод: | JC64-00802A |

| Деталь: | HOLDER-T2, CLP-680ND,POM,10.4,32,BLACK,12 |

| Парткод: | JC61-05463A |

| Деталь: | PLATE-BIAS-TRANSFER, CLP-680ND,STS304,0.2 |

| Парткод: | JC61-05471A |

| Деталь: | BUSH-TR, CLP-510,Fe+Cu+Zn-Slearate,6, |

| Парткод: | JC61-00983A |

| Деталь: | HOLDER-NIP-T2 L, CLP-680ND,POM,4,R10,BLAC |

| Парткод: | JC61-05837A |

| Деталь: | LOCKER-TRANSFER R, CLP-680ND,POM,WHITE,42 |

| Парткод: | JC64-00803A |

| Деталь: | CASSETTE |

| Парткод: | JC90-01599A |

| Деталь: | CASSETTE FRAME |

| Парткод: | JC90-01600A |

| Деталь: | HANDLE-CASSETTE |

| Парткод: | JC64-01024A |

| Деталь: | LEVER-GUIDE EXTENSION |

| Парткод: | JC66-05065A |

| Деталь: | GUIDE-EXTENSION |

| Парткод: | JC61-07999A |

| Деталь: | CASSETTE SUB-GUIDE REAR |

| Парткод: | JC90-01601A |

| Деталь: | SPRING ETC |

| Парткод: | JC61-08018A |

| Деталь: | CASSETTE SUB-GUIDE |

| Парткод: | JC90-01603A |

| Деталь: | ROLLER IDLE-PRESSURE_CASSETTE |

| Парткод: | JC61-03882A |

| Деталь: | FRAME-CASSETTE |

| Парткод: | JC61-07992A |

| Деталь: | GEAR-RDCN CST LIFT |

| Парткод: | JC66-05076A |

| Деталь: | GEAR-IDLE CST LIFT |

| Парткод: | JC66-05081A |

| Деталь: | GEAR-CASSETTE LIFT |

| Парткод: | JC66-05064A |

| Деталь: | CASSETTE SUB-GUIDE RE |

| Парткод: | JC90-01602A |

| Деталь: | COVER-GEAR |

| Парткод: | JC63-05499A |

| Деталь: | GEAR-M_PINION 24 |

| Парткод: | JC66-01020A |

| Деталь: | PLATE-LEVER |

| Парткод: | JC61-03206A |

| Деталь: | PLATE-KNOCK UP |

| Парткод: | JC61-07990A |

| Деталь: | FRICTION PAD-CASSETTE |

| Парткод: | JC67-00870A |

| Деталь: | FRAME SUB-SEPARATION, C3510 |

| Парткод: | JC93-01336A |

| Деталь: | PHOTO-INTERRUPTER, TR,75mW,BGA,TR |

| Парткод: | 0604-001393 |

| Деталь: | CABLE CLAMP, 4,Nylon66 |

| Парткод: | 6502-001131 |

| Деталь: | BRACKET-SHAFT, CLP-680ND,SECC,1,272.5,PRE |

| Парткод: | JC61-05390A |

| Деталь: | HOLDER-CAM, CLP-680ND,POM,21.8 |

| Парткод: | JC61-05392A |

| Деталь: | FRAME-RETARD, CLP-680ND,ABS,Black,2T,293. |

| Парткод: | JC61-05441A |

| Деталь: | PLATE-GUIDE PAPER, CLP-680ND,EGI-SECC,1.0 |

| Парткод: | JC61-05540A |

| Деталь: | SPRING CS, C30,SWPB,0.7,4.1 |

| Парткод: | JC61-07860A |

| Деталь: | SPRING CS, C3510,SWPB,0.6,4.3,5.5,8,8.5 |

| Парткод: | JC61-08080A |

| Деталь: | BRACKET-BRUSH, C4060,STS304,0.5,17,46,PRE |

| Парткод: | JC61-08165A |

| Деталь: | BRACKET GUIDE-PATH, C4060,EGI-SECC,1.0T,2 |

| Парткод: | JC61-08166A |

| Деталь: | GROUND-PICK UP, CLP-680ND,STS,0.2T,GROUND |

| Парткод: | JC63-03704A |

| Деталь: | SHEET-GUIDE, CLP-680ND,PET,0.125,219 |

| Парткод: | JC63-03868A |

| Деталь: | SHEET-REGI, SL-C4010ND,PET,0.075,12,223.5 |

| Парткод: | JC63-05685A |

| Деталь: | SHEET GUIDE-REGI IDLE, C4060,PET,0.188 |

| Парткод: | JC63-05694A |

| Деталь: | CAM-KICKER, CLP-680ND,POM,2,4.05 |

| Парткод: | JC66-03592A |

| Деталь: | CAM-LEVER LEFT, C30,POM,NATURAL(WHITE),NW |

| Парткод: | JC66-04987A |

| Деталь: | CAM-LEVER RIGHT, C30,POM,NATURAL(WHITE),N |

| Парткод: | JC66-04988A |

| Деталь: | LEVER-SEPARATION, C3510,POM,F20-02,NATURA |

| Парткод: | JC66-05106A |

| Деталь: | BRUSH-ANTISTATIC, ML-1660,SUS FIBER,11.5 |

| Парткод: | JC67-00496A |

| Деталь: | DRIVE-GEAR KNOCK UP, CLP-680ND |

| Парткод: | JC93-00760A |

| Деталь: | FRAME SUB-SEPARATION, SL-C4080ND/SEE |

| Парткод: | JC93-01469A |

| Деталь: | SPRING-CS, SUS,0.4,5.2,5,5.4,11.25,RIGHT, |

| Парткод: | 6107-003349 |

| Деталь: | GUIDE-KICKER L, CLP-680ND,PC+ABS,NH-1000T |

| Парткод: | JC61-05388A |

| Деталь: | GUIDE-KICKER R, C4060,ABS+PC,NH-1000T,G61 |

| Парткод: | JC61-08254A |

| Деталь: | FRAME-RETARD COVER, CLP-680ND,ABS,HF-0660 |

| Парткод: | JC61-05442A |

| Деталь: | SHEET-RETARD, ML-3710,PET,0.125,30,11.6,B |

| Парткод: | JC63-02933A |

| Цена: | 260 ₽ |

| Деталь: | LEVER-KICKER LINK, CLP-680ND,ABS,51.6,LIN |

| Парткод: | JC66-03588A |

| Деталь: | FRAME-ROLLER RETARD, CLP-680ND |

| Парткод: | JC93-00682A |

| Деталь: | HOLDER-RETARD ROLLER, CLP-680ND,ABS,38,HB |

| Парткод: | JC61-05385A |

| Деталь: | ROLLER IDLE-MAT_RETARD, ML-2950ND,EPDM |

| Парткод: | JC66-02939B |

| Цена: | 350 ₽ |

| Деталь: | COUPLER-TORQUE_LIMITER, ML-6510ND,NTR,290 |

| Парткод: | JC67-00465A |

Коды ошибок

11-2T11, 11-2T21, 11-2T31

11-2T41, 11-2T61

31-1A01

31-1A02

31-1A03

31-1A04

31-1A05

31-1A06

31-1A07

31-1A08

31-1A09

31-1A0A

31-1A21

31-1A22

31-1A23

31-1A24

31-1E01

31-1E02

31-1E03

31-1E04

31-1E05

31-1E06

31-1E07

31-1E08

41-1111

41-1112

41-1113

41-1114

41-1115

41-1116

41-1121

41-1122

41-1123

41-1124

41-1125

41-1126

41-1127

41-1128

41-1F01

51-1D01

61-1111

61-1500

61-1Y70

61-C401

A1-1210

A1-3622, A1-4310

A2-1210, A2-2110, A2-2610

A3-2113, A3-4114

A3-3211, A3-3212

A3-3311, A3-3312

A3-3320

A-3610, A1-3621

A3-6110

C2-2110

C2-2120, C2-2140, C2-2150

C2-2160, C2-2170

C2-2410

C2-2512, C2-2515, C2-2517

C2-2518, C2-2526

C2-2711, C2-2712

C2-2713, C2-2714

C2-3110

C2-3120, C2-3140, C2-3150

C2-3160, C2-3170

C2-3410

C2-3512, C2-3515, C2-3517

C2-3518, C2-3526

C2-3711, C2-3712

C2-3713, C2-3714

C2-4110

C2-4120, C2-4140, C2-4150

C2-4160, C2-4170

C2-4410

C2-4512, C2-4515, C2-4517

C2-4518, C2-4526

C2-4711, C2-4712

C2-4713, C2-4714

C2-5110

C2-5120, C2-5150

C2-5160, C2-5170

C2-5410

C2-5512, C2-5515, C2-5517

C2-5518, C2-5526

C2-5711, C2-5712

C2-5713, C2-5714

C5-1110, C5-1120

C5-1310

C5-1410

C5-1710

C6-1110, C6-1120

C7-1110, C7-1130

C7-1311

C9-1115

C9-1122, C9-1125

C9-1132, C9-1135

H1-1210, H1-1211

H1-1222

H1-1252

H1-1253

H1-1310, H1-1311

H1-1322

H1-1352, H1-1354

H1-1353

H1-1410

H1-1422

H1-1452, H1-1454

H1-1453

M1-1110

M1-1610

M1-3122

M1-4111

M1-5112, M1-5113, M1-5120

M1-5612

M2-1111, M2-1114, M2-2210

M2-2214, M2-2310

M3-1110, M3-1112

M3-2130

S1-1113

S1-1114

S1-1411

S1-2000

S1-2433, S1-2443, S1-2444

S1-2434, S1-2435, S1-2436

S1-2437, S1-2438, S1-2439

S1-2445, S1-2446, S1-2447

S1-2448, S1-2449

S1-3110

S2-1110, S2-1210

S2-33xx

S2-4120

S3-3122

S5-311x

S6-3113, S6-3122

S6-3114

S6-3123

S6-3128

S7-1110

S7-1120

U1-2115

U1-2116

U1-211x, U1-213x, U1-231x

U1-232x, U1-233x, U1-234x

U2-2113, U2-5113, U2-6121

U2-6122, U2-6123

U3-3113, U3-3213, U3-3214

U3-3313, U3-3314, U3-3414

U3-3513, U3-3514

U3-4210

Описание

| Error code: | 11-2T11, 11-2T21, 11-2T31 |

| Description: | Paper mismatch Tray X Paper mismatch MPT |

| Causes: | Paper in tray is not matched to the machine paper setting. |

| Remedy: | 1) Check and change the paper setting of the corresponding tray properly. |

| Error code: | 11-2T41, 11-2T61 |

| Description: | Tray 1 Paper Mismatch Tray 2 Paper Mismatch Tray 3 Paper Mismatch Tray 4 Paper Mismatch MP Paper Mismatch |

| Causes: | Paper in tray is not matched to the machine paper setting. |

| Remedy: | 1) Check and change the paper setting of the corresponding tray properly. |

| Error code: | 31-1A01 |

| Description: | Job is completed with error: Authentication Error |

| Causes: | Scan to Email job is completed with error. “Authentication Error” or same meaning message appears. |

| Remedy: | 1) Access SyncThru Web Service with administrator account. 2) Make sure valid login ID or password in SyncThru Web Service Network Settings Outgoing Mail Server (SMTP) SMTP Login Information. 3) Press Test button for connection test. |

| Error code: | 31-1A02 |

| Description: | Job is completed with error: Authentication Required |

| Causes: | Scan to Email job is completed with error. “Authentication Required” or same meaning message appears. |

| Remedy: | 1) Access SyncThru Web Service with administrator account. 2) Make SyncThru Web Service Network Settings Outgoing Mail Server (SMTP) SMTP Requires Authentication enabled and type login ID and password. 3) Press Test button for connection test. |

| Error code: | 31-1A03 |

| Description: | Job is completed with error: Could not Connect to configured SMTP server |

| Causes: | Scan to Email job is completed with error. “Could not connect to configured SMTP server” or same meaning message appears. |

| Remedy: | 1) Connect network cable. Or, connect Wi-Fi. 2) Access SyncThru Web Service with administrator privilege. Make Ethernet or Wi-Fi enabled in SyncThru Web Service System Security Feature Management Physical Ports. 3) Make sure valid SMTP server address (IP address or Host name) in SyncThru Web Service Network Settings Outgoing Mail Server (SMTP). When the above address is described with the Hostname, check that the DNS server is prope |

| Error code: | 31-1A04 |

| Description: | Job is completed with error: Mail size exceeds the server limits |

| Causes: | Scan to Email job is completed with error. “Mail size exceeds the server limits” or same meaning message appears. |

| Remedy: | 1) Contact SMTP server administrator to check maximum mail size. 2) Access SyncThru Web Service with administrator privilege. Decrease Maximum Message Size in SyncThru Web Service Network Settings Outgoing Mail Server (SMTP). 3) Change low resolution in scan original or mono in color mode. |

| Error code: | 31-1A05 |

| Description: | Job is completed with error: Mail size too large |

| Causes: | Scan to Email job is completed with error. “Mail size too large” or same meaning message appears. |

| Remedy: | 1) Change scan options to reduce scanned image in resolution or color mode and so on. 2) Access SyncThru Web Service with administrator privilege. Increase Maximum Message Size in SyncThru Web Service Network Settings Outgoing Mail Server (SMTP). 3) Change low resolution in scan original or mono in color mode. |

| Error code: | 31-1A06 |

| Description: | Job is completed with error: Network Error |

| Causes: | Scan to Email job is completed with error. “Mail size too large” or same meaning message appears. |

| Remedy: | 1) Send email job again. Power off then on if the problem persists. |

| Error code: | 31-1A07 |

| Description: | Job is completed with error: Send Failed |

| Causes: | Scan to Email job is completed with error. “Send Failed” or same meaning message appears. Condition: Scan to Email job terminated. |

| Remedy: | 1) Access SyncThru with administrator account. 2) Make SyncThru Web Service Network Settings Outgoing Mail Server (SMTP) SMTP Requires Authentication enabled and type login ID and password. Additionally, you can test server connection with ‘Test’ button. |

| Error code: | 31-1A08 |

| Description: | Job is completed with error: DNS resolution failure |

| Causes: | Scan to Email job is completed with error. “DNS Resolution Failure” or same meaning message appears. Condition: Scan to Email job terminated. |

| Remedy: | 1) Access SyncThru Web Service with administrator account. 2) Make sure valid Domain Name or Primary DNS server address in SyncThru Web Service Network Setting Interface Ethernet TCP/IPv4 Domain Name. Or Input Secondary DNS server address in SyncThru Web Service Network Setting Interface Ethernet TCP/IPv4 Domain Name. 3) Then test connection of the DNS server. Try same job again after few minutes. Or Input any server address as IP address type. |

| Error code: | 31-1A09 |

| Description: | Job is completed with error: Not support SSL encryption method |

| Causes: | Scan to Email job is completed with error. “Not supported SSL encryption” or same meaning message appears. |

| Remedy: | 1) Please contact SMTP server administrator in order to change SSL encryption method. Press Test button to try to connect SMTP Server. |

| Error code: | 31-1A0A |

| Description: | Job is completed with error: Wrong email address(es) |

| Causes: | Scan to Email job is completed with error. |

| Remedy: | 1) Check the left side and right side of @ in the e-mail addresses. |

| Error code: | 31-1A21 |

| Description: | Job is completed with error: POP3 Authentication Failure |

| Causes: | Scan to Email job is completed with error. “POP3 Authentication Failure” or same meaning message appears. |

| Remedy: | 1) Access SyncThru Web Service with administrator account. 2) Make sure valid login ID and password in SyncThru Web Service Network Setting Outgoing Mail Server (SMTP) POP3 Authentication. Additionally, you can test server connection with ‘Test’ button. |

| Error code: | 31-1A22 |

| Description: | Job is completed with error: POP3 Authentication Required |

| Causes: | Scan to Email job is completed with error. “POP3 Authentication Required” or same meaning message appears. |

| Remedy: | 1) Access SyncThru Web Service with administrator account. 2) Make SMTP Requires POP3 Before SMTP Authentication as enabled in SyncThru Web Service Network Setting Outgoing Mail Server (SMTP) POP3 Authentication. Then, Input Login ID and Password. Additionally, you can test server connection with ‘Test’ button |

| Error code: | 31-1A23 |

| Description: | Job is completed with error: POP3 Connection Error |

| Causes: | Scan to Email job is completed with error. “POP3 Connection Error” or same meaning message appears. |

| Remedy: | 1) Access SyncThru Web Service with administrator account. 2) Make sure valid IP address of POP3 server in SyncThru Web Service Network Setting Outgoing Mail Server (SMTP) POP3 Authentication. Additionally, you can test server connection with ‘Test’ button. 3) If host name is used in POP3 server address, Make sure valid DNS server in SyncThru Web Service Network Setting Interface Ethernet TCP/IPv4 Domain Name. 4) If problem persists, contact network administrator. |

| Error code: | 31-1A24 |

| Description: | Job is completed with error: POP3 Error |

| Causes: | Scan to Email job is completed with error. “POP3 Error” or same meaning message appears. Condition: Scan to Email job terminated. |

| Remedy: | 1) Access SyncThru Web Service with administrator account. 2) Make sure valid IP address of POP3 server in SyncThru Web Service Network Setting Outgoing Mail Server (SMTP) POP3 Authentication. Additionally, you can test server connection with ‘Test’ button. 3) If host name is used in POP3 server address, Make sure valid DNS server in SyncThru Web Service Network Setting Interface Ethernet TCP/IPv4 Domain Name. 4) If problem persists, contact network administrator. |

| Error code: | 31-1E01 |

| Description: | Job is completed with error: Invalid Server Address |

| Causes: | Scan to Server job is completed with error. “Invalid Server Address” or same meaning message appears. |

| Remedy: | 1) Access SyncThru Web Service with administrator account. 2) Make sure valid IP address of server in SyncThru Web Service Address Book Individual Select the contact Click Edit SMB or FTP Server Address. Additionally, you can test server connection with ‘Test’ button. 3) If host name is used in server address, Make sure valid DNS server in SyncThru Web Service Network Setting Interface Ethernet TCP/IPv4 Domain Name. 4) If problem persists, contact network administrator. |

| Error code: | 31-1E02 |

| Description: | Job is completed with error: Authentication Failure |

| Causes: | Scan to Server job is completed with error. “Authentication Failure” or same meaning message appears. Condition: Scan to Server job terminated. |

| Remedy: | 1) There are 2 ways to input server ID/PW. The one way is to input ID/PW in SyncThru Web Service. Access SyncThru Web Service with administrator privilege. Make sure valid ID/Password of server in SyncThru Web Service Address Book Individual Select the contact Click Edit SMB or FTP Login ID and Password. Additionally, you can test server connection with ‘Test’ button. The other way is to input ID/PW in Local UI. Execute application for server job. Then select the contact. When Local UI prompts window for ID/PW, input valid ID/PW. If problem persists, contact SMB or FTP server administrator. |

| Error code: | 31-1E03 |

| Description: | Job is completed with error: Communication Error |

| Causes: | Scan to Server job is completed with error. “Communication Error” or same meaning message appears. Condition: Scan to Server job terminated. |

| Remedy: | 1) To make protocol support. • Access SyncThru Web Service with administrator privilege. - Make sure SMB or FTP protocol enabled in SyncThru Web Service Machine Settings Scan&Send or Scan SMB or FTP. 2) To change port number. • Contact SMB or FTP server administrator to get valid port number. • Access SyncThru Web Service with administrator privilege. • Change port number in SyncThru Web Service Address Book Individual Select the contact Click Edit SMB or FTP Server Port. |

| Error code: | 31-1E04 |

| Description: | Job is completed with error: File Existed |

| Causes: | Scan to Server job is completed with error. File Existed or same meaning message appears. Condition: Scan to Server job terminated. |

| Remedy: | 1) Access SyncThru Web Service with administrator privilege. 2) Change Filing policy from Cancel to Overwrite or Change Name in SyncThru Web Service Address Book Individual Select the contact Click Edit SMB or FTP. Additionally, you can test server connection with ‘Test’ button. If problem persists, contact SMB or FTP server administrator. |

| Error code: | 31-1E05 |

| Description: | Job is completed with error: Over limit File name |

| Causes: | Scan to Server job is completed with error. Over limit File Name or same meaning message appears. Condition: Scan to Server job terminated. |

| Remedy: | 1) Change short file name in Local UI Scan&Send or Scan to Server File Name. 2) Or, Change short file name in SyncThru Web Service Address Book Individual Select the contact Click Edit SMB or FTP after access SyncThru Web Service with administrator privilege. Additionally, you can test server connection with ‘Test’ button. If problem persists, contact SMB or FTP server administrator. |

| Error code: | 31-1E06 |

| Description: | Job is completed with error: File Access Denied |

| Causes: | Scan to Server job is completed with error. “File Access Denied” or same meaning message appears. Condition: Scan to Server job terminated. |

| Remedy: | 1) This issue is out of device system scope. Contact SMB or FTP server administrator to get file write access. After you get file write access, Try to create new file in the server. |

| Error code: | 31-1E07 |

| Description: | Job is completed with error: Network Error |

| Causes: | Scan to Server job is completed with error. “Network Error” or same meaning message appears. Condition: Scan to Server job terminated. |

| Remedy: | 1) Send server job again. Power off then on if the problem persists. |

| Error code: | 31-1E08 |

| Description: | Job is completed with error: Exceed maximum connection of SMB server |

| Causes: | Scan to Server job is completed with error. “Exceed Maximum Connection” or same meaning message appears. |

| Remedy: | 1) This issue is out of device system scope. Contact SMB or FTP server administrator to get connection or to increase amount of connection. |

| Error code: | 41-1111 |

| Description: | Job is completed with error: Communication Error |

| Causes: | Fax line condition has some errors. |

| Remedy: | 1) Check after setting up the menu Smart Fax Diag - VoIP - Noise - Big Noise 2) Check after changing ECM config: On - Off or Off - On 3) Check after Service Mode - Fax Diagnostics - Continuous Frame: Off 4) Check after Service Mode - Fax Diagnostics - TCF duration: 3sec. 5) Change Tel. line 6) Contact commoncarrier |

| Error code: | 41-1112 |

| Description: | Job is completed with error: No Answer |

| Causes: | No answer when transmission |

| Remedy: | • Error of dialing 1) Check the prefix config. 2) Check after Service Mode - Fax Diagnostics - DTMF Timing: 7sec. 3) Check after Service Mode - Fax Diagnostics - Autodial Start Pause Time: 5sec. • Error of fax line 1) Check after setting up the menu Smart Fax Diag - VoIP - Noise - Big Noise 2) Check after Service Mode - Fax Diagnostics - Continuous Frame: Off 3) Check after Service Mode - Fax Diagnostics - TCF duration: 3sec. 4) Change Tel. line 5) Contact commoncarrier |

| Error code: | 41-1113 |

| Description: | Job is completed with error: Line Busy |

| Causes: | Line is busy |

| Remedy: | 1) Check the phone number 2) Check the prefix config. 3) Check after Service Mode - Fax Diagnostics - Busy Signal Detect: Off 4) Change Tel. line |

| Error code: | 41-1114 |

| Description: | Job is completed with error: Communication Error |

| Causes: | Communication error occurs when transmission |

| Remedy: | 1) If the same error occurs, refer to the followings (User Config. menu) 2) Change the setting of Smart Fax Diag VoIP- Noise - Big Noise (Service Config. menu) 3) Check after Service Mode - Fax Diagnostics - TCF duration: 3sec. 4) Check after Service Mode - Fax Diagnostics - Continuous Frame: Off |

| Error code: | 41-1115 |

| Description: | Job is completed with error: Communication Error |

| Causes: | Communication error occurs when transmission |

| Remedy: | 1) Check after setting up the menu Smart Fax Diag - VoIP - Noise - Big Noise 2) Check after changing ECM config: On - Off or Off - On 3) Check after changing resolution to standard |

| Error code: | 41-1116 |

| Description: | Job is completed with error : Communication Error |

| Causes: | Direct TX Communication error occurs |

| Remedy: | 1) If there is simultaneous job, try to send the fax after finish it. 2) Try to send fax after power reboot. |

| Error code: | 41-1121 |

| Description: | Job is completed with error: Communication Error |

| Causes: | Fax receiving error |

| Remedy: | 1) Check after setting up the menu Smart Fax Diag - VoIP - Noise - Big Noise 2) Check after changing ECM config: On - Off or Off - On 3) Check after Service Mode - Fax Diagnostics - Continuous Frame: Off - Check after Service Mode - Fax Diagnostics - TCF duration: 3sec. 4) Change Tel. line 5) Contact commoncarrier |

| Error code: | 41-1122 |

| Description: | Job is completed with error: No Answer |

| Causes: | No answer when receiving |

| Remedy: | 1) Check after setting up the menu Smart Fax Diag - VoIP - Noise - Big Noise 2) Change Tel. line 3) Contact commoncarrier |

| Error code: | 41-1123 |

| Description: | Job is completed with error: Line Error |

| Causes: | Fax line error and no printout |

| Remedy: | 1) Check after setting up the menu Smart Fax Diag - VoIP - Noise - Big Noise 2) Check after changing ECM config: On - Off or Off - On 3) Change Tel. line |

| Error code: | 41-1124 |

| Description: | Job is completed with error: Communication Error |

| Causes: | Communication error occurs when receiving |

| Remedy: | 1) If the same error occurs, refer to the followings (User Config. menu) 2) Change the setting of Smart Fax Diag VoIP- Noise - Big Noise |

| Error code: | 41-1125 |

| Description: | Job is completed with error: Communication Error |

| Causes: | Communication error occurs when receiving |

| Remedy: | 1) Check after setting up the menu Smart Fax Diag - VoIP - Noise - Big Noise 2) Check after changing ECM config: On - Off or Off - On 3) Change Tel. line 4) Contact commoncarrier |

| Error code: | 41-1126 |

| Description: | Job is completed with error: Communication Error |

| Causes: | Communication error occurs when receiving |

| Remedy: | 1) Check after setting up the menu Smart Fax Diag - VoIP - Noise - Big Noise 2) Check after changing ECM config: On - Off or Off - On 3) Change Tel. line 4) Contact commoncarrier |

| Error code: | 41-1127 |

| Description: | Job is completed with error: Line Error |

| Causes: | Line error with blank printout |

| Remedy: | 1) Check after setting up the menu Smart Fax Diag - VoIP - Noise - Big Noise 2) Check after changing ECM config: Off - On |

| Error code: | 41-1128 |

| Description: | Job is completed with error: Line Error |

| Causes: | Line error with blank printout or data |

| Remedy: | 1) Check after setting up the menu Smart Fax Diag - VoIP - Noise - Big Noise 2) Check after changing ECM config: On - Off or Off - On 3) Check after Service Mode - Fax Diagnostics - Continuous Frame: Off 4) Check after Service Mode - Fax Diagnostics - TCF duration: 3sec. 5) Change Tel. line 6) Contact commoncarrier |

| Error code: | 41-1F01 |

| Description: | Job is completed with error: Junk Fax Blocked |

| Causes: | Line disconnection & Junk Fax Blocking before ringing and fax receiving |

| Remedy: | 1) Check the Fax number at job status or Fax Received Report 2) Delete the Fax number at the Junk Fax config. menu of Fax Settings |

| Error code: | 51-1D01 |

| Description: | Software Integrity Failure: #51-1D01. Please call for service |

| Causes: | SW integrity verification is failed inside machine. |

| Remedy: | • Backup user data at the HDD and system configuration. 1) Enter the service mode 2) HDD format 3) Restore the backup date after system booting |

| Error code: | 61-1111 |

| Description: | Booting Failure: #61-1111. Turn off then on. Call for service if the problem persists |

| Causes: | Hibernation image creation is failed. |

| Remedy: | 1) Turn the machine on with a normal booting. 2) Enter the SVC mode. Select “Hibernation On” again. |

| Error code: | 61-1500 |

| Description: | Unverified application(s) installed. Please contact administrator |

| Causes: | When unverified 3rd party solution is installed, user or administrator is not easily noticed for the unverified solution, which might cause market issue sooner or later. |

| Remedy: | 1) Access SyncThru Web Service. You can check up Samsung Verified information in SyncThru Web Service Maintenance Application Management Application. 2) If necessary, only administrator can delete the unverified application(s) or make them disabled. |

| Error code: | 61-1Y70 |

| Description: | Scanner Failure: #61-1Y70. Turn off then on. Call for service if the problem persists |

| Causes: | A white or black line or band appears on an image scanned, copied, or transmitted by fax with the dual scanner. |

| Remedy: | • If the problem persists after the printer is turned off and then back on, perform shading again on the Diagnostics mode. (A technician visit is required for Tech mode.) |

| Error code: | 61-C401 |

| Description: | Job is completed with error: DNS Error |

| Causes: | Scan to Email job is completed with error. “DNS Error” or same meaning message appears. |

| Remedy: | 1) Access SyncThru Web Service with administrator priviliage. Make sure valid Domain Name or Primary DNS server address in SyncThru Web Service Network Setting Interface Ethernet TCP/IPv4 Domain Name. 2) Input Secondary DNS server address in SyncThru Web Service Network Setting Interface Ethernet TCP/IPv4 Domain Name. Then test connection of the DNS server. Try same job again after few minutes. 3) Input any server address as IP address type. |

| Error code: | A1-1210 |

| Display: | Actuator Motor Failure #A1-1210: Turn off then on. |

| Description: | Error #A1-1210 Call for service |

| Causes: | The fuser motor does not operate. / The fuser motor is operating but is recognized as stop status. |

| Remedy: | 1) Turn the machine off then on. If the error persists, turn the machine off again. 2) Remove the rear and right cover. 3) Check if there are any obstacles or paper around the fuser unit. 4) Check if the connection between main board and fuser motor are correct. 5) If the connection is OK, replace the fuser motor. 6) If the problem persists, replace the main board. |

| Error code: | A1-3622, A1-4310 |

| Description: | Development Motor Failure: #A1-36xx. Turn off then on. Call for service if the problem persists Engage Motor Failure: #A1-4310. Turn off then on. Call for service if the problem persists |

| Causes: | The motor for OPC/Deve/ITB/Engage does not operate normally. • A1-3610 : The developer motor for the color printing system does not operate correctly. • A1-3621 : The developer black motor for the color printing system does not operate correctly. • A1-3622 : The developer color motor for the color printing system does not operate correctly. • A1-4310 : The motor that moves the ITB transfer1 roller operates, but the position of the ITB transfer1 roller does not change. |

| Remedy: | 1) Turn the machine off then on. If the error persists, turn the machine off again. 2) Remove the right cover. 3) Check if the connection between main board and related motor is correct. 4) If the motor is defective, replace it. 5) If there is a motor test for this component, please try it first. If the problem persists, replace the main board. |

| Error code: | A2-1210, A2-2110, A2-2610 |

| Description: | SMPS Fan Failure: #A2-1210. Turn off then on. Call for service if the problem persists Fuser Fan Failure: #A2-2110. Turn off then on. Call for service if the problem persists Development Fan Failure: #A2-2610. Turn off then on. Call for service if the problem persists |

| Causes: | The fan for SMPS/Fuser/Deve does not operate normally. • A2–1210 : SMPS fan error • A2–2110 : Fuser fan error • A2–2610 : Deve fan error |

| Remedy: | 1) Turn the machine off then on. If the error persists, turn the machine off again. 2) Remove the side cover. 3) Check if the connection between main board and the related fan is correct. 4) If the connection is OK, replace the defective fan. |

| Error code: | A3-2113, A3-4114 |

| Description: | The CTD/ACR sensor is dirty. Please clean it with soft cloth or paper. |

| Causes: | CTD/ACR sensor window is contaminated. |

| Remedy: | 1) Open the side cover. 2) Clean the sensor window [A] with a soft cloth. 3) Close the side cover. 4) Enter SVC mode. Select the “CTD Sensor Cleaning” (Diagnostics Image Management > Auto Color Tone Adjustment Condition > CTD Sensor Cleaning) 5) When pop up appears, select the “Yes” button. NOTE a) CTD sensor calibration will start. Then “CTD sensor failure” error will be solved b) If you don’t execute the CTD sensor cleaning in SVC mode, error message persists. |

| Error code: | A3-3211, A3-3212 |

| Display: | Actuator Sensor Failure #: Call for service if the problem persists. |

| Description: | Error #A3-3211 Call for service Error #A3-3212 Call for service |

| Causes: | The inner temperature sensor is defective. |

| Remedy: | 1) Turn the machine off then on. If the error persists, turn the machine off again. 2) Enter the tech mode. Check the temperature sensor output. 3) If the sensor is defective, replace it. 4) If the temperature sensor is OK, replace the main board. |

| Error code: | A3-3311, A3-3312 |

| Display: | Actuator Sensor Failure #: Call for service if the problem persists. |

| Description: | Error #A3-3311 Call for service Error #A3-3312 Call for service |

| Causes: | The outer temperature sensor is defective. |

| Remedy: | 1) Turn the machine off then on. If the error persists, turn the machine off again. 2) Enter the tech mode. Check the temperature sensor output. 3) If the sensor is defective, replace it. 4) If the temperature sensor is OK, replace the main board. |

| Error code: | A3-3320 |

| Display: | Not proper room temperature. Change room temperature. |

| Description: | Not proper room temp. Move set |

| Causes: | The value of the outer temperature sensor is out of normal area. |

| Remedy: | 1) Check if the machine is installed in the proper area. 2) If the temperature sensor is defective, replace it. |

| Error code: | A-3610, A1-3621 |

| Description: | Development Motor Failure: #A1-36xx. Turn off then on. Call for service if the problem persists Engage Motor Failure: #A1-4310. Turn off then on. Call for service if the problem persists |

| Causes: | The motor for OPC/Deve/ITB/Engage does not operate normally. • A1-3610 : The developer motor for the color printing system does not operate correctly. • A1-3621 : The developer black motor for the color printing system does not operate correctly. • A1-3622 : The developer color motor for the color printing system does not operate correctly. • A1-4310 : The motor that moves the ITB transfer1 roller operates, but the position of the ITB transfer1 roller does not change. |

| Remedy: | 1) Turn the machine off then on. If the error persists, turn the machine off again. 2) Remove the right cover. 3) Check if the connection between main board and related motor is correct. 4) If the motor is defective, replace it. 5) If there is a motor test for this component, please try it first. If the problem persists, replace the main board. |

| Error code: | A3-6110 |

| Display: | Error #A3-6110 Turn off then on |

| Description: | Error #A3-6110 Turn off then on |

| Causes: | The Deve Home sensor is defecitve. |

| Remedy: | 1) Turn the machine off then on. If the error persists, turn the machine off again. 2) Remove the right cover. 3) Check if the Deve home sensor connector is connected correctly. 4) If the sensor is defective, replace it. |

| Error code: | C2-2110 |

| Description: | Yellow toner is low |

| Causes: | There is not enough toner in the yellow toner cartridge |

| Remedy: | 1) Print the supply information report. Check the life remaining of the toner cartridge. 2) If its life is at the end, turn the machine off and replace the toner cartridge with new one. |

| Error code: | C2-2120, C2-2140, C2-2150 |

| Description: | Yellow toner is very low End of life, Replace with new yellow toner cartridge |

| Causes: | The yellow toner cartridge is at the end of its life. |

| Remedy: | 1) If its life is at the end, turn the machine off and replace the yellow toner cartridge with new one. |

| Error code: | C2-2160, C2-2170 |

| Description: | Yellow toner is very low End of life, Replace with new yellow toner cartridge |

| Causes: | The yellow toner cartridge is at the end of its life. |

| Remedy: | 1) If its life is at the end, turn the machine off and replace the yellow toner cartridge with new one. |

| Error code: | C2-2410 |

| Description: | Install yellow toner cartridge |

| Causes: | The yellow toner cartridge is not installed or the CRUM has some problem. |

| Remedy: | 1) Check if the yellow toner cartridge is installed properly. Turn the machine off then on. 2) If the error message is not disappear, remove the yellow toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3) If the problem persists, check that the CRUM contact area is contaminated. Clean it. 4) If the problem persists, replace the yellow toner cartridge with new one. |

| Error code: | C2-2512, C2-2515, C2-2517 |

| Description: | Yellow toner cartridge is not compatible. Check the user guide Yellow toner cartridge is not available in the country set in the machine. Install a toner cartridge that is compatible with your country Yellow Toner Cartridge Failure: #C2-2517. Call for service Yellow Toner Cartridge Failure: #C2-2518. Call for service Toner mismatch on yellow toner cartridge position. Install again in the proper position. |

| Causes: | The yellow toner cartridge is not compatible. |

| Remedy: | 1) If the toner cartridge is not a Samsung genuine toner cartridge, replace with new one. |

| Error code: | C2-2518, C2-2526 |

| Description: | Yellow toner cartridge is not compatible. Check the user guide Yellow toner cartridge is not available in the country set in the machine. Install a toner cartridge that is compatible with your country Yellow Toner Cartridge Failure: #C2-2517. Call for service Yellow Toner Cartridge Failure: #C2-2518. Call for service Toner mismatch on yellow toner cartridge position. Install again in the proper position. |

| Causes: | The yellow toner cartridge is not compatible. |

| Remedy: | 1) If the toner cartridge is not a Samsung genuine toner cartridge, replace with new one. |

| Error code: | C2-2711, C2-2712 |

| Description: | Toner Cartridge Failure: #C2-2711. Yellow toner cartridge is not installed. Install the cartridge Toner Cartridge Failure: #C2-2712. Call for service Yellow Toner Cartridge Failure: #C2-271x. Call for service |

| Causes: | The yellow toner cartridge is not installed or the CRUM has some problem. |

| Remedy: | 1) Check if the yellow toner cartridge is installed properly. Turn the machine off then on.| 2) If the error message is not disappear, remove the yellow toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3) If the problem persists, check that the CRUM contact area is contaminated. Clean it. 4) If the problem persists, replace the yellow toner cartridge with new one. |

| Error code: | C2-2713, C2-2714 |

| Description: | Toner Cartridge Failure: #C2-2711. Yellow toner cartridge is not installed. Install the cartridge Toner Cartridge Failure: #C2-2712. Call for service Yellow Toner Cartridge Failure: #C2-271x. Call for service |

| Causes: | The yellow toner cartridge is not installed or the CRUM has some problem. |

| Remedy: | 1) Check if the yellow toner cartridge is installed properly. Turn the machine off then on.| 2) If the error message is not disappear, remove the yellow toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3) If the problem persists, check that the CRUM contact area is contaminated. Clean it. 4) If the problem persists, replace the yellow toner cartridge with new one. |

| Error code: | C2-3110 |

| Description: | Magenta toner is low |

| Causes: | There is not enough toner in the magenta toner cartridge |

| Remedy: | 1) Print the supply information report. Check the life remaining of the toner cartridge. 2) If its life is at the end, turn the machine off and replace the magenta toner cartridge with new one. |

| Error code: | C2-3120, C2-3140, C2-3150 |

| Description: | Magenta toner is very low End of life, Replace with new magenta toner cartridge |

| Causes: | The magenta toner cartridge is at the end of its life. |

| Remedy: | 1) If its life is at the end, turn the machine off and replace the magenta toner cartridge with new one. |

| Error code: | C2-3160, C2-3170 |

| Description: | Magenta toner is very low End of life, Replace with new magenta toner cartridge |

| Causes: | The magenta toner cartridge is at the end of its life. |

| Remedy: | 1) If its life is at the end, turn the machine off and replace the magenta toner cartridge with new one. |

| Error code: | C2-3410 |

| Description: | Install magenta toner cartridge |

| Causes: | The magenta toner cartridge is not installed or the CRUM has some problem. |

| Remedy: | 1) Check if the magenta toner cartridge is installed properly. Turn the machine off then on. 2) If the error message is not disappear, remove the magenta toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3) If the problem persists, check that the CRUM contact area is contaminated. Clean it. 4) If the problem persists, replace the magenta toner cartridge with new one. |

| Error code: | C2-3512, C2-3515, C2-3517 |

| Description: | Magenta toner cartridge is not compatible. Check the user guide Magenta toner cartridge is not available in the country set in the machine. Install a toner cartridge that is compatible with your country Magenta Toner Cartridge Failure: #C2-3517. Call for service Magenta Toner Cartridge Failure: #C2-3518. Call for service Toner mismatch on magenta toner cartridge position. Install again in the proper position. |

| Causes: | The magenta toner cartridge is not compatible. |

| Remedy: | 1) If the toner cartridge is not a Samsung genuine toner cartridge, replace with new one. |

| Error code: | C2-3518, C2-3526 |

| Description: | Magenta toner cartridge is not compatible. Check the user guide Magenta toner cartridge is not available in the country set in the machine. Install a toner cartridge that is compatible with your country Magenta Toner Cartridge Failure: #C2-3517. Call for service Magenta Toner Cartridge Failure: #C2-3518. Call for service Toner mismatch on magenta toner cartridge position. Install again in the proper position. |

| Causes: | The magenta toner cartridge is not compatible. |

| Remedy: | 1) If the toner cartridge is not a Samsung genuine toner cartridge, replace with new one. |

| Error code: | C2-3711, C2-3712 |

| Description: | Toner Cartridge Failure: #C2-3711. Magenta toner cartridge is not installed. Install the cartridge Toner Cartridge Failure: #C2-3712. Call for service Magenta Toner Cartridge Failure: #C2-371x. Call for service |

| Causes: | The magenta toner cartridge is not installed or the CRUM has some problem. |

| Remedy: | 1) Check if the magenta toner cartridge is installed properly. Turn the machine off then on. 2) If the error message is not disappear, remove the magenta toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3) If the problem persists, check that the CRUM contact area is contaminated. Clean it. 4) If the problem persists, replace the magenta toner cartridge with new one. |

| Error code: | C2-3713, C2-3714 |

| Description: | Toner Cartridge Failure: #C2-3711. Magenta toner cartridge is not installed. Install the cartridge Toner Cartridge Failure: #C2-3712. Call for service Magenta Toner Cartridge Failure: #C2-371x. Call for service |

| Causes: | The magenta toner cartridge is not installed or the CRUM has some problem. |

| Remedy: | 1) Check if the magenta toner cartridge is installed properly. Turn the machine off then on. 2) If the error message is not disappear, remove the magenta toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3) If the problem persists, check that the CRUM contact area is contaminated. Clean it. 4) If the problem persists, replace the magenta toner cartridge with new one. |

| Error code: | C2-4110 |

| Description: | Cyan toner is low |

| Causes: | There is not enough toner in the cyan toner cartridge |

| Remedy: | 1) Print the supply information report. Check the life remaining of the toner cartridge. 2) If its life is at the end, turn the machine off and replace the cyan toner cartridge with new one. |

| Error code: | C2-4120, C2-4140, C2-4150 |

| Description: | Cyan toner is very low End of life, Replace with new cyan toner cartridge |

| Causes: | The cyan toner cartridge is at the end of its life. |

| Remedy: | 1) If its life is at the end, turn the machine off and replace the cyan toner cartridge with new one. |

| Error code: | C2-4160, C2-4170 |

| Description: | Cyan toner is very low End of life, Replace with new cyan toner cartridge |

| Causes: | The cyan toner cartridge is at the end of its life. |

| Remedy: | 1) If its life is at the end, turn the machine off and replace the cyan toner cartridge with new one. |

| Error code: | C2-4410 |

| Description: | Install cyan toner cartridge |

| Causes: | The cyan toner cartridge is not installed or the CRUM has some problem. |

| Remedy: | 1) Check if the cyan toner cartridge is installed properly. Turn the machine off then on. 2) If the error message is not disappear, remove the cyan toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3) If the problem persists, check that the CRUM contact area is contaminated. Clean it. 4) If the problem persists, replace the cyan toner cartridge with new one. |

| Error code: | C2-4512, C2-4515, C2-4517 |

| Description: | Cyan toner cartridge is not compatible. Check the user guide Cyan toner cartridge is not available in the country set in the machine. Install a toner cartridge that is compatible with your country Cyan Toner Cartridge Failure: #C2-4517. Call for service Cyan Toner Cartridge Failure: #C2-4518. Call for service Toner mismatch on cyan toner cartridge position. Install again in the proper position. |

| Causes: | The cyan toner cartridge is not compatible. |

| Remedy: | 1) If the toner cartridge is not a Samsung genuine toner cartridge, replace with new one. |

| Error code: | C2-4518, C2-4526 |

| Description: | Cyan toner cartridge is not compatible. Check the user guide Cyan toner cartridge is not available in the country set in the machine. Install a toner cartridge that is compatible with your country Cyan Toner Cartridge Failure: #C2-4517. Call for service Cyan Toner Cartridge Failure: #C2-4518. Call for service Toner mismatch on cyan toner cartridge position. Install again in the proper position. |

| Causes: | The cyan toner cartridge is not compatible. |

| Remedy: | 1) If the toner cartridge is not a Samsung genuine toner cartridge, replace with new one. |

| Error code: | C2-4711, C2-4712 |

| Description: | Error: #C2-4711 Install C toner Error: #C2-471x Call for Service |

| Causes: | The cyan toner cartridge is not installed or the CRUM has some problem. |

| Remedy: | 1) Check if the cyan toner cartridge is installed properly. Turn the machine off then on. 2) If the error message is not disappear, remove the cyan toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3) If the problem persists, check that the CRUM contact area is contaminated. Clean it. 4) If the problem persists, replace the cyan toner cartridge with new one. |

| Error code: | C2-4713, C2-4714 |

| Description: | Error: #C2-4711 Install C toner Error: #C2-471x Call for Service |

| Causes: | The cyan toner cartridge is not installed or the CRUM has some problem. |

| Remedy: | 1) Check if the cyan toner cartridge is installed properly. Turn the machine off then on. 2) If the error message is not disappear, remove the cyan toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3) If the problem persists, check that the CRUM contact area is contaminated. Clean it. 4) If the problem persists, replace the cyan toner cartridge with new one. |

| Error code: | C2-5110 |

| Description: | Black toner is low |

| Causes: | There is not enough toner in the black toner cartridge |

| Remedy: | 1) Print the supply information report. Check the life remaining of the toner cartridge. 2) If its life is at the end, turn the machine off and replace the black toner cartridge with new one. |

| Error code: | C2-5120, C2-5150 |

| Display: | Replace with new (color) toner cartridge. |

| Description: | Replace Toner |

| Causes: | The toner cartridge is at the end of its life. |

| Remedy: | 1) If its life is at the end, turn the machine off and replace the toner cartridge with new one. |

| Error code: | C2-5160, C2-5170 |

| Description: | Black toner is very low End of life, Replace with new black toner cartridge |

| Causes: | The black toner cartridge is at the end of its life. |

| Remedy: | 1) If its life is at the end, turn the machine off and replace the black toner cartridge with new one. |

| Error code: | C2-5410 |

| Description: | Install black toner cartridge |

| Causes: | The black toner cartridge is not installed or the CRUM has some problem. |

| Remedy: | 1) Check if the black toner cartridge is installed properly. Turn the machine off then on. 2) If the error message is not disappear, remove the black toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3) If the problem persists, check that the CRUM contact area is contaminated. Clean it. 4) If the problem persists, replace the black toner cartridge with new one. |

| Error code: | C2-5512, C2-5515, C2-5517 |

| Description: | Black toner cartridge is not compatible. Check the user guide Black toner cartridge is not available in the country set in the machine. Install a toner cartridge that is compatible with your country Black Toner Cartridge Failure: #C2-5517. Call for service Black Toner Cartridge Failure: #C2-5518. Call for service Toner mismatch on black toner cartridge position. Install again in the proper position. |

| Causes: | The black toner cartridge is not compatible. |

| Remedy: | 1) If the toner cartridge is not a Samsung genuine toner cartridge, replace with new one. |

| Error code: | C2-5518, C2-5526 |

| Description: | Black toner cartridge is not compatible. Check the user guide Black toner cartridge is not available in the country set in the machine. Install a toner cartridge that is compatible with your country Black Toner Cartridge Failure: #C2-5517. Call for service Black Toner Cartridge Failure: #C2-5518. Call for service Toner mismatch on black toner cartridge position. Install again in the proper position. |

| Causes: | The black toner cartridge is not compatible. |

| Remedy: | 1) If the toner cartridge is not a Samsung genuine toner cartridge, replace with new one. |

| Error code: | C2-5711, C2-5712 |

| Description: | Toner Cartridge Failure: #C2-5711. Black toner cartridge is not installed. Install the cartridge Toner Cartridge Failure: #C2-5712. Call for service Black Toner Cartridge Failure: #C2-571x. Call for service |

| Causes: | The black toner cartridge is not installed or the CRUM has some problem. |

| Remedy: | 1) Check if the black toner cartridge is installed properly. Turn the machine off then on. 2) If the error message is not disappear, remove the black toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3) If the problem persists, check that the CRUM contact area is contaminated. Clean it. 4) If the problem persists, replace the black toner cartridge with new one. |

| Error code: | C2-5713, C2-5714 |

| Description: | Toner Cartridge Failure: #C2-5711. Black toner cartridge is not installed. Install the cartridge Toner Cartridge Failure: #C2-5712. Call for service Black Toner Cartridge Failure: #C2-571x. Call for service |

| Causes: | The black toner cartridge is not installed or the CRUM has some problem. |

| Remedy: | 1) Check if the black toner cartridge is installed properly. Turn the machine off then on. 2) If the error message is not disappear, remove the black toner cartridge. Thoroughly roll the cartridge five or six times to distribute the toner evenly inside the cartridge. And reinstall the toner cartridge. 3) If the problem persists, check that the CRUM contact area is contaminated. Clean it. 4) If the problem persists, replace the black toner cartridge with new one. |

| Error code: | C5-1110, C5-1120 |

| Display: | Prepare new Transfer belt Replace new Transfer belt |

| Description: | Prepare new Transfer belt Replace new Transfer belt |

| Causes: | The ITB Unit is at the end of its life. |

| Remedy: | 1) Print the supply information report. Check the life remaining of the ITB unit. 2) If its life is at the end, turn the machine off and replace the ITB unit with new one. |

| Error code: | C5-1310 |

| Display: | Install image transfer belt unit. |

| Description: | Install TR belt unit. |

| Causes: | The ITB Unit is not installed properly. |

| Remedy: | 1) Turn the machine off. Remove and reinstall the ITB unit. 2) Turn the machine on. If the problem persists, replace the ITB unit. |

| Error code: | C5-1410 |

| Display: | Image transfer belt unit is not compatible. Check users guide. |

| Description: | Not compatible transfer belt |

| Causes: | The ITB unit is not compatible. |

| Remedy: | 1) Print the supply information report. Check information of the ITB Unit. 2) If the toner cartridge is not a Samsung genuine ITB Unit, replace with new one. |

| Error code: | C5-1710 |

| Display: | Transfer Belt Error |

| Description: | Transfer Belt Error |

| Causes: | The ITB home position sensor has the problem. |

| Remedy: | 1) Turn the machine off. Replace the ITB Unit. |

| Error code: | C6-1110, C6-1120 |

| Display: | Prepare new fuser unit. Replace with new fuser unit. |

| Description: | Replace Fuser Soon Replace new Fuser unit |

| Causes: | The fuser unit is at the end of its life. |

| Remedy: | 1) Print the supply information report. Check the life remaining of the fuser unit. 2) If its life is at the end, turn the machine off and replace the fuser unit with new one. |

| Error code: | C7-1110, C7-1130 |

| Display: | Waste toner container is almost full. Order new one. Waste toner container is full. Replace it. |

| Description: | Waste toner container is almost full. Order new one. Waste toner container is full. Replace it. |

| Causes: | The life of the waste toner container expires soon or has expired. |

| Remedy: | 1) Open the front cover. 2) Remove the waste toner container. Install a new waste toner container. 3) Close the front cover. |

| Error code: | C7-1311 |

| Display: | Waste toner container is not installed. Install it. |

| Description: | Not Installed Waste tank |

| Causes: | The waste toner container is not installed |

| Remedy: | 1) Check if the waste toner container is installed properly. 2) Remove and reinstall the waste toner container. |

| Error code: | C9-1115 |

| Display: | Replace retard roller / Replace with new tray 1 retard roller |

| Description: | Tray1 reverse roller is worn out. |

| Causes: | The pick up / forward / separation rollers for tray1 are at the end of its life. |

| Remedy: | 1) Remove the tray1 cassette. 2) Remove the reverse roller(JC90-01032A). |

| Error code: | C9-1122, C9-1125 |

| Description: | Replace with new tray 2 pickup roller Replace with new tray 2 retard roller |

| Causes: | The pick up / forward / separation rollers for tray2 are at the end of its life. |

| Remedy: | 1) Turn the machine off. 2) Replace the pick up/forward/separation rollers for Tray2. 3) Enter the service mode and then, reset its count. |

| Error code: | C9-1132, C9-1135 |

| Description: | Replace with new tray 3 pickup roller Replace with new tray 3 retard roller |